LAND ROVER DEFENDER 1999 Service Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 41 of 667

ProCarManuals.com

Page 42 of 667

07 - GENERAL FITTING REMINDERS

CONTENTS

Page

INFORMATION

GENERAL FITTING REMINDERS 1.......................................................................

PRECAUTIONS AGAINST DAMAGE 1..................................................................

SAFETY PRECAUTIONS 1....................................................................................

PREPARATION 2....................................................................................................

DISMANTLING 2.....................................................................................................

INSPECTION-GENERAL 2.....................................................................................

BALL AND ROLLER BEARINGS 3.........................................................................

OIL SEALS 4...........................................................................................................

JOINTS AND JOINT FACES 5................................................................................

FLEXIBLE HYDRAULIC PIPES, HOSES 5.............................................................

FUEL SYSTEM HOSES 6.......................................................................................

METRIC BOLT IDENTIFICATION 6........................................................................

METRIC NUT IDENTIFICATION 6..........................................................................

KEYS AND KEYWAYS 6........................................................................................

TAB WASHERS 6...................................................................................................

COTTER PINS 7.....................................................................................................

NUTS7 ...................................................................................................................

LOCKING WIRE 7...................................................................................................

SCREW THREADS 7..............................................................................................

UNIFIED THREAD IDENTIFICATION 7..................................................................

ProCarManuals.com

Page 43 of 667

ProCarManuals.com

Page 44 of 667

GENERAL FITTING REMINDERS

1

INFORMATION GENERAL FITTING REMINDERS

WORKSHOP SAFETY IS YOUR RESPONSIBILITY!

The suggestions, cautions and warnings in the

section are intended to serve as reminders for

trained and experienced mechanics. This manual

is not a definitive guide to automotive mechanics

or workshop safety.

Shop equipment, shop environment, and the use

and disposal of solvents, fluids, and chemicals

are subject to government regulations which are

intended to provide a level of safety. It is your

responsibility to know and comply with such

regulations.

PRECAUTIONS AGAINST DAMAGE

1.Always fit covers to protect fenders before

commencing work in engine compartment.

2.Cover seats and carpets, wear clean overalls

and wash hands or wear gloves before working

inside vehicle.

3.Avoid spilling hydraulic fluid or battery acid on

paint work. Wash off with water immediately if

this occurs. Use Polythene sheets to protect

carpets and seats.

4.Always use a recommended Service Tool where

specified.

5.Protect temporarily exposed screw threads by

replacing nuts or fitting plastic caps.SAFETY PRECAUTIONS

1.Whenever possible, use a lift when working

beneath vehicle, in preference to jacking. Chock

wheels as well as applying parking brake.

WARNING: Do not use a pit when

removing fuel system components.

2.Never rely on a jack alone to support vehicle.

Use axle stands carefully placed at jacking

points to provide rigid support.

3.Ensure that a suitable form of fire extinguisher is

conveniently located.

4.Check that any lifting equipment used has

adequate capacity and is fully serviceable.

5.Disconnect battery.

WARNING: Do not disconnect any pipes in

air conditioning system, unless trained

and instructed to do so. A refrigerant is

used which can cause blindness if allowed to

contact eyes.

6.Ensure that adequate ventilation is provided

when volatile degreasing agents are being used.

7.Do not apply heat in an attempt to free stiff

fixings; as well as causing damage to protective

coatings, there is a risk of damage to electronic

equipment and brake linings from stray heat.

ProCarManuals.com

Page 45 of 667

07GENERAL FITTING REMINDERS

2

INFORMATION PREPARATION

1.Clean components and surrounding area prior to

removal.

2.Blank off any openings exposed by component

removal using greaseproof paper and masking

tape.

3.Immediately seal fuel, oil or hydraulic lines when

separated, using plastic caps or plugs, to

prevent loss of fluid and entry of dirt.

