oil LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 37 of 873

GENERAL SPECIFICATION DATA

19

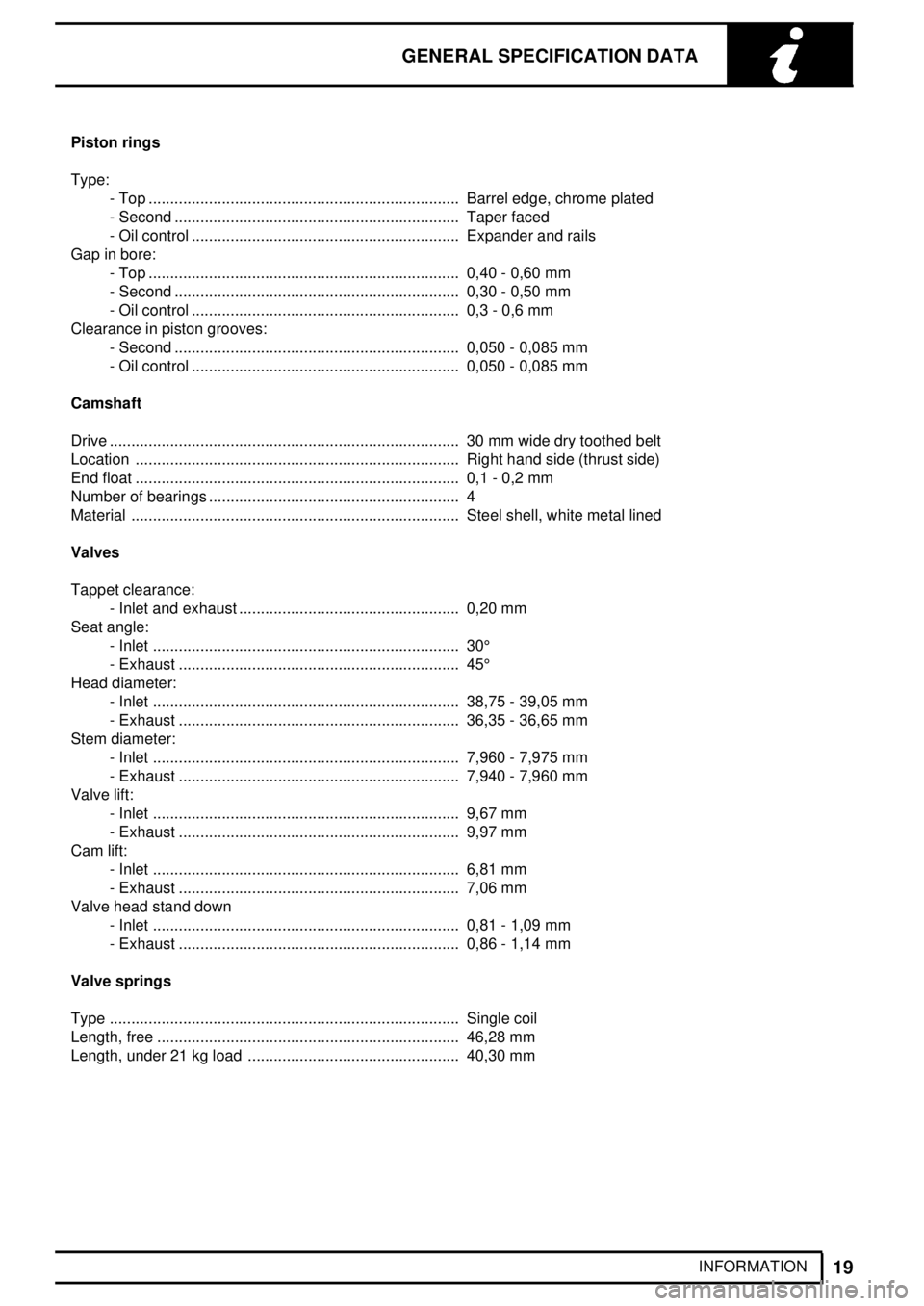

INFORMATION Piston rings

Type:

- Top Barrel edge, chrome plated........................................................................

- Second Taper faced..................................................................

- Oil control Expander and rails..............................................................

Gap in bore:

- Top 0,40 - 0,60 mm........................................................................

- Second 0,30 - 0,50 mm..................................................................

- Oil control 0,3 - 0,6 mm..............................................................

Clearance in piston grooves:

- Second 0,050 - 0,085 mm..................................................................

- Oil control 0,050 - 0,085 mm..............................................................

Camshaft

Drive 30 mm wide dry toothed belt.................................................................................

Location Right hand side (thrust side)...........................................................................

End float 0,1 - 0,2 mm...........................................................................

Number of bearings 4..........................................................

Material Steel shell, white metal lined............................................................................

Valves

Tappet clearance:

- Inlet and exhaust 0,20 mm...................................................

Seat angle:

- Inlet 30° .......................................................................

- Exhaust 45° .................................................................

Head diameter:

- Inlet 38,75 - 39,05 mm.......................................................................

- Exhaust 36,35 - 36,65 mm.................................................................

Stem diameter:

- Inlet 7,960 - 7,975 mm.......................................................................

- Exhaust 7,940 - 7,960 mm.................................................................

Valve lift:

- Inlet 9,67 mm.......................................................................

- Exhaust 9,97 mm.................................................................

Cam lift:

- Inlet 6,81 mm.......................................................................

- Exhaust 7,06 mm.................................................................

Valve head stand down

- Inlet 0,81 - 1,09 mm.......................................................................

- Exhaust 0,86 - 1,14 mm.................................................................

Valve springs

Type Single coil.................................................................................

Length, free 46,28 mm......................................................................

Length, under 21 kg load 40,30 mm.................................................

