LAND ROVER DISCOVERY 1995 Service Repair Manual

DISCOVERY 1995

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57245/w960_57245-0.png

LAND ROVER DISCOVERY 1995 Service Repair Manual

Trending: sunroof, warning light, differential, ECO mode, buttons, seats, brake sensor

Page 891 of 976

ENGINE

14

DESCRIPTION AND OPERATION

Page 892 of 976

ENGINE

DESCRIPTION AND OPERATION15

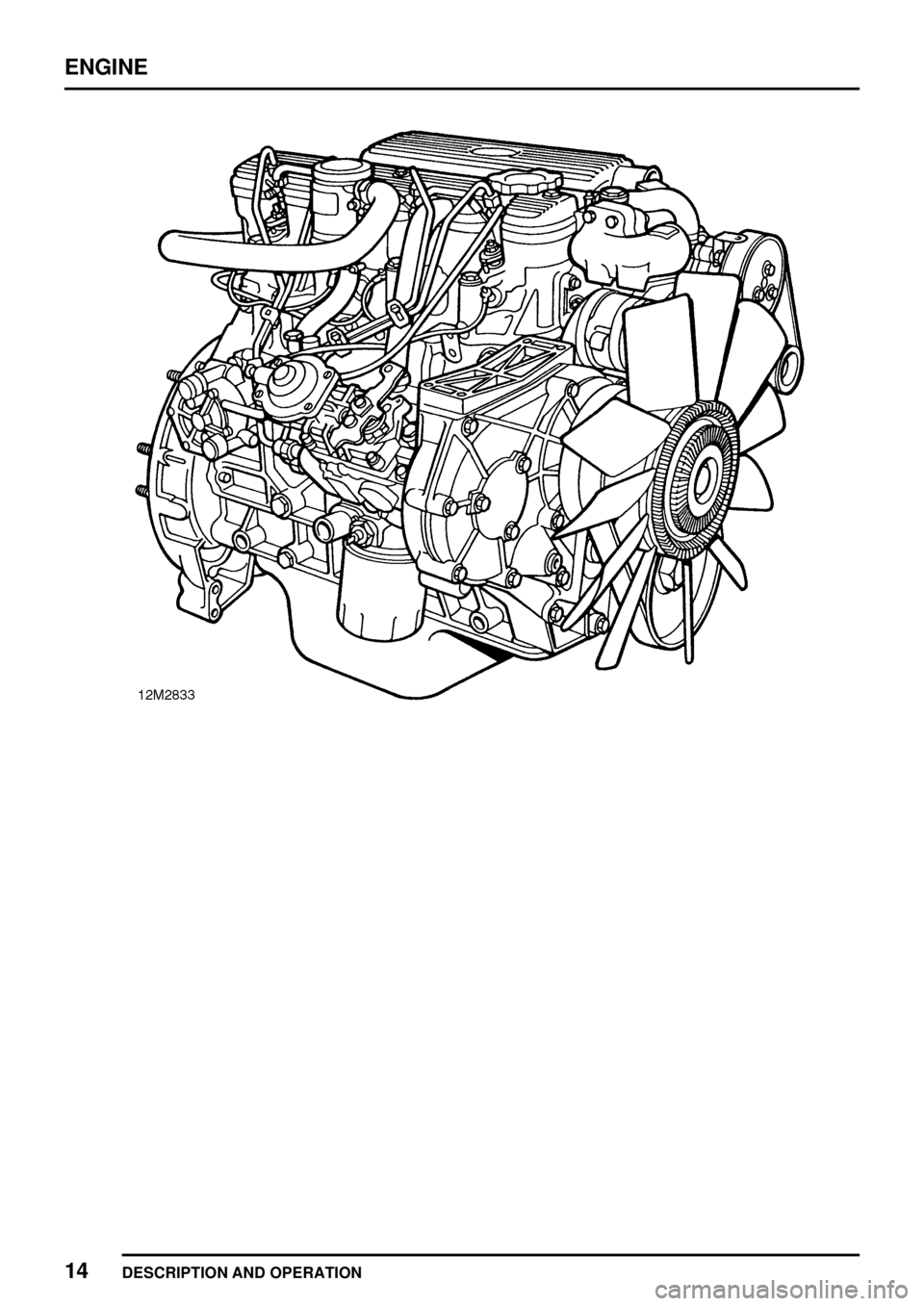

OPERATION

The 300 TDi is a 4 cylinder, water cooled,

turbocharged diesel engine with a capacity of 2.5

litres.

The cast iron cylinder block is integral with the

crankcase and incorporates direct bored cylinders.

The crankshaft is carried in 5 main bearings,

end-float being controlled by thrust washers which

are positioned on both sides of the centre main

bearing.

The flywheel/drive plate housing is an aluminium

alloy casting secured to the rear of the cylinder

block, it also forms the mounting for the starter

motor. A plugged aperture in the housing allows

access for the insertion of the timing pin.