4.Close open ends of oilways, exposed by

component removal, with tapered hardwood

plugs or readily visible plastic plugs.

5.Immediately a component is removed, place it in

a suitable container; use a separate container for

each component and its associated parts.

6.Before dismantling a component, clean it

thoroughly with a recommended cleaning agent;

check that agent is suitable for all materials of

component.

7.Clean bench and provide marking materials,

labels, containers and locking wire before

dismantling a component.

DISMANTLING

1.Observe scrupulous cleanliness when

dismantling components, particularly when

brake, fuel or hydraulic system parts are being

worked on. A particle of dirt or a cloth fragment

could cause a dangerous malfunction if trapped

in these systems.

2.Blow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

O-rings used for sealing are correctly replaced or

renewed, if disturbed.

3.Use marking ink to identify mating parts, to

ensure correct reassembly. If a centre punch or

scriber is used they may initiate cracks or

distortion of components.

4.Wire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

5.Wire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

6.Do not discard a part due for renewal until it has

been compared with the new part, to ensure that

its correct replacement has been obtained.INSPECTION-GENERAL

1.Never inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an incipient

failure.

2.When a component is to be checked

dimensionally against figures quoted for it, use

correct equipment (surface plates, micrometers,

dial gauges, etc.) in serviceable condition.

Makeshift checking equipment can be

dangerous.

3.Reject a component if its dimensions are outside

limits quoted, or if damage is apparent. A part

may, however, be refitted if its critical dimension

is exactly limit size, and is otherwise satisfactory.

4.Use’Plastigauge’12 Type PG-1 for checking

bearing surface clearances. Directions for its

use, and a scale giving bearing clearances in

0,0025 mm steps are provided with it.

ProCarManuals.com

Page 46 of 667

GENERAL FITTING REMINDERS

3

INFORMATION BALL AND ROLLER BEARINGS

CAUTION: Never refit a ball or roller

bearing without first ensuring that it is in a

fully serviceable condition.

1.Remove all traces of lubricant from bearing

under inspection by washing in a suitable

degreaser; maintain absolute cleanliness

throughout operations.

2.Inspect visually for markings of any form on

rolling elements, raceways, outer surface of

outer rings or inner surface of inner rings. Reject

any bearings found to be marked, since any

marking in these areas indicates onset of wear.

3.Holding inner race between finger and thumb of

one hand, spin outer race and check that it

revolves absolutely smoothly. Repeat, holding

outer race and spinning inner race.

4.Rotate outer ring gently with a reciprocating

motion, while holding inner ring; feel for any

check or obstruction to rotation, and reject

bearing if action is not perfectly smooth.

5.Lubricate bearing generously with lubricant

appropriate to installation.

6.Inspect shaft and bearing housing for

discolouration or other marking suggesting that

movement has taken place between bearing and

seatings. (This is particularly to be expected if

related markings were found in operation 2).

7.Ensure that shaft and housing are clean and free

from burrs before fitting bearing.8.If one bearing assembly of a pair shows an

imperfection it is generally advisable to replace

both with new bearings; an exception could be

made if the faulty bearing had covered a low

mileage, and it could be established that

damage was confined to it only.

