LAND ROVER DEFENDER 1999 Repair Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 61 of 667

10MAINTENANCE

2

MAINTENANCE SEATS AND SEAT BELTS

1.Check seat frames are secured to floor and

show no signs of movement.

2.Check operation of seat slide and tilt

mechanisms, ensuring there is no excessive

play between seat cushion and seat back.

3.Check tightness of accessible seat fixings.

4.Fully extract seat belt and allow it to return under

its own recoil mechanism.

5.Check entire length of seat belt webbing for

signs of fraying or damage. Repeat for all belts.

6.Check security of seat belt upper mountings.

7.Check security of seat belt buckle mountings.

8.Connect each belt to the correct buckle, check

seat belt buckle and tongue are secure. Release

seat belt buckle and check for correct operation.

9.Check tightness of accessible seat belt

mountingsLAMPS, HORNS AND WARNING INDICATORS

1.Switch on side, head and tail lights and check

operation.

2.Check headlamp dim/dip operation.

3.Check headlamp levelling operation.

4.Check turn signals and hazard warning lights

operation.

5.Press brake pedal and check operation of brake

lights.

6.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to head lamp

lenses for signs of stone chips or damage.

7.Check horn for loud clear sound.

8.Check operation of all instrument pack warning

and indicator lights.

9.Check for correct operation of interior courtesy

lights.

ProCarManuals.com

Page 62 of 667

MAINTENANCE

3

MAINTENANCE WIPERS AND WASHERS

1.Operate screen washer and switch on wipers.

Check washer jets are correctly aimed and

check for smooth smearless operation across

screen of wiper blades at all speeds, including

intermittent.

2.Repeat operation for rear screen

wipers/washers.

3.Check all wiper blades for condition and signs of

splits or damage.

4.Check security of wiper arms.HANDBRAKE

1.With the vehicle stationary, apply handbrake and

check for correct operation.See BRAKES,

Adjustment.

2.Release handbrake and check for correct

operation.

NOTE: Any adjustment required as a result

of the checking process will be subject to

additional labour and/or material cost and

should not be carried out without the

authorisation of the customer.

Adjust handbrake (First 12,000 miles/12 months

only

1.Adjust handbrake cable.See BRAKES,

Adjustment.

NOTE: Additional time is built into the first

12,000/12 months service time to allow for

handbrake cable adjustment.