The aluminium alloy cylinder head carries a

conventional rocker shaft and rockers, operating 2

valves per cylinder via camshaft followers and push

rods from a single camshaft, supported in the

cylinder block by 4 bearings and driven by a gear

and toothed belt from the crankshaft. A lobe formed

between the 2 inner bearing journals provides drive

for the fuel lift pump and another lobe, between the 2

drive end journals provides drive for the brake servo

pump. Camshaft end-float is controlled by a thrust

plate bolted to the cylinder block.

Graphite coated, aluminium alloy pistons are fitted

with 2 compression and an oil control ring and are

secured to the connecting rods by semi-floating

gudgeon pins which are an interference fit in the

small end bush. A swirl chamber is incorporated in

the piston crown to facilitate combustion.

The timing case consists of cast aluminium alloy

front and rear covers which house the oil pump,

crankshaft and camshaft front oil seals and which

also carry the fuel injection pump and drive belt idler

pulley. Housed within the timing case housing is the

crankshaft gear which provides drive for the

camshaft and fuel injection pump gears via a rubber

toothed belt.

Page 893 of 976

ENGINE

16

DESCRIPTION AND OPERATION

Page 894 of 976

ENGINE

DESCRIPTION AND OPERATION17

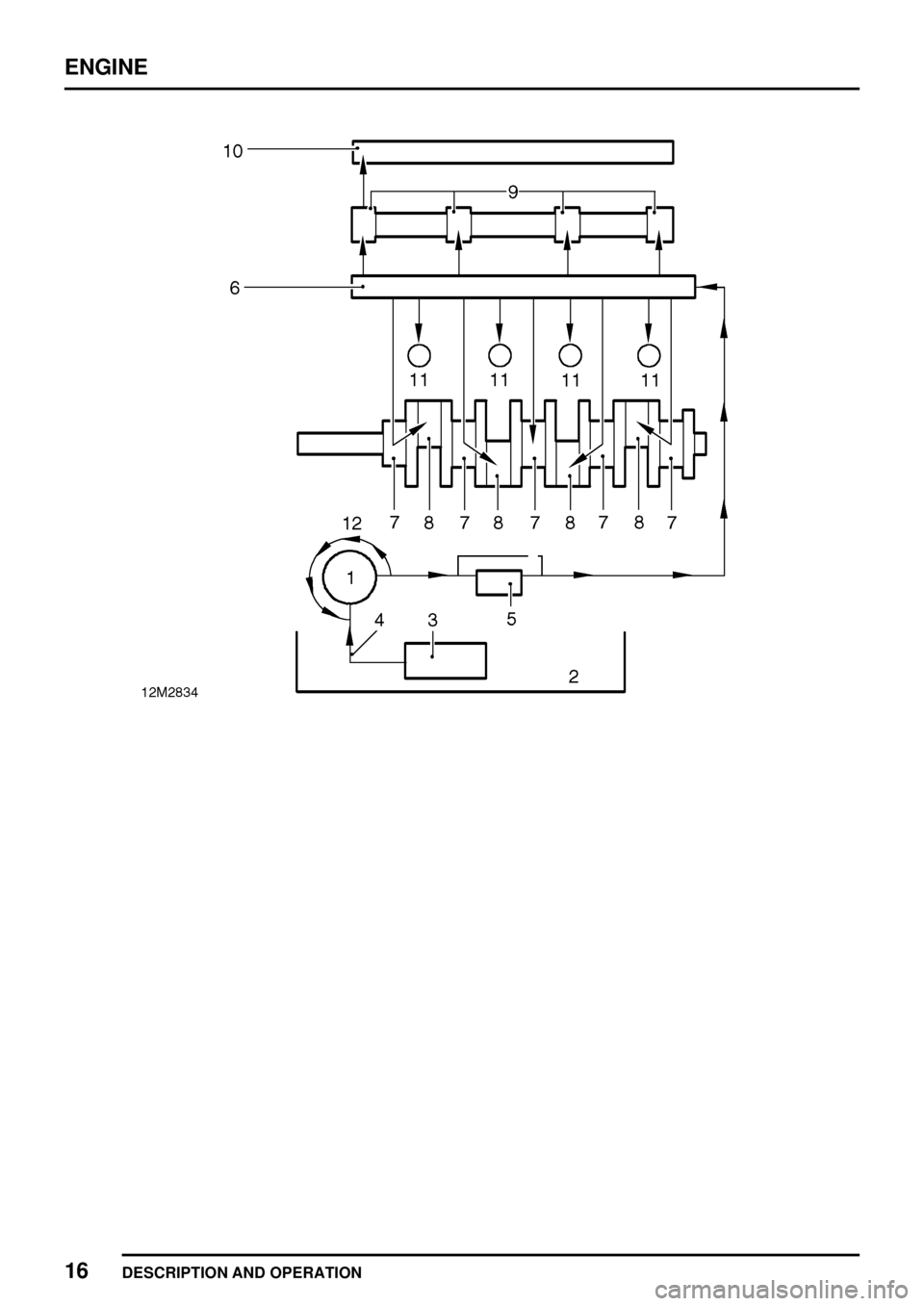

Lubrication

The engine lubrication system is of the wet sump

type, oil pressure being provided by the rotor type oil

pump (1) driven directly by the crankshaft.