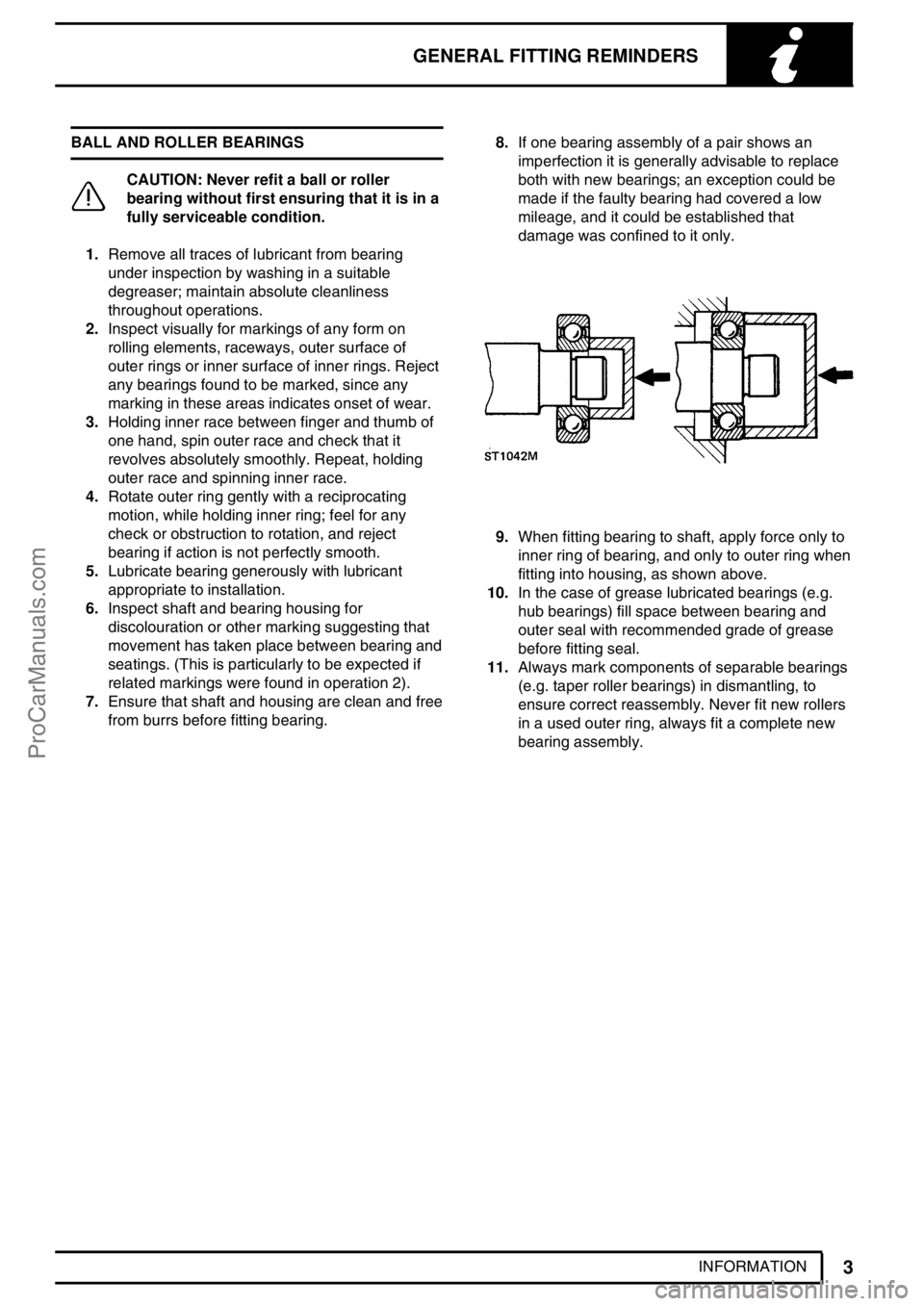

9.When fitting bearing to shaft, apply force only to

inner ring of bearing, and only to outer ring when

fitting into housing, as shown above.

10.In the case of grease lubricated bearings (e.g.

hub bearings) fill space between bearing and

outer seal with recommended grade of grease

before fitting seal.

11.Always mark components of separable bearings

(e.g. taper roller bearings) in dismantling, to

ensure correct reassembly. Never fit new rollers

in a used outer ring, always fit a complete new

bearing assembly.

ProCarManuals.com

Page 47 of 667

07GENERAL FITTING REMINDERS

4

INFORMATION OIL SEALS

NOTE: Ensure that the seal running track

is free from pits, scores, corrosion and

general damage prior to fitting

replacement seal.

1.Always fit new oil seals when rebuilding an

assembly.

