LAND ROVER DEFENDER 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 371 of 667

41TRANSFER GEARBOX

10

REPAIR Refit

8.Clean oil seal recess.

9.Lubricate new input shaft oil seal with transfer

gearbox oil.

10.Fit oil seal usingLRT-41-012.

NOTE: Use end of tool marked ’FRONT’ to

fit seal.

11.Position drive flange, fit new felt and steel

washers.

12.PositionLRT-51-003fit new drive flange nut and

tighten to148 Nm (109 lbf.ft).

13.Align marks and position front propeller shaft to

output flange. Fit new nuts and tighten to48 Nm

(35 lbf.ft).

14.Fit underbelly panel.See CHASSIS AND

BODY, Repair.

15.Check/top-up transfer gearbox oil.SEAL - REAR OUTPUT SHAFT

Service repair no - 41.20.54

Remove

1.Loosen brake shoe adjuster bolt.

2.Remove rear propeller shaft.See PROPELLER

SHAFTS, Repair.

ProCarManuals.com

Page 372 of 667

TRANSFER GEARBOX

11

REPAIR

3.Remove screw securing brake drum.

4.Remove brake drum.

5.Restrain transfer gearbox drive flange using

LRT-51-003, remove and discard drive flange

nut, remove and discard steel and felt washers.

6.UsingLRT-99-500if necessary, remove drive

flange from transfer gearbox.

7.Remove and discard rear output shaft oil seal

from transfer gearbox.

Refit

8.Clean seal recess.

9.Lubricate new oil seal with transfer gearbox oil.

ProCarManuals.com

Page 373 of 667

41TRANSFER GEARBOX

12

REPAIR

10.Fit new seal usingLRT-41-012.

NOTE: Use end of tool marked’REAR’to

fit seal.

11.Position drive flange, fit new felt and steel

washers.

12.PositionLRT-51-003fit and tighten new drive

flange nut to148 Nm (109 lbf.ft).

13.Position brake drum and tighten screw.

14.Tighten adjuster bolt to25 Nm (18 lbf.ft)then

back off 1 1/2 turns.

15.Check that brake drum is free to rotate.

16.Fit propeller shaft.See PROPELLER SHAFTS,

Repair.

17.Top-up transfer gearbox oil.GASKET - REAR OUTPUT SHAFT HOUSING

Service repair no - 41.20.55

Remove

1.Drain transfer gearbox oil.See

MAINTENANCE ,

2.Remove rear output shaft seal.See this

Section.

3.Mark output shaft housing to main casing for

assembly purposes.

4.Note position of shoulder bolt, remove 6 bolts

securing housing to main casing.

Refit

5.Clean output shaft housing, mating face on main

casing and sealant from bolt threads.

6.Apply Hylosil RTV 102 to mating flange on

output shaft housing.

7.Fit output shaft housing to main casing ensuring

that splines of output shaft are engaged in

differential.

8.Apply Loctite 290 to bolt threads.

9.Fit bolts and tighten by diagonal selection to45

Nm (33 lbf.ft).

10.Fit rear output shaft seal.See this Section.

11.Fill transfer gearbox with oil.See

MAINTENANCE ,

ProCarManuals.com

Page 374 of 667

TRANSFER GEARBOX

13

REPAIR SWITCH - LOW DETECT

Service repair no - 41.30.05

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove gear lever knobs.

4.Remove gearbox tunnel carpet.

5.Remove gear lever(s) gaiter.

6.Release and remove insulation pad from around

gear levers.

7.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

8.Release bulkhead carpet from LH side of tunnel

and move aside.

9.Remove 2 bolts securing hand-brake lever to

body and move lever aside.

10.Remove 13 screws securing tunnel cover.

11.Release and remove tunnel cover.12.Release switch multiplug from bracket on

transfer gearbox, disconnect from harness.

13.Remove switch.

Refit

14.Clean switch and mating face on transfer

gearbox.

15.Fit nut/spacer to switch with counterbore

positioned towards switch head.

16.Apply Hylomar PL32 sealant to switch threads.

17.Fit switch and tighten to24 Nm (19 lbf.ft).

18.Connect multiplug to harness.

19.Fit and align tunnel cover, fit and tighten screws.

