lock LAND ROVER DEFENDER 1996 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 181 of 455

51REAR AXLE AND FINAL DRIVE

2

DESCRIPTION AND OPERATION

Rear axle hub - 110/130

1.Axle casing

2.Ventilation pipe

3.Axle shaft

4.Wheel studs and hub

5.Wheel bearing stub axle

6.Wheel bearings

7.Inner hub seal8.Outer hub/axle shaft seal

9.Hub lock plate, thrust washer and nuts

10.Brake disc

11.Drive flange

12.Drive shaft circlip

13.Dust cap

Page 182 of 455

REAR AXLE AND FINAL DRIVE

1

FAULT DIAGNOSIS FAULT DIAGNOSIS

Complaint - Oil leaks

An external leak of lubrication from the hub seals can

be caused by a faulty internal seal. For example, if the

seals which separate the differential from the hubs are

faulty and the vehicle is operating or parked on an

embankment, oil from the differential may flood one

hub resulting in a lack of lubrication in the differential.

When a seal is found to be leaking check the axle

ventilation system, as a blockage can cause internal

pressure to force oil past the seals.

See 'Description and Operation' for illustrations of oil

seal locations.

When investigating hub seal leaks check the grease

for dilution with oil. Also check the differential oil level,

for signs of metal particles in the oil and the condition

of internal seals.

If the vehicle is driven in deep water with defective oil

seals, water may contaminate the lubricants and raise

the differential oil level, giving a false impression that

the housing has been overfilled.

Do not assume that a high oil level in the

differential is due to over filling or, that a low level

is because of an external leak.

Page 185 of 455

REAR AXLE AND FINAL DRIVE

3

REPAIR REAR HUB ASSEMBLY - 90

Service repair no - 64.15.01

Remove

1.Place rear axle onto axle stands and remove

road wheel.

2.Release brake hose clips and remove brake

caliper bolts. Secure to one side.

WARNING: Take care not to kink brake

hose.

3.Remove 5 bolts and withdraw axle shaft.

4.Remove joint washer.

5.Bend back lock washer tabs.

6.Remove locknut and lock washer.

7.Remove hub adjusting nut.

8.Remove spacing washer.

9.Remove hub and brake disc assembly complete

with bearings.

Rear hub components - 90

1.Axle shaft.

2.Axle shaft joint washer.

3.Axle shaft retaining bolt.

4.Lock nut.

5.Lock washer.

6.Hub adjusting nut.

7.Spacing washer.8.Outer bearing.

9.Hub.

10.Inner bearing.

11.Grease seal.

12.Brake disc.

13.Disc retaining bolt.