Page 38 of 873

04GENERAL SPECIFICATION DATA

20

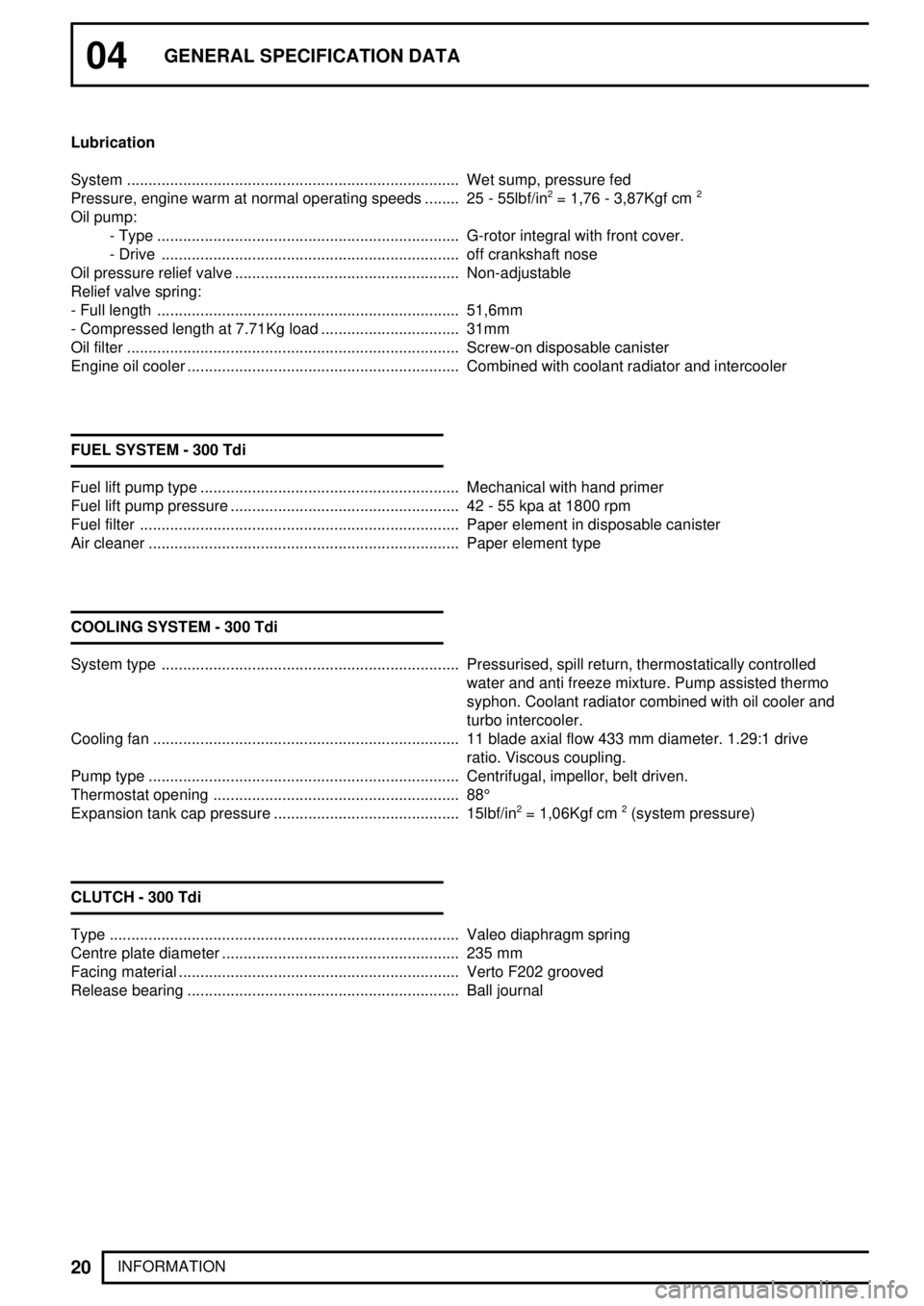

INFORMATION Lubrication

System Wet sump, pressure fed.............................................................................

Pressure, engine warm at normal operating speeds 25 - 55lbf/in

2= 1,76 - 3,87Kgf cm2........

Oil pump:

- Type G-rotor integral with front cover.......................................................................

- Drive off crankshaft nose.....................................................................

Oil pressure relief valve Non-adjustable....................................................

Relief valve spring:

- Full length 51,6mm......................................................................

- Compressed length at 7.71Kg load 31mm................................

Oil filter Screw-on disposable canister.............................................................................

Engine oil cooler Combined with coolant radiator and intercooler...............................................................

FUEL SYSTEM - 300 Tdi

Fuel lift pump type Mechanical with hand primer............................................................

Fuel lift pump pressure 42 - 55 kpa at 1800 rpm.....................................................

Fuel filter Paper element in disposable canister..........................................................................

Air cleaner Paper element type........................................................................

COOLING SYSTEM - 300 Tdi

System type Pressurised, spill return, thermostatically controlled.....................................................................

water and anti freeze mixture. Pump assisted thermo

syphon. Coolant radiator combined with oil cooler and

turbo intercooler.

Cooling fan 11 blade axial flow 433 mm diameter. 1.29:1 drive.......................................................................

ratio. Viscous coupling.

Pump type Centrifugal, impellor, belt driven.........................................................................

Thermostat opening 88° .........................................................

Expansion tank cap pressure 15lbf/in

2= 1,06Kgf cm2(system pressure) ...........................................

CLUTCH - 300 Tdi

Type Valeo diaphragm spring.................................................................................

Centre plate diameter 235 mm.......................................................

Facing material Verto F202 grooved.................................................................