20.Position hand-brake lever and tighten bolts to25

Nm (18 lbf.ft).

21.Secure bulkhead carpet to LH side of tunnel.

22.Position relay/fuse panel, fit spacers and tighten

screws.

23.Fit insulation pad around gear levers.

24.Fit gear lever (s) gaiter.

25.Fit gearbox tunnel carpet.

26.Fit gear lever knobs.

27.Reconnect battery negative lead.

28.Fit battery cover.

ProCarManuals.com

Page 375 of 667

41TRANSFER GEARBOX

14

REPAIR

ProCarManuals.com

Page 376 of 667

47 - PROPELLER SHAFTS

CONTENTS

Page

REPAIR

PROPELLER SHAFT - FRONT 1...........................................................................

PROPELLER SHAFT - REAR 1..............................................................................

OVERHAUL

PROPELLER SHAFT - FRONT 1...........................................................................

PROPELLOR SHAFT - REAR 2.............................................................................

ProCarManuals.com

Page 377 of 667

ProCarManuals.com

Page 378 of 667

PROPELLER SHAFTS

1

REPAIR PROPELLER SHAFT - FRONT

Service repair no - 47.15.02

Remove

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

NOTE: To remove the underbelly panel,

the propeller shaft has to be released from

the front differential flange.

2.Mark propeller shaft to transfer gearbox.

3.Remove 4 nuts securing propeller shaft to

transfer gearbox flange.

4.Remove propeller shaft.

Refit

5.Clean propeller shaft flanges and mating faces.

6.Position propeller shaft to transfer gearbox

flange and tighten nuts to48 Nm (35 lbf.ft).

7.Fit underbelly panel.See CHASSIS AND

BODY, Repair.PROPELLER SHAFT - REAR

Service repair no - 47.15.03

Remove

1.Raise rear of vehicle.

WARNING: Support on safety stands.

2.Using a centre punch, mark relationship of

propeller shaft flanges.

3.Remove 4 nuts securing propeller shaft to park

brake flange.

NOTE: Rotation of propeller shaft may be

required during the above procedure.

4.Remove 4 nuts and bolts securing propeller

shaft to rear axle flange.

NOTE: Rotation of propeller shaft may be

required during the above procedure.

5.Release propeller shaft from park brake.

6.Remove propeller shaft.

ProCarManuals.com

Page 379 of 667

47PROPELLER SHAFTS

2

REPAIR Refit

7.Grease propeller shaft universal joints.

8.Grease propeller shaft spline.

9.Clean propeller shaft flange mating faces.

10.Fit propeller shaft to park brake flange bolts.

NOTE: Ensure relationship marks align.

11.Position propeller shaft to rear axle flange and fit

bolts.

12.Fit nuts and bolts securing propeller shaft to rear

axle flange and tighten to48 Nm (35 lbf.ft).

NOTE: Rotation of propeller shaft may be

required during the above procedure.

13.Fit nuts securing propeller shaft to park brake

and tighten to48 Nm (35 lbf.ft).

NOTE: Rotation of propeller shaft may be

required during the above procedure.

14.Remove stand(s) and lower vehicle.

