LAND ROVER DEFENDER 1999 Manual PDF

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 71 of 667

10MAINTENANCE

12

MAINTENANCE AUXILIARY DRIVE BELT

Check

1.Check auxiliary drive belt for signs of splits,

fraying, oil contamination and wear.

NOTE: Any requirement to replace the

auxiliary drive belt should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

Renew

1.Renew auxiliary drive belt.See ELECTRICAL,

Repair.

NOTE: Additional time is built into the

96,000/8 year service time to allow for

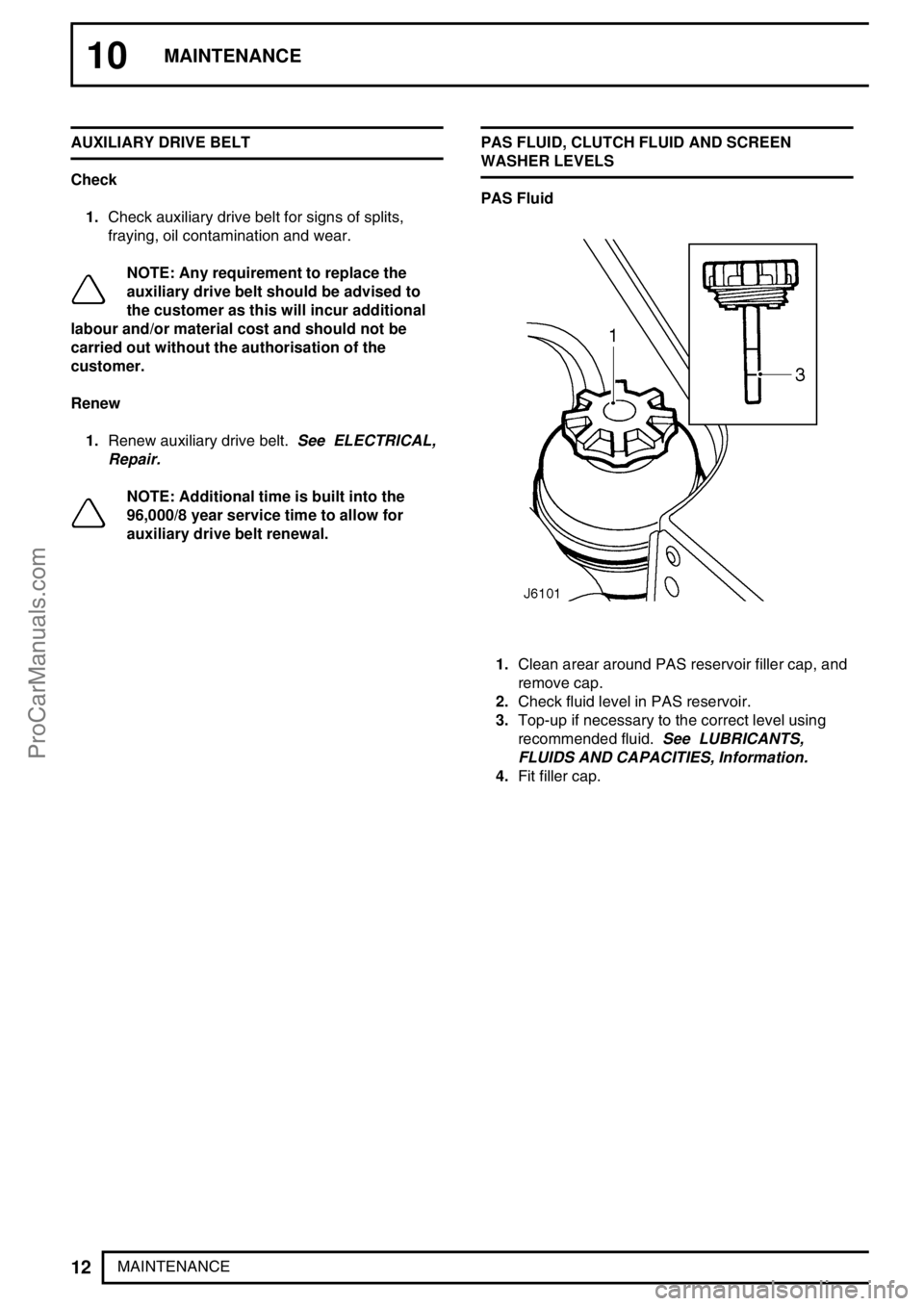

auxiliary drive belt renewal.PAS FLUID, CLUTCH FLUID AND SCREEN

WASHER LEVELS

PAS Fluid

1.Clean arear around PAS reservoir filler cap, and

remove cap.

2.Check fluid level in PAS reservoir.

3.Top-up if necessary to the correct level using

recommended fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

4.Fit filler cap.