Page 186 of 455

51REAR AXLE AND FINAL DRIVE

4

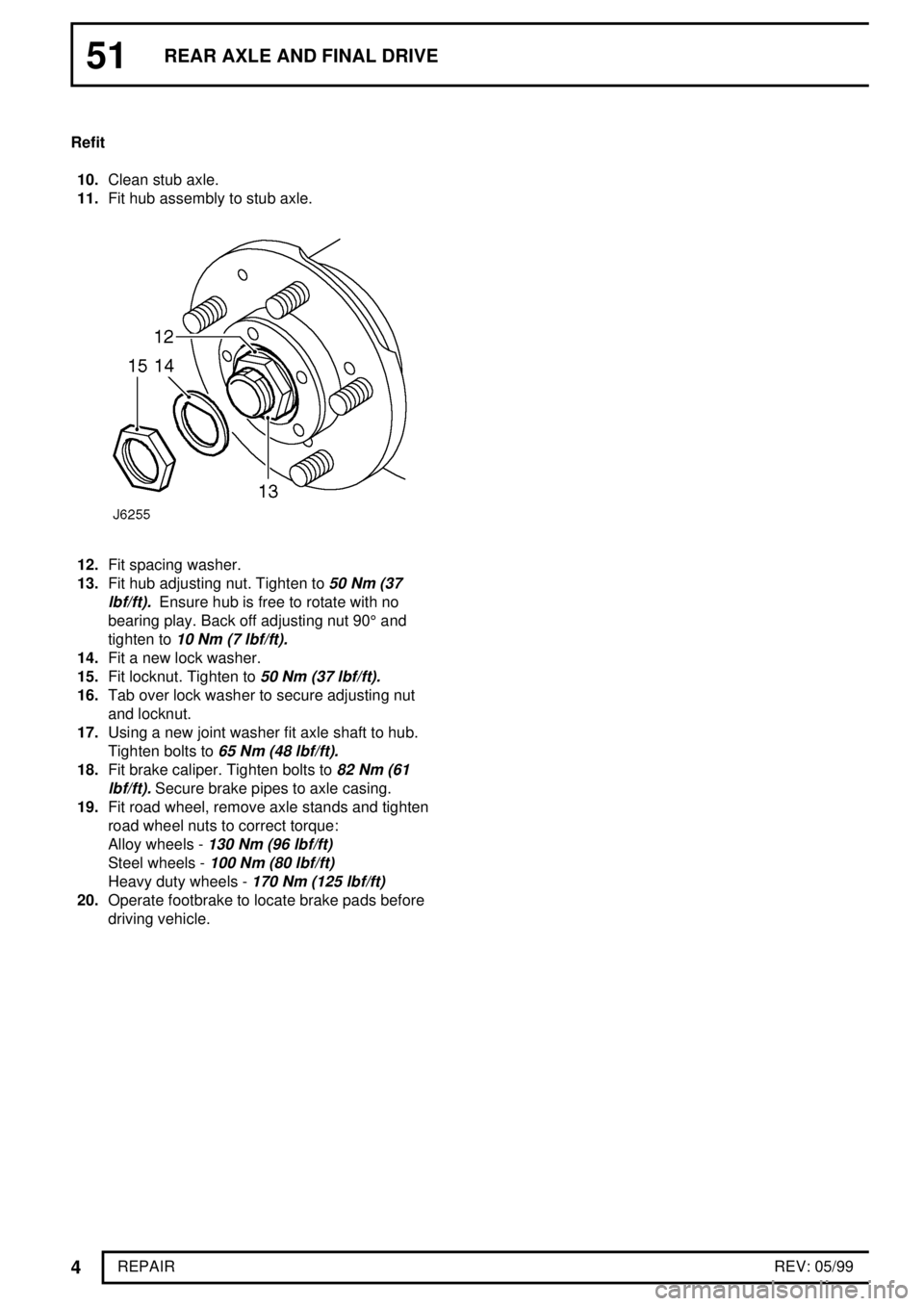

REPAIRREV: 05/99 Refit

10.Clean stub axle.

11.Fit hub assembly to stub axle.

12.Fit spacing washer.

13.Fit hub adjusting nut. Tighten to

50 Nm (37

lbf/ft).

Ensure hub is free to rotate with no

bearing play. Back off adjusting nut 90°and

tighten to

10 Nm (7 lbf/ft).

14.Fit a new lock washer.

15.Fit locknut. Tighten to

50 Nm (37 lbf/ft).

16.Tab over lock washer to secure adjusting nut

and locknut.

17.Using a new joint washer fit axle shaft to hub.

Tighten bolts to

65 Nm (48 lbf/ft).

18.Fit brake caliper. Tighten bolts to82 Nm (61

lbf/ft).

Secure brake pipes to axle casing.

19.Fit road wheel, remove axle stands and tighten

road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

20.Operate footbrake to locate brake pads before

driving vehicle.

Page 187 of 455

REAR AXLE AND FINAL DRIVE

5

REPAIR REAR HUB ASSEMBLY - 110/130

Service repair no - 64.15.01

Remove

1.Loosen rear wheel nuts, jack up vehicle and

lower onto axle stands. Remove road wheel.