Release bearing Ball journal...............................................................

Page 40 of 873

04GENERAL SPECIFICATION DATA

22

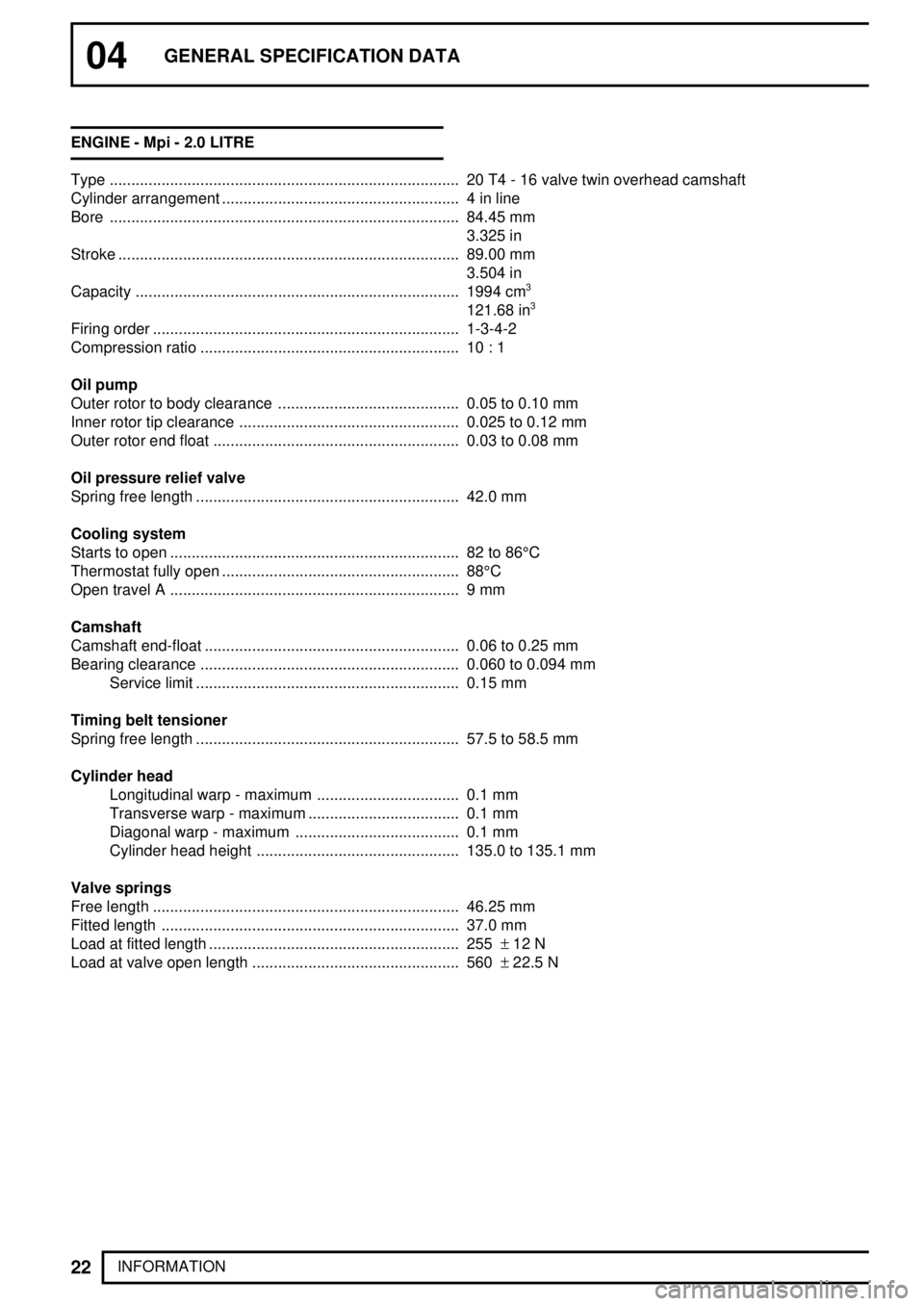

INFORMATION ENGINE - Mpi - 2.0 LITRE

Type 20 T4 - 16 valve twin overhead camshaft.................................................................................

Cylinder arrangement 4 in line.......................................................

Bore 84.45 mm.................................................................................

3.325 in

Stroke 89.00 mm...............................................................................

3.504 in

Capacity 1994 cm

3...........................................................................

121.68 in3

Firing order 1-3-4-2.......................................................................

Compression ratio 10 : 1............................................................

Oil pump

Outer rotor to body clearance 0.05 to 0.10 mm..........................................

Inner rotor tip clearance 0.025 to 0.12 mm...................................................

Outer rotor end float 0.03 to 0.08 mm.........................................................

Oil pressure relief valve

Spring free length 42.0 mm.............................................................

Cooling system

Starts to open 82 to 86°C ...................................................................

Thermostat fully open 88°C .......................................................

Open travel A 9 mm...................................................................

Camshaft

Camshaft end-float 0.06 to 0.25 mm...........................................................

Bearing clearance 0.060 to 0.094 mm............................................................

Service limit 0.15 mm.............................................................

Timing belt tensioner

Spring free length 57.5 to 58.5 mm.............................................................

Cylinder head

Longitudinal warp - maximum 0.1 mm.................................

Transverse warp - maximum 0.1 mm...................................

Diagonal warp - maximum 0.1 mm......................................

Cylinder head height 135.0 to 135.1 mm...............................................

Valve springs

Free length 46.25 mm.......................................................................

Fitted length 37.0 mm.....................................................................

Load at fitted length 255±12 N ..........................................................

Load at valve open length 560±22.5 N ................................................