ProCarManuals.com

Page 72 of 667

MAINTENANCE

13

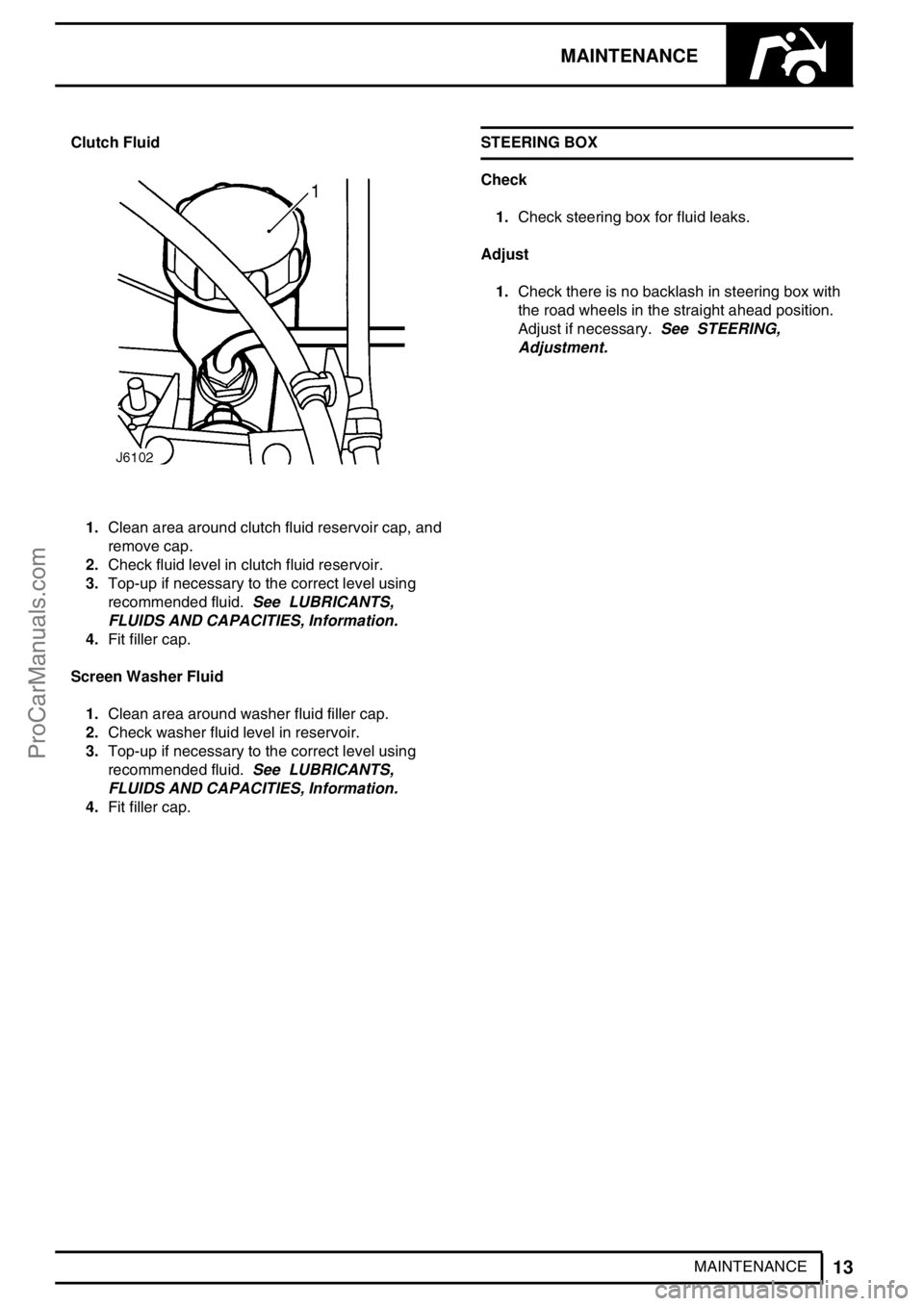

MAINTENANCE Clutch Fluid

1.Clean area around clutch fluid reservoir cap, and

remove cap.

2.Check fluid level in clutch fluid reservoir.

3.Top-up if necessary to the correct level using

recommended fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

4.Fit filler cap.

Screen Washer Fluid

1.Clean area around washer fluid filler cap.

2.Check washer fluid level in reservoir.

3.Top-up if necessary to the correct level using

recommended fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

4.Fit filler cap.STEERING BOX

Check

1.Check steering box for fluid leaks.

Adjust

1.Check there is no backlash in steering box with

the road wheels in the straight ahead position.

Adjust if necessary.See STEERING,

Adjustment.

