engine LAND ROVER DEFENDER 1996 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 67 of 455

12ENGINE

8

REPAIR Refit

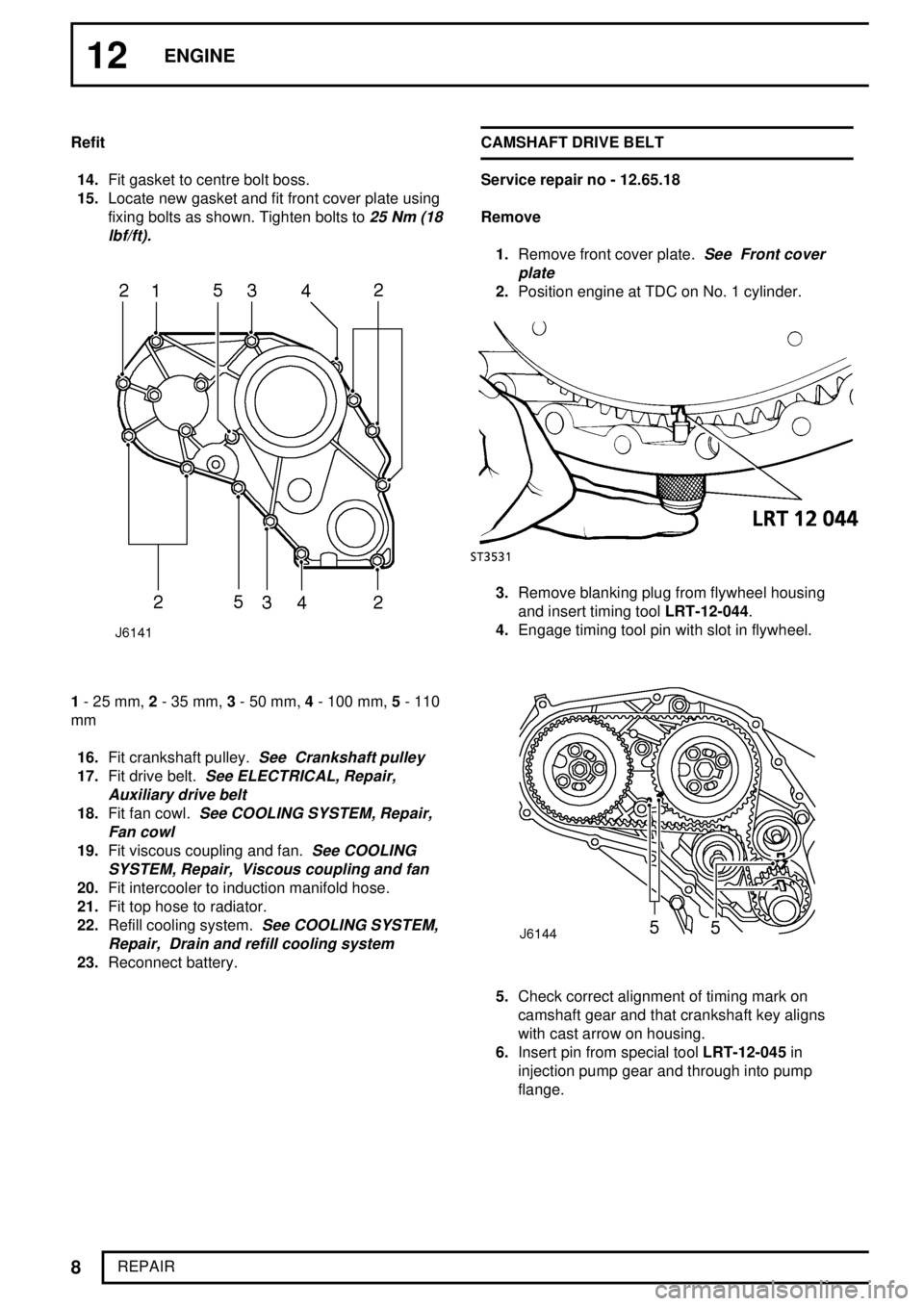

14.Fit gasket to centre bolt boss.

15.Locate new gasket and fit front cover plate using

fixing bolts as shown. Tighten bolts to

25 Nm (18

lbf/ft).

1- 25 mm,2- 35 mm,3- 50 mm,4- 100 mm,5- 110

mm

16.Fit crankshaft pulley.

