LAND ROVER DISCOVERY 1995 Service Repair Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 901 of 976

ENGINE

6

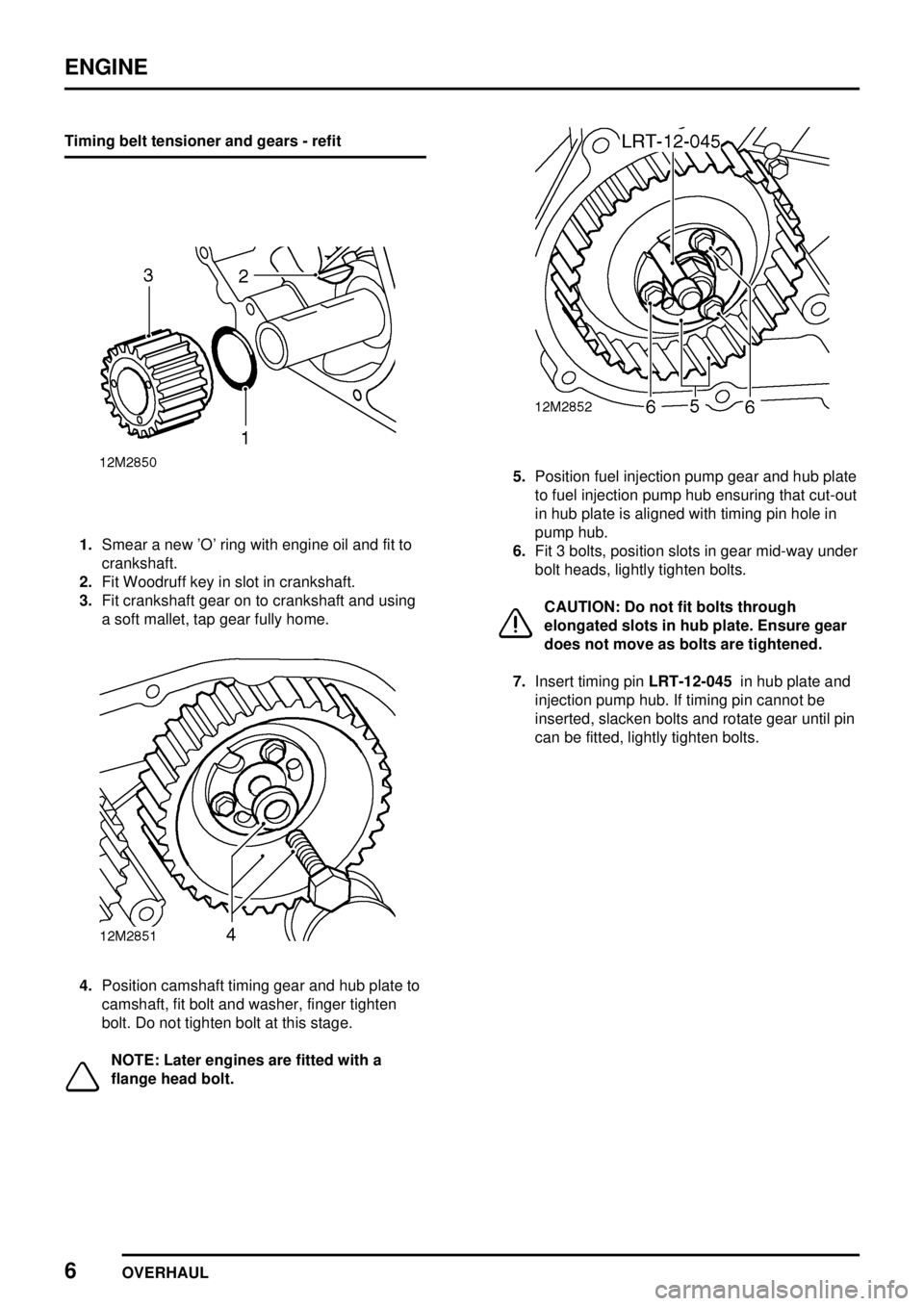

OVERHAUL Timing belt tensioner and gears - refit

1.Smear a new 'O' ring with engine oil and fit to

crankshaft.

2.Fit Woodruff key in slot in crankshaft.

3.Fit crankshaft gear on to crankshaft and using

a soft mallet, tap gear fully home.

4.Position camshaft timing gear and hub plate to

camshaft, fit bolt and washer, finger tighten

bolt. Do not tighten bolt at this stage.

NOTE: Later engines are fitted with a

flange head bolt.

5.Position fuel injection pump gear and hub plate

to fuel injection pump hub ensuring that cut-out

in hub plate is aligned with timing pin hole in

pump hub.

6.Fit 3 bolts, position slots in gear mid-way under

bolt heads, lightly tighten bolts.

CAUTION: Do not fit bolts through

elongated slots in hub plate. Ensure gear

does not move as bolts are tightened.

7.Insert timing pinLRT-12-045in hub plate and

injection pump hub. If timing pin cannot be

inserted, slacken bolts and rotate gear until pin

can be fitted, lightly tighten bolts.

Page 902 of 976

ENGINE

OVERHAUL7

8.Position flanged spacer on idler pulley stud.

