LAND ROVER DEFENDER 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 341 of 667

33CLUTCH

4

REPAIR Clutch pedal setting

1.Loosen both locknuts on master cylinder push

rod.

2.Check distance from lower edge of clutch pedal

to floor. Correct measurement is 140 mm (5.50

in) without floor mat.

3.Adjust pedal stop to obtain correct setting.

4.Adjust master cylinder push rod to obtain

approximately 1.5 mm (0.06 in) free play

between push rod and master cylinder piston.

5.Tighten push rod locknuts.

6.Check operation of clutch pedal and ensure that

there is minimum of 6 mm (0.25in) of free play

before pressure is felt.

7.Fit pedal box top cover and multiplug bracket

using a new gasket and secure with screws.

8.Connect multiplug and harness clip to pedal

bracket.

9.Bleed clutch hydraulic system.See

Adjustment.CYLINDER - CLUTCH SLAVE

Service repair no - 33.35.01

Remove

1.Disconnect pipe from slave cylinder.

CAUTION: Plug the connections.

2.Position container to catch spillage.

3.Remove 2 bolts securing slave cylinder to bell

housing.

4.Withdraw slave cylinder from bell housing and

push rod.

Refit

5.Clean ends of pipes, bell housing and slave

cylinder mating faces.

6.Lubricate end of push rod with Molybdenum

disulphide gease.

7.Locate slave cylinder to push rod and bell

housing.

8.Fit bolts and tighten to25 Nm (18 lbf.ft).

9.Connect clutch pipe to slave clyinder.

10.Bleed clutch system.See Adjustment.

ProCarManuals.com

Page 342 of 667

37 - MANUAL GEARBOX

CONTENTS

Page

ADJUSTMENT

SPRINGS - GEAR LEVER BIAS 1..........................................................................

GEARBOX OIL - DRAIN AND REFILL 2.................................................................

REPAIR

COVER - FRONT - RESEAL AND FIT NEW INPUT SHAFT OIL SEAL 1..............

LEVER - GEAR CHANGE 3....................................................................................

MECHANISM AND HOUSING - GEAR SELECTOR 4...........................................

MECHANISM AND HOUSING - GEAR SELECTOR - RESEAL 6..........................

GEARBOX 7...........................................................................................................

SWITCH - REVERSE LIGHT 12.............................................................................

ProCarManuals.com

Page 343 of 667

ProCarManuals.com

Page 344 of 667

MANUAL GEARBOX

1

ADJUSTMENT SPRINGS - GEAR LEVER BIAS

Service repair no - 37.16.26

Check

NOTE: The purpose of this adjustment is

to set both bolts so that the bias spring

legs apply equal pressure on both ends of

the gear lever cross pin when 3rd or 4th gear is

engaged. This will ensure that when the gear lever

is in neutral, the gear change mechanism is

automatically aligned for 3rd or 4th gears.

1.Remove gear lever knobs.

2.Release and remove gear lever gaiter.

3.Select 3rd or 4th gear.

4.Adjust the two adjusting screws until both legs of

the spring are approximately 0.5 mm (0.02 in)

clear of cross pin in the gear lever.

5.Apply a light load to the gear lever in a RH

direction and adjust the LH adjusting screw

downwards until the LH spring leg just makes

contact with the cross pin.

6.Repeat the same procedure for the RH adjusting

screw.

7.Lower both adjusting screws equal amounts until

the radial play is just eliminated. Tighten lock

nuts.

8.Return gear lever to neutral position and move

gear lever across the gate several times. The

gear lever should return to the 3rd and 4th gate.

9.Fit gear lever gaiter.

10.Fit gear lever knobs.

ProCarManuals.com

Page 345 of 667

37MANUAL GEARBOX

2

ADJUSTMENT GEARBOX OIL - DRAIN AND REFILL

Service repair no - 37.24.01

Drain

1.The oil should be drained when the gearbox is

warm and the vehicle is standing on a level

surface.

WARNING: Observe due care when

draining gearbox as oil can be very hot.

2.Raise vehicle on ramp.

3.Position container to collect oil.

4.Clean area around filler/level plug.

5.Remove filler/level plug.

NOTE: Later gearboxes: Use No. 55 Torx

bit to remove filler/level plug.

6.Remove gearbox drain plug and discard sealing

washer.Refill

1.Clean gearbox drain plug and fit new sealing

washer.

2.Fit gearbox drain plug and tighten to50 Nm (36

lbf.ft).

3.Fill gearbox with correct grade of oil.See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information.

4.Apply Loctite 290 to the filler/level plug and

tighten to30 Nm (22 lbf.ft).

5.Remove fluid container.

6.Lower vehicle on ramp.