2.Carefully examine seal before fitting to ensure

that it is clean and undamaged.

3.Coat the sealing lips with clean grease; pack

dust excluder seals with grease, and heavily

grease duplex seals in cavity between sealing

lips.

4.Ensure that seal spring, if provided, is correctly

fitted.

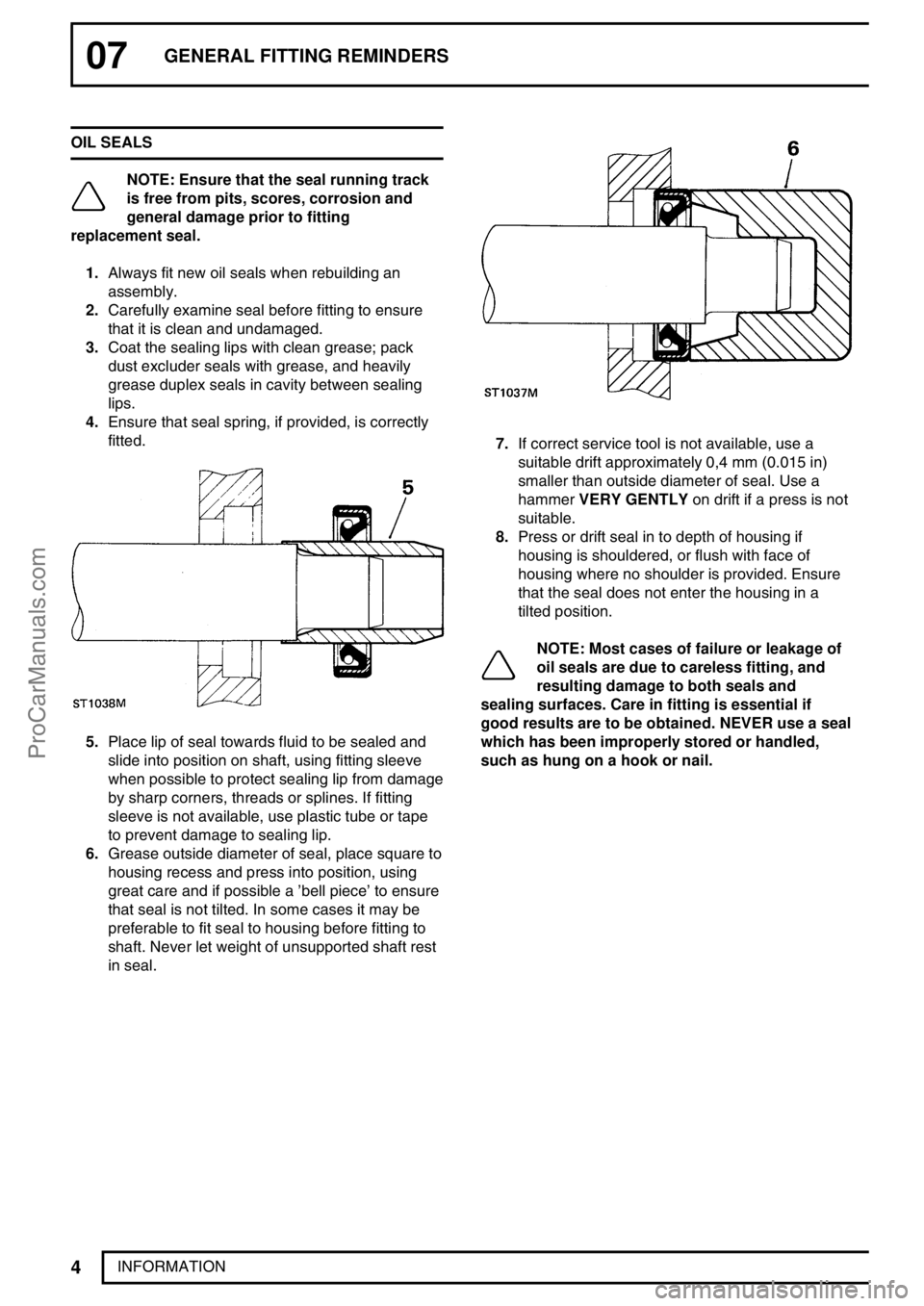

5.Place lip of seal towards fluid to be sealed and

slide into position on shaft, using fitting sleeve

when possible to protect sealing lip from damage

by sharp corners, threads or splines. If fitting

sleeve is not available, use plastic tube or tape

to prevent damage to sealing lip.

6.Grease outside diameter of seal, place square to

housing recess and press into position, using

great care and if possible a’bell piece’to ensure

that seal is not tilted. In some cases it may be

preferable to fit seal to housing before fitting to

shaft. Never let weight of unsupported shaft rest

in seal.

7.If correct service tool is not available, use a

suitable drift approximately 0,4 mm (0.015 in)

smaller than outside diameter of seal. Use a

hammerVERY GENTLYon drift if a press is not

suitable.

8.Press or drift seal in to depth of housing if

housing is shouldered, or flush with face of

housing where no shoulder is provided. Ensure

that the seal does not enter the housing in a

tilted position.

NOTE: Most cases of failure or leakage of

oil seals are due to careless fitting, and

resulting damage to both seals and

sealing surfaces. Care in fitting is essential if

good results are to be obtained. NEVER use a seal

which has been improperly stored or handled,

such as hung on a hook or nail.

ProCarManuals.com

Page 48 of 667

GENERAL FITTING REMINDERS

5

INFORMATION JOINTS AND JOINT FACES

1.Always use correct gaskets where they are

specified.

2.Use jointing compound only when

recommended. Otherwise fit joints dry.