ProCarManuals.com

Page 380 of 667

PROPELLER SHAFTS

1

OVERHAUL PROPELLER SHAFT - FRONT

Service repair no - 47.15.11

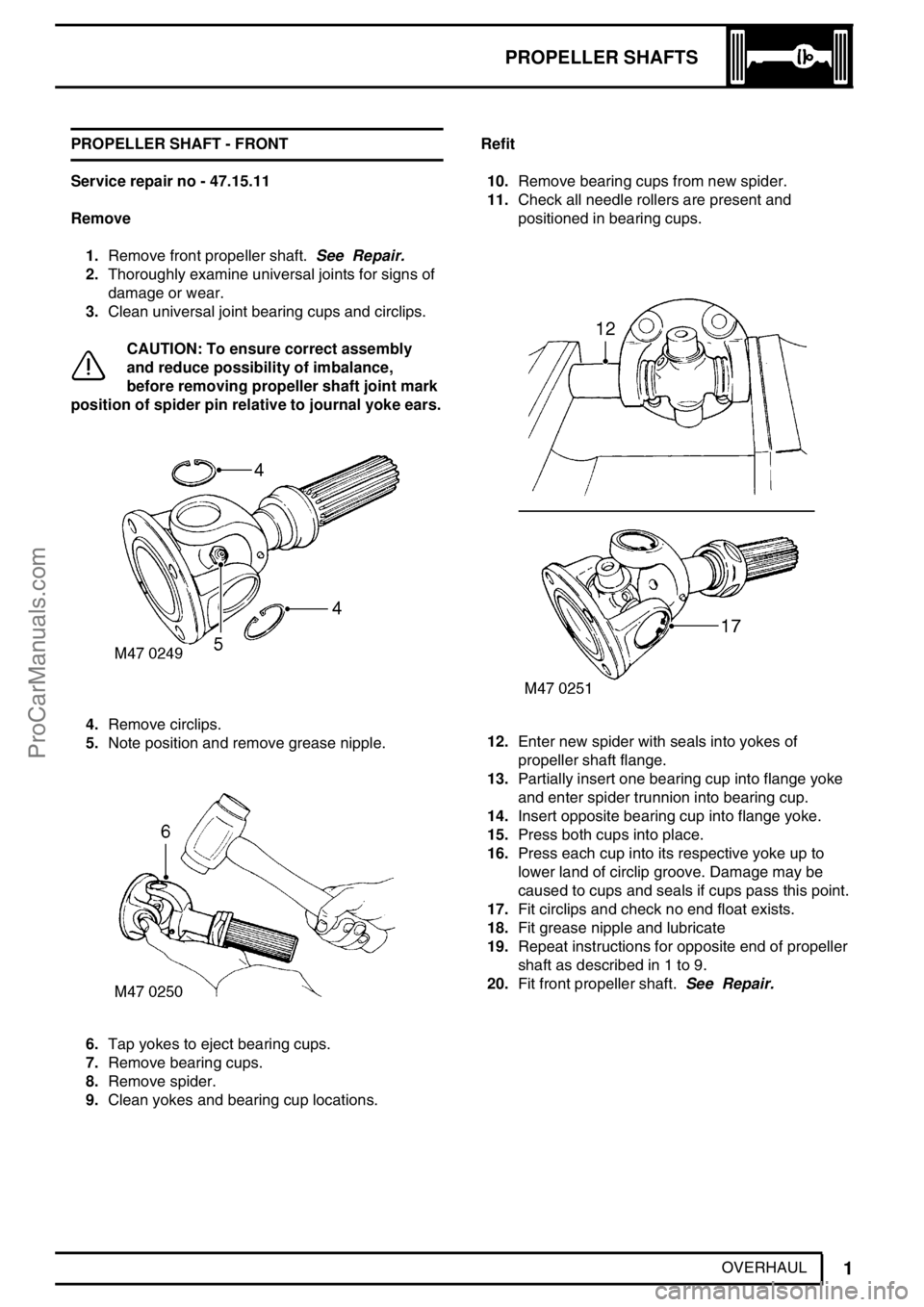

Remove

1.Remove front propeller shaft.See Repair.

2.Thoroughly examine universal joints for signs of

damage or wear.

3.Clean universal joint bearing cups and circlips.

CAUTION: To ensure correct assembly

and reduce possibility of imbalance,

before removing propeller shaft joint mark

position of spider pin relative to journal yoke ears.

4.Remove circlips.

5.Note position and remove grease nipple.

6.Tap yokes to eject bearing cups.

7.Remove bearing cups.

8.Remove spider.

9.Clean yokes and bearing cup locations.Refit

10.Remove bearing cups from new spider.

11.Check all needle rollers are present and

positioned in bearing cups.

12.Enter new spider with seals into yokes of

propeller shaft flange.

13.Partially insert one bearing cup into flange yoke

and enter spider trunnion into bearing cup.

14.Insert opposite bearing cup into flange yoke.

15.Press both cups into place.

16.Press each cup into its respective yoke up to

lower land of circlip groove. Damage may be

caused to cups and seals if cups pass this point.

17.Fit circlips and check no end float exists.

18.Fit grease nipple and lubricate

19.Repeat instructions for opposite end of propeller

shaft as described in 1 to 9.

20.Fit front propeller shaft.See Repair.

ProCarManuals.com