9.Fit timing belt tensioner pulley and bracket

ensuring that hole in tensioner bracket is

located on flanged spacer.

10.Fit slotted washer with the slot vertical and fit

bolt, finger tight.

11.Temporarily fit crankshaft pulley bolt to

crankshaft.

NOTE: Flywheel illustrated

12.

Manual gearbox:Rotate crankshaft clockwise

using crankshaft pulley bolt until tool

LRT-12-044can be inserted in slot in flywheel.

13.

Automatic gearbox:Rotate crankshaft

clockwise using crankshaft pulley bolt until tool

LRT-12-044can be inserted in slot in drive

plate.

14.Check that crankshaft Woodruff key is aligned

with arrow on timing belt rear cover.

15.If necessary, rotate camshaft timing gear using

the centre bolt until timing mark on gear is

aligned with timing mark on timing belt rear

cover.

16.Remove crankshaft pulley bolt.

Page 903 of 976

ENGINE

8

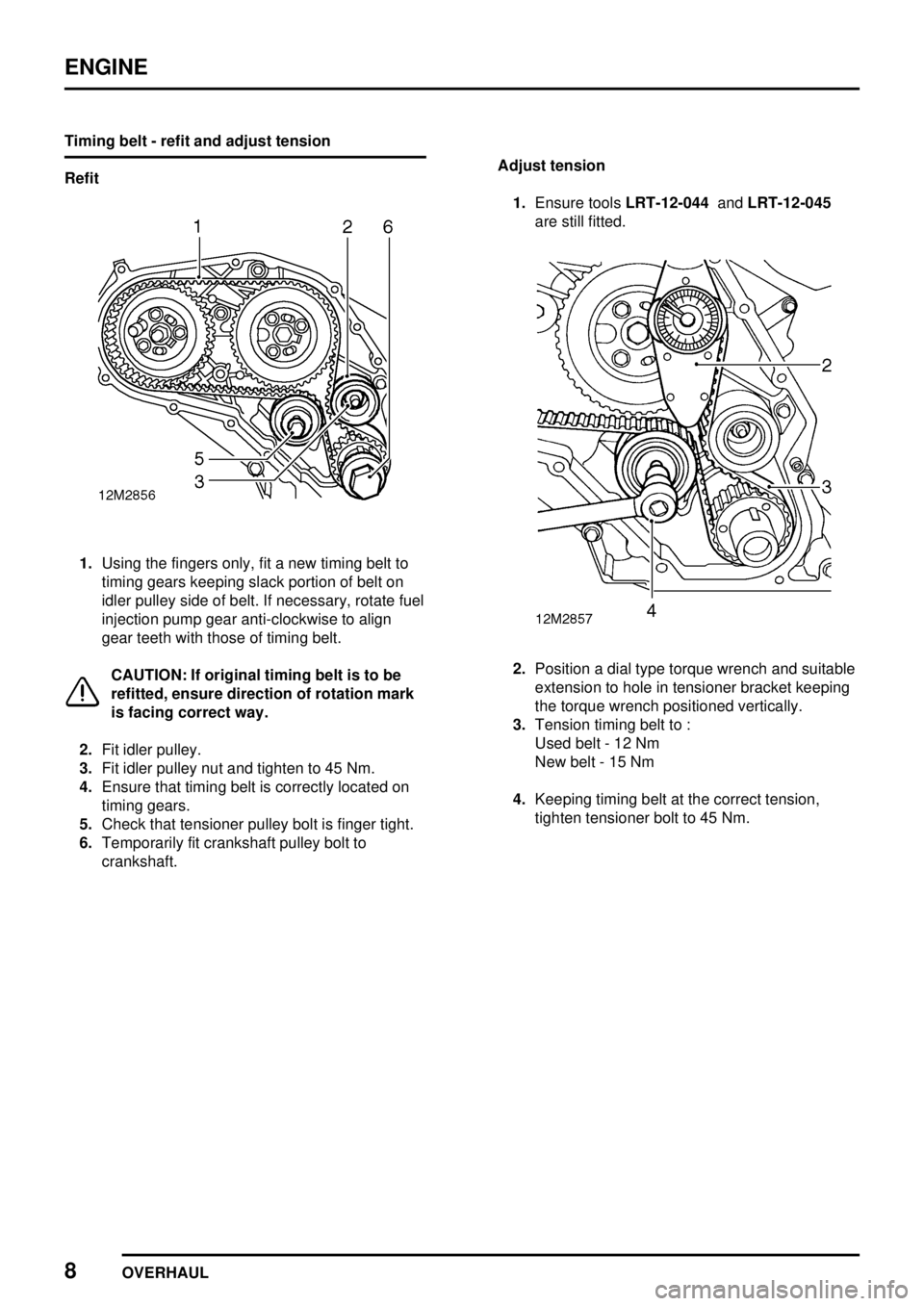

OVERHAUL Timing belt - refit and adjust tension

Refit

1.Using the fingers only, fit a new timing belt to

timing gears keeping slack portion of belt on

idler pulley side of belt. If necessary, rotate fuel

injection pump gear anti-clockwise to align

gear teeth with those of timing belt.