Oil is drawn from the sump (2) through the strainer

(3), suction pipe (4) and passes through internal

drillings in the cylinder block to an external, full flow

filter (5). Further drillings feed oil to the cylinder

block main oil gallery (6) which, in turn, supplies the

crankshaft main bearings (7). Cross drillings in the

crankshaft carry oil to the connecting rod big-end

bearings (8). The camshaft bearings (9) are supplied

with oil from the main oil gallery.

An internal oilway from the camshaft front bearing

connects the cylinder block to the cylinder head and

feeds oil to the rocker shaft assembly (10),

lubricating the valves and springs.

The pistons, gudgeon pins and small end bushes

are lubricated and cooled by oil jets (11) which are

supplied from the main oil gallery via relief valves

which allow the oil to flow at a pre-determined

pressure.

Oil pressure is controlled by a pressure relief valve

(12) incorporated in the timing case housing

together with the oil pump. The valve allows excess

oil to be recirculated back into the oil feed gallery.

The rotor type oil pump is driven by 2 flats machined

on the front of the crankshaft.

Oil cooling is maintained by an oil cooler which is

integral with the radiator and linked to adaptors on

the oil filter head by pre-formed feed and return

hoses. A thermostatic valve in the filter head allows

oil to flow to the cooler when it reaches a

pre-determined temperature.

