LAND ROVER DEFENDER 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 401 of 667

51REAR AXLE AND FINAL DRIVE

8

OVERHAUL 86.Before adjusting shim thickness, check pinion

face marking and if it has a plus (+) figure,

subtract that from shim thickness figure obtained

in previous instruction. Alternatively if pinion has

a minus (-) figure, add amount to shim thickness

figure.

87.Adjust shim thickness under pinion inner cup as

necessary, by amount determined in instructions

85 and 86.

88.Recheck pinion height setting instructions 82 to

84. If setting is correct, mean reading on dial

gauge will agree with figure marked on pinion

end face. For example, with an end face marking

of +3, dial gauge reading should indicate that

pinion is 0.003 in (0.0762 mm) below nominal.

89.When pinion setting is satisfactory, temporarily

remove pinion outer bearing.

90.Fit a new collapsable bearing spacer, flared end

outward, to drive pinion and refit outer bearing.

91.Fit pinion oil seal.

92.Fit oil seal gasket.

93.Fit pinion oil seal, lipped side first, using general

purpose grease or, where available, a

molybdenum disulphide based grease on seal

lip, usingLRT-51-002to drift in seal.

94.Fit coupling flange and plain washer and loosely

fit a new flange nut. SecureLRT-51-003to

coupling flange, using slave fixings.

95.Alternately tighten flange nut and check drive

pinion resistance to rotation until following

figures are achieved, as applicable:

A.Assemblies re-using original pinion bearings:

17,3 to 34,5 kgf cm.

B.Assemblies with new pinion bearings: 34,5 to

46,0 kgf cm.

NOTE: Once the bearing spacer has

started to collapse the torque resistance

build-up is rapid, therefore check

frequently, using a spring balance, to ensure the

correct figures are not exceeded, otherwise a new

collapsable bearing spacer will be required.