ProCarManuals.com

Page 346 of 667

MANUAL GEARBOX

1

REPAIR COVER - FRONT - RESEAL AND FIT NEW INPUT

SHAFT OIL SEAL

Service repair no - 37.12.33.01

Remove

1.Remove gearbox.See this Section.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release fork,

remove retaining clip and remove clutch release

fork.

4.Remove 2 bolts securing release bearing sleeve,

remove bearing sleeve.

5.Remove 6 bolts securing clutch housing, remove

housing.

6.Remove and discard 6 bolts securing front

cover, remove cover.

ProCarManuals.com

Page 347 of 667

37MANUAL GEARBOX

2

REPAIR

7.Using a soft metal drift, carefully remove input

shaft front bearing track from front cover.

CAUTION: Take care not to damage

bearing track, if track is damaged, it will be

necessary to fit a new input shaft front

bearing.

8.Remove input shaft oil seal from front cover;

discard oil seal.

Refit

9.Using a suitable solvent clean seal recess, front

cover and gearbox mating faces; clean threads

of bolts and bolt holes.

10.Clean bearings and bearing races.

11.Lubricate a new oil seal with gearbox oil.

12.Fit oil seal using a suitable mandrel.

13.Fit input shaft front bearing track using a press

and suitable mandrel.

14.Apply sealant, Part No. STC 4404 to front cover.

15.Position front cover, apply Loctite 290 to threads

of bolts; fit new bolts and tighten by diagonal

selection to25 Nm (18 lbf.ft).

16.Clean clutch housing mating faces, dowels and

dowel holes.

17.Position clutch housing, fit bolts and tighten by

diagonal selection to75 Nm (55 lbf.ft).

18.Clean bearing sleeve mating faces, dowel and

dowel holes.

19.Position bearing sleeve, fit bolts and tighten to

25 Nm (18 lbf.ft).

20.Examine clutch release fork pivot points for wear

and replace as required.

21.Apply a smear of Molybdenum disulphide grease

to pivot points and position release fork.

22.Fit retaining clip ensuring it locates over pivot

point washer, fit bolt and tighten to10 Nm (7

lbf.ft).23.Clean release bearing and bearing sleeve

mating faces.

24.Apply smear of Molybdenum disulphide grease

to release bearing sleeve.

25.Fit release bearing and secure with retaining

peg.

26.Fit gearbox.See this Section.

ProCarManuals.com

Page 348 of 667

MANUAL GEARBOX

3

REPAIR LEVER - GEAR CHANGE

Service repair no - 37.16.04

Remove

1.Remove gear lever knob.

2.Release and remove gear lever gaiter(s).

3.Remove nut securing upper gear lever to lower

gear lever.

4.Remove upper gear lever from lower gear lever.

5.Using a suitable piece of tubing fitted over end of

bias spring, release both ends of bias spring

from ball pins.

6.Remove bolt and special washer securing gear

lever to housing.

7.Carefully withdraw gear lever from housing

ensuring that spring loaded nylon pad is retained

during removal.

WARNING: Personal injury may result if

nylon pad is not retained.

Refit

8.Clean gear lever, housing and nylon pad.

9.Lubricate ball pin with multi-purpose grease and

fit nylon pad and spring.

10.Depress nylon pad against spring pressure,

position gear lever in housing with the nylon pad

facing away from bias spring location.

11.Fit gear lever retaining bolt and special washer

and tighten bolt to10 Nm (7 lbf.ft).

12.Using a suitable piece of tubing fitted over ends

of bias spring, locate each end of bias spring to

ball pins.

13.Fit upper gear lever to lower gear lever and

tighten retaining nut to25 Nm (18 lbf.ft).

14.Adjust bias spring.See Adjustment.

15.Fit gear lever gaiter(s).

16.Fit gear lever knob.