Page 895 of 976

ENGINE

18

DESCRIPTION AND OPERATION

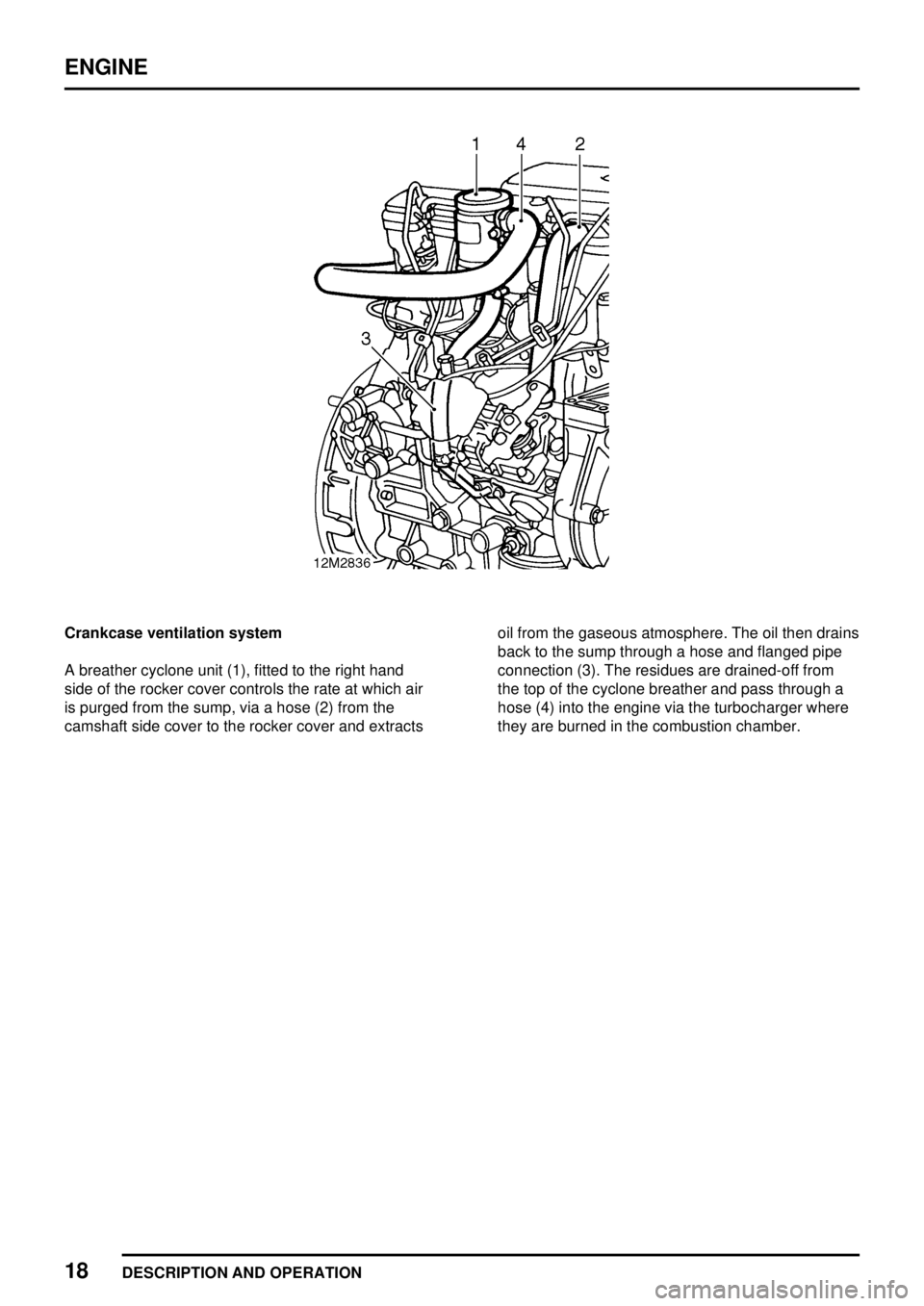

Crankcase ventilation system

A breather cyclone unit (1), fitted to the right hand

side of the rocker cover controls the rate at which air

is purged from the sump, via a hose (2) from the

camshaft side cover to the rocker cover and extractsoil from the gaseous atmosphere. The oil then drains

back to the sump through a hose and flanged pipe

connection (3). The residues are drained-off from

the top of the cyclone breather and pass through a

hose (4) into the engine via the turbocharger where

they are burned in the combustion chamber.

Page 896 of 976

ENGINE

OVERHAUL1

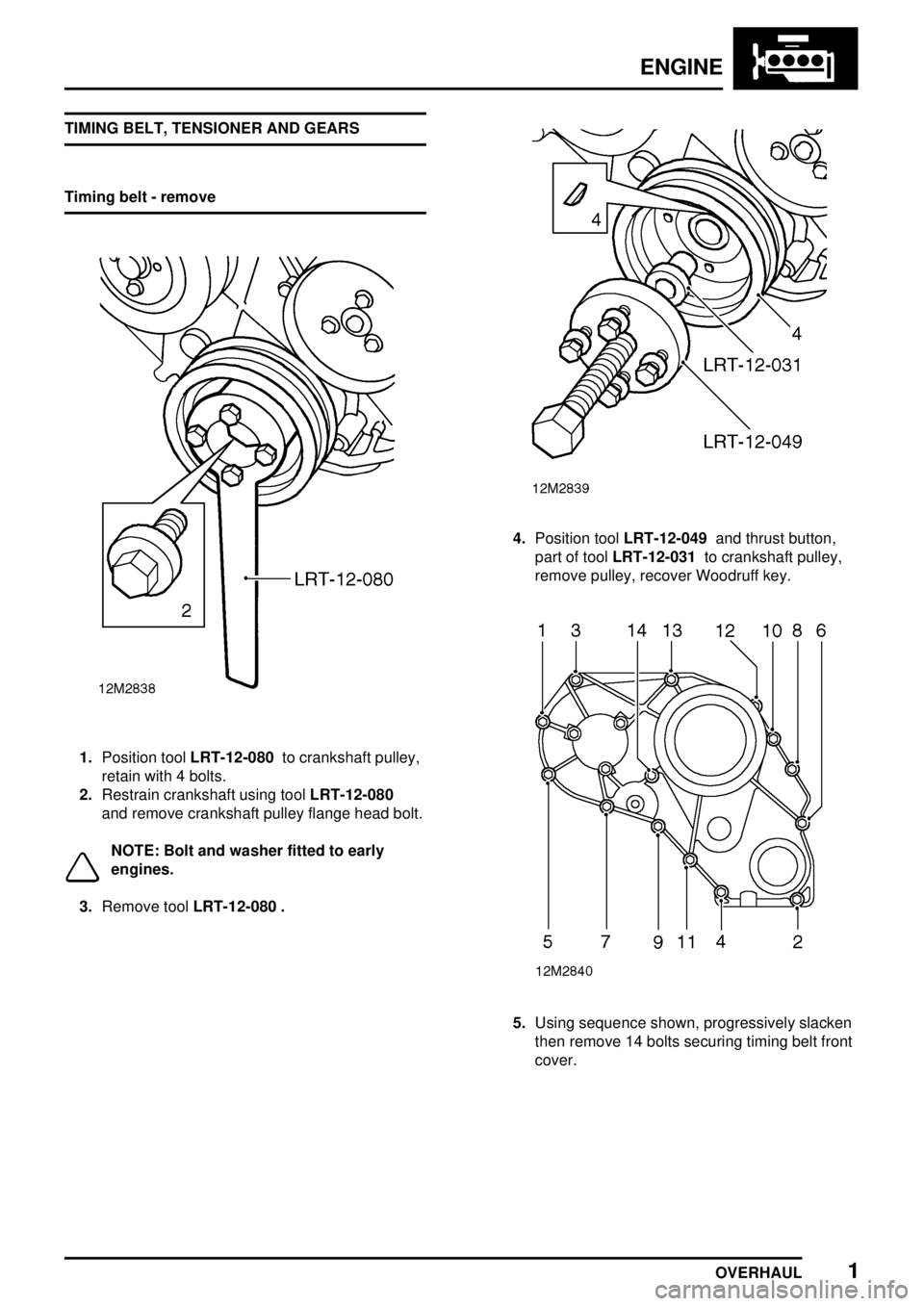

TIMING BELT, TENSIONER AND GEARS

Timing belt - remove

1.Position toolLRT-12-080to crankshaft pulley,

retain with 4 bolts.