ProCarManuals.com

Page 402 of 667

REAR AXLE AND FINAL DRIVE

9

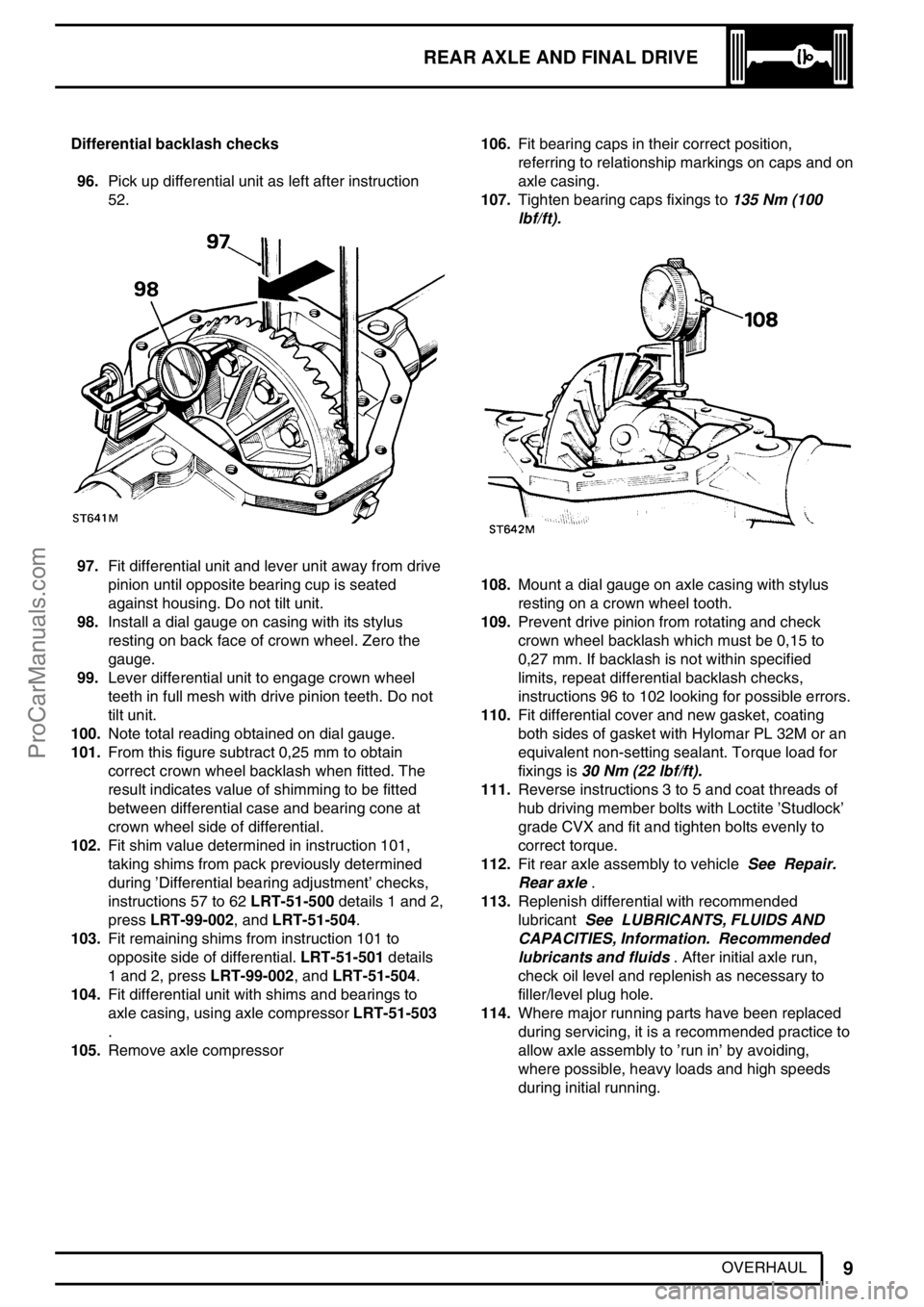

OVERHAUL Differential backlash checks

96.Pick up differential unit as left after instruction

52.

97.Fit differential unit and lever unit away from drive

pinion until opposite bearing cup is seated

against housing. Do not tilt unit.

98.Install a dial gauge on casing with its stylus

resting on back face of crown wheel. Zero the

gauge.

99.Lever differential unit to engage crown wheel

teeth in full mesh with drive pinion teeth. Do not

tilt unit.

100.Note total reading obtained on dial gauge.

101.From this figure subtract 0,25 mm to obtain

correct crown wheel backlash when fitted. The

result indicates value of shimming to be fitted

between differential case and bearing cone at

crown wheel side of differential.

102.Fit shim value determined in instruction 101,

taking shims from pack previously determined

during’Differential bearing adjustment’checks,

instructions 57 to 62LRT-51-500details 1 and 2,

pressLRT-99-002, andLRT-51-504.

103.Fit remaining shims from instruction 101 to

opposite side of differential.LRT-51-501details

1 and 2, pressLRT-99-002, andLRT-51-504.

104.Fit differential unit with shims and bearings to

axle casing, using axle compressorLRT-51-503

.

105.Remove axle compressor106.Fit bearing caps in their correct position,

referring to relationship markings on caps and on

axle casing.

107.Tighten bearing caps fixings to135 Nm (100

lbf/ft).

108.Mount a dial gauge on axle casing with stylus

resting on a crown wheel tooth.

109.Prevent drive pinion from rotating and check

crown wheel backlash which must be 0,15 to

0,27 mm. If backlash is not within specified

limits, repeat differential backlash checks,

instructions 96 to 102 looking for possible errors.

110.Fit differential cover and new gasket, coating

both sides of gasket with Hylomar PL 32M or an

equivalent non-setting sealant. Torque load for

fixings is30 Nm (22 lbf/ft).

111.Reverse instructions 3 to 5 and coat threads of

hub driving member bolts with Loctite’Studlock’

grade CVX and fit and tighten bolts evenly to

correct torque.

112.Fit rear axle assembly to vehicleSee Repair.

Rear axle.

113.Replenish differential with recommended

lubricantSee LUBRICANTS, FLUIDS AND

CAPACITIES, Information. Recommended

lubricants and fluids. After initial axle run,

check oil level and replenish as necessary to

filler/level plug hole.

114.Where major running parts have been replaced

during servicing, it is a recommended practice to

allow axle assembly to’run in’by avoiding,

where possible, heavy loads and high speeds

during initial running.

ProCarManuals.com

Page 403 of 667

51REAR AXLE AND FINAL DRIVE

10

OVERHAUL REAR HUB ASSEMBLY - 90

Service repair no - 64.15.13.

1.Remove rear hubSee Repair. Rear hub

assembly.

2.Remove outer bearing.

3.Mark, for reassembly, position of hub to brake

disc.4.Remove 5 bolts and separate hub from brake

disc.

WARNING: A maximum of two road wheel

retaining studs can be renewed. Should

more studs be unserviceable fit new hub

with studs.

5.Remove grease seal and inner bearing from

hub.

6.Remove inner and outer bearing tracks.

REAR HUB COMPONENTS - 90

1.Axle shaft.

2.Axle shaft joint washer.

3.Axle shaft retaining bolt.

4.Lock nut.

5.Lock washer.

6.Hub adjusting nut.

7.Spacing washer.8.Outer bearing.

9.Hub.

10.Inner bearing.

11.Grease seal.

12.Brake disc.

13.Disc retaining bolt.

ProCarManuals.com

Page 404 of 667

REAR AXLE AND FINAL DRIVE

11

OVERHAUL

Refit

7.Clean hub and fit inner and outer bearing tracks.