ProCarManuals.com

Page 349 of 667

37MANUAL GEARBOX

4

REPAIR MECHANISM AND HOUSING - GEAR SELECTOR

Service repair no - 37.16.37

Remove

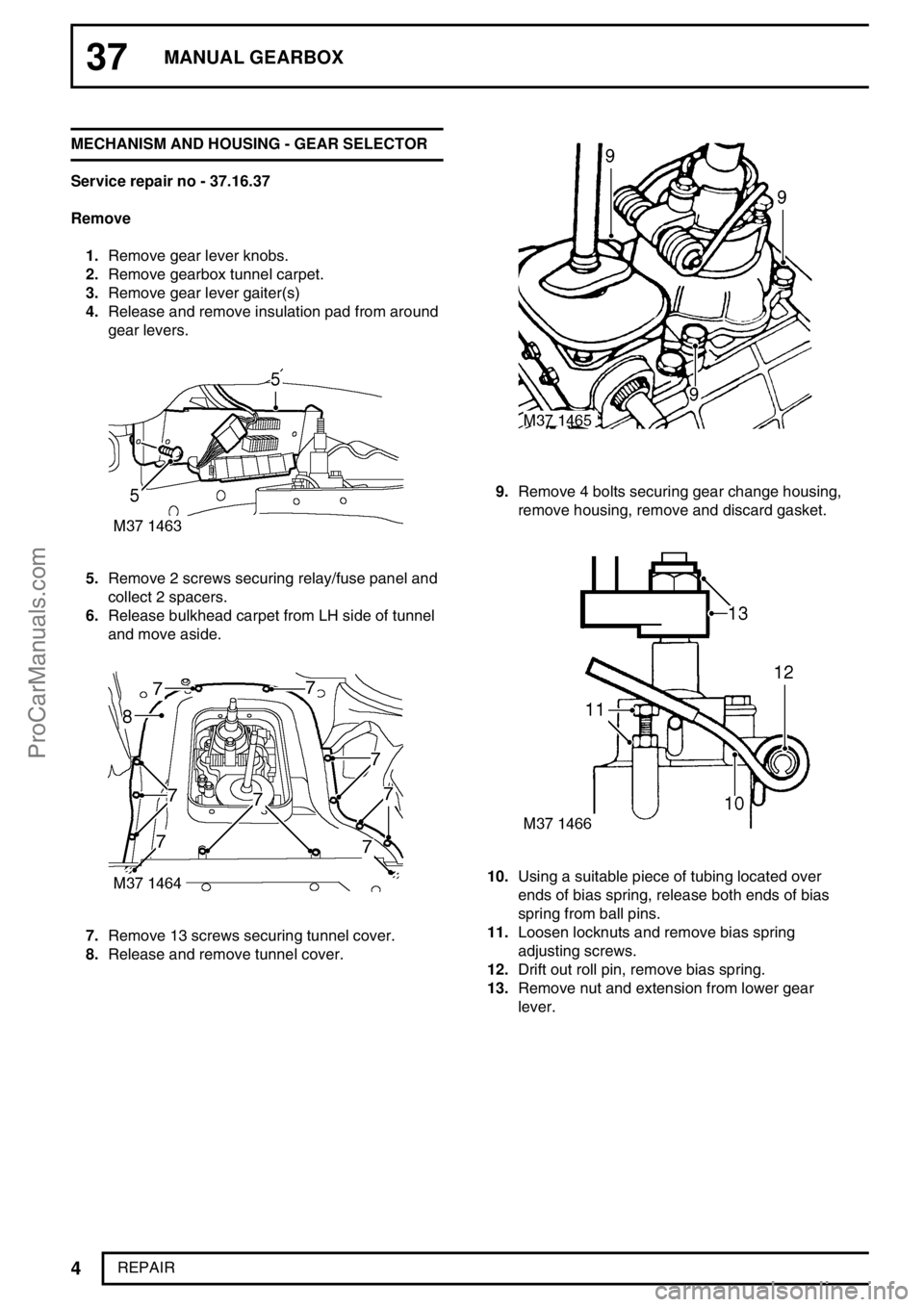

1.Remove gear lever knobs.

2.Remove gearbox tunnel carpet.

3.Remove gear lever gaiter(s)

4.Release and remove insulation pad from around

gear levers.

5.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

6.Release bulkhead carpet from LH side of tunnel

and move aside.

7.Remove 13 screws securing tunnel cover.

8.Release and remove tunnel cover.

9.Remove 4 bolts securing gear change housing,

remove housing, remove and discard gasket.

10.Using a suitable piece of tubing located over

ends of bias spring, release both ends of bias

spring from ball pins.

11.Loosen locknuts and remove bias spring

adjusting screws.

12.Drift out roll pin, remove bias spring.

13.Remove nut and extension from lower gear

lever.