2.Restrain crankshaft using toolLRT-12-080

and remove crankshaft pulley flange head bolt.

NOTE: Bolt and washer fitted to early

engines.

3.Remove toolLRT-12-080 .

4.Position toolLRT-12-049and thrust button,

part of toolLRT-12-031to crankshaft pulley,

remove pulley, recover Woodruff key.

5.Using sequence shown, progressively slacken

then remove 14 bolts securing timing belt front

cover.

Page 897 of 976

ENGINE

2

OVERHAUL

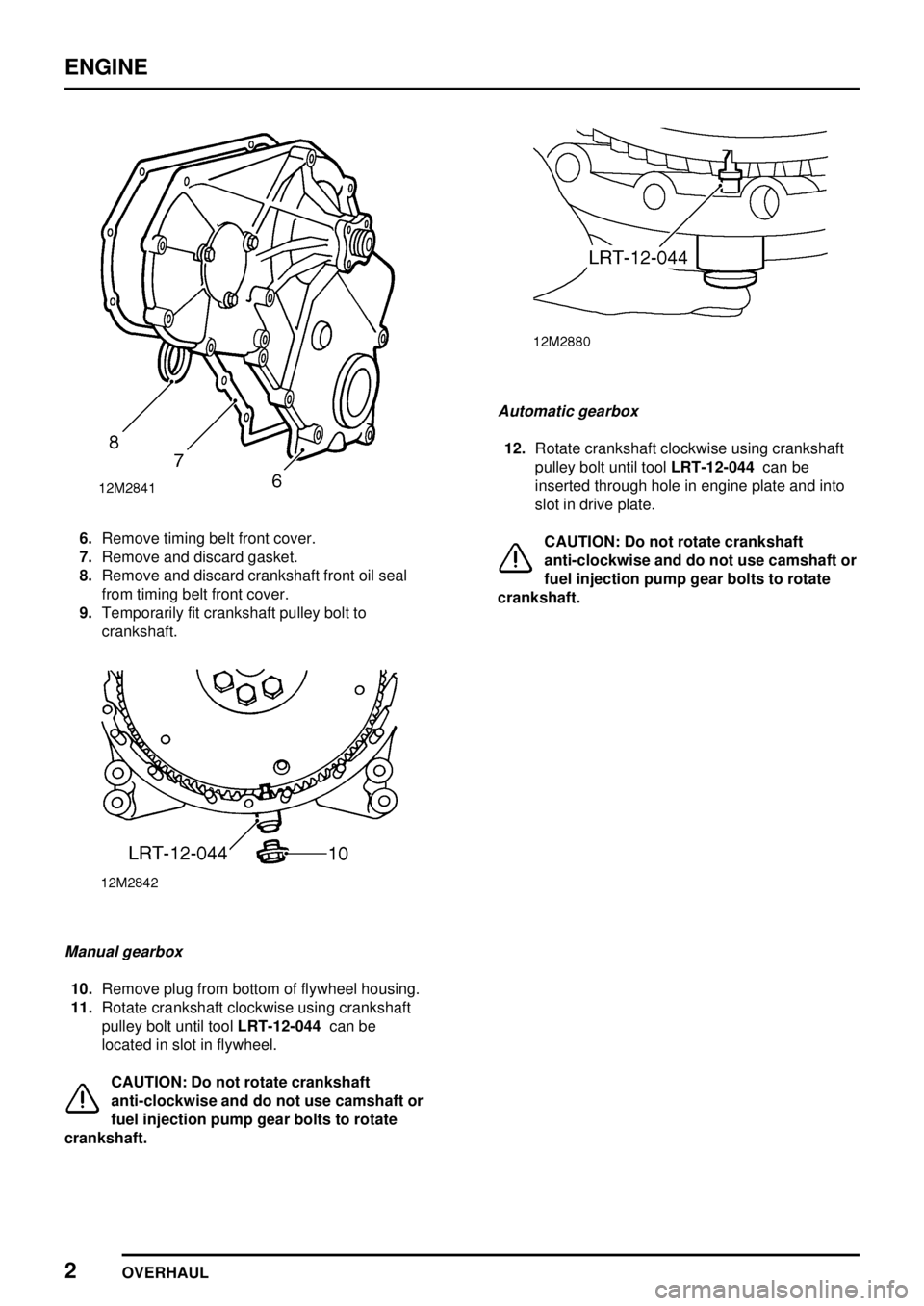

6.Remove timing belt front cover.

