sensor LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 17 of 667

01INTRODUCTION

10

INFORMATION CROSS REFERENCE OF EMISSION SYSTEM

TERMINOLOGY

NEW TERM (ACRONYM)

Accelerator pedal (AP).................................................

Air cleaner (ACL)..........................................................

Air conditioning (A/C)...................................................

Battery positive voltage (B+)........................................

Closed loop (CL)..........................................................

Closed throttle position (CTP)......................................

Canister purge valve (CANPV)....................................

Data link connector (DLC)...........................................

Diagnostic trouble code (DTC).....................................

Distributor ignition (DI).................................................

Engine control module (ECM)......................................

Engine coolant level (ECL)...........................................

Engine coolant temperature (ECT)..............................

Engine speed (RPM)....................................................

Evaporative emission system (EVAP)..........................

Engine fuel temperature sensor (EFTS)......................

4th gear, 3rd gear etc. (4GR, 3GR)..............................

Fuel pump (FP)............................................................

Fan control module (FCM)...........................................

Generator (GEN)..........................................................

Ground (GND)..............................................................

Heated oxygen sensor (H02S)....................................

Idle air control (IAC)......................................................

Idle air control valve (IACV).........................................

Ignition control module (ICM).......................................

Intake air temperature (IAT).........................................

Manifold vacuum zone (MVZ)......................................

Mass air flow sensor (MAF).........................................

Open loop (OL)............................................................

Relay module (RM)......................................................

Solid state relay module (SSRM).................................

Three way catalytic converter (TWC)..........................

Throttle body (TB)........................................................

Throttle position sensor (TP)........................................

Transmission range (TR)..............................................

Wide open throttle (WOT)............................................OLD TERM (ACRONYM)

Throttle pedal (-)..........................................................

Air cleaner (-)...............................................................

Air conditioning (AC)....................................................

Battery plus, bat +, bat feed (B+).................................

Closed loop (-).............................................................

Closed throttle, idle position (-)....................................

Charcoal canister purge valve (-).................................

Serial link (-)................................................................

Fault code (-)...............................................................

Electronic ignition (-)....................................................

Electronic control unit (ECU)........................................

Coolant level (-)...........................................................

Coolant temperature (temp).........................................

Coolant temperature thermistor (-)..............................

Engine speed (rev/min)................................................

Evaporative loss system (ELC)...................................

Fuel temperature thermistor (-)....................................

Fourth gear, 3rd gear (-)..............................................

Fuel pump (-)...............................................................

Condenser fan timer (-)................................................

Alternator (-)................................................................

Ground, earth (B-)........................................................

Lambda (02) sensor (-)................................................

Idle speed control (ISC)................................................

Stepper motor (-).........................................................

Ignition module (-)........................................................

Intake temperature/ambient temperature (-)................

Manifold depression, vacuum (-).................................

Air flow meter (-)..........................................................

Fault code display unit (-)............................................

Open loop (-)...............................................................

Relay (-).......................................................................

Control unit (-)..............................................................

Catalyst, catalytic converter (CAT)..............................

Throttle housing (-)......................................................

Transmission gear (-)...................................................

Full throttle, wide open throttle (WOT).........................

ProCarManuals.com

Page 58 of 667

10 - MAINTENANCE

CONTENTS

Page

MAINTENANCE

UNDERBONNET VIEW - Td5 1..............................................................................

SEATS AND SEAT BELTS 2..................................................................................

LAMPS, HORNS AND WARNING INDICATORS 2................................................

WIPERS AND WASHERS 3...................................................................................

HANDBRAKE 3.......................................................................................................

BATTERY CONDITION - Td5 4..............................................................................

HANDSET BATTERY 5...........................................................................................

HEADLAMP ALIGNMENT 5....................................................................................

ROAD WHEELS 6...................................................................................................

TYRE PRESSURES, CONDITION AND TREAD DEPTH 6....................................

BRAKE PADS, CALIPERS AND DISCS 7..............................................................

ROAD WHEEL SPEED SENSOR HARNESS - Td5 7............................................

FUEL FILTER ELEMENT 8.....................................................................................

FUEL FILTER SEDIMENTER - Td5 8.....................................................................

INTERCOOLER / COOLING SYSTEM 9................................................................

AMBIENT AIR PRESSURE (AAP) SENSOR - Td5 9..............................................

DOOR LOCKS AND HINGES 10............................................................................

ENGINE COOLANT 10...........................................................................................

BRAKE FLUID 11....................................................................................................

AIR FILTER ELEMENT AND DUMP VALVE 11.....................................................

AUXILIARY DRIVE BELT 12...................................................................................