See Crankshaft pulley

17.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

18.Fit fan cowl.See COOLING SYSTEM, Repair,

Fan cowl

19.Fit viscous coupling and fan.See COOLING

SYSTEM, Repair, Viscous coupling and fan

20.Fit intercooler to induction manifold hose.

21.Fit top hose to radiator.

22.Refill cooling system.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

23.Reconnect battery.CAMSHAFT DRIVE BELT

Service repair no - 12.65.18

Remove

1.Remove front cover plate.

See Front cover

plate

2.Position engine at TDC on No. 1 cylinder.

3.Remove blanking plug from flywheel housing

and insert timing toolLRT-12-044.

4.Engage timing tool pin with slot in flywheel.

5.Check correct alignment of timing mark on

camshaft gear and that crankshaft key aligns

with cast arrow on housing.

6.Insert pin from special toolLRT-12-045in

injection pump gear and through into pump

flange.

Page 68 of 455

ENGINE

9

REPAIR

NOTE: If the camshaft gear is to be

removed during these operations its

retaining bolt should be slackened before

the timing belt is removed.

7.Slacken belt tensioner bolt.

8.Remove idler pulley.

9.Remove timing belt.

NOTE: If excessive timing belt debris is

evident in the front cover, this is probably

due to the misalignment of the front timing

cover caused by incorrect assembly of the fuel

injection pump bracket.

See FUEL SYSTEM,

Repair, Fuel Injection pump

NOTE: During use, a belt develops a wear

pattern relative to its running direction, if

the original belt is to be re-used it must be

refitted so that it rotates in the original direction.

Mark belt direction of rotation, using soft chalk, to

ensure correct refitment.

CAUTION: The belt must be stored on its

edge on a clean surface and in such a

manner that bends are not less than 50

mm (2.0in.) radius. Do not bend belts at an acute

angle, otherwise premature failure could result.Belt tensioner

NOTE: The belt tensioner need only be

removed if it is being replaced or for

access purposes to remove front cover.

10.Remove securing bolt and withdraw tensioner

complete with spacer.

Refit

11.If necessary, fit belt tensioner and spacer.

Tighten fixing bolt to

45 Nm (33lbf/ft).

Timing belt fitting and tensioning

NOTE: It is important that belt tensioning

is carried out carefully and accurately. The

following procedure involves tensioning

the belt twice to ensure that it is equally tensioned

between each gear. New and original belts are

tensioned to different figures.

12.Ensure timing marks are correctly aligned, pin

from special toolLRT-12-045is correctly

inserted in injection pump gear and timing tool

LRT-12-044is fitted to flywheel housing with pin

located in flywheel slot.

13.Fit belt, observing rotational marks made during

removal. Feed belt over gears keeping it tight on

drive side.

14.Fit idler pulley.

15.Slacken injection pump gear retaining bolts.

16.Adjust belt to correctly sit in gears.