ProCarManuals.com

Page 73 of 667

10MAINTENANCE

14

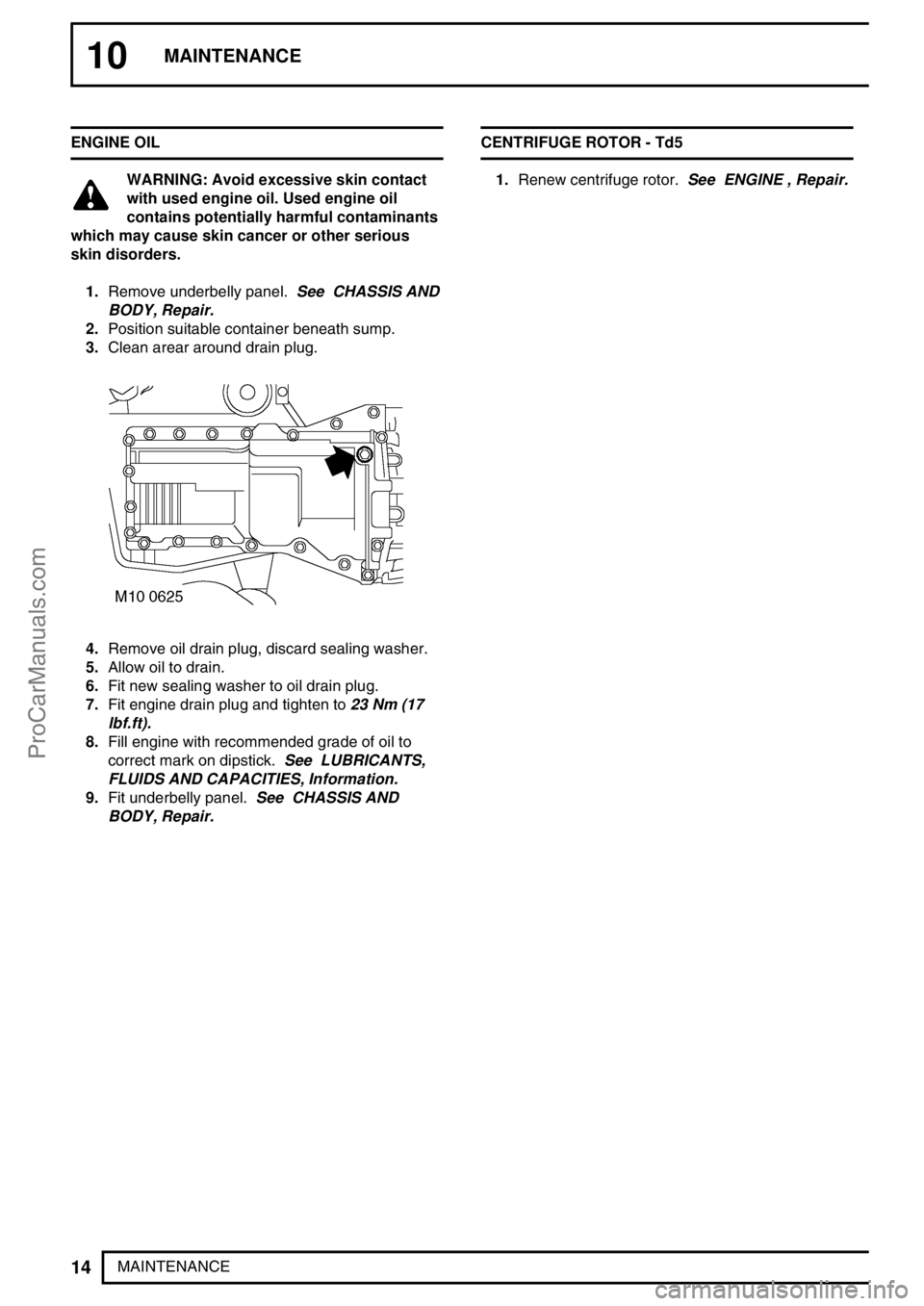

MAINTENANCE ENGINE OIL

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other serious

skin disorders.

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Position suitable container beneath sump.

3.Clean arear around drain plug.

4.Remove oil drain plug, discard sealing washer.

5.Allow oil to drain.

6.Fit new sealing washer to oil drain plug.

7.Fit engine drain plug and tighten to23 Nm (17

lbf.ft).

8.Fill engine with recommended grade of oil to

correct mark on dipstick.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

9.Fit underbelly panel.See CHASSIS AND

BODY, Repair.CENTRIFUGE ROTOR - Td5

1.Renew centrifuge rotor.See ENGINE , Repair.

ProCarManuals.com

Page 74 of 667

MAINTENANCE

15

MAINTENANCE FULL FLOW OIL FILTER

1.Renew full flow oil filter.See ENGINE , Repair.GEARBOX OIL

WARNING: Avoid excessive skin contact

with used gearbox oil. Used gearbox oil

contains potentially harmful contaminants

which may cause skin cancer or other serious

skin disorders.

1.Renew gearbox oil.See MANUAL GEARBOX,

Adjustment.

ProCarManuals.com

Page 75 of 667

10MAINTENANCE

16

MAINTENANCE TRANSFER BOX OIL

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

Check

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Clean area around oil filler/level plug.

3.Remove oil filler/level plug.

4.Check that oil level is to bottom of oil filler/level

plug hole.

5.Remove all traces of sealant from threads of oil

filler/level plug.

6.Apply Loctite 290 to threads of oil filler/level plug

and tighten to25 Nm (18 lbf.ft).

7.Remove all traces of oil from main casing.

8.Fit underbelly panel.See CHASSIS AND

BODY, Repair.Renew

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Place a suitable container beneath transfer box

to catch any fluid spillage.

3.Clean area around oil filler/level and drain plugs.

4.Remove oil filler/level plug.

5.Remove oil drain plug.

6.Allow oil to drain.

7.Apply Loctite 290 to threads of oil drain plug.

8.Fit transfer box drain plug and tighten to30 Nm

(22 lbf.ft).