CAUTION: If original timing belt is to be

refitted, ensure direction of rotation mark

is facing correct way.

2.Fit idler pulley.

3.Fit idler pulley nut and tighten to 45 Nm.

4.Ensure that timing belt is correctly located on

timing gears.

5.Check that tensioner pulley bolt is finger tight.

6.Temporarily fit crankshaft pulley bolt to

crankshaft.Adjust tension

1.Ensure toolsLRT-12-044andLRT-12-045

are still fitted.2.Position a dial type torque wrench and suitable

extension to hole in tensioner bracket keeping

the torque wrench positioned vertically.

3.Tension timing belt to :

Used belt - 12 Nm

New belt - 15 Nm

4.Keeping timing belt at the correct tension,

tighten tensioner bolt to 45 Nm.

Page 904 of 976

ENGINE

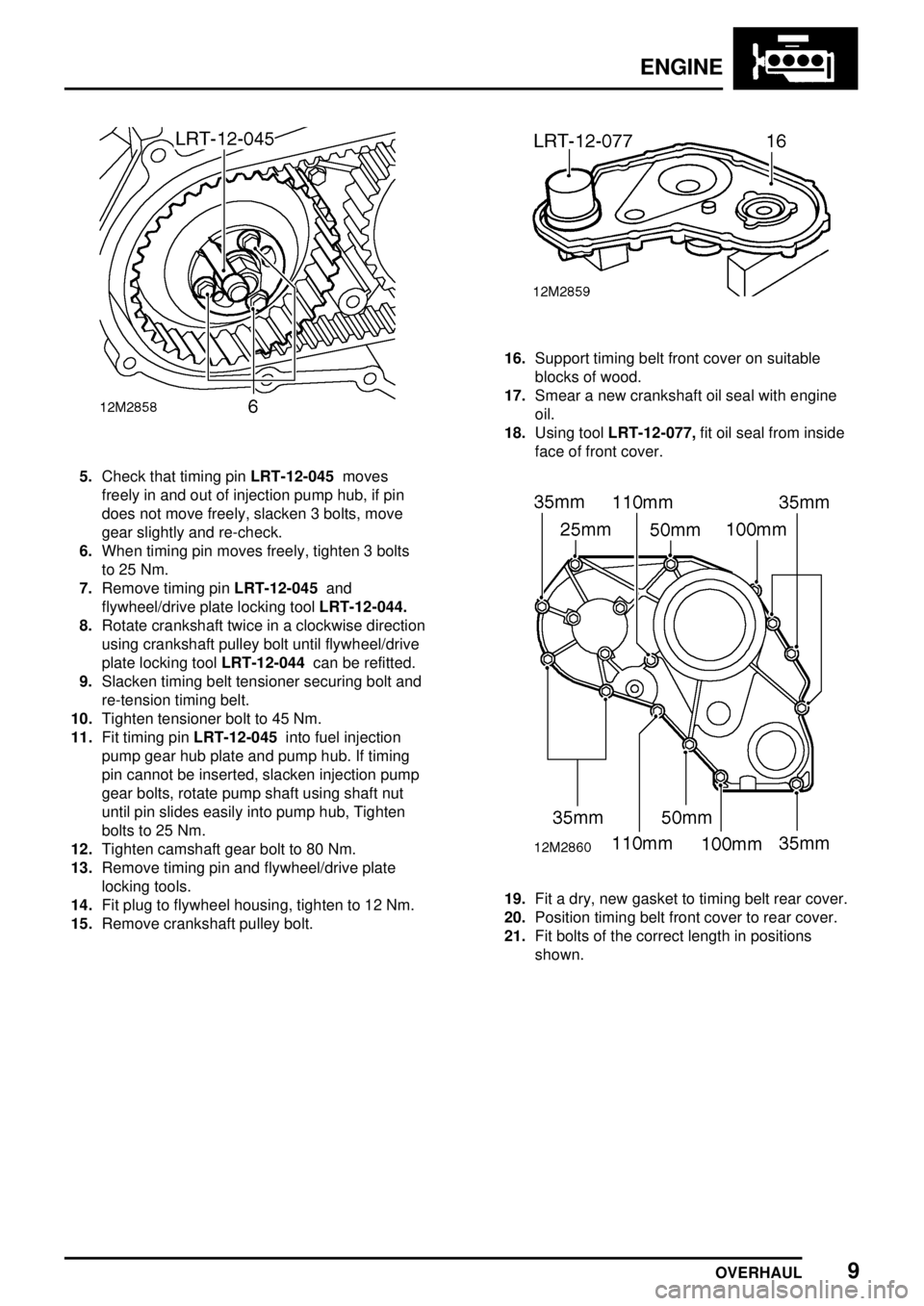

OVERHAUL9

5.Check that timing pinLRT-12-045moves

freely in and out of injection pump hub, if pin

does not move freely, slacken 3 bolts, move

gear slightly and re-check.

6.When timing pin moves freely, tighten 3 bolts

to 25 Nm.

7.Remove timing pinLRT-12-045and

flywheel/drive plate locking toolLRT-12-044.

8.Rotate crankshaft twice in a clockwise direction

using crankshaft pulley bolt until flywheel/drive

plate locking toolLRT-12-044can be refitted.