2.Release brake pipe clips, remove brake caliper

and brake disc shield bolts. Secure to one side.

WARNING: Take care not to kink brake

hose.3.Lever off dust cap.

4.Remove circlip from driveshaft.

5.Remove 5 bolts and withdraw driving member

and joint washer.

6.Bend back lock washer tabs.

7.Remove locknut and lock washer.

8.Remove hub adjusting nut.

9.Remove spacing washer.

10.Remove hub and brake disc assembly complete

with bearings.

Hub components

1.Dust cap.

2.Drive shaft circlip.

3.Drive member.

4.Drive member joint washer.

5.Drive member retaining bolt.

6.Lock nut.

7.Lock washer.

8.Hub adjusting nut.9.Spacing washer.

10.Outer bearing.

11.Hub.

12.Inner bearing.

13.Grease seal.

14.Brake disc

15.Disc retaining bolt.

Page 188 of 455

51REAR AXLE AND FINAL DRIVE

6

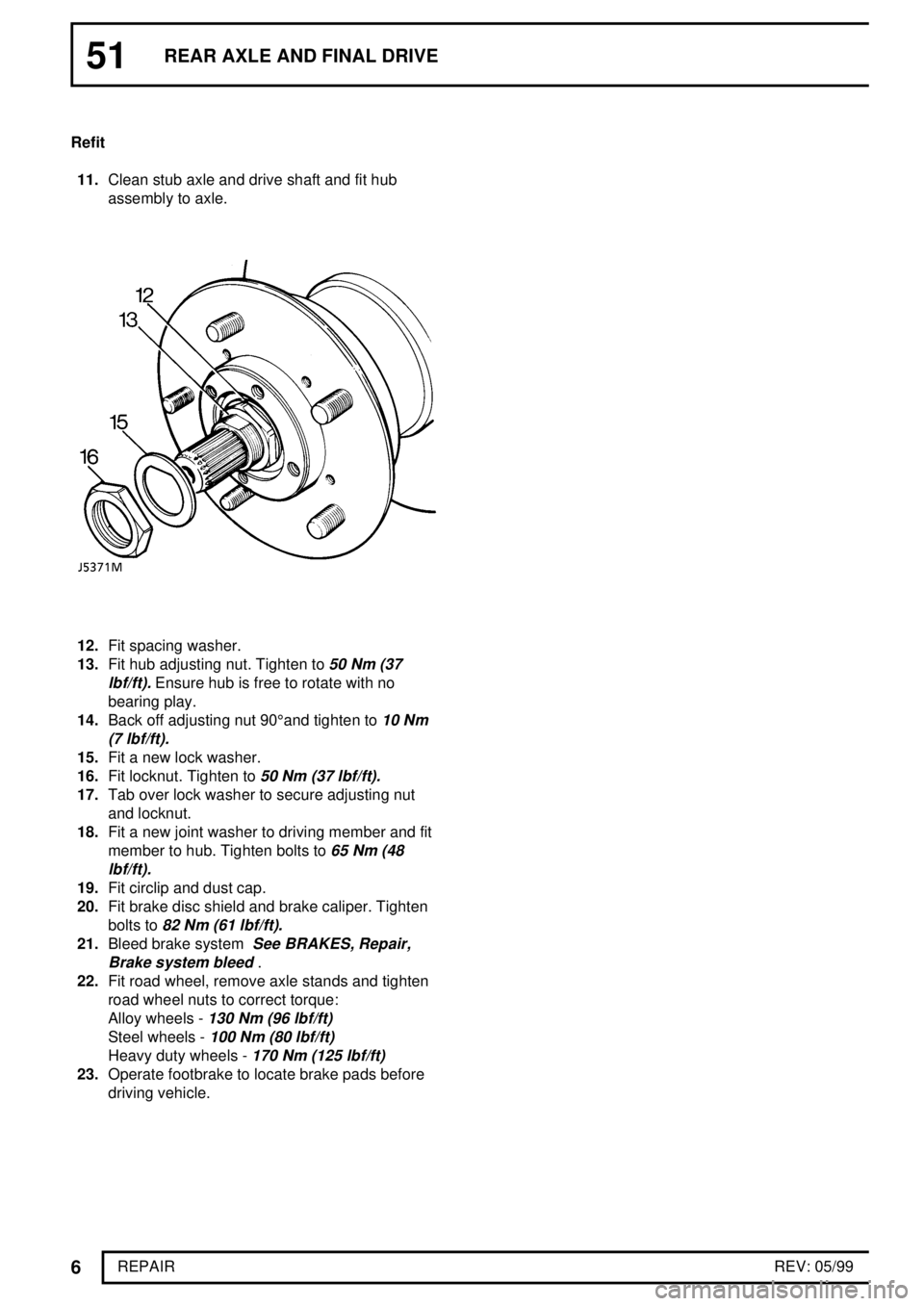

REPAIRREV: 05/99 Refit

11.Clean stub axle and drive shaft and fit hub

assembly to axle.

12.Fit spacing washer.

13.Fit hub adjusting nut. Tighten to

50 Nm (37

lbf/ft).

Ensure hub is free to rotate with no

bearing play.

14.Back off adjusting nut 90°and tighten to

10 Nm

(7 lbf/ft).

15.Fit a new lock washer.

16.Fit locknut. Tighten to

50 Nm (37 lbf/ft).

17.Tab over lock washer to secure adjusting nut

and locknut.

18.Fit a new joint washer to driving member and fit

member to hub. Tighten bolts to

65 Nm (48

lbf/ft).

19.Fit circlip and dust cap.

20.Fit brake disc shield and brake caliper. Tighten

bolts to

82 Nm (61 lbf/ft).

21.Bleed brake systemSee BRAKES, Repair,

Brake system bleed

.

22.Fit road wheel, remove axle stands and tighten

road wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

23.Operate footbrake to locate brake pads before

driving vehicle.