Page 69 of 455

12ENGINE

10

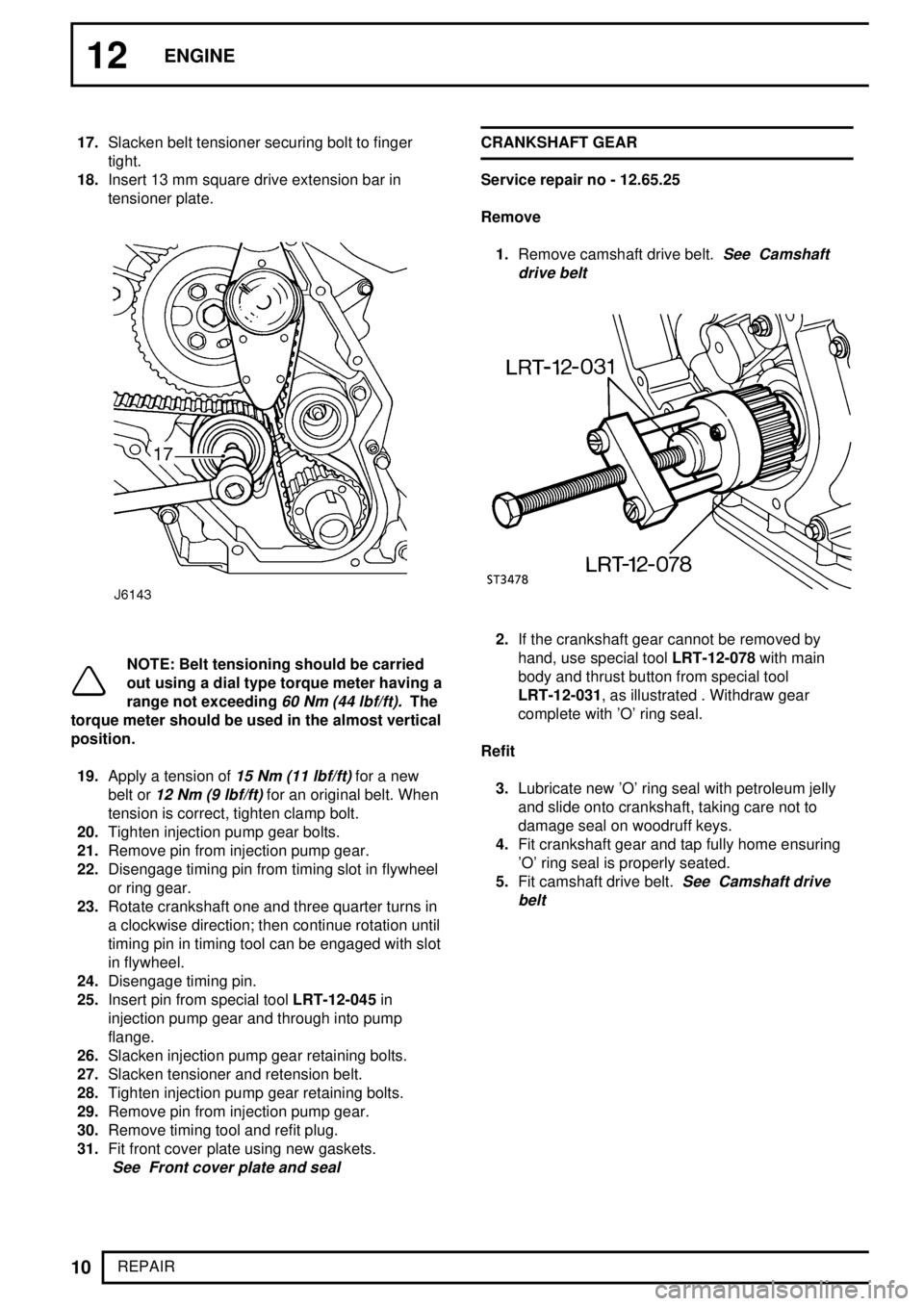

REPAIR 17.Slacken belt tensioner securing bolt to finger

tight.

18.Insert 13 mm square drive extension bar in

tensioner plate.

NOTE: Belt tensioning should be carried

out using a dial type torque meter having a

range not exceeding

60 Nm (44 lbf/ft).The

torque meter should be used in the almost vertical

position.

19.Apply a tension of

15 Nm (11 lbf/ft)for a new

belt or

12 Nm (9 lbf/ft)for an original belt. When

tension is correct, tighten clamp bolt.

20.Tighten injection pump gear bolts.

21.Remove pin from injection pump gear.

22.Disengage timing pin from timing slot in flywheel

or ring gear.

23.Rotate crankshaft one and three quarter turns in

a clockwise direction; then continue rotation until

timing pin in timing tool can be engaged with slot

in flywheel.

24.Disengage timing pin.

25.Insert pin from special toolLRT-12-045in

injection pump gear and through into pump

flange.

26.Slacken injection pump gear retaining bolts.

27.Slacken tensioner and retension belt.

28.Tighten injection pump gear retaining bolts.

29.Remove pin from injection pump gear.

30.Remove timing tool and refit plug.

31.Fit front cover plate using new gaskets.

See Front cover plate and seal

CRANKSHAFT GEAR

Service repair no - 12.65.25

Remove

1.Remove camshaft drive belt.

See Camshaft

drive belt

2.If the crankshaft gear cannot be removed by

hand, use special toolLRT-12-078with main

body and thrust button from special tool

LRT-12-031, as illustrated . Withdraw gear

complete with 'O' ring seal.

Refit

3.Lubricate new 'O' ring seal with petroleum jelly

and slide onto crankshaft, taking care not to

damage seal on woodruff keys.

4.Fit crankshaft gear and tap fully home ensuring

'O' ring seal is properly seated.

5.Fit camshaft drive belt.