9.Slacken timing belt tensioner securing bolt and

re-tension timing belt.

10.Tighten tensioner bolt to 45 Nm.

11.Fit timing pinLRT-12-045into fuel injection

pump gear hub plate and pump hub. If timing

pin cannot be inserted, slacken injection pump

gear bolts, rotate pump shaft using shaft nut

until pin slides easily into pump hub, Tighten

bolts to 25 Nm.

12.Tighten camshaft gear bolt to 80 Nm.

13.Remove timing pin and flywheel/drive plate

locking tools.

14.Fit plug to flywheel housing, tighten to 12 Nm.

15.Remove crankshaft pulley bolt.

16.Support timing belt front cover on suitable

blocks of wood.

17.Smear a new crankshaft oil seal with engine

oil.

18.Using toolLRT-12-077,fit oil seal from inside

face of front cover.

19.Fit a dry, new gasket to timing belt rear cover.

20.Position timing belt front cover to rear cover.

21.Fit bolts of the correct length in positions

shown.

Page 905 of 976

ENGINE

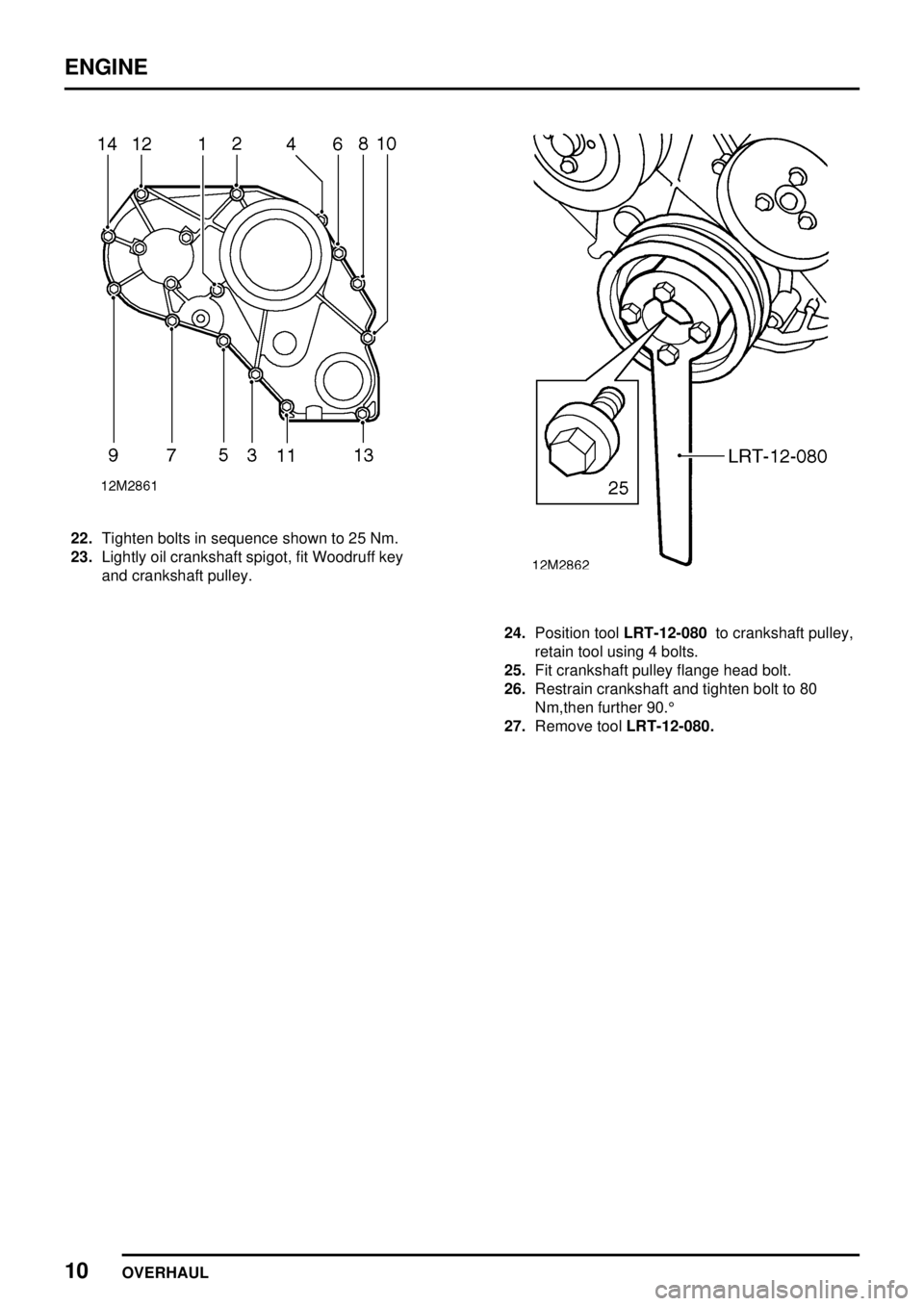

10

OVERHAUL

22.Tighten bolts in sequence shown to 25 Nm.

23.Lightly oil crankshaft spigot, fit Woodruff key

and crankshaft pulley.