7.Remove and discard gasket.

8.Remove and discard crankshaft front oil seal

from timing belt front cover.

9.Temporarily fit crankshaft pulley bolt to

crankshaft.

Manual gearbox

10.Remove plug from bottom of flywheel housing.

11.Rotate crankshaft clockwise using crankshaft

pulley bolt until toolLRT-12-044can be

located in slot in flywheel.

CAUTION: Do not rotate crankshaft

anti-clockwise and do not use camshaft or

fuel injection pump gear bolts to rotate

crankshaft.

Automatic gearbox

12.Rotate crankshaft clockwise using crankshaft

pulley bolt until toolLRT-12-044can be

inserted through hole in engine plate and into

slot in drive plate.

CAUTION: Do not rotate crankshaft

anti-clockwise and do not use camshaft or

fuel injection pump gear bolts to rotate

crankshaft.

Page 898 of 976

ENGINE

OVERHAUL3

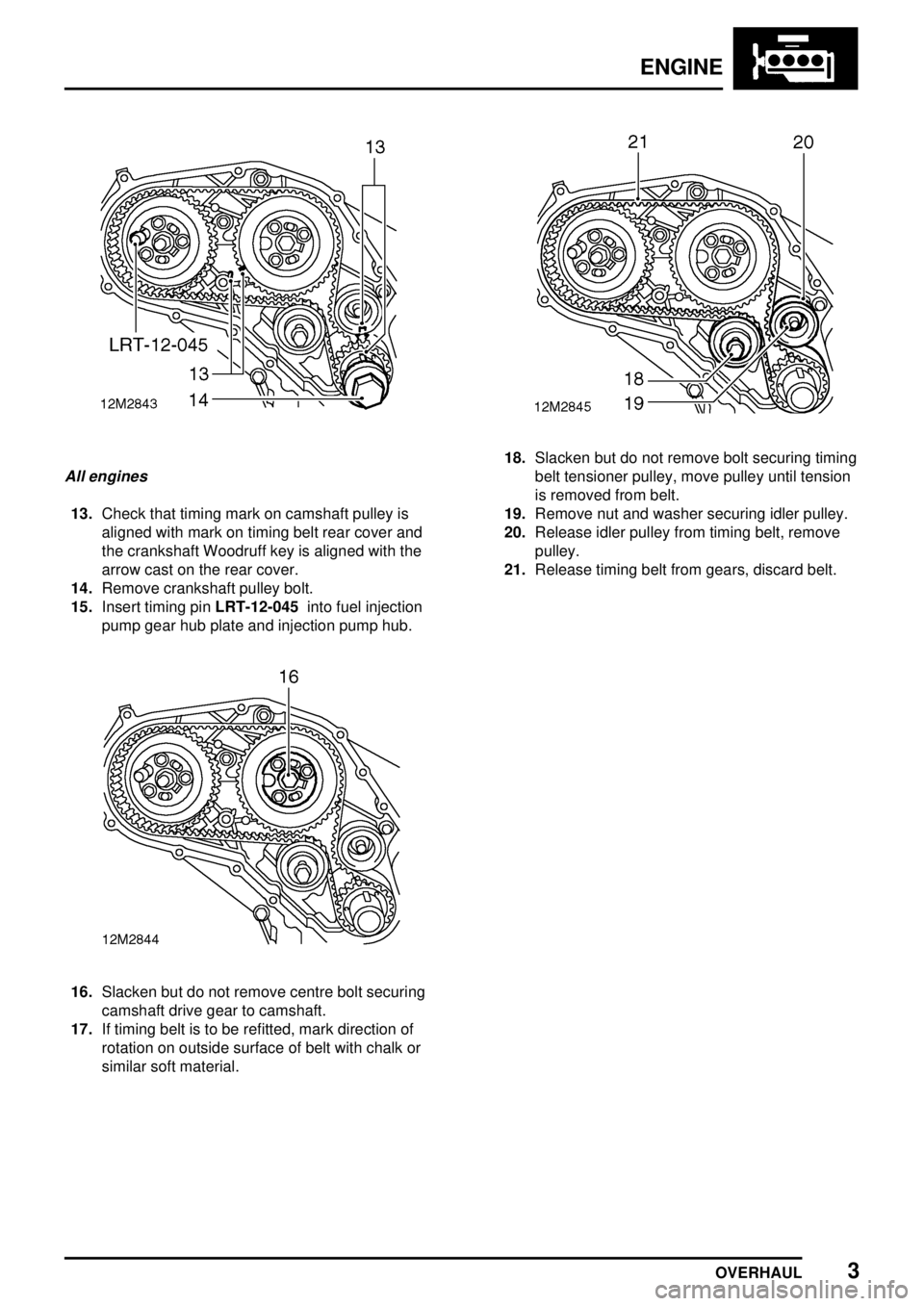

All engines

13.Check that timing mark on camshaft pulley is

aligned with mark on timing belt rear cover and

the crankshaft Woodruff key is aligned with the

arrow cast on the rear cover.