9.Fill transfer box with recommended oil to bottom

of oil filler/level plug hole.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

10.Remove all traces of sealant from threads of oil

filler/level plug.

11.Apply Loctite 290 to threads of oil filler/level plug

and tighten to25 Nm (18 lbf.ft).

12.Remove all traces of oil from main casing.

13.Fit underbelly panel.See CHASSIS AND

BODY, Repair.

ProCarManuals.com

Page 76 of 667

MAINTENANCE

17

MAINTENANCE FRONT AND REAR AXLE OIL

Renew

A- Front and rear axle, 90 models, front, 110/130

models.

B- Rear axle, 110/130 models.

WARNING: Avoid excessive skin contact

with used axle oil. Used axle oil contains

potentially harmful contaminants which

may cause skin cancer or other serious skin

disorders.1.Ensure vehicle is level and place suitable tray

under axle to be drained.

2.Using 13mm square drive wrench, remove drain

and filler/level plugs from axle and allow oil to

drain completely.

3.Clean and refit drain plug.

4.Inject new oil, until it runs out from filler/level

hole. Allow excess oil to drain and wipe clean.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information.

5.Clean and refit filler/level plug.

Check

1.Ensure vehicle is level.

2.Using 13 mm square drive wrench, remove

filler/level plug.

3.If necessary inject new oiluntil oil runs out from

filler/level hole. Allow excess oil to drain and

wipe clean.See LUBRICANTS, FLUIDS AND

CAPACITIES, Information.

4.Clean and refit filler/level plug.

ProCarManuals.com

Page 77 of 667

10MAINTENANCE

18

MAINTENANCE PROPELLER SHAFTS

1.Clean area around front universal joint grease

nipple.

2.Apply recommended grease to the grease

nipple.See LUBRICANTS, FLUIDS AND

CAPACITIES, Information.CLUTCH PIPES AND UNIONS

Check

1.Check route of clutch pipe from master cylinder

to slave cylinder. Ensure that pipe is correctly

retained and shows no signs of fluid leakage or

chafing.

2.Check unions for signs of fluid leakage.

ProCarManuals.com

Page 78 of 667

MAINTENANCE

19

MAINTENANCE PAS PIPES AND UNIONS

Check

1.Check PAS pipes for correct, secure routing and

signs of chafing.

2.Check for signs of fluid leakage from PAS pump,

hoses, and hose unions.ENGINE, GEARBOX, TRANSFER BOX AND AXLES

Check

1.Check for oil leaks from engine, gearbox, tansfer

box, and front and rear axles. Pay particular

attention to areas around oil seals.

ProCarManuals.com

Page 79 of 667

10MAINTENANCE

20

MAINTENANCE EXHAUST SYSTEM

1.Visually check condition of exhaust system for

signs of damage.

2.Check condition of exhaust heat shields.

3.Check exhaust system is firmly secured and

check condition of exhaust mounting rubbers,

clamps and brackets.STEERING BOX AND SUSPENSION

1.Check steering box fixings. Tighten if necessary

to81 Nm (60 lbf.ft).

2.Check LH and RH front radius arm fixings.

Tighten if necessary.See FRONT

SUSPENSION, Repair.

3.Check Panhard rod fixings. Tighten if necessary.

See FRONT SUSPENSION, Repair.

4.Check all rear axle fixings. Tighten if necessary.

ProCarManuals.com

Page 80 of 667

MAINTENANCE

21

MAINTENANCE STEERING BALL JOINTS

1.Check for wear in joints by moving ball joint up

and down vigorously. If free movement is

apparent, fit a new joint assembly.

2.Check condition of steering ball joints paying

particular attention to dust covers.

NOTE: Any requirement to replace the

steering ball joints should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

NOTE: Ball joints are lubricated for life

during manufacture and require no further

lubrication unless the rubber boot has

been dislodged or damaged. All joints should be

checked at specified service intervals, but more

frequently if vehicle is used under arduous

conditions.

ProCarManuals.com