See Camshaft drive

belt

Page 70 of 455

ENGINE

11

REPAIR CRANKSHAFT OIL SEAL

Service repair no - 12.21.14

Remove

1.Remove crankshaft gear.

See Crankshaft gear

2.Prise out oil seal from front cover.

Refit

3.Lubricate a new crankshaft oil seal with clean

engine oil.

4.With lip side leading, drive in seal squarely using

special toolLRT-12-079.

5.Fit crankshaft gear.

See Crankshaft gear

CAMSHAFT GEAR

Service repair no - 12.65.24

Remove

1.Remove camshaft drive belt.

See Camshaft

drive belt

2.Remove centre bolt and withdraw camshaft

gear, complete with hub and retaining plate.

Refit

3.Fit camshaft gear. Tighten bolt to

80 Nm (59

lbf/ft).

4.Fit camshaft drive belt.See Camshaft drive

belt

Page 71 of 455

12ENGINE

12

REPAIR CAMSHAFT OIL SEAL

Service repair no - 12.13.05

Remove

1.Remove camshaft gear.

See Camshaft gear

2.Remove camshaft oil seal from front cover using

special toolLRT-12-083.

Refit

3.Lubricate a new camshaft oil seal with clean

engine oil.

4.With lip side leading, drive in seal squarely using

special toolLRT-12-082.

5.Fit camshaft gear.

See Camshaft gear

INJECTION PUMP GEAR

Service repair no - 19.30.06

Remove

1.Remove camshaft drive belt.

See Camshaft

drive belt

2.Slacken 3 bolts on front of injector pump gear.

3.Remove special tool pin from gear.

4.Remove 3 bolts and withdraw gear and retaining

plate.

Refit

CAUTION: It is important to ensure that

when the injection pump is locked no

attempt must be made to rotate it. Take

care not to allow the crankshaft to be turned.

5.Fit gear and retaining plate. Tighten bolts to

25

Nm (18 lbf/ft).

6.Insert pin from special toolLRT-12-045in

injection pump gear and through into pump

flange.

7.Fit camshaft drive belt.

See Camshaft drive

belt

Page 72 of 455

ENGINE

13

REPAIR FRONT COVER GASKET

Service repair no - 12.65.10

Remove

1.Remove camshaft drive belt.