8.Pack hub inner bearing with grease and fit to

hub.

9.With lip side leading, fit a new seal flush with

rear face of hub. Using service toolLRT-54-003

(LST137)seal replacer and drift. Apply grease

between seal lips.10.Assemble brake disc to hub, line up reassembly

marks. Applying Loctite 270, fit and tighten

retaining bolts to73 Nm (54 lbf/ft).

11.Pack hub outer bearing with grease and fit to

hub.

12.Fit rear hub assemblySee Repair. Rear hub

assembly.

ProCarManuals.com

Page 405 of 667

51REAR AXLE AND FINAL DRIVE

12

OVERHAUL REAR STUB AXLE - 90

Service repair no - 64.15.22.

STUB AXLE COMPONENTS

1.Stub axle to axle casing bolt.

2.Mud shield.

3.Stub axle.

4.Stub axle joint washer.

5.Axle case.Overhaul

1.Remove hub assemblySee Repair. Rear hub

assembly.

2.Remove 6 bolts from stub axle to axle casing.

3.Remove mud shield.

4.Remove stub axle and joint washer.

Renew rear stub axle oil seal

5.Remove and discard oil seal. Lubricate seal and

lip with EP90 oil. Using special toolLRT-51-004

(LST 138)fit new oil seal lip side trailing so that

seal is flush with rear face of stub axle.

Refit

6.Fit new joint washer, stub axle and mud shield

bolts. Tighten bolts to65 Nm (48 lbf/ft).

7.Refit hub assemblySee Repair. Rear Hub

Assembly.

ProCarManuals.com

Page 406 of 667

REAR AXLE AND FINAL DRIVE

13

OVERHAUL REAR STUB AXLE - 110/130

Service repair no - 64.15.22

STUB AXLE COMPONENTS

1.Rear axle shaft

2.Stub axle to axle casing bolt

3.Mud shield

4.Stub axle

5.Stub axle joint washer

6.Axle caseOverhaul

1.Remove hub assemblySee REAR

SUSPENSION, Repair. Rear hub bearing.

2.Remove 6 bolts from stub axle to axle casing.

3.Remove mud shield.

4.Remove stub axle and joint washer.

5.Remove rear axle shaft from axle casing.

Renew rear stub axle oil seal

6.Remove and discard oil seal. Lubricate seal and

lip EP90 oil. Using special toolLRT-51-004

(LST138) fit new seal lip side trailing so that seal

is flush with rear face of stub axle.

Refit

7.Fit new joint washer, stub axle and mud shield.

Tighten bolts to65 Nm (48 lbf/ft).

8.Fit rear axle shaft, avoid damaging stub axle

seal.

9.Refit hub assemblySee REAR SUSPENSION,

Repair. Rear hub bearing.

ProCarManuals.com

Page 407 of 667

ProCarManuals.com

Page 408 of 667

54 - FRONT AXLE AND FINAL DRIVE

CONTENTS

Page

DESCRIPTION AND OPERATION

DESCRIPTION 1.....................................................................................................

FAULT DIAGNOSIS

FAULT DIAGNOSIS 1.............................................................................................

REPAIR

FRONT AXLE ASSEMBLY 1..................................................................................

OVERHAUL

FRONT DIFFERENTIAL 1......................................................................................

FRONT HUB 1........................................................................................................

FRONT STUB AXLE, CONSTANT VELOCITY JOINT AND SWIVEL PIN

HOUSING 3............................................................................................................

ProCarManuals.com

Page 409 of 667

ProCarManuals.com

Page 410 of 667

FRONT AXLE AND FINAL DRIVE

1

DESCRIPTION AND OPERATION DESCRIPTION

The welded steel front axle casing houses a separate

spiral bevel type differential unit, which is off-set to the

right of the vehicle centre line. The differential unit

drives the front wheels via the axle shafts and

constant velocity joints which are totally enclosed in

the spherical and swivel housings.The front wheels are pivoted on tape roller bearings at

the top and bottom of the swivel housing. The wheel

hubs on all axles are supported by two taper bearings

and driven by drive flanges which are splined to the

one piece, stub shaft/constant velocity joint.

Front axle hub and swivel housing

1.Axle casing

2.Ventilation pipe

3.Axle shaft

4.Wheel studs and hub

5.Stub axle

6.Wheel bearings

7.Inner and outer hub seals

8.Axle shaft seal

9.Hub lock plate, thrust washer and nuts

10.Brake disc

11.Drive flange

12.Shim washer and circlip13.Dust cap

14.Constant velocity joint/shaft

15.Thrust collar for CV joint

16.Roller bearing

17.Spacer

18.Circlip

19.Top and bottom swivel taper bearing

20.Top and bottom swivel pins

21.Spherical housing, seal and retainer

22.Swivel housing

23.Constant velocity shaft seal

ProCarManuals.com