PAS FLUID, CLUTCH FLUID AND SCREEN WASHER LEVELS 12.....................

STEERING BOX 13................................................................................................

ENGINE OIL 14.......................................................................................................

CENTRIFUGE ROTOR - Td5 14.............................................................................

FULL FLOW OIL FILTER 15...................................................................................

GEARBOX OIL 15...................................................................................................

TRANSFER BOX OIL 16.........................................................................................

FRONT AND REAR AXLE OIL 17..........................................................................

PROPELLER SHAFTS 18.......................................................................................

CLUTCH PIPES AND UNIONS 18..........................................................................

PAS PIPES AND UNIONS 19.................................................................................

ENGINE, GEARBOX, TRANSFER BOX AND AXLES 19.......................................

EXHAUST SYSTEM 20...........................................................................................

STEERING BOX AND SUSPENSION 20...............................................................

STEERING BALL JOINTS 21.................................................................................

SHOCK ABSORBERS 22.......................................................................................

TOWING BRACKET 22...........................................................................................

ENGINE AND TRANSMISSION MOUNTINGS 23..................................................

ProCarManuals.com

Page 66 of 667

MAINTENANCE

7

MAINTENANCE BRAKE PADS, CALIPERS AND DISCS

1.With front road wheels removed, check brake

pad thickness and ensure that both pads are

wearing evenly.

2.Check brake discs for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirement to replace brake

pads or brake disc should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

3.Check for any signs of brake fluid leakage from

caliper seals, hoses or unions.

4.Using brake cleaner, remove excessive deposits

of brake dust from pads, calipers and disc

shields.ROAD WHEEL SPEED SENSOR HARNESS - Td5

1.Check each sensor harness is correctly and

securely routed.

2.Inspect each harness for chafing or damage.

NOTE: Any requirement to replace a road

wheel speed sensor should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

ProCarManuals.com

Page 68 of 667

MAINTENANCE

9

MAINTENANCE INTERCOOLER / COOLING SYSTEM

1.Visually check for any obstructions in the

radiator and intercooler matrix and remove

debris as necessary.

2.Visually check fan blades for damage.

3.Check cooling, intercooler and heating systems

for leaks, hoses and oil pipes for security and

condition.

4.Check accessible hose clips for tightness.

5.Check coolant level, top-up if necessary

Cooling System Top-Up

1.With engine cold, remove expansion tank filler

cap.

2.Top-up with recommended mixture of coolant

until level reaches mark on expansion tank.

3.Fit expansion tank filler cap.

Intercooler Flush

1.Remove intercooler.See FUEL SYSTEM,

Repair.

2.Flush intercooler element using Unicorn

Chemicals’C’Solve following the manufaturers

instructions.

3.Thoroughly dry intercooler ensuring that no trace

of solvent remains in the element.

4.Refit intercooler.See FUEL SYSTEM, Repair.AMBIENT AIR PRESSURE (AAP) SENSOR - Td5

1.Check ambient air pressure sensor for damage.

ProCarManuals.com

Page 110 of 667

ENGINE

25

DESCRIPTION AND OPERATION CYLINDER HEAD COMPONENTS

The cylinder head components are described below:

Cylinder head

The cylinder head is of aluminium construction. It is not possible to reface the cylinder head if it becomes worn or

damaged. An alloy camshaft carrier is bolted directly to the upper surface of the cylinder head. Two dowels are

included in the cylinder head upper face for correct location of the camshaft carrier.

The EU3 cylinder head has a single internal fuel rail for delivering fuel to the injectors and an external fuel pipe for

returning spill fuel back to the fuel connector block. Therefore, pre EU3 and EU3 cylinder heads are not

interchangeable.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any

contamination which enters these drillings could cause engine running problems or injector

failure. It is therefore, essential that absolute cleanliness is maintained when carrying out work on

the cylinder head.

The camshaft carrier and cylinder head assembly is attached to the cylinder block by twelve cylinder head

retaining bolts which pass through the camshaft carrier and the cylinder head to secure the assembly to the

cylinder block.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the

cylinder head and will be damaged if the cylinder head is stored face down.

The camshaft is located between the cylinder head and the camshaft carrier, and the bearing journals are line

bored between the two components to form a matched pair.

CAUTION: Always fit plugs to open connections to prevent contamination.

The valve guides and valve seat inserts are sintered components which are an interference fit to the cylinder

head. The cylinder head machining also provide the locations for the electronic unit injectors, glow plugs, hydraulic

lash adjusters, finger followers and low pressure fuel rail.

Cooling to the cylinder head is provided by coolant flow through a water jacket machined into the cylinder head.