Page 41 of 873

GENERAL SPECIFICATION DATA

23

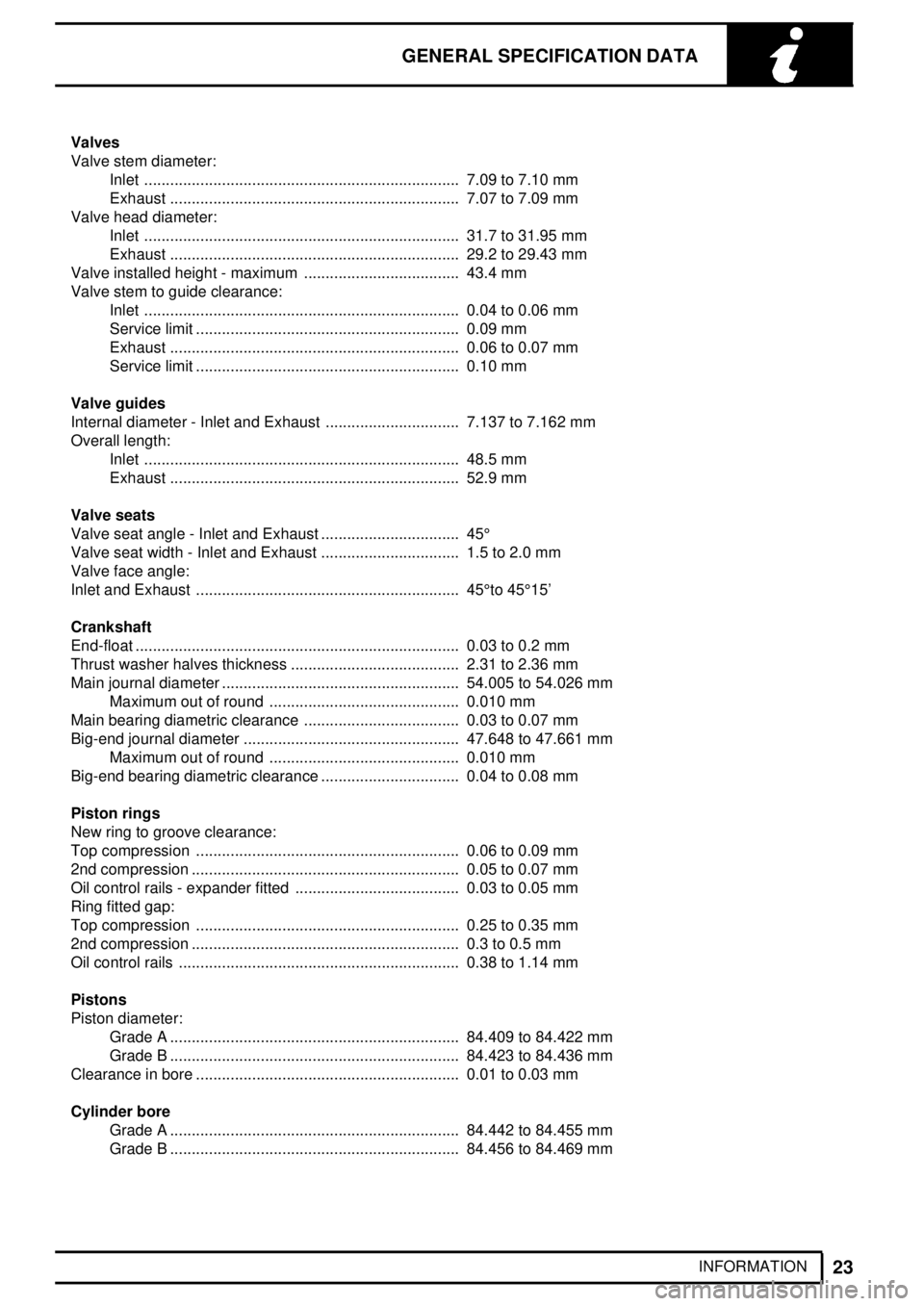

INFORMATION Valves

Valve stem diameter:

Inlet 7.09 to 7.10 mm.........................................................................

Exhaust 7.07 to 7.09 mm...................................................................

Valve head diameter:

Inlet 31.7 to 31.95 mm.........................................................................

Exhaust 29.2 to 29.43 mm...................................................................

Valve installed height - maximum 43.4 mm....................................

Valve stem to guide clearance:

Inlet 0.04 to 0.06 mm.........................................................................

Service limit 0.09 mm.............................................................

Exhaust 0.06 to 0.07 mm...................................................................

Service limit 0.10 mm.............................................................

Valve guides

Internal diameter - Inlet and Exhaust 7.137 to 7.162 mm...............................

Overall length:

Inlet 48.5 mm.........................................................................

Exhaust 52.9 mm...................................................................

Valve seats

Valve seat angle - Inlet and Exhaust 45° ................................

Valve seat width - Inlet and Exhaust 1.5 to 2.0 mm................................

Valve face angle:

Inlet and Exhaust 45°to 45°15' .............................................................

Crankshaft

End-float 0.03 to 0.2 mm...........................................................................

Thrust washer halves thickness 2.31 to 2.36 mm.......................................

Main journal diameter 54.005 to 54.026 mm.......................................................

Maximum out of round 0.010 mm............................................

Main bearing diametric clearance 0.03 to 0.07 mm....................................

Big-end journal diameter 47.648 to 47.661 mm..................................................

Maximum out of round 0.010 mm............................................

Big-end bearing diametric clearance 0.04 to 0.08 mm................................

Piston rings

New ring to groove clearance:

Top compression 0.06 to 0.09 mm.............................................................

2nd compression 0.05 to 0.07 mm..............................................................

Oil control rails - expander fitted 0.03 to 0.05 mm......................................