See Camshaft

drive belt

2.Remove crankshaft gear.See Crankshaft gear

3.Remove camshaft gear.See Camshaft gear

4.Remove injection pump gear.See Injection

pump gear

5.Remove fuel injection pump.See FUEL

SYSTEM, Repair, Fuel injection pump

6.Remove engine oil sump.See Engine oil

sump

7.Remove oil pick up strainer.See Oil pick-up

strainer

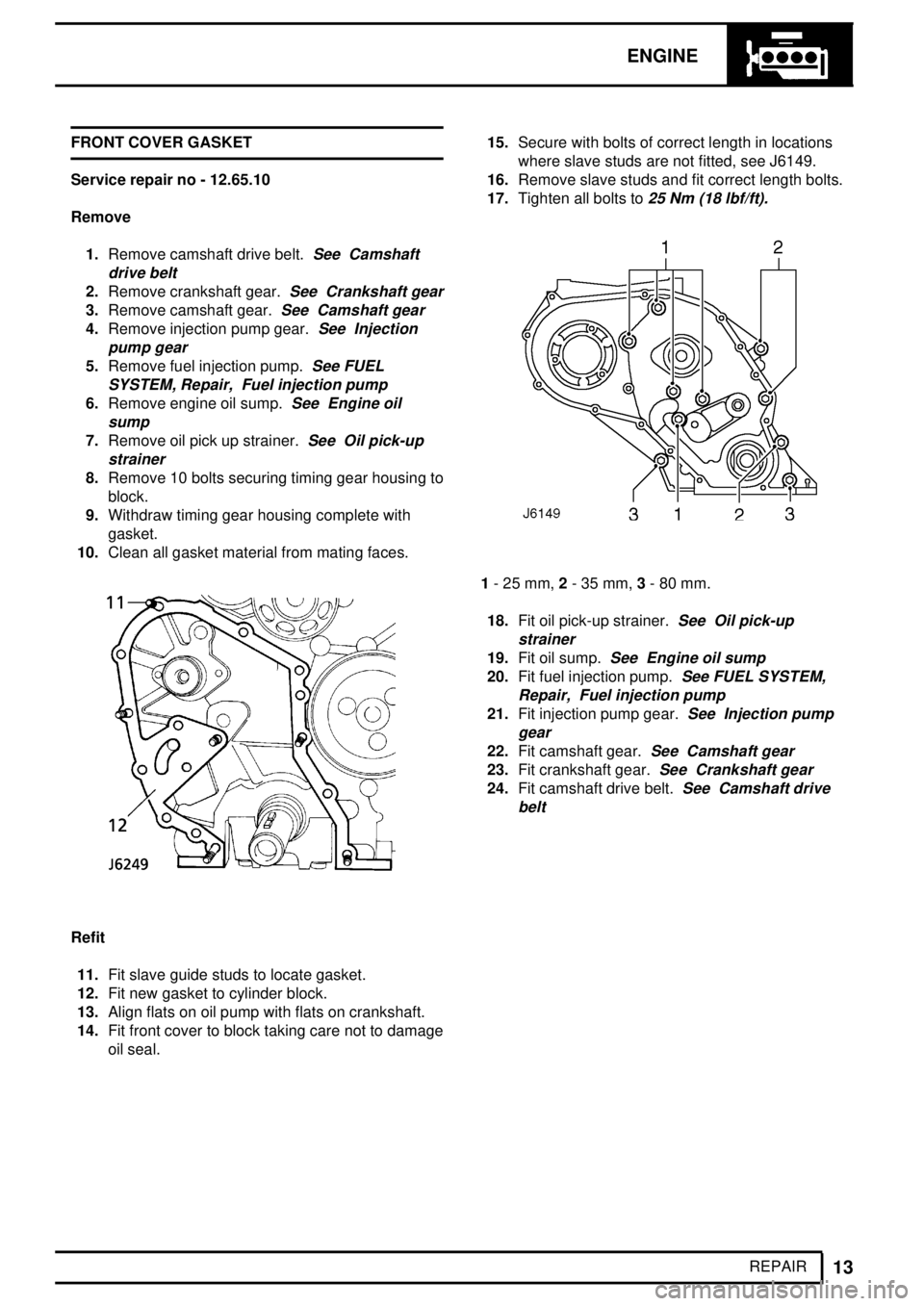

8.Remove 10 bolts securing timing gear housing to

block.

9.Withdraw timing gear housing complete with

gasket.

10.Clean all gasket material from mating faces.

Refit

11.Fit slave guide studs to locate gasket.

12.Fit new gasket to cylinder block.

13.Align flats on oil pump with flats on crankshaft.

14.Fit front cover to block taking care not to damage

oil seal.15.Secure with bolts of correct length in locations

where slave studs are not fitted, see J6149.

16.Remove slave studs and fit correct length bolts.

17.Tighten all bolts to

25 Nm (18 lbf/ft).

1- 25 mm,2- 35 mm,3- 80 mm.

18.Fit oil pick-up strainer.

See Oil pick-up

strainer

19.Fit oil sump.See Engine oil sump

20.Fit fuel injection pump.See FUEL SYSTEM,

Repair, Fuel injection pump

21.Fit injection pump gear.See Injection pump

gear

22.Fit camshaft gear.See Camshaft gear

23.Fit crankshaft gear.See Crankshaft gear

24.Fit camshaft drive belt.See Camshaft drive

belt

Page 73 of 455

12ENGINE

14

REPAIR ENGINE OIL SUMP

Service repair no - 12.60.44

Remove

1.Disconnect battery.

2.Drain engine oil.

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray and/or

integral access panels.

See CHASSIS AND BODY, Repair, Front

undertray

orSee CHASSIS AND BODY, Repair,

Rear undertray

3.Slacken sump securing bolts.

4.Break sealant around sump flange, using a

sharp knife.

5.Remove 22 bolts and withdraw sump.

Refit

6.Clean mating faces of sump, timing gear housing

and cylinder block.

7.Apply a 2,0 mm bead of 'Hylosil RTV102' to the

sump flange, ensuring bead is applied inboard of

the bolt holes.

8.Secure sump to block with 22bolts. Tighten to

25

Nm (18 lbf/ft).

9.Refill engine oil.See LUBRICANTS, FLUIDS

AND CAPACITIES, Information, Capacities

10.Reconnect battery.OIL PICK-UP STRAINER

Service repair no - 12.60.20

Remove

1.Disconnect battery.

2.Drain engine oil.