ProCarManuals.com

Page 63 of 667

10MAINTENANCE

4

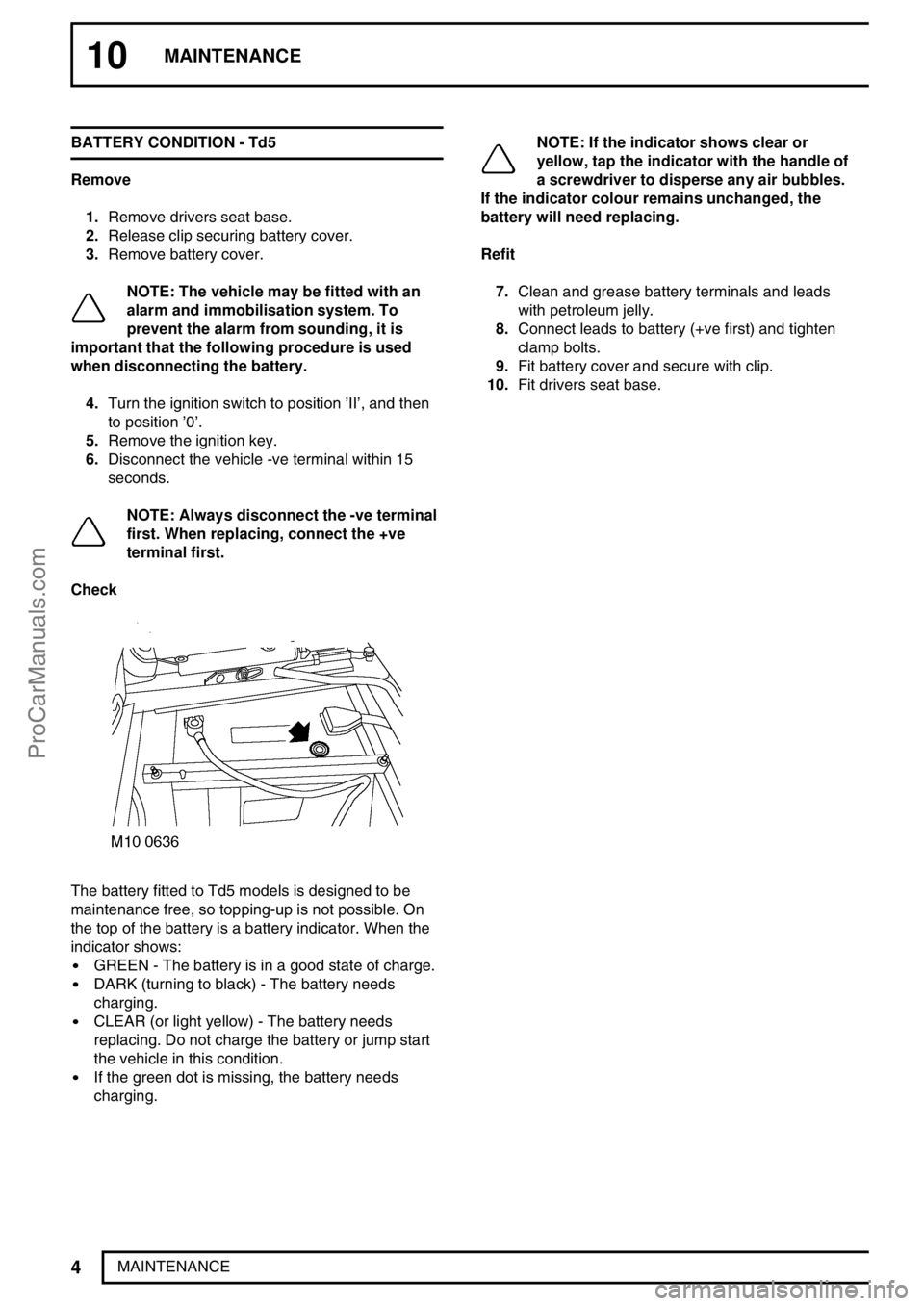

MAINTENANCE BATTERY CONDITION - Td5

Remove

1.Remove drivers seat base.

2.Release clip securing battery cover.

3.Remove battery cover.

NOTE: The vehicle may be fitted with an

alarm and immobilisation system. To

prevent the alarm from sounding, it is

important that the following procedure is used

when disconnecting the battery.

4.Turn the ignition switch to position’II’, and then

to position’0’.

5.Remove the ignition key.

6.Disconnect the vehicle -ve terminal within 15

seconds.

NOTE: Always disconnect the -ve terminal

first. When replacing, connect the +ve

terminal first.

Check

The battery fitted to Td5 models is designed to be

maintenance free, so topping-up is not possible. On

the top of the battery is a battery indicator. When the

indicator shows:

GREEN - The battery is in a good state of charge.

DARK (turning to black) - The battery needs

charging.

CLEAR (or light yellow) - The battery needs

replacing. Do not charge the battery or jump start

the vehicle in this condition.

If the green dot is missing, the battery needs

charging.

NOTE: If the indicator shows clear or

yellow, tap the indicator with the handle of

a screwdriver to disperse any air bubbles.

If the indicator colour remains unchanged, the

battery will need replacing.

Refit

7.Clean and grease battery terminals and leads

with petroleum jelly.

8.Connect leads to battery (+ve first) and tighten

clamp bolts.

9.Fit battery cover and secure with clip.

10.Fit drivers seat base.

ProCarManuals.com

Page 64 of 667

MAINTENANCE

5

MAINTENANCE HANDSET BATTERY

Remove

NOTE: Do not remove a battery until you

are ready to install the replacement.

Always fit a Land Rover STC4080 or a

Panasonic CR2032 replacement battery.

1.Unlock the vehicle and disarm the alarm system.

2.Turn the ignition switch to position’II’, then turn

to position’0’and remove the key.

3.Carefully prise the handset apart, starting from

the keyring end. Avoid damaging the seal

between the two halves of the case.

CAUTION: Do not allow moisture to get

inside the handset.

4.Slide the battery out of its clip, taking care to

avoid touching the circuit board or the contact

surfaces of the clip.

5.Press and hold one of the buttons for at least 5

seconds to drain any residual power from the

handset.

Refit

6.Fit the new battery, ensuring that correct polarity

is maintained (+ve side facing up). Finger marks

will adversely affect battery life. Avoid touching

the flat surfaces of the battery, and wipe clean

before fitment.

7.Reassemble the two halves of the handset.

Operate the Padlock symbol button at least 4

times within range of the vehicle to

resynchronise the hanset.HEADLAMP ALIGNMENT

1.Check alignment of headlamps.See

ELECTRICAL, Adjustment.

ProCarManuals.com

Page 65 of 667

10MAINTENANCE

6

MAINTENANCE ROAD WHEELS

Remove

1.Loosen wheel nuts. Raise vehicle for wheel free

condition and remove the wheel nuts.

2.Mark the wheel to stud relationship to ensure

that the wheels are refitted in the same

orientation.

Refit

3.Apply a thin coat of anti-seize compound to

wheel hub centre.

4.Refit wheels to original hub position.

NOTE: When refitting road wheel nuts do

not overtighten using powered tools.

Ensure the wheel nuts are correctly

torqued in the correct sequence.

5.Tighten wheel nuts.

