LAND ROVER DISCOVERY 1995 Service Repair Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 871 of 976

ELECTRICAL

1

OVERHAUL DISTRIBUTOR-LUCAS 35DLM8

Overhaul

DISTRIBUTOR CAP

Service repair no - 86.35.10

1.Unclip and remove cap

2.Fit a new cap if faulty.

3.Clean cap and HT brush with a lint free cloth.

ROTOR ARM

Service repair no - 86.35.16

1.Pull rotor arm from shaft.

2.Fit a new rotor arm if faulty.

INSULATION COVER (FLASH SHIELD)

Service repair no - 86.35.40

1.Remove cover secured by three screws.

2.Fit a new cover if faulty.

VACUUM UNIT

Service repair no - 86.35.21

1.Remove two screws from vacuum unit securing

bracket. Disengage vacuum unit connecting rod

from pick-up base plate connecting peg.

Withdraw vacuum unit from distributor body.AMPLIFIER MODULE

Service repair no - 86.35.30

1.Remove two screws and withdraw module.

2.Remove gasket.

3.Remove two screws and cast heatsink.

WARNING: Amplifier module is a sealed

unit containing Beryllia. This substance is

extremely dangerous if handled. DO NOT

attempt to open or crush module.

PICK-UP AND BASE PLATE ASSEMBLY

Service repair no - 86.35.42

1.Use circlip pliers to remove circlip retaining

reluctor on rotor shaft.

2.Remove flat washer, and 'O' ring recessed in top

of reluctor.

3.Gently withdraw reluctor from shaft, taking care

not to damage teeth.

NOTE: Coupling ring fitted beneath

reluctor.

4.Remove three support pillars and cable

grommet. Lift out pick-up and base plate

assembly.

NOTE: Do not disturb two barrel nuts

securing pick-up module, otherwise air

gap will need re-adjustment.

5.Fit a new pick-up and base plate assembly if

module is known to be faulty, otherwise check

pick-up winding resistance (2k-5k ohm).

Reassemble

6.This is mainly a reversal of dismantling

procedure, noting following points:

Page 872 of 976

86ELECTRICAL

2

OVERHAUL

LUBRICATION

Apply clean engine oil:

a. A spot into rotor spindle before fitting rotor

arm.

Apply Omnilube 2 (or equivalent) grease.

b. Auto advance mechanism.

c. Pick-up plate centre bearing.

d. Pre tilt spring and its rubbing area (pick-up

and base plate assembly).

e. Vacuum unit connecting peg (pick-up and

base plate assembly).

f. Connecting peg hole in vacuum unit

connecting rod.