3.When jointing compound is used, apply in a thin

uniform film to metal surfaces; take great care to

prevent it from entering oilways, pipes or blind

tapped holes.

4.Remove all traces of old jointing materials prior

to reassembly. Do not use a tool which could

damage joint faces.

5.Inspect joint faces for scratches or burrs and

remove with a fine file or oil stone; do not allow

removed material or dirt to enter tapped holes or

enclosed parts.

6.Blow out any pipes, channels or crevices with

compressed air, fit new’O’rings or seals

displaced by air blast.FLEXIBLE HYDRAULIC PIPES, HOSES

1.Before removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

2.Obtain appropriate plugs or caps before

detaching hose end fittings, so that ports can be

immediately covered to exclude dirt.

3.Clean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any hose found faulty.

4.When refitting hose, ensure that no unnecessary

bends are introduced, and that hose is not

twisted before or during tightening of union nuts.

5.Containers for hydraulic fluid must be kept

absolutely clean.

6.Do not store brake fluid in an unsealed

container. It will absorb water, and fluid in this

condition would be dangerous to use due to a

lowering of its boiling point.

7.Do not allow brake fluid to be contaminated with

mineral oil, or use a container which has

previously contained mineral oil.

8.Do not re-use brake fluid bled from system.

9.Always use clean brake fluid to clean hydraulic

components.

10.Fit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of dirt.

11.Absolute cleanliness must be observed with

hydraulic components at all times.

12.After any work on hydraulic systems, inspect

carefully for leaks underneath the vehicle while a

second operator applies maximum pressure to

the brakes (engine running) and operates the

steering.