Steel wheels -100 Nm (80 lbf/ft)

Alloy wheels -130 Nm (96 lbf/ft)

Heavy Duty wheels -170 Nm (125 lbf/ft)TYRE PRESSURES, CONDITION AND TREAD

DEPTH

1.Check for any apparent damage to tyres, paying

particular attention to side walls.

2.Look at tyre treads and check for any unusual

wear patterns which may indicate out of

specification adjustment of steering or

suspension.

NOTE: Any adjustments to steering or

suspension will be subject to additional

labour and/or material cost and should not

be carried out without the authorisation of the

customer.

3.Measure the tread depth across the width of the

tyre and around the circumference. Annotate the

maintenance check sheet with the lowest figure

obtained from each tyre.

NOTE: Any requirement to replace tyres

should be advised to the customer before

any remedial work is carried out. This will

be subject to additional labour and/or material

cost and should not be carried out without the

authorisation of the customer.

ProCarManuals.com

Page 66 of 667

MAINTENANCE

7

MAINTENANCE BRAKE PADS, CALIPERS AND DISCS

1.With front road wheels removed, check brake

pad thickness and ensure that both pads are

wearing evenly.

2.Check brake discs for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirement to replace brake

pads or brake disc should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

3.Check for any signs of brake fluid leakage from

caliper seals, hoses or unions.

4.Using brake cleaner, remove excessive deposits

of brake dust from pads, calipers and disc

shields.ROAD WHEEL SPEED SENSOR HARNESS - Td5

1.Check each sensor harness is correctly and

securely routed.

2.Inspect each harness for chafing or damage.

NOTE: Any requirement to replace a road

wheel speed sensor should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

ProCarManuals.com

Page 67 of 667

10MAINTENANCE

8

MAINTENANCE FUEL FILTER ELEMENT

1.Renew fuel filter element.See FUEL SYSTEM,

Repair.FUEL FILTER SEDIMENTER - Td5

WARNING: Fuel vapour is highly

flammable and in contained speces is also

explosive and toxic. Always have a fire

extinguisher containing FOAM, CO2, GAS OR

POWDER close at hand when handling or draining

fuel.

1.Disconnect battery negative lead.

2.Position suitable container beneath fuel filter

3.Disconnect multiplug from sedimenter

4.Rotate sedimenter anti-clockwise until water

flows from drain tube.

5.Allow to drain until diesel fuel flows from drain

tube.

6.Rotate sedimenter fully clockwise.

7.Connect multiplug.

8.Reconnect battery negative lead.

ProCarManuals.com

Page 68 of 667

MAINTENANCE

9

MAINTENANCE INTERCOOLER / COOLING SYSTEM

1.Visually check for any obstructions in the

radiator and intercooler matrix and remove

debris as necessary.

2.Visually check fan blades for damage.

3.Check cooling, intercooler and heating systems

for leaks, hoses and oil pipes for security and

condition.

4.Check accessible hose clips for tightness.

5.Check coolant level, top-up if necessary

Cooling System Top-Up

1.With engine cold, remove expansion tank filler

cap.

2.Top-up with recommended mixture of coolant

until level reaches mark on expansion tank.

3.Fit expansion tank filler cap.

Intercooler Flush

1.Remove intercooler.See FUEL SYSTEM,

Repair.

2.Flush intercooler element using Unicorn

Chemicals’C’Solve following the manufaturers

instructions.

3.Thoroughly dry intercooler ensuring that no trace

of solvent remains in the element.

4.Refit intercooler.See FUEL SYSTEM, Repair.AMBIENT AIR PRESSURE (AAP) SENSOR - Td5

1.Check ambient air pressure sensor for damage.

ProCarManuals.com

Page 69 of 667

10MAINTENANCE

10

MAINTENANCE DOOR LOCKS AND HINGES

Front, rear and tail doors

1.Open each door in turn and lubricate door

hinges and check strap using recommended

lubricant.

2.Lubricate door lock, striker and private lock using

PTFE lubricant. Remove excessive lubricant,

particularly from door striker area, to avoid

customer complaint.

3.Check tightness of accessible door lock and

striker fixings

4.Open and close door to check for smooth,

noise-free operation. Ensure door closes

securely.

5.Check for smooth operation of private lock.

Bonnet

1.With bonnet open, lubricate hinges, striker, lock

and safety catch using a suitable lubricant.ENGINE COOLANT

1.Renew engine coolant.See COOLING

SYSTEM, Adjustment.

ProCarManuals.com

Page 70 of 667

MAINTENANCE

11

MAINTENANCE BRAKE FLUID

1.Renew brake fluid.See BRAKES,

Adjustment.AIR FILTER ELEMENT AND DUMP VALVE

1.Replace air cleaner element.See FUEL

SYSTEM, Repair.

2.Remove all dirt from dump valve.

ProCarManuals.com