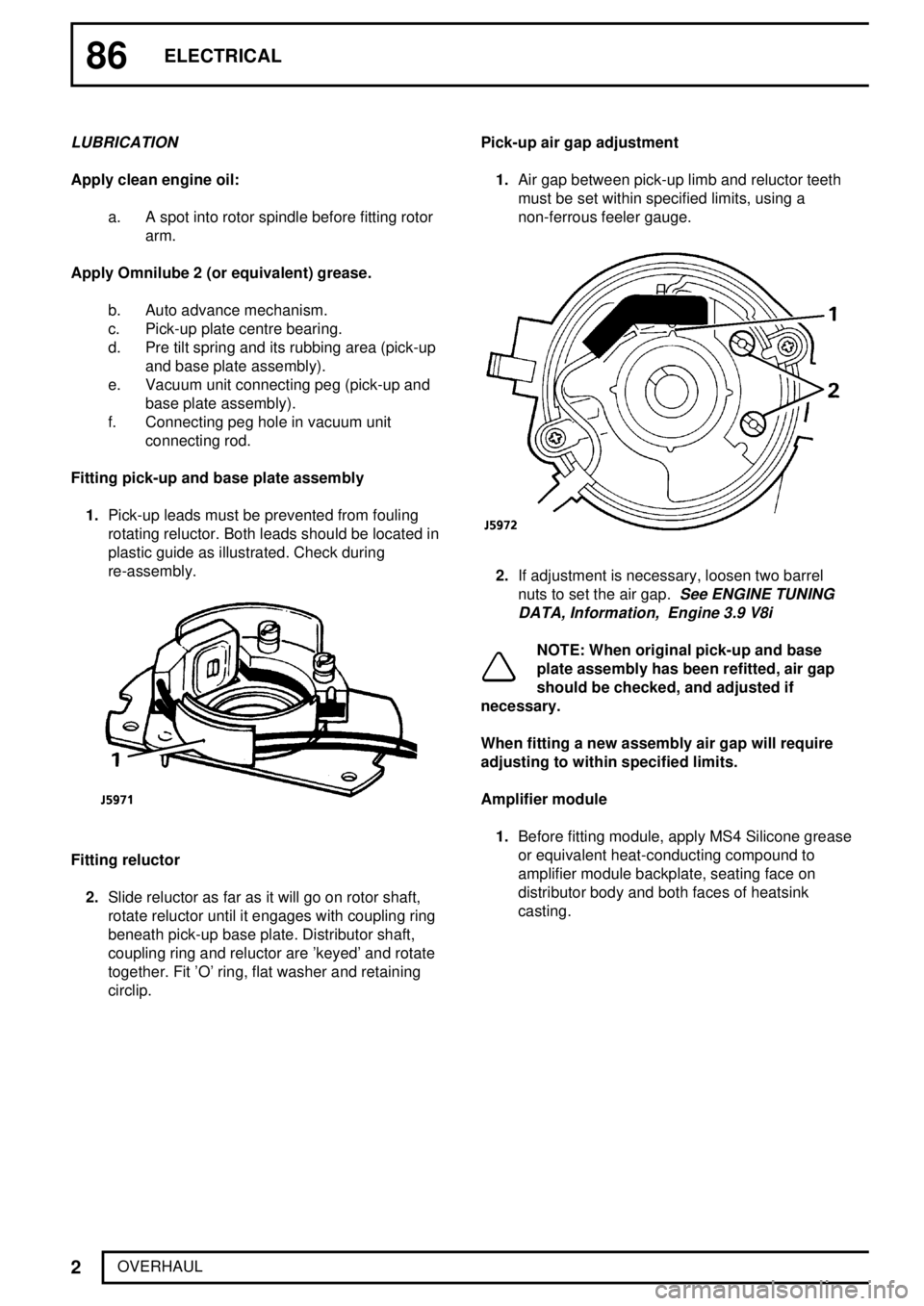

Fitting pick-up and base plate assembly

1.Pick-up leads must be prevented from fouling

rotating reluctor. Both leads should be located in

plastic guide as illustrated. Check during

re-assembly.

Fitting reluctor

2.Slide reluctor as far as it will go on rotor shaft,

rotate reluctor until it engages with coupling ring

beneath pick-up base plate. Distributor shaft,

coupling ring and reluctor are 'keyed' and rotate

together. Fit 'O' ring, flat washer and retaining

circlip.Pick-up air gap adjustment

1.Air gap between pick-up limb and reluctor teeth

must be set within specified limits, using a

non-ferrous feeler gauge.

2.If adjustment is necessary, loosen two barrel

nuts to set the air gap.

See ENGINE TUNING

DATA, Information, Engine 3.9 V8i

NOTE: When original pick-up and base

plate assembly has been refitted, air gap

should be checked, and adjusted if

necessary.

When fitting a new assembly air gap will require

adjusting to within specified limits.

Amplifier module

1.Before fitting module, apply MS4 Silicone grease

or equivalent heat-conducting compound to

amplifier module backplate, seating face on

distributor body and both faces of heatsink

casting.