ProCarManuals.com

Page 49 of 667

07GENERAL FITTING REMINDERS

6

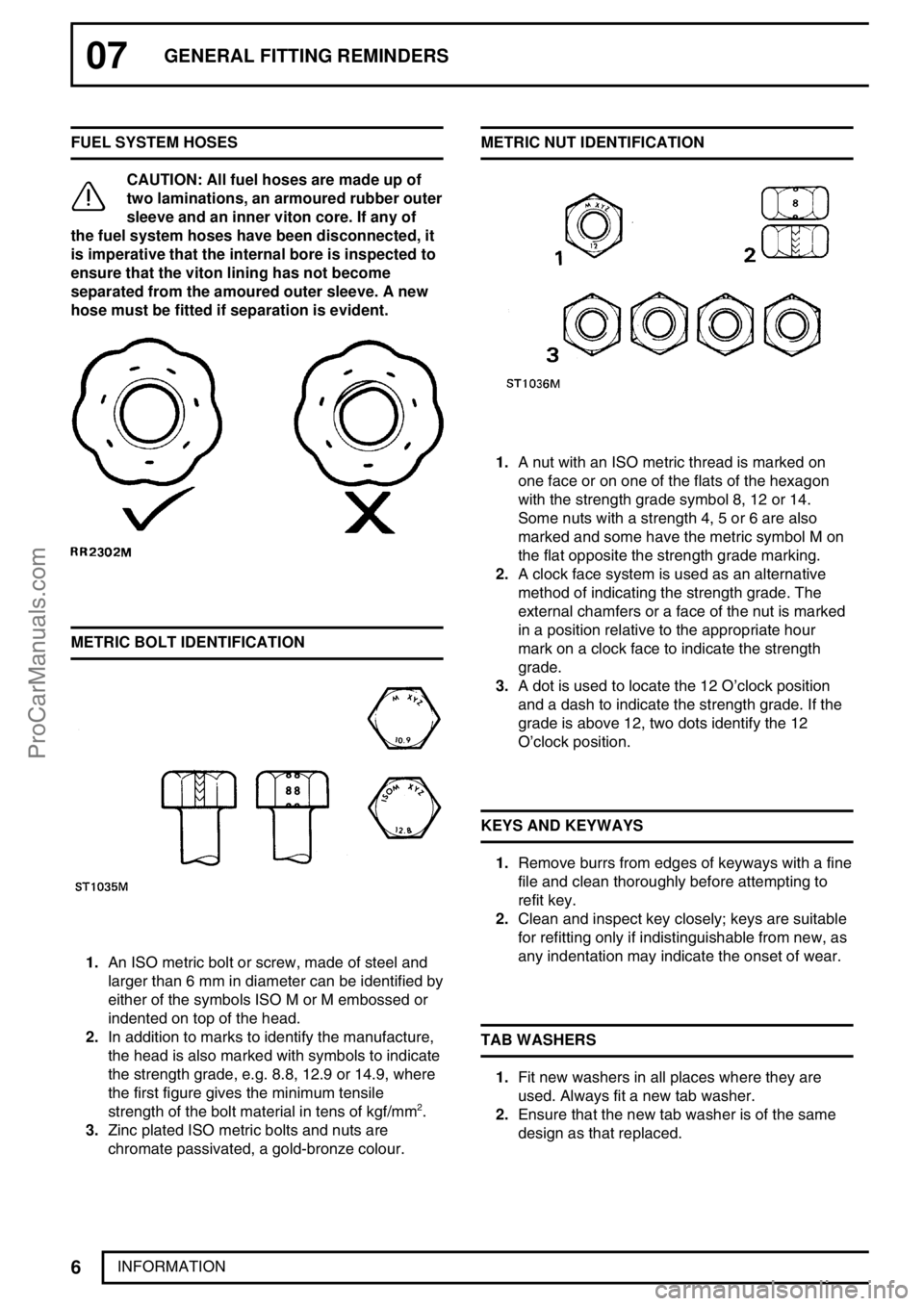

INFORMATION FUEL SYSTEM HOSES

CAUTION: All fuel hoses are made up of

two laminations, an armoured rubber outer

sleeve and an inner viton core. If any of

the fuel system hoses have been disconnected, it

is imperative that the internal bore is inspected to

ensure that the viton lining has not become

separated from the amoured outer sleeve. A new

hose must be fitted if separation is evident.