24.Position toolLRT-12-080to crankshaft pulley,

retain tool using 4 bolts.

25.Fit crankshaft pulley flange head bolt.

26.Restrain crankshaft and tighten bolt to 80

Nm,then further 90.°

27.Remove toolLRT-12-080.

Page 906 of 976

ENGINE

OVERHAUL11

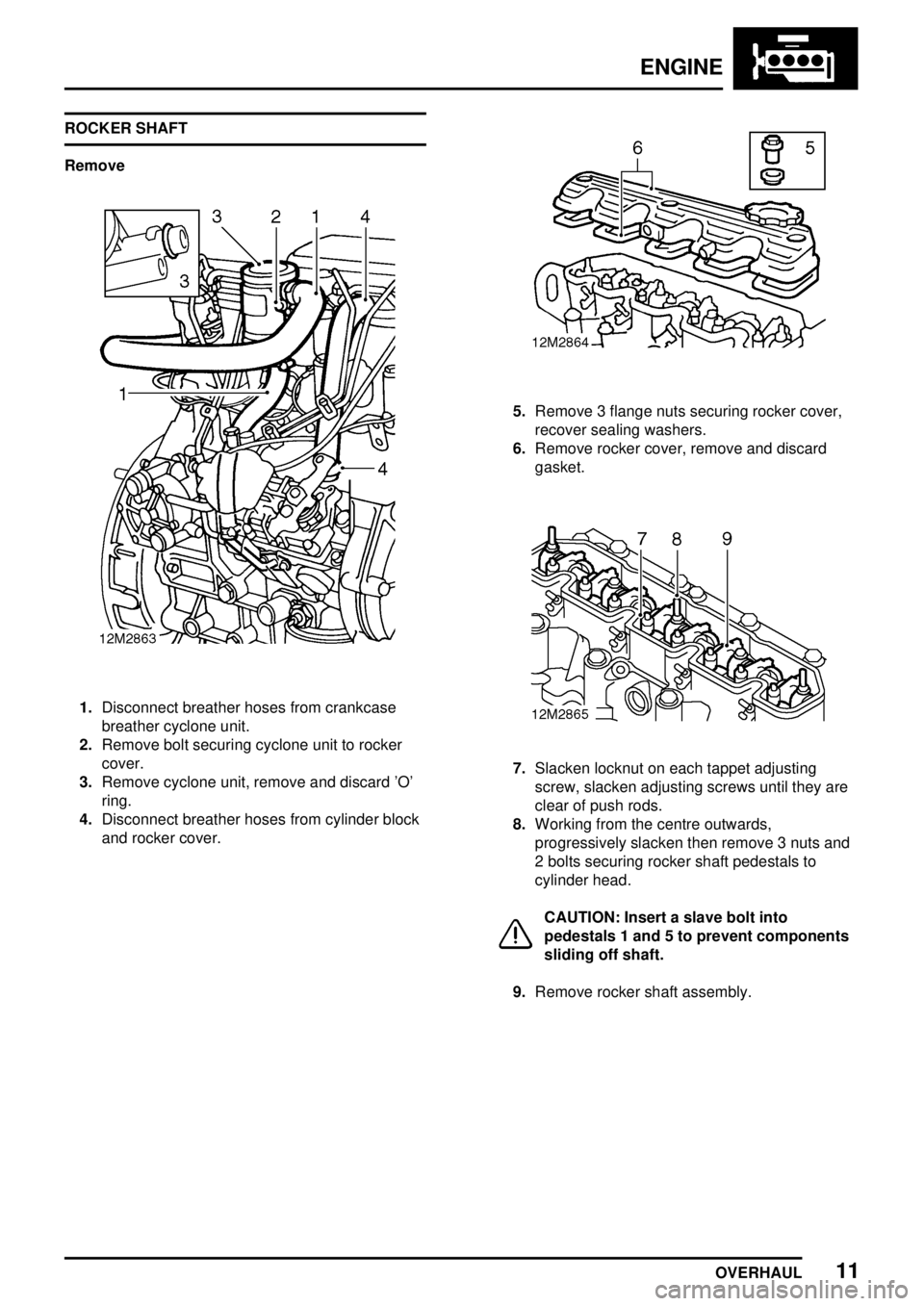

ROCKER SHAFT

Remove

1.Disconnect breather hoses from crankcase

breather cyclone unit.

2.Remove bolt securing cyclone unit to rocker

cover.

3.Remove cyclone unit, remove and discard 'O'

ring.

4.Disconnect breather hoses from cylinder block

and rocker cover.

5.Remove 3 flange nuts securing rocker cover,

recover sealing washers.

6.Remove rocker cover, remove and discard

gasket.

7.Slacken locknut on each tappet adjusting

screw, slacken adjusting screws until they are

clear of push rods.

8.Working from the centre outwards,

progressively slacken then remove 3 nuts and

2 bolts securing rocker shaft pedestals to

cylinder head.

CAUTION: Insert a slave bolt into

pedestals 1 and 5 to prevent components

sliding off shaft.

9.Remove rocker shaft assembly.