Drillings through the block provide lubrication channels for pressurised oil supply to cylinder head components

such as the lash adjusters, finger followers, rocker arms and camshaft bearings.

A coolant outlet elbow is fitted to the front LH side of the cylinder head to allow flow of coolant from the cylinder

head back to the radiator. A metal gasket is used to seal the joint between the water outlet elbow and the cylinder

head. A coolant temperature sensor is located in a port in the side of the water outlet elbow for monitoring coolant

temperature.

A stub pipe is connected at the front RH side of the cylinder block above the timing cover which connects a pipe to

supply oil to the vacuum pump. The timing chain tensioner adjuster is screwed in a thread in the cylinder head at a

location on the front RH side of the engine below the oil feed port for the vacuum pump.

An access hole for the camshaft gear is included at the front of the cylinder head which is sealed with a plastic

plug and rubber’O’ring. A press-fit core plug for the chain chest is located on the front face of the cylinder head.

A press-fit core plug for the cylinder head water jacket is located at the rear of the cylinder head and a threaded

brass plug for the water jacket is located on the LH side of the cylinder head beneath the exhaust manifold

assembly.

ProCarManuals.com

Page 111 of 667

12ENGINE

26

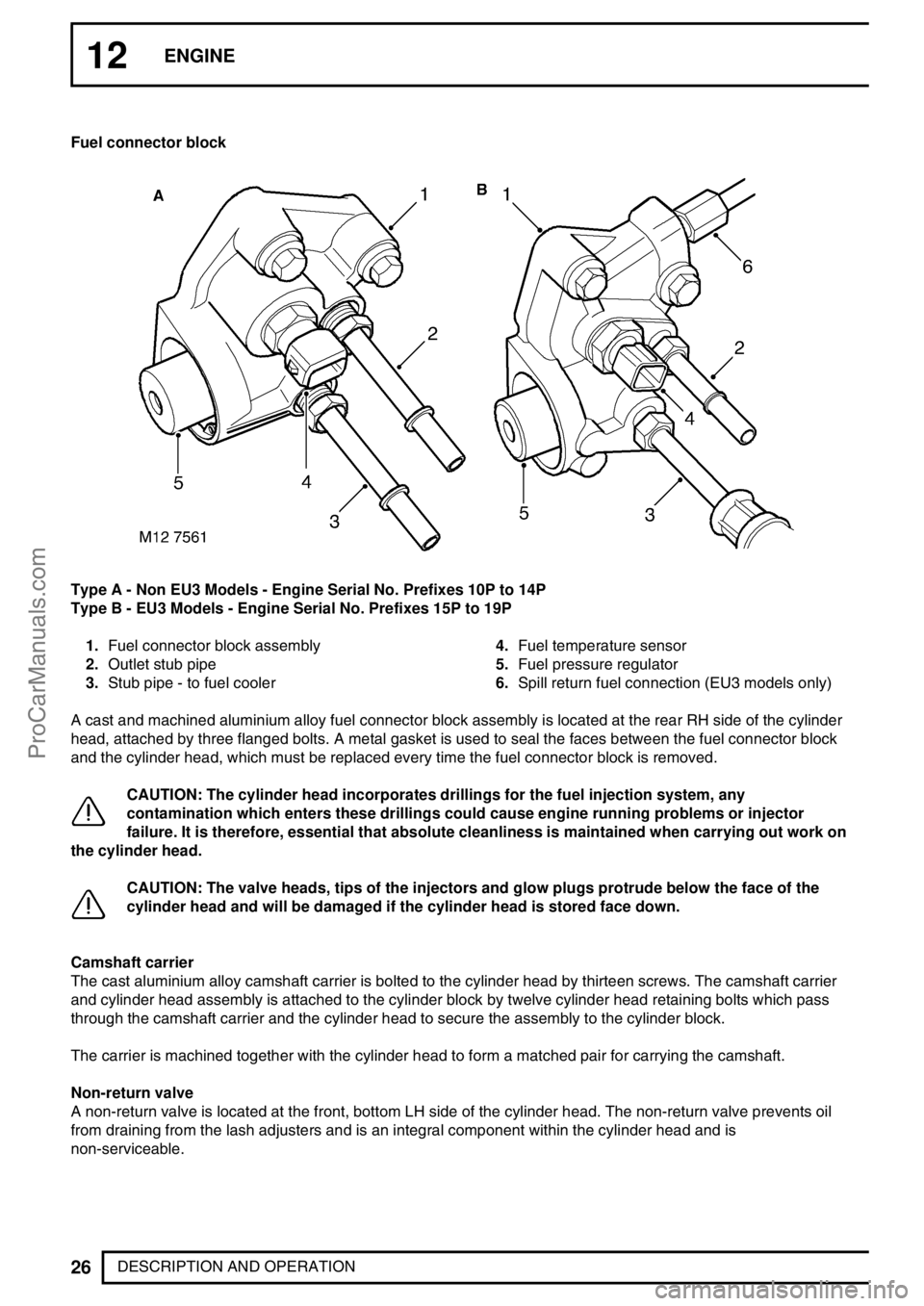

DESCRIPTION AND OPERATION Fuel connector block

Type A - Non EU3 Models - Engine Serial No. Prefixes 10P to 14P

Type B - EU3 Models - Engine Serial No. Prefixes 15P to 19P

1.Fuel connector block assembly

2.Outlet stub pipe

3.Stub pipe - to fuel cooler4.Fuel temperature sensor

5.Fuel pressure regulator

6.Spill return fuel connection (EU3 models only)

A cast and machined aluminium alloy fuel connector block assembly is located at the rear RH side of the cylinder

head, attached by three flanged bolts. A metal gasket is used to seal the faces between the fuel connector block

and the cylinder head, which must be replaced every time the fuel connector block is removed.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any

contamination which enters these drillings could cause engine running problems or injector

failure. It is therefore, essential that absolute cleanliness is maintained when carrying out work on

the cylinder head.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the

cylinder head and will be damaged if the cylinder head is stored face down.

Camshaft carrier

The cast aluminium alloy camshaft carrier is bolted to the cylinder head by thirteen screws. The camshaft carrier

and cylinder head assembly is attached to the cylinder block by twelve cylinder head retaining bolts which pass

through the camshaft carrier and the cylinder head to secure the assembly to the cylinder block.

The carrier is machined together with the cylinder head to form a matched pair for carrying the camshaft.

Non-return valve

A non-return valve is located at the front, bottom LH side of the cylinder head. The non-return valve prevents oil

from draining from the lash adjusters and is an integral component within the cylinder head and is

non-serviceable.