3.Remove engine oil sump.

See Engine oil

sump

4.Remove 2 bolts securing pipe support bracket to

main bearing cap fixings.

5.Remove bolts from pipe flanges.

6.Withdraw pick-up strainer assembly.

Refit

7.Postion pick-up strainer assembly, fitting a new

'O' ring seal at oil pump connection.

8.Apply Loctite 242E to threads of bolts at main

bearing cap. Fit bolts, tighten to

9 Nm (7 lbf/ft).

9.Fit bolts to pipe flanges. Tighten to25 Nm (18

lbf/ft).

10.Fit sump.See Engine oil sump

11.Reconnect battery.

Page 74 of 455

ENGINE

15

REPAIR FLYWHEEL

Service repair no - 12.53.07

Remove

1.Disconnect battery.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

assembly

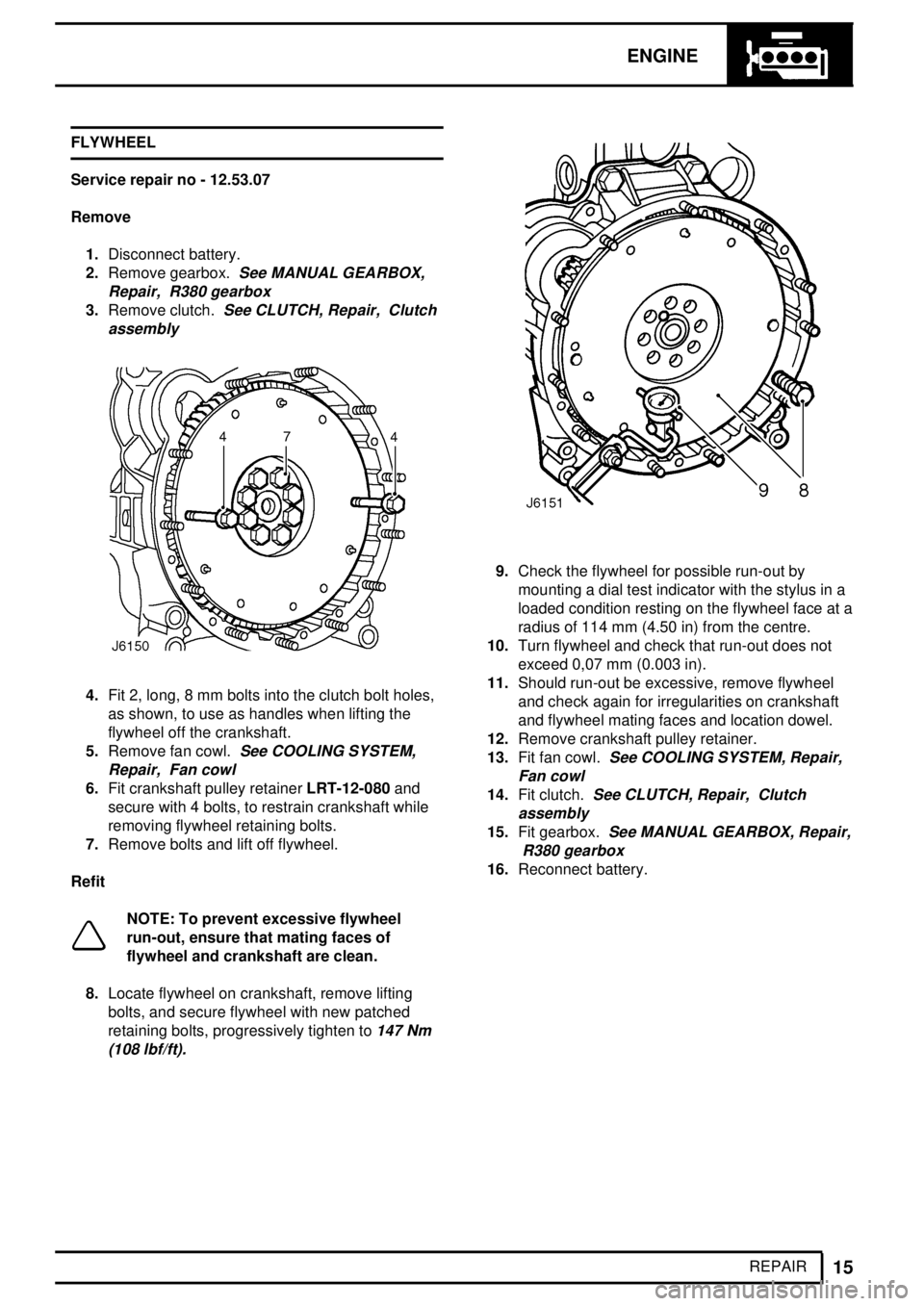

4.Fit 2, long, 8 mm bolts into the clutch bolt holes,

as shown, to use as handles when lifting the

flywheel off the crankshaft.