Page 189 of 455

REAR AXLE AND FINAL DRIVE

7

REPAIR DIFFERENTIAL ASSEMBLY - 90

Service repair no - 51.15.01

Remove

1.Using suitable container, drain axle oil.

2.Mark differential and propeller shaft flanges to

facilitate reassembly.

3.Remove 4 bolts and disconnect propeller shaft

from differential. Tie aside.

4.Remove 5 hub drive member bolts and withdraw

axle half shafts sufficiently to disengage from

differential unit.

5.Remove 10 nuts securing differential to axle

case.

6.Withdraw differential unit.

NOTE: The differential unit can only be

serviced as a complete assembly with

matching drive pinion. For advice ring

Land Rover Service Department.Refit

7.Ensure mating faces are clean and apply a bead

of RTV sealant to axle case.

8.Support differential unit and position on axle

casing.

9.Secure with self locking nuts and tighten to

40

Nm (30lbf/ft).

10.Align marks on flanges and secure propeller

shaft to differential. Tighten bolts to

48 Nm (35

lbf/ft).

11.Refit half shafts, using new drive member

gaskets. Tighten bolts to

65 Nm (48 lbf/ft).

12.Refill axle oil with approved lubricantSee

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

.

Page 192 of 455

REAR AXLE AND FINAL DRIVE

3

OVERHAUL

25.Withdraw four dished thrust washers.

26.Withdraw lower differential wheel and thrust

washer.

27.Remove differential bearing cones using

LRT-51-500, adaptors 1 and 2 and press

LRT-99-002.

28.Withdraw shim washers fitted between bearing

cones and differential casings.

Remove final drive pinion

29.UsingLTR-51-003to prevent coupling flange

from rotating, remove flange locknut and plain

washer.

30.Support drive pinion and remove coupling flange

by tapping with a hide hammer.