14.Remove crankshaft pulley bolt.

15.Insert timing pinLRT-12-045into fuel injection

pump gear hub plate and injection pump hub.

16.Slacken but do not remove centre bolt securing

camshaft drive gear to camshaft.

17.If timing belt is to be refitted, mark direction of

rotation on outside surface of belt with chalk or

similar soft material.

18.Slacken but do not remove bolt securing timing

belt tensioner pulley, move pulley until tension

is removed from belt.

19.Remove nut and washer securing idler pulley.

20.Release idler pulley from timing belt, remove

pulley.

21.Release timing belt from gears, discard belt.

Page 899 of 976

ENGINE

4

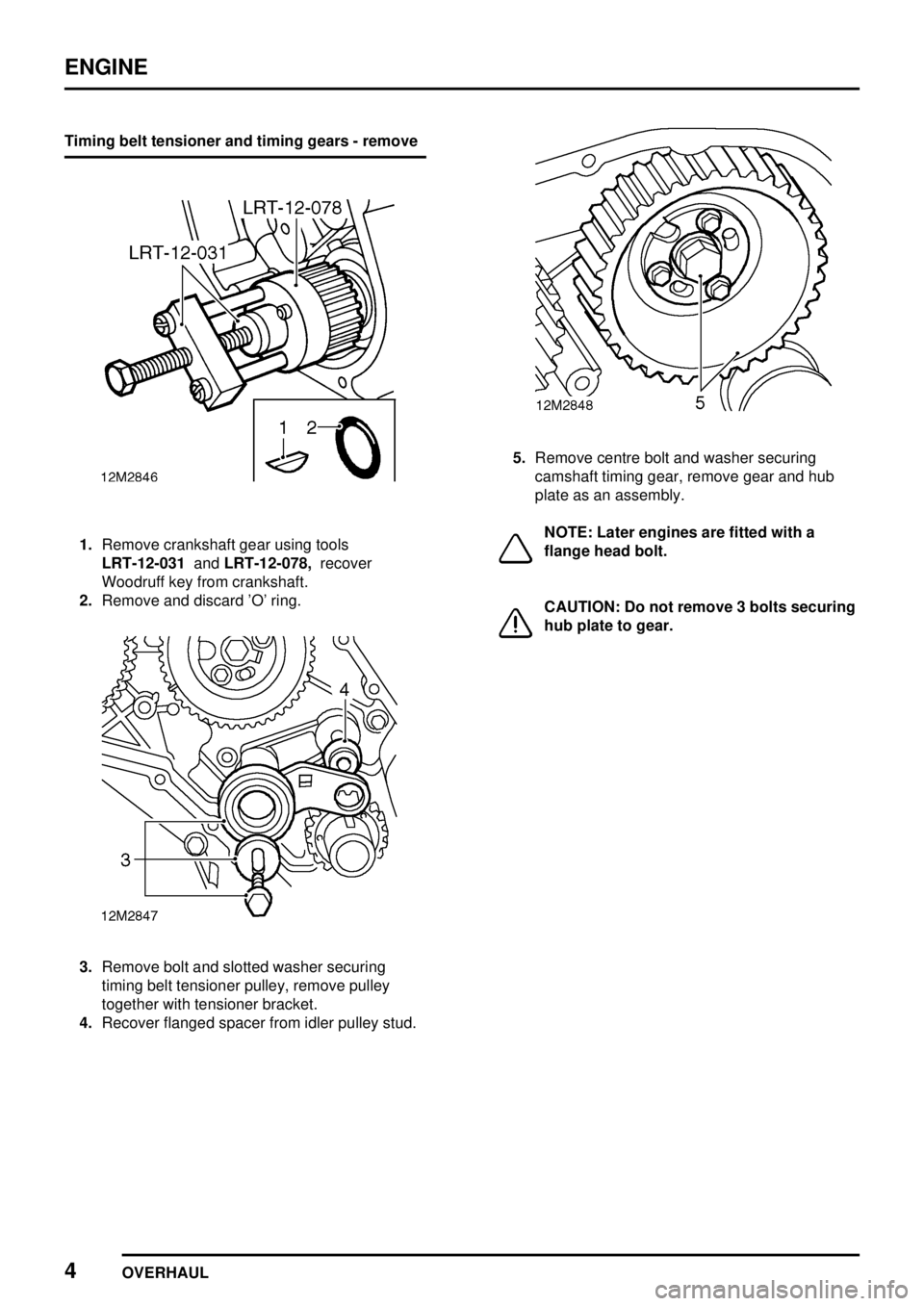

OVERHAUL Timing belt tensioner and timing gears - remove

1.Remove crankshaft gear using tools

LRT-12-031andLRT-12-078,recover

Woodruff key from crankshaft.

2.Remove and discard 'O' ring.