Page 907 of 976

ENGINE

12

OVERHAUL

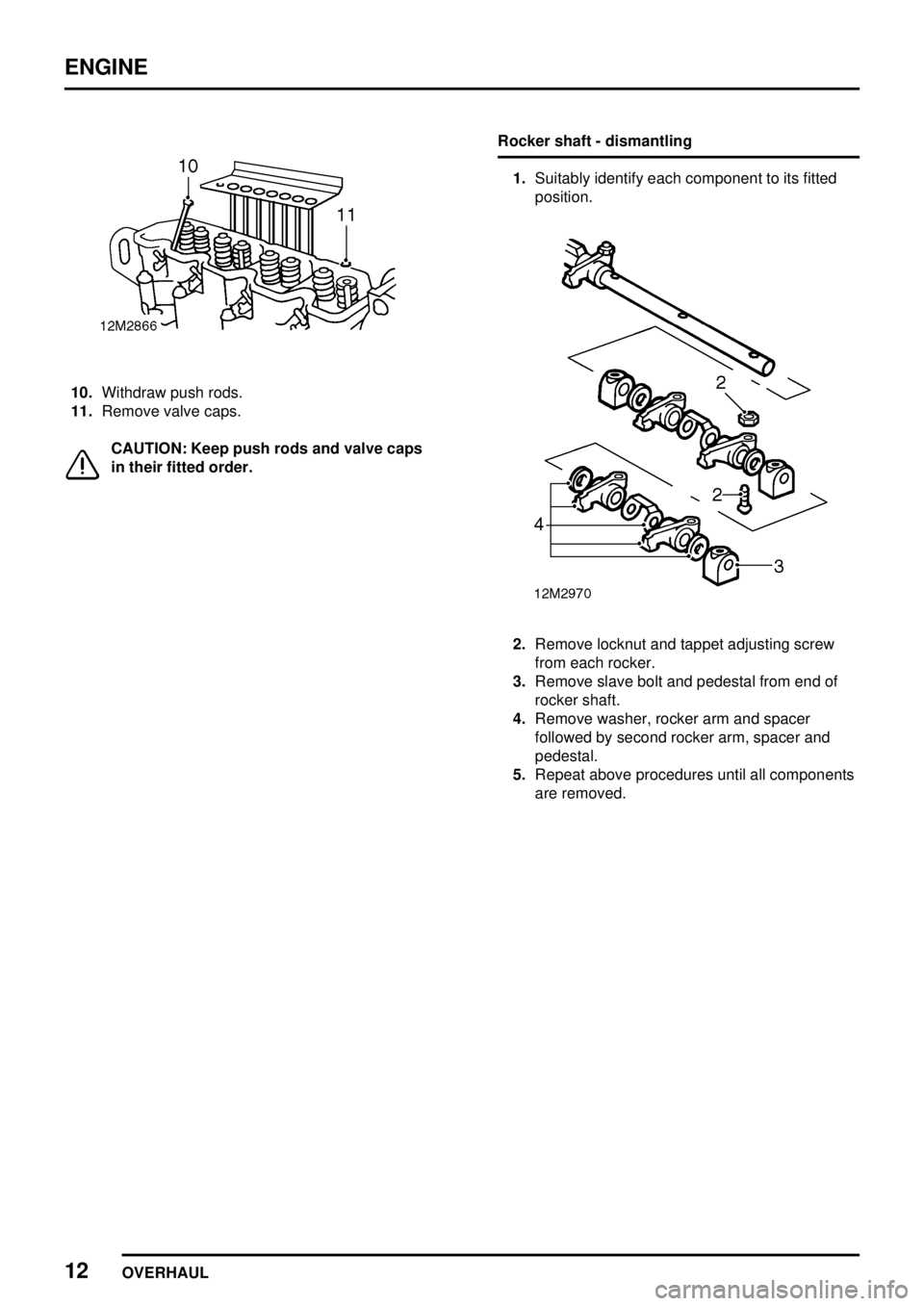

10.Withdraw push rods.

11.Remove valve caps.

CAUTION: Keep push rods and valve caps

in their fitted order.Rocker shaft - dismantling

1.Suitably identify each component to its fitted

position.

2.Remove locknut and tappet adjusting screw

from each rocker.

3.Remove slave bolt and pedestal from end of

rocker shaft.

4.Remove washer, rocker arm and spacer

followed by second rocker arm, spacer and

pedestal.

5.Repeat above procedures until all components

are removed.