5.Remove fan cowl.

See COOLING SYSTEM,

Repair, Fan cowl

6.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts, to restrain crankshaft while

removing flywheel retaining bolts.

7.Remove bolts and lift off flywheel.

Refit

NOTE: To prevent excessive flywheel

run-out, ensure that mating faces of

flywheel and crankshaft are clean.

8.Locate flywheel on crankshaft, remove lifting

bolts, and secure flywheel with new patched

retaining bolts, progressively tighten to

147 Nm

(108 lbf/ft).

9.Check the flywheel for possible run-out by

mounting a dial test indicator with the stylus in a

loaded condition resting on the flywheel face at a

radius of 114 mm (4.50 in) from the centre.

10.Turn flywheel and check that run-out does not

exceed 0,07 mm (0.003 in).

11.Should run-out be excessive, remove flywheel

and check again for irregularities on crankshaft

and flywheel mating faces and location dowel.

12.Remove crankshaft pulley retainer.

13.Fit fan cowl.

See COOLING SYSTEM, Repair,

Fan cowl

14.Fit clutch.See CLUTCH, Repair, Clutch

assembly

15.Fit gearbox.See MANUAL GEARBOX, Repair,

R380 gearbox

16.Reconnect battery.

Page 75 of 455

12ENGINE

16

REPAIR CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

Remove

NOTE: The crankshaft rear oil seal is

retained in its own housing, if the seal

requires replacing, the complete housing

assembly (1) must be renewed. Housing and seal

assemblies are supplied with their own

former/seal guide (2) already fitted. This former

must not be removed before fitting the assembly

to the engine. If a seal and housing assembly is

received without a former/guide fitted it must be

returned to the supplier. Used formers/guides

must be discarded immediately after use, under

no circumstances should they be reused on other

assemblies.

NOTE: A different rear oil seal housing,

with integral 'O' ring seal and gasket, was

fitted on earlier engines. They must be

replaced with the current housing and gasket (3)

shown below.

1.Disconnect battery.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

assembly

4.Remove flywheel.See Flywheel

5.Remove 5 bolts and withdraw seal housing,

complete with gasket.

Refit

NOTE: The raised side of groove at the

bottom of seal housing gasket must be

fitted to cylinder block face.

6.Insert slave studs to locate seal housing gasket.

7.Position new gasket over slave studs and

crankshaft flange onto cylinder block.

8.Fit new seal housing assembly, with

former/guide in-situ, over crankshaft flange. This

action will eject former/guide.

9.Secure assembly to cylinder block, removing

slave studs individually and inserting bolts.

Tighten to

25 Nm (18 lbf/ft).

10.Refit flywheel.See Flywheel

Page 76 of 455

ENGINE

17

REPAIR 11.Refit clutch.

See CLUTCH, Repair, Clutch

assembly

12.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 gearbox

13.Reconnect battery.

CRANKSHAFT BEARING BUSH

Service repair no - 12.21.45

Remove

1.Disconnect battery.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

assembly

4.Remove flywheel.See Flywheel

5.Remove bearing bush.

NOTE: The bearing bush can be removed

by using one of the following methods.

Method 1.

Obtain a short length of steel rod of a diameter having

a good slide fit in the bore of the bush. Pack the bore

with grease and insert the steel rod into the end of the

bore, give a sharp blow with a hammer and the

grease should drive out the bush. It is recommended

that the bush and rod be covered by a suitable cloth

or rag to prevent grease from splashing.Method 2.

Thread the bore of the existing bush and using a

suitable bolt extract the bush. Thoroughly clean bush

location ensuring all swarf is removed.

Refit

1.Fit new bush using a suitable shouldered drift,

inserting bush flush with end of crankshaft.

2.Refit flywheel.

See Flywheel

3.Refit clutch.See CLUTCH, Repair, Clutch

assembly

4.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 gearbox

5.Reconnect battery.