31.Withdraw drive pinion toger with inner bearing

cone.

32.Withdraw and discard collapsable bearing

spacer.

33.Withdraw oil seal, gasket and oil thrower.

34.Withdraw outer bearing cone.

35.UsingLRT-51-502, extract pinion inner bearing

cup and shim washers from casing. Note shim

washer thickness. .

36.Extract pinion outer bearing cup from casing

usingLRT-51-502.

Page 193 of 455

51REAR AXLE AND FINAL DRIVE

4

OVERHAUL

37.UsingLRT-51-500and pressLRT-99-002,

remove inner bearing cone from pinion.

INSPECTION

38.Examine all components for obvious wear or

damage.

39.Bearing cones must be a press fit on their

locations, except drive pinion flange and bearing

which is a slide fit.

40.The crown wheel and pinion are supplied as a

matched pair and must not be interchanged

separately. A new crown wheel and pinion

matched pair may be fitted to an original gear

carrier casing if sound. original crown wheel and

pinion, if sound, may be fitted into a replacement

casing.

41.The two parts of differential unit casing are

matched and must not be replaced separately.

42.Discard and renew all thrust washers.

43.Differential housings with worn thrust washer

seatings must be replaced as a pair.

44.Examine differential case to crown wheel joint

face for burrs and damage which could lead to

crown wheel run-out when fitted.ASSEMBLE

Differential

45.Fit differential lower wheel and thrust washer to

differential case. See illustration following

instruction 23.

46.Fit dished thrust washers.

47.Fit cross-shaft and pinions.

48.Fit differential upper wheel and thrust washer.

49.Fit differential upper case lining-up marks.

50.Secure assembly with bolts using Loctite

'Studlock' grade CVX on threads and tighten

evenly and diametrically to

95 Nm (70 lbf/ft).

51.Fit crown wheel to differential casing. Use Loctite

'Studlock' grade CVX on fixing bolt threads and

tighten to correct torque.

52.Press on differential roller bearing cones less

shim washers, usingLRT-51-504, and leave to

one side until required for instruction 96.

53.Fit bearing cups to differential.

54.Fit differential unit and bearings to gear carrier

casing, and rotate unit to centralize bearings. Do

not fit bearing caps.

Page 195 of 455

51REAR AXLE AND FINAL DRIVE

6

OVERHAUL

70.Press inner bearing cone onto drive pinion using,

LRT-51-502details 1 and 2 and press

LRT-99-002.

71.Position pinion and bearing in casing; omit

collapsable spacer at this stage.

72.Fit outer bearing cone onto pinion.

73.Fit coupling flange and plain washer and loosely

fit flange nut.

74.Tighten coupling flange locknut to remove

end-float from pinion.

75.Rotate pinion to settle bearings and slowly

tighten flange locknut. Use a spring balance to

obtain a torque resistance of 11 Kgf/cm (18

lbf/in) to rotate pinion.

Drive pinion markings

76.Check that serial number marked on pinion end

face matches that marked on crown wheel.

77.The markings on end face adjacent to serial

number are of no significance during servicing.

78.The figure marked on end face opposite to serial

number indicates, in thousandths of an inch,

deviation from nominal required to correctly set

pinion. A pinion marked plus (+) must be set

below nominal, a minus (-) pinion must be set

above nominal. An unmarked pinion must be set

at nominal.

79.The nominal setting dimension is represented by

setting gauge block18G191PorLRT-54-503,

which is referenced from pinion end face to

bottom radius of differential bearing bore. The

latter gauge is illustrated following instruction 85.

Drive pinion adjustment

80.Ensure that pinion end face is free of raised

burrs around etched markings.

81.Remove keep disc from magnetized base of dial

gauge tool18G191.

82.Place dial gauge and setting gauge18G191Por

LRT-54-503on a flat surface and zero dial

gauge stylus on to setting gauge.