Page 908 of 976

ENGINE

OVERHAUL13

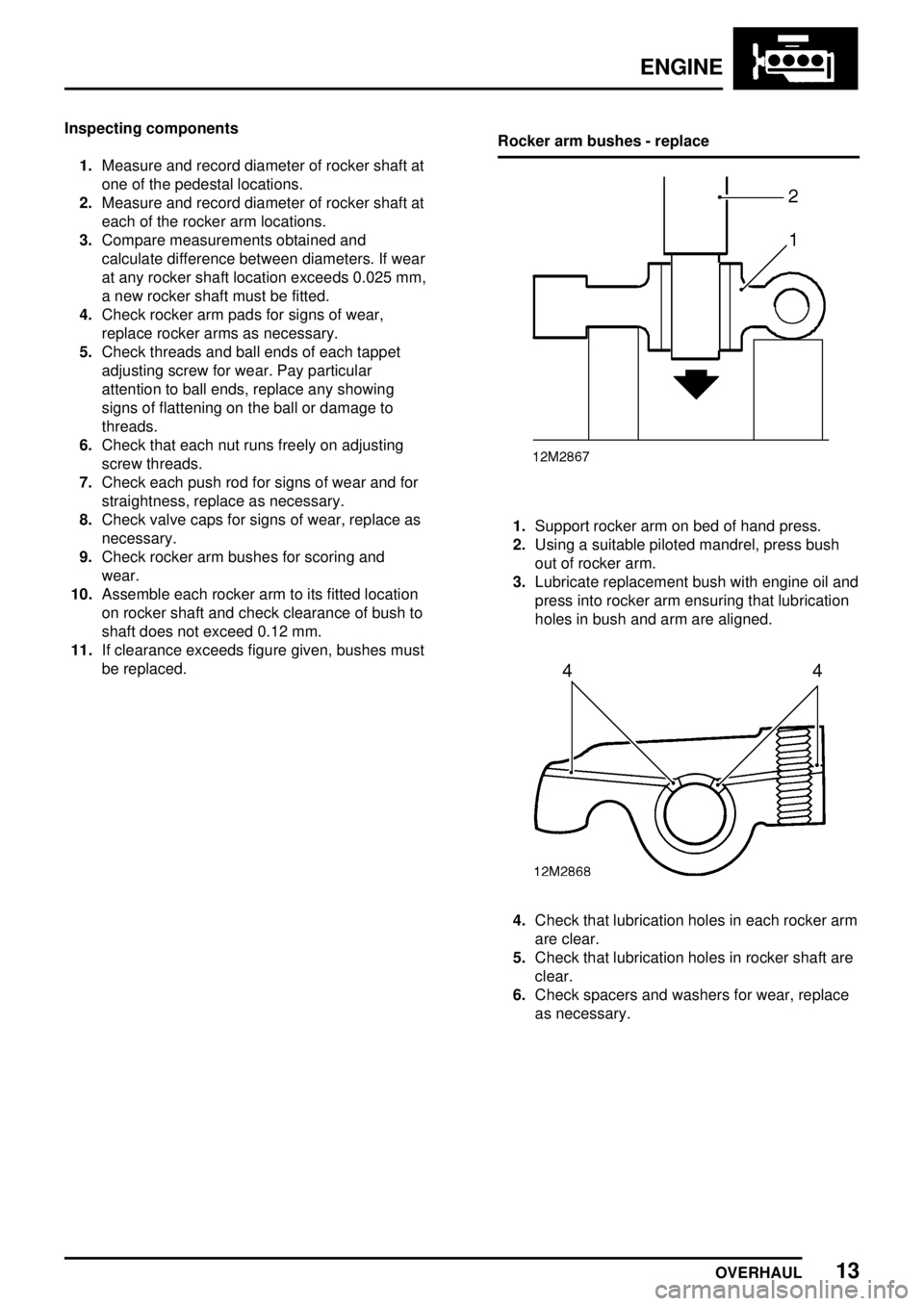

Inspecting components

1.Measure and record diameter of rocker shaft at

one of the pedestal locations.

2.Measure and record diameter of rocker shaft at

each of the rocker arm locations.

3.Compare measurements obtained and

calculate difference between diameters. If wear

at any rocker shaft location exceeds 0.025 mm,

a new rocker shaft must be fitted.

4.Check rocker arm pads for signs of wear,

replace rocker arms as necessary.

5.Check threads and ball ends of each tappet

adjusting screw for wear. Pay particular

attention to ball ends, replace any showing

signs of flattening on the ball or damage to

threads.

6.Check that each nut runs freely on adjusting

screw threads.

7.Check each push rod for signs of wear and for

straightness, replace as necessary.

8.Check valve caps for signs of wear, replace as

necessary.

9.Check rocker arm bushes for scoring and

wear.

10.Assemble each rocker arm to its fitted location

on rocker shaft and check clearance of bush to

shaft does not exceed 0.12 mm.

11.If clearance exceeds figure given, bushes must

be replaced.Rocker arm bushes - replace

1.Support rocker arm on bed of hand press.

2.Using a suitable piloted mandrel, press bush

out of rocker arm.

3.Lubricate replacement bush with engine oil and

press into rocker arm ensuring that lubrication

holes in bush and arm are aligned.

4.Check that lubrication holes in each rocker arm

are clear.

5.Check that lubrication holes in rocker shaft are

clear.

6.Check spacers and washers for wear, replace

as necessary.

Page 909 of 976

ENGINE

14

OVERHAUL Rocker shaft - assembling

1.Lubricate all components with engine oil.

2.Assemble rocker arms, spacers, washers and

pedestals to rocker shaft ensuring that they are

in their original fitted positions.

3.Retain pedestals 1 and 5 with slave bolts.Rocker shaft - refit

1.Lubricate push rods with engine oil and fit to

their original positions. Ensure that ball end of

each push rod is correctly located in each cam

follower slide.

2.Screw each tappet adjusting screw into its

respective rocker arm until ball end is flush with

underside of arm; fit but do not tighten

locknuts.