Ring fitted gap:

Top compression 0.25 to 0.35 mm.............................................................

2nd compression 0.3 to 0.5 mm..............................................................

Oil control rails 0.38 to 1.14 mm.................................................................

Pistons

Piston diameter:

Grade A 84.409 to 84.422 mm...................................................................

Grade B 84.423 to 84.436 mm...................................................................

Clearance in bore 0.01 to 0.03 mm.............................................................

Cylinder bore

Grade A 84.442 to 84.455 mm...................................................................

Grade B 84.456 to 84.469 mm...................................................................

Page 44 of 873

ENGINE TUNING DATA

1

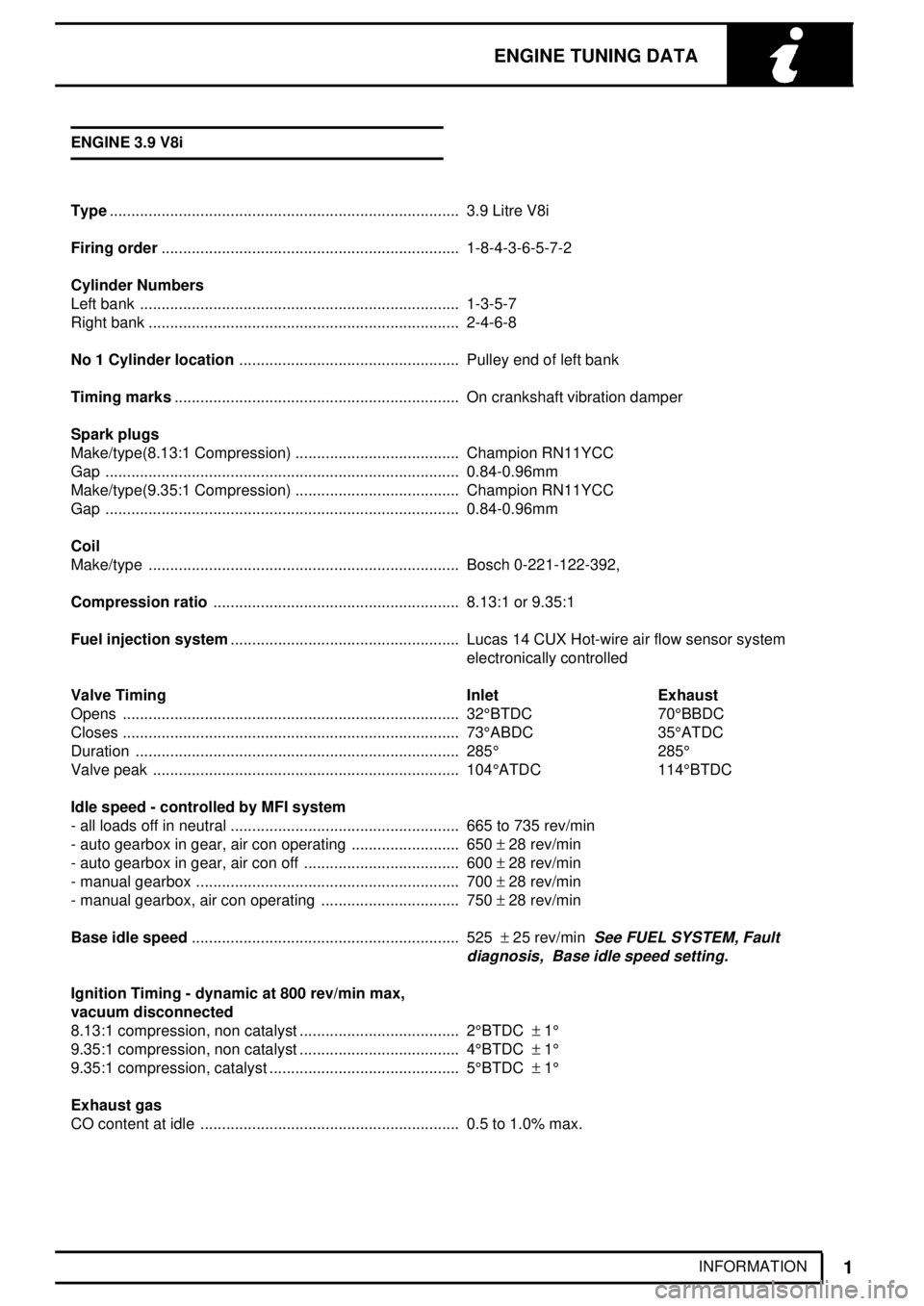

INFORMATION ENGINE 3.9 V8i

Type3.9 Litre V8i .................................................................................

Firing order1-8-4-3-6-5-7-2 .....................................................................

Cylinder Numbers

Left bank 1-3-5-7..........................................................................

Right bank 2-4-6-8........................................................................

No 1 Cylinder locationPulley end of left bank ...................................................

Timing marksOn crankshaft vibration damper ..................................................................

Spark plugs

Make/type(8.13:1 Compression) Champion RN11YCC......................................

Gap 0.84-0.96mm..................................................................................

Make/type(9.35:1 Compression) Champion RN11YCC......................................

Gap 0.84-0.96mm..................................................................................

Coil

Make/type Bosch 0-221-122-392,........................................................................

Compression ratio8.13:1 or 9.35:1 .........................................................

Fuel injection systemLucas 14 CUX Hot-wire air flow sensor system .....................................................

electronically controlled

Valve Timing Inlet Exhaust

Opens 32°BTDC .............................................................................. 70°BBDC

Closes 73°ABDC .............................................................................. 35°ATDC

Duration 285° ........................................................................... 285°

Valve peak 104°ATDC ....................................................................... 114°BTDC

Idle speed - controlled by MFI system

- all loads off in neutral 665 to 735 rev/min.....................................................