3.Remove bolt and slotted washer securing

timing belt tensioner pulley, remove pulley

together with tensioner bracket.

4.Recover flanged spacer from idler pulley stud.

5.Remove centre bolt and washer securing

camshaft timing gear, remove gear and hub

plate as an assembly.

NOTE: Later engines are fitted with a

flange head bolt.

CAUTION: Do not remove 3 bolts securing

hub plate to gear.

Page 900 of 976

ENGINE

OVERHAUL5

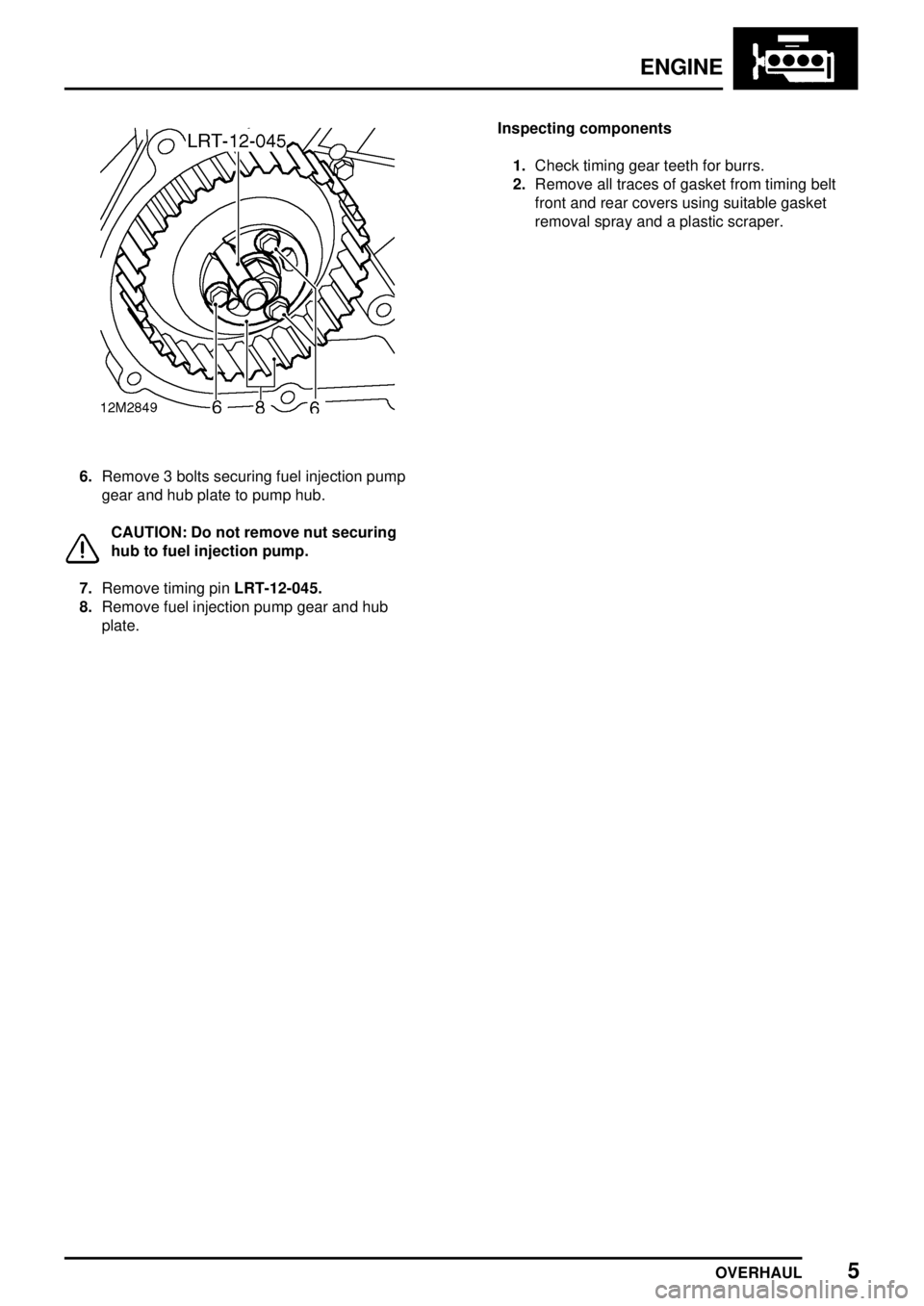

6.Remove 3 bolts securing fuel injection pump

gear and hub plate to pump hub.

CAUTION: Do not remove nut securing

hub to fuel injection pump.

7.Remove timing pinLRT-12-045.

8.Remove fuel injection pump gear and hub

plate.Inspecting components

1.Check timing gear teeth for burrs.

2.Remove all traces of gasket from timing belt

front and rear covers using suitable gasket

removal spray and a plastic scraper.

Trending: fuse box, fuel consumption, auxiliary battery, wheel bolts, wheel size, mirror controls, spark plugs replace