3.Lubricate valve pads with engine oil and fit to

their original positions.

4.Position rocker shaft to cylinder head, fit but do

not tighten 3 nuts.

5.Remove slave bolts from pedestals 1 and 5, fit

but do not tighten 2 bolts.

6.Locate each push rod in turn beneath its

respective tappet adjusting screw and tighten

each screw until ball end locates in recess in

push rod.

7.Working from the centre outwards,

progressively tighten 3 nuts and 2 bolts to 5

Nm.

Page 910 of 976

ENGINE

OVERHAUL15

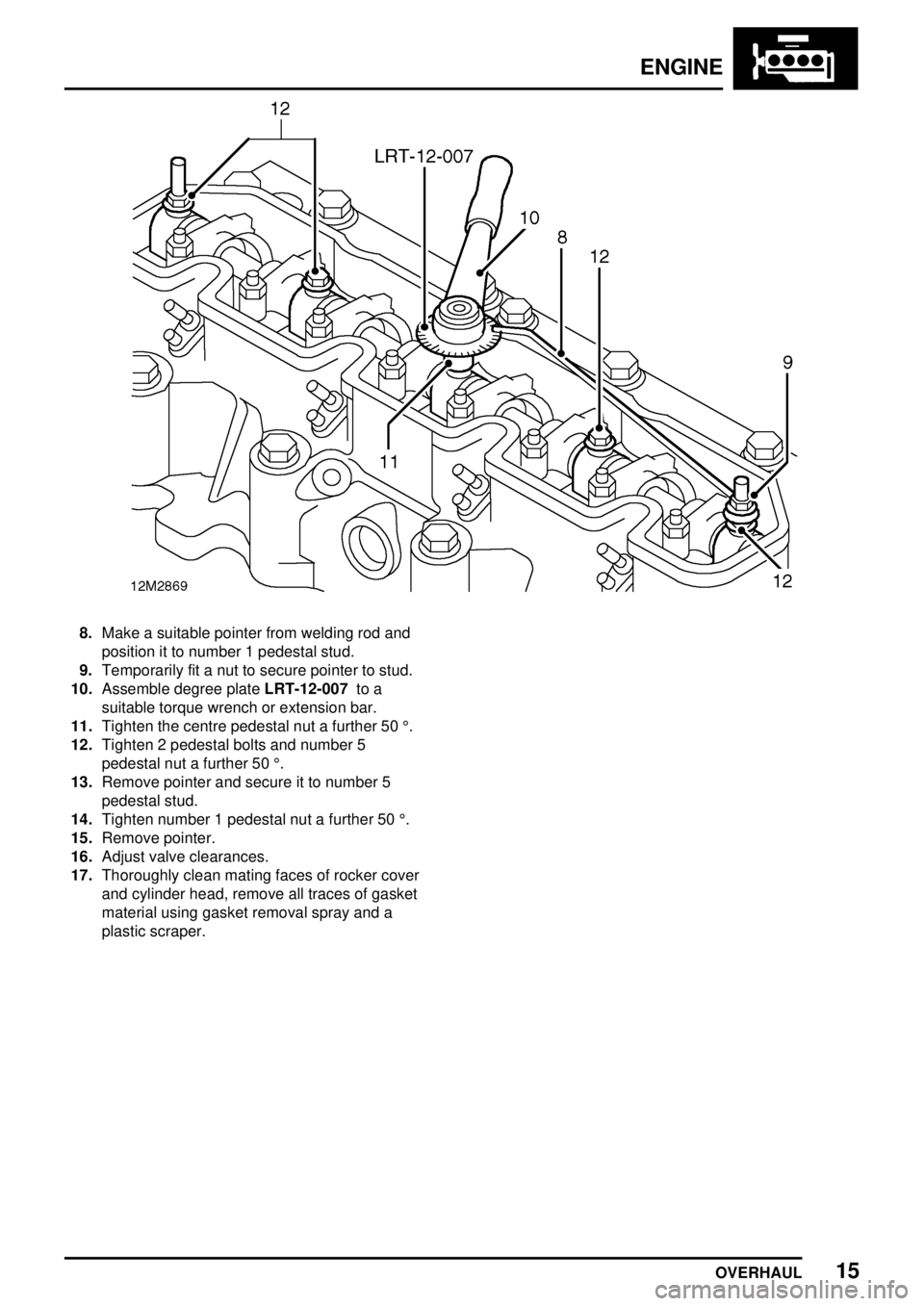

8.Make a suitable pointer from welding rod and

position it to number 1 pedestal stud.

9.Temporarily fit a nut to secure pointer to stud.

10.Assemble degree plateLRT-12-007to a

suitable torque wrench or extension bar.

11.Tighten the centre pedestal nut a further 50°.

12.Tighten 2 pedestal bolts and number 5

pedestal nut a further 50°.

13.Remove pointer and secure it to number 5

pedestal stud.

14.Tighten number 1 pedestal nut a further 50°.

15.Remove pointer.

16.Adjust valve clearances.

17.Thoroughly clean mating faces of rocker cover

and cylinder head, remove all traces of gasket

material using gasket removal spray and a

plastic scraper.