ProCarManuals.com

Page 350 of 667

MANUAL GEARBOX

5

REPAIR

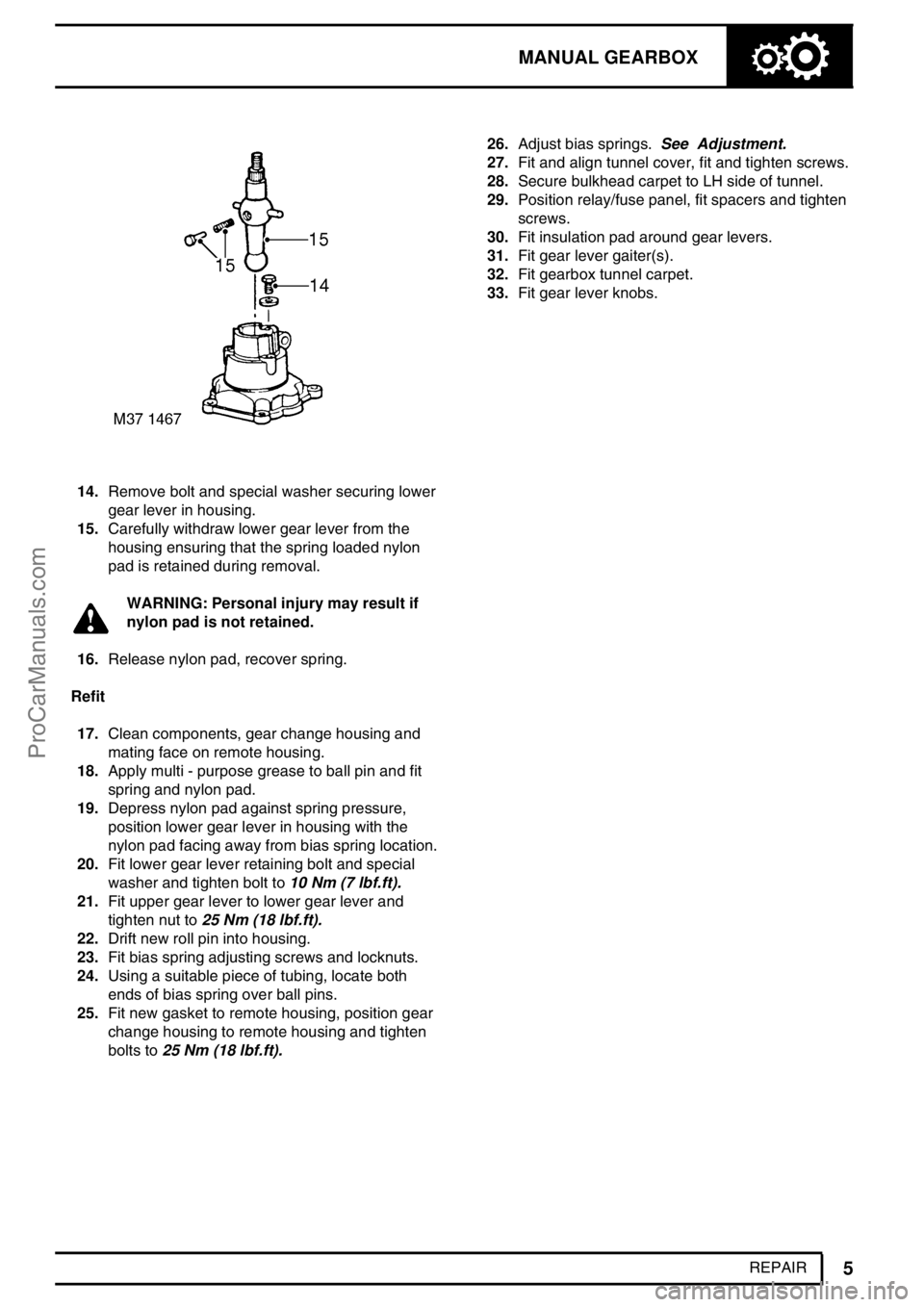

14.Remove bolt and special washer securing lower

gear lever in housing.

15.Carefully withdraw lower gear lever from the

housing ensuring that the spring loaded nylon

pad is retained during removal.

WARNING: Personal injury may result if

nylon pad is not retained.

16.Release nylon pad, recover spring.

Refit

17.Clean components, gear change housing and

mating face on remote housing.

18.Apply multi - purpose grease to ball pin and fit

spring and nylon pad.

19.Depress nylon pad against spring pressure,

position lower gear lever in housing with the

nylon pad facing away from bias spring location.

20.Fit lower gear lever retaining bolt and special

washer and tighten bolt to10 Nm (7 lbf.ft).

21.Fit upper gear lever to lower gear lever and

tighten nut to25 Nm (18 lbf.ft).

22.Drift new roll pin into housing.

23.Fit bias spring adjusting screws and locknuts.

24.Using a suitable piece of tubing, locate both

ends of bias spring over ball pins.

25.Fit new gasket to remote housing, position gear

change housing to remote housing and tighten

bolts to25 Nm (18 lbf.ft).26.Adjust bias springs.See Adjustment.

27.Fit and align tunnel cover, fit and tighten screws.

28.Secure bulkhead carpet to LH side of tunnel.

29.Position relay/fuse panel, fit spacers and tighten

screws.

30.Fit insulation pad around gear levers.

31.Fit gear lever gaiter(s).

32.Fit gearbox tunnel carpet.

33.Fit gear lever knobs.

ProCarManuals.com