Page 873 of 976

ELECTRICAL

1

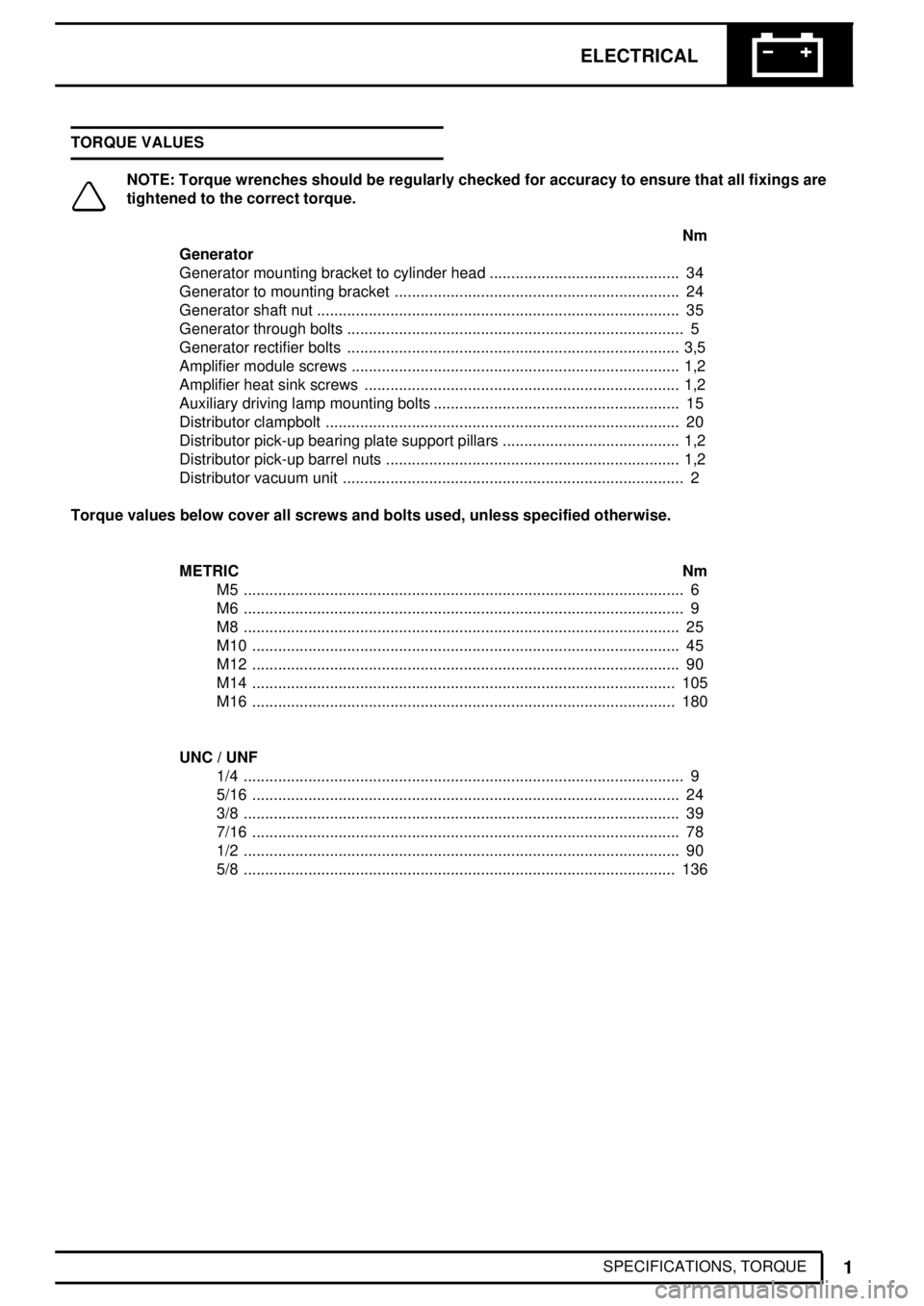

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Generator

Generator mounting bracket to cylinder head 34............................................

Generator to mounting bracket 24..................................................................

Generator shaft nut 35....................................................................................

Generator through bolts 5..............................................................................

Generator rectifier bolts 3,5.............................................................................

Amplifier module screws 1,2............................................................................

Amplifier heat sink screws 1,2.........................................................................

Auxiliary driving lamp mounting bolts 15.........................................................

Distributor clampbolt 20..................................................................................

Distributor pick-up bearing plate support pillars 1,2.........................................

Distributor pick-up barrel nuts 1,2....................................................................

Distributor vacuum unit 2...............................................................................

Torque values below cover all screws and bolts used, unless specified otherwise.

METRIC Nm

M5 6......................................................................................................

M6 9......................................................................................................

M8 25.....................................................................................................

M10 45...................................................................................................

M12 90...................................................................................................

M14 105..................................................................................................