ProCarManuals.com

Page 131 of 667

12ENGINE

6

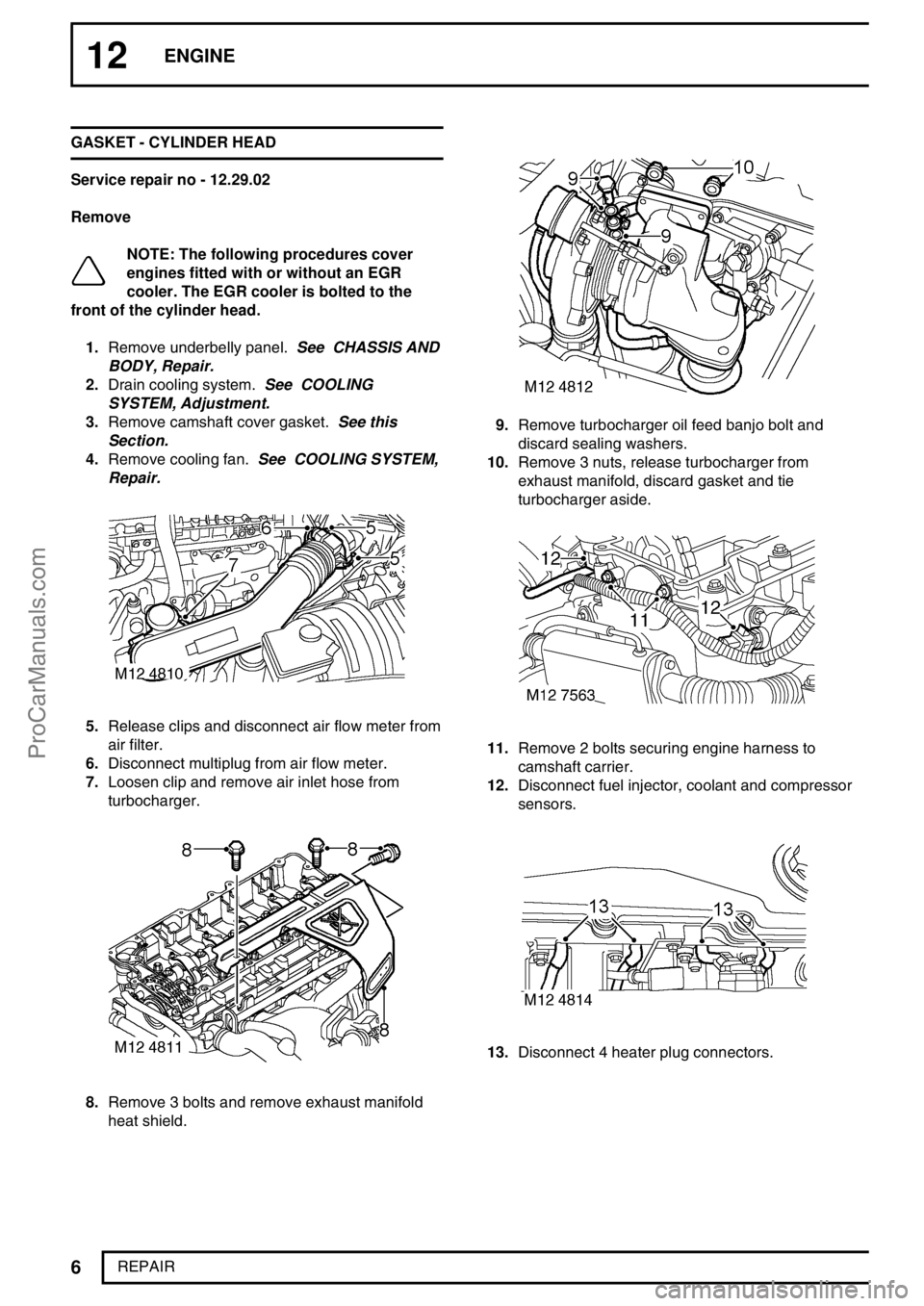

REPAIR GASKET - CYLINDER HEAD

Service repair no - 12.29.02

Remove

NOTE: The following procedures cover

engines fitted with or without an EGR

cooler. The EGR cooler is bolted to the

front of the cylinder head.

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Drain cooling system.See COOLING

SYSTEM, Adjustment.

3.Remove camshaft cover gasket.See this

Section.

4.Remove cooling fan.See COOLING SYSTEM,

Repair.

5.Release clips and disconnect air flow meter from

air filter.

6.Disconnect multiplug from air flow meter.

7.Loosen clip and remove air inlet hose from

turbocharger.

8.Remove 3 bolts and remove exhaust manifold

heat shield.

9.Remove turbocharger oil feed banjo bolt and

discard sealing washers.

10.Remove 3 nuts, release turbocharger from

exhaust manifold, discard gasket and tie

turbocharger aside.

11.Remove 2 bolts securing engine harness to

camshaft carrier.

12.Disconnect fuel injector, coolant and compressor

sensors.

13.Disconnect 4 heater plug connectors.

ProCarManuals.com

Page 132 of 667

ENGINE

7

REPAIR

14.Disconnect MAP sensor multiplug from inlet

manifold.

15.Position engine harness clear of inlet manifold.

16.Disconnect vacuum hose from EGR valve.

17.Loosen clip screw and disconnect air intake

hose from EGR valve.

18.Release 3 clips and disconnect coolant hoses

from fuel cooler.

19.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Plug the connections.