METRIC BOLT IDENTIFICATION

1.An ISO metric bolt or screw, made of steel and

larger than 6 mm in diameter can be identified by

either of the symbols ISO M or M embossed or

indented on top of the head.

2.In addition to marks to identify the manufacture,

the head is also marked with symbols to indicate

the strength grade, e.g. 8.8, 12.9 or 14.9, where

the first figure gives the minimum tensile

strength of the bolt material in tens of kgf/mm

2.

3.Zinc plated ISO metric bolts and nuts are

chromate passivated, a gold-bronze colour.METRIC NUT IDENTIFICATION

1.A nut with an ISO metric thread is marked on

one face or on one of the flats of the hexagon

with the strength grade symbol 8, 12 or 14.

Some nuts with a strength 4, 5 or 6 are also

marked and some have the metric symbol M on

the flat opposite the strength grade marking.

2.A clock face system is used as an alternative

method of indicating the strength grade. The

external chamfers or a face of the nut is marked

in a position relative to the appropriate hour

mark on a clock face to indicate the strength

grade.

3.A dot is used to locate the 12 O’clock position

and a dash to indicate the strength grade. If the

grade is above 12, two dots identify the 12

O’clock position.

KEYS AND KEYWAYS

1.Remove burrs from edges of keyways with a fine

file and clean thoroughly before attempting to

refit key.

2.Clean and inspect key closely; keys are suitable

for refitting only if indistinguishable from new, as

any indentation may indicate the onset of wear.

TAB WASHERS

1.Fit new washers in all places where they are

used. Always fit a new tab washer.

2.Ensure that the new tab washer is of the same

design as that replaced.