M16 180..................................................................................................

UNC / UNF

1/4 9......................................................................................................

5/16 24...................................................................................................

3/8 39.....................................................................................................

7/16 78...................................................................................................

1/2 90.....................................................................................................

5/8 136....................................................................................................

Page 874 of 976

Page 875 of 976

300 TDi

ENGINE

OVERHAUL

MANUAL

This engine is fitted to the following Models from

1995 onwards:

Discovery

Defender

Range Rover Classic

Publication Part No. LRL 0070ENG

Published by Rover Technical Communication

Ó1997 Rover Group Limited

Page 876 of 976

INTRODUCTION

INTRODUCTION1

INTRODUCTION

How to use this manual

To assist in the use of this manual the section title is

given at the top and the relevant sub-section is given

at the bottom each page.

This manual contains procedures for overhaul of the

engine. For all other information regarding

adjustments, removal of oil seals and engine,

consult the Repair Manual for the model concerned.

This manual is divided into 3 sections:

·Description and Operation,

·Overhaul and

·Data, Torque & Tools.

To assist filing of revised information, each

sub-section is numbered from page 1.

Individual items are to be overhauled in the

sequence in which they appear in this Manual. Items

numbered in the illustrations are referred to in the

text.

Overhaul operations include reference to Service

Tool numbers and the associated illustration depicts

the tool. Where usage is not obvious the tool is

shown in use. Operations also include reference to

wear limits, relevant data, torque figures, specialist

information and useful assembly details.

WARNINGS, CAUTIONS and Notes have the

following meanings:

WARNING: Procedures which must be

followed precisely to avoid the possibility

of injury.

CAUTION: Calls attention to procedures

which must be followed to avoid damage

to components.

NOTE: Gives helpful information.References

With the engine and gearbox assembly removed,

the crankshaft pulley end of the engine is referred to

as the front.

Operations covered in this manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and tested after

completion and if necessary a road test of the

vehicle is carried out particularly where safety

related items are concerned

Dimensions

The dimensions quoted are to design engineering

specification with Service limits where applicable.

Page 877 of 976

INTRODUCTION

2

INTRODUCTION REPAIRS AND REPLACEMENTS

When replacement parts are required it is essential

that only Land Rover recommended parts are used.

Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement

parts and accessories.

Safety features and corrosion prevention treatments

embodied in the car may be impaired if other than

Land Rover recommended parts are fitted. In certain

territories, legislation prohibits the fitting of parts not

to the manufacturer's specification.

Torque wrench setting figures given in this Manual

must be used. Locking devices, where specified,

must be fitted. If the efficiency of a locking device is

impaired during removal it must be renewed.

The terms of the vehicle Warranty may be

invalidated by the fitting of other than Land Rover

recommended parts. All Land Rover recommended

parts have the full backing of the vehicle Warranty.

Land Rover Dealers are obliged to supply only Land

Rover recommended parts.SPECIFICATION

Land Rover are constantly seeking to improve the

specification, design and production of their vehicles

and alterations take place accordingly. While every

effort has been made to ensure the accuracy of this

Manual, it should not be regarded as an infallible

guide to current specifications of any particular

component or vehicle.

This Manual does not constitute an offer for sale of

any particular component or vehicle. Land Rover

Dealers are not agents of the Company and have no

authority to bind the manufacturer by any expressed

or implied undertaking or representation.