20.Disconnect fuel hose from fuel cooler and secure

to connector block on cylinder head. This is to

prevent contamination of the fuel injection

system.

ProCarManuals.com

Page 140 of 667

ENGINE

15

REPAIR

NOTE: Non EU3 model illustrated.

9.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Plug the connections.

10.Disconnect fuel hose from fuel cooler and secure

to connector block on cylinder head. This to

prevent contamination of the fuel system.

11.Release servo vacuum pipe, remove 4 bolts and

remove fuel cooler.

12.Release servo vacuum pipe from engine rear

cover clips and vacuum pump.

NOTE: Non EU3 model illustrated.

13.Disconnect vacuum hose from EGR valve.

14.Release EGR vacuum hose from vacuum pipe.

15.Disconnect multiplug from condensor cooling

fan.

NOTE: Non EU3 model illustrated.

16.Disconnect multiplugs from EGR solenoid, inlet

manifold sensor and injector harness.

ProCarManuals.com

Page 141 of 667

12ENGINE

16

REPAIR

NOTE: Non EU3 model illustrated.

17.Disconnect multiplug from fuel temperature

sensor.

18.Disconnect multiplug from CKP sensor. Remove

bolt securing CKP sensor, remove sensor and

discard’O’ring.

CAUTION: If fitted:- Retain CKP sensor

spacer.

19.Disconnect 4 glow plug leads.

20.Remove nut securing alternator lead and

disconnect multiplug.

NOTE: Non EU3 model illustrated.

21.Remove 2 bolts securing engine harness to

camshaft carrier.

22.Disconnect A/C compressor and ECT sensor

multiplugs.

ProCarManuals.com