- auto gearbox in gear, air con operating 650±28 rev/min .........................

- auto gearbox in gear, air con off 600±28 rev/min ....................................

- manual gearbox 700±28 rev/min .............................................................

- manual gearbox, air con operating 750±28 rev/min ................................

Base idle speed525±25 rev/min

See FUEL SYSTEM, Fault..............................................................

diagnosis, Base idle speed setting.

Ignition Timing - dynamic at 800 rev/min max,

vacuum disconnected

8.13:1 compression, non catalyst 2°BTDC±1° .....................................

9.35:1 compression, non catalyst 4°BTDC±1° .....................................

9.35:1 compression, catalyst 5°BTDC±1° ............................................

Exhaust gas

CO content at idle 0.5 to 1.0% max.............................................................

Page 46 of 873

ENGINE TUNING DATA

3

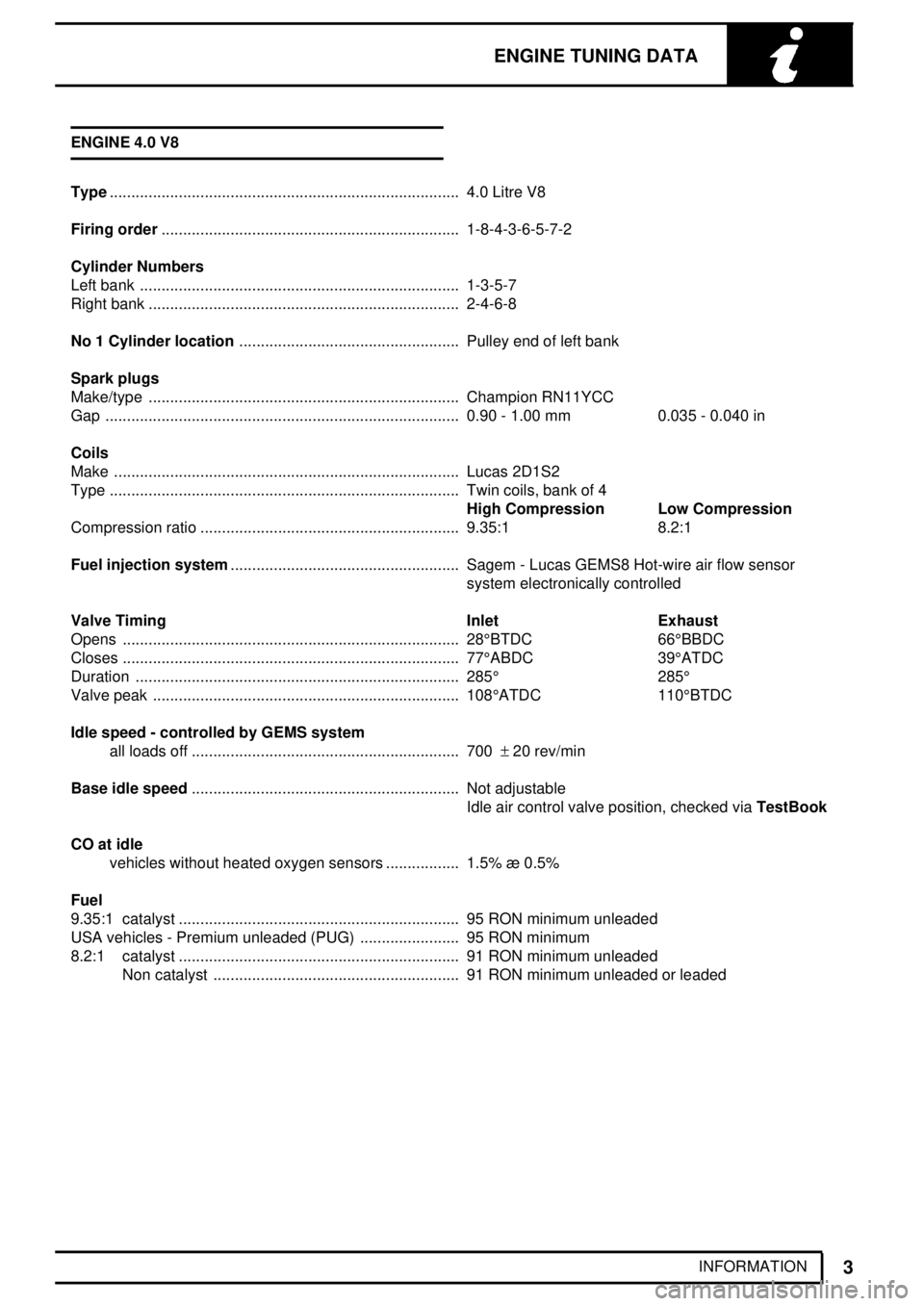

INFORMATION ENGINE 4.0 V8

Type4.0 Litre V8 .................................................................................

Firing order1-8-4-3-6-5-7-2 .....................................................................

Cylinder Numbers

Left bank 1-3-5-7..........................................................................

Right bank 2-4-6-8........................................................................

No 1 Cylinder locationPulley end of left bank ...................................................

Spark plugs

Make/type Champion RN11YCC........................................................................

Gap 0.90 - 1.00 mm.................................................................................. 0.035 - 0.040 in

Coils

Make Lucas 2D1S2................................................................................

Type Twin coils, bank of 4.................................................................................