ProCarManuals.com

Page 50 of 667

GENERAL FITTING REMINDERS

7

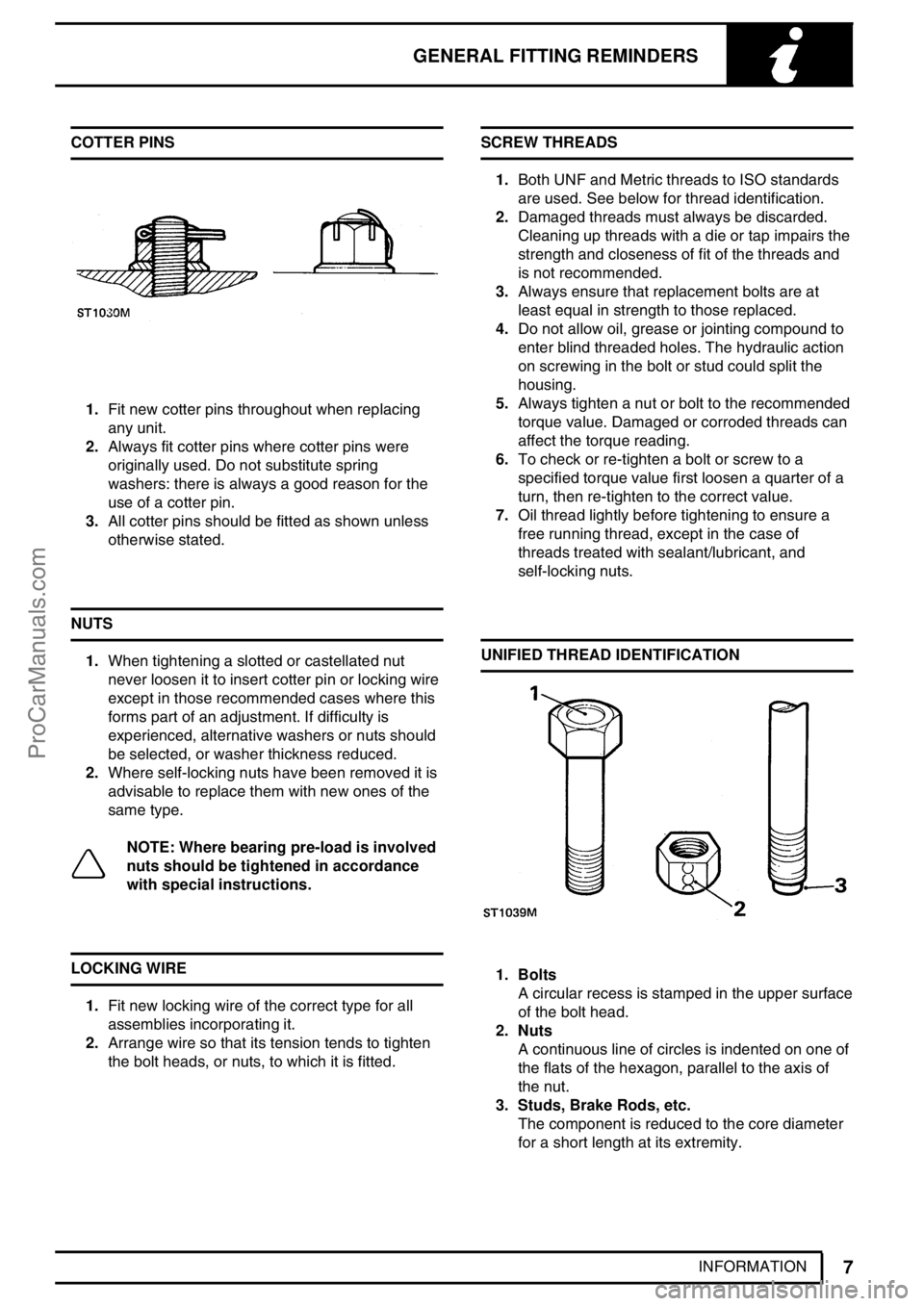

INFORMATION COTTER PINS

1.Fit new cotter pins throughout when replacing

any unit.

2.Always fit cotter pins where cotter pins were

originally used. Do not substitute spring

washers: there is always a good reason for the

use of a cotter pin.

3.All cotter pins should be fitted as shown unless

otherwise stated.

NUTS

1.When tightening a slotted or castellated nut

never loosen it to insert cotter pin or locking wire

except in those recommended cases where this

forms part of an adjustment. If difficulty is

experienced, alternative washers or nuts should

be selected, or washer thickness reduced.

2.Where self-locking nuts have been removed it is

advisable to replace them with new ones of the

same type.

NOTE: Where bearing pre-load is involved

nuts should be tightened in accordance

with special instructions.

LOCKING WIRE

1.Fit new locking wire of the correct type for all

assemblies incorporating it.

2.Arrange wire so that its tension tends to tighten

the bolt heads, or nuts, to which it is fitted.SCREW THREADS

1.Both UNF and Metric threads to ISO standards

are used. See below for thread identification.

2.Damaged threads must always be discarded.

Cleaning up threads with a die or tap impairs the

strength and closeness of fit of the threads and

is not recommended.

3.Always ensure that replacement bolts are at

least equal in strength to those replaced.

4.Do not allow oil, grease or jointing compound to

enter blind threaded holes. The hydraulic action

on screwing in the bolt or stud could split the

housing.

5.Always tighten a nut or bolt to the recommended

torque value. Damaged or corroded threads can

affect the torque reading.

6.To check or re-tighten a bolt or screw to a

specified torque value first loosen a quarter of a

turn, then re-tighten to the correct value.

7.Oil thread lightly before tightening to ensure a

free running thread, except in the case of

threads treated with sealant/lubricant, and

self-locking nuts.

UNIFIED THREAD IDENTIFICATION

1. Bolts

A circular recess is stamped in the upper surface

of the bolt head.

2. Nuts

A continuous line of circles is indented on one of

the flats of the hexagon, parallel to the axis of

the nut.

3. Studs, Brake Rods, etc.

The component is reduced to the core diameter

for a short length at its extremity.

ProCarManuals.com