Page 878 of 976

ENGINE

DESCRIPTION AND OPERATION1

This page is intentionally left blank

Page 879 of 976

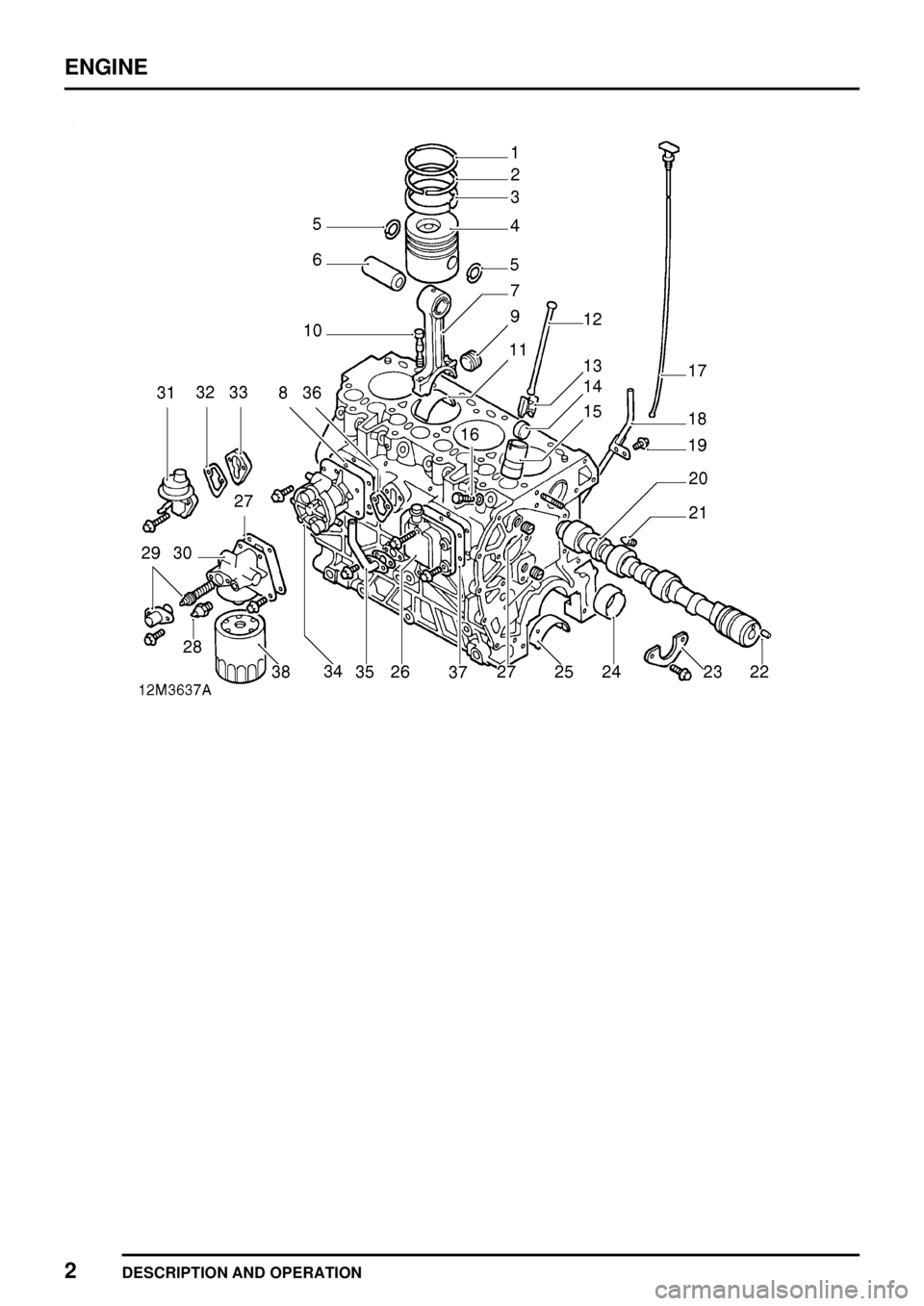

ENGINE

2

DESCRIPTION AND OPERATION

Page 880 of 976

ENGINE

DESCRIPTION AND OPERATION3

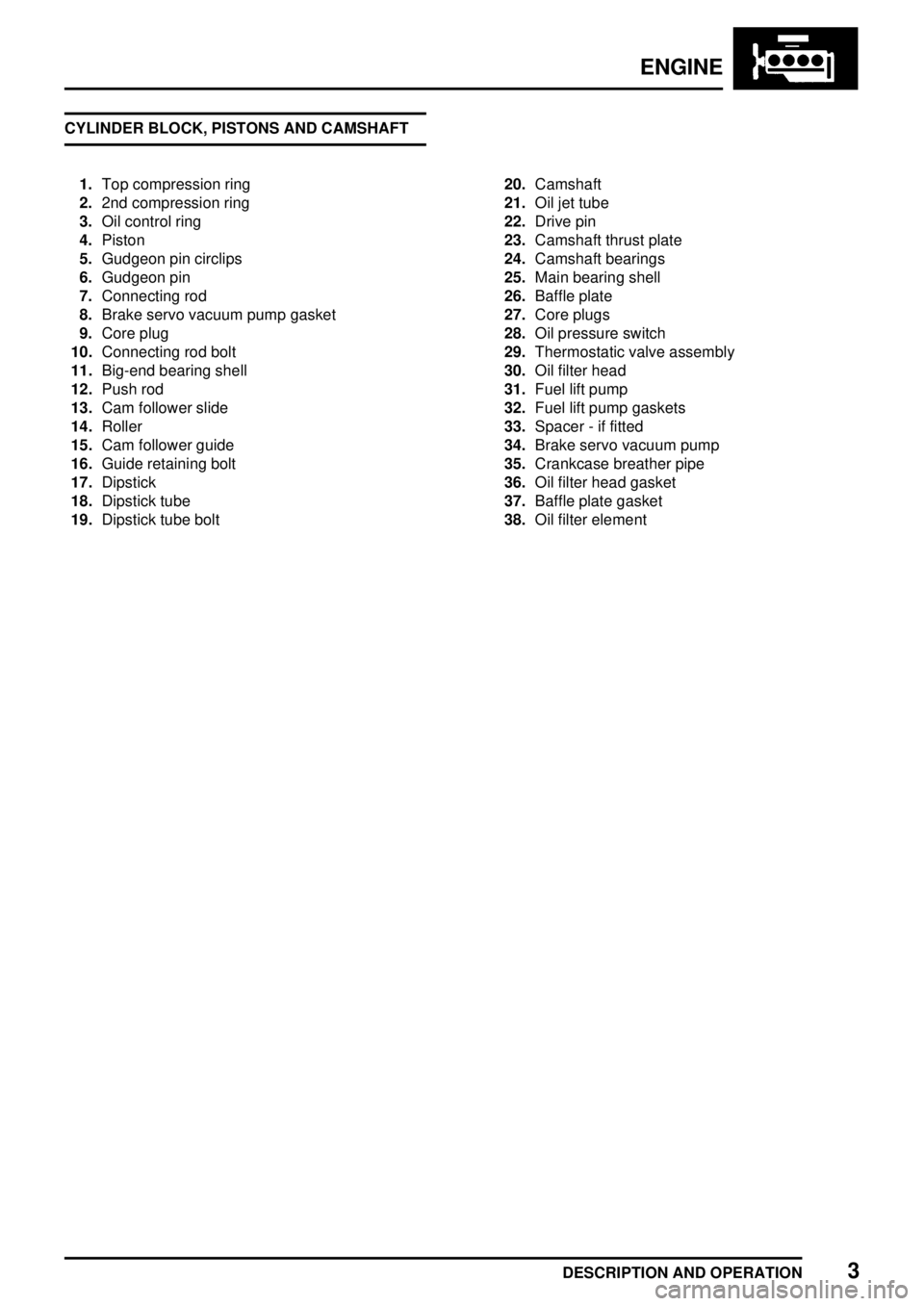

CYLINDER BLOCK, PISTONS AND CAMSHAFT

1.Top compression ring

2.2nd compression ring

3.Oil control ring

4.Piston

5.Gudgeon pin circlips

6.Gudgeon pin

7.Connecting rod

8.Brake servo vacuum pump gasket

9.Core plug

10.Connecting rod bolt

11.Big-end bearing shell

12.Push rod

13.Cam follower slide

14.Roller

15.Cam follower guide

16.Guide retaining bolt

17.Dipstick

18.Dipstick tube

19.Dipstick tube bolt20.Camshaft

21.Oil jet tube

22.Drive pin

23.Camshaft thrust plate

24.Camshaft bearings

25.Main bearing shell

26.Baffle plate

27.Core plugs

28.Oil pressure switch

29.Thermostatic valve assembly

30.Oil filter head

31.Fuel lift pump

32.Fuel lift pump gaskets

33.Spacer - if fitted

34.Brake servo vacuum pump

35.Crankcase breather pipe

36.Oil filter head gasket

37.Baffle plate gasket

38.Oil filter element