High Compression Low Compression

Compression ratio 9.35:1............................................................ 8.2:1

Fuel injection systemSagem - Lucas GEMS8 Hot-wire air flow sensor .....................................................

system electronically controlled

Valve Timing Inlet Exhaust

Opens 28°BTDC .............................................................................. 66°BBDC

Closes 77°ABDC .............................................................................. 39°ATDC

Duration 285° ........................................................................... 285°

Valve peak 108°ATDC ....................................................................... 110°BTDC

Idle speed - controlled by GEMS system

all loads off 700±20 rev/min ..............................................................

Base idle speedNot adjustable ..............................................................

Idle air control valve position, checked viaTestBook

CO at idle

vehicles without heated oxygen sensors 1.5% ñ 0.5%.................

Fuel

9.35:1 catalyst 95 RON minimum unleaded.................................................................

USA vehicles - Premium unleaded (PUG) 95 RON minimum.......................

8.2:1 catalyst 91 RON minimum unleaded.................................................................

Non catalyst 91 RON minimum unleaded or leaded.........................................................

Page 49 of 873

05ENGINE TUNING DATA

6

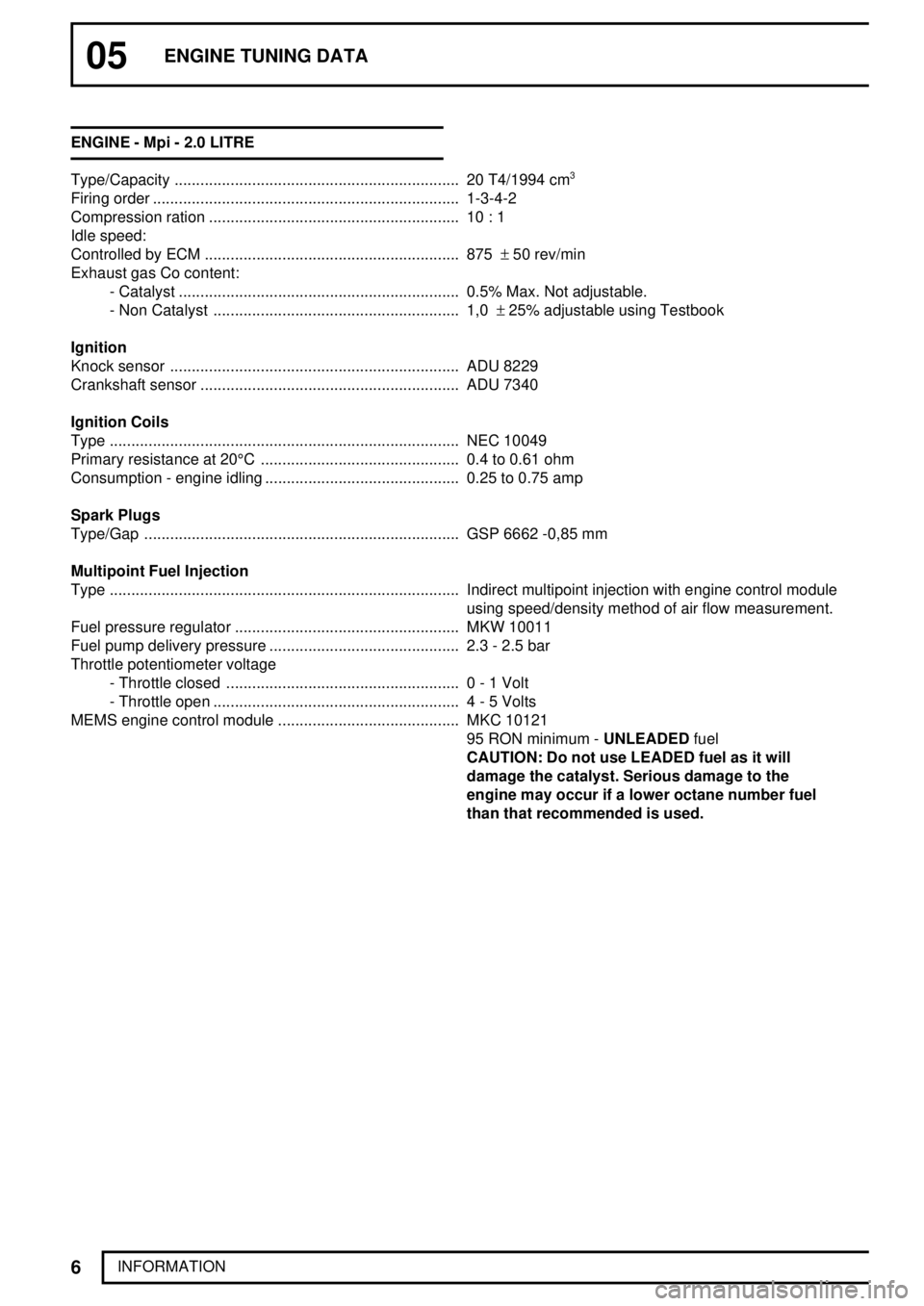

INFORMATION ENGINE - Mpi - 2.0 LITRE

Type/Capacity 20 T4/1994 cm

3..................................................................

Firing order 1-3-4-2.......................................................................

Compression ration 10 : 1..........................................................

Idle speed:

Controlled by ECM 875±50 rev/min ...........................................................

Exhaust gas Co content:

- Catalyst 0.5% Max. Not adjustable..................................................................

- Non Catalyst 1,0±25% adjustable using Testbook .........................................................

Ignition

Knock sensor ADU 8229...................................................................

Crankshaft sensor ADU 7340............................................................

Ignition Coils

Type NEC 10049.................................................................................

Primary resistance at 20°C 0.4 to 0.61 ohm..............................................

Consumption - engine idling 0.25 to 0.75 amp.............................................

Spark Plugs

Type/Gap GSP 6662 -0,85 mm.........................................................................

Multipoint Fuel Injection

Type Indirect multipoint injection with engine control module.................................................................................

using speed/density method of air flow measurement.

Fuel pressure regulator MKW 10011....................................................

Fuel pump delivery pressure 2.3 - 2.5 bar............................................

Throttle potentiometer voltage

- Throttle closed 0 - 1 Volt......................................................

- Throttle open 4 - 5 Volts.........................................................

MEMS engine control module MKC 10121..........................................

95 RON minimum -UNLEADEDfuel

CAUTION: Do not use LEADED fuel as it will

damage the catalyst. Serious damage to the

engine may occur if a lower octane number fuel

than that recommended is used.

Page 51 of 873

07GENERAL FITTING REMINDERS

2

INFORMATION PREPARATION

1.Before removing a component, clean it and its

surrounding areas as thoroughly as possible.

2.Blank off any openings exposed by component

removal, using greaseproof paper and masking

tape.

3.Immediately seal fuel, oil or hydraulic lines when

separated, using plastic caps or plugs, to

prevent loss of fluid and entry of dirt.

4.Close open ends of oilways, exposed by

component removal, with tapered hardwood

plugs or readily visible plastic plugs.

5.Immediately a component is removed, place it in

a suitable container; use a separate container for

each component and its associated parts.

6.Before dismantling a component, clean it

thoroughly with a recommended cleaning agent;

check that agent is suitable for all materials of

component.

7.Clean bench and provide marking materials,

labels, containers and locking wire before

dismantling a component.

DISMANTLING

1.Observe scrupulous cleanliness when

dismantling components, particularly when

brake, fuel or hydraulic system parts are being

worked on. A particle of dirt or a cloth fragment

could cause a dangerous malfunction if trapped

in these systems.

2.Blow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

O-rings used for sealing are correctly replaced or

renewed, if disturbed.

3.Use marking ink to identify mating parts, to

ensure correct reassembly. If a centre punch or

scriber is used they may initiate cracks or

distortion of components.

4.Wire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

5.Wire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

6.Do not discard a part due for renewal until after

comparing it with a new part, to ensure that its

correct replacement has been obtained.INSPECTION-GENERAL

1.Never inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an incipient

failure.

2.When a component is to be checked

dimensionally against figures quoted for it, use

correct equipment (surface plates, micrometers,

dial gauges, etc.) in serviceable condition.

Makeshift checking equipment can be

dangerous.

3.Reject a component if its dimensions are outside

limits quoted, or if damage is apparent. A part

may, however, be refitted if its critical dimension

is exactly limit size, and is otherwise satisfactory.

4.Use 'Plastigauge' 12 Type PG-1 for checking

bearing surface clearances. Directions for its

use, and a scale giving bearing clearances in

0,0025 mm steps are provided with it.

Page 53 of 873

07GENERAL FITTING REMINDERS

4

INFORMATION OIL SEALS

NOTE: Ensure that the seal running track

is free from pits, scores, corrosion and

general damage prior to fitting

replacement seal.

1.Always fit new oil seals when rebuilding an

assembly.

2.Carefully examine seal before fitting to ensure

that it is clean and undamaged.

3.Coat the sealing lips with clean grease; pack

dust excluder seals with grease, and heavily

grease duplex seals in cavity between sealing

lips.

4.Ensure that seal spring, if provided, is correctly

fitted.

5.Place lip of seal towards fluid to be sealed and

slide into position on shaft, using fitting sleeve

when possible to protect sealing lip from damage

by sharp corners, threads or splines. If fitting

sleeve is not available, use plastic tube or tape

to prevent damage to sealing lip.

6.Grease outside diameter of seal, place square to

housing recess and press into position, using

great care and if possible a 'bell piece' to ensure

that seal is not tilted. (In some cases it may be

preferable to fit seal to housing before fitting to

shaft). Never let weight of unsupported shaft rest

in seal.

7.If correct service tool is not available, use a

suitable drift approximately 0.4mm (0.015 in)

smaller than outside diameter of seal. Use a

hammerVERY GENTLYon drift if a press is not

suitable.

8.Press or drift seal in to depth of housing if

housing is shouldered, or flush with face of

housing where no shoulder is provided. Ensure

that the seal does not enter the housing in a

tilted position.

NOTE: Most cases of failure or leakage of

oil seals are due to careless fitting, and

resulting damage to both seals and

sealing surfaces. Care in fitting is essential if

good results are to be obtained. NEVER use a seal

which has been improperly stored or handled,

such as hung on a hook or nail.

Page 54 of 873

GENERAL FITTING REMINDERS

5

INFORMATION JOINTS AND JOINT FACES

1.Always use correct gaskets where they are

specified.

2.Use jointing compound only when

recommended. Otherwise fit joints dry.

3.When jointing compound is used, apply in a thin

uniform film to metal surfaces; take great care to

prevent it from entering oilways, pipes or blind

tapped holes.

4.Remove all traces of old jointing materials prior

to reassembly. Do not use a tool which could

damage joint faces.

5.Inspect joint faces for scratches or burrs and

remove with a fine file or oil stone; do not allow

removed material or dirt to enter tapped holes or

enclosed parts.

6.Blow out any pipes, channels or crevices with

compressed air, fit new 'O' rings or seals

displaced by air blast.FLEXIBLE HYDRAULIC PIPES, HOSES

1.Before removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

2.Obtain appropriate plugs or caps before

detaching hose end fittings, so that ports can be

immediately covered to exclude dirt.

3.Clean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any hose found faulty.

4.When refitting hose, ensure that no unnecessary

bends are introduced, and that hose is not

twisted before or during tightening of union nuts.

5.Containers for hydraulic fluid must be kept

absolutely clean.

6.Do not store brake fluid in an unsealed

container. It will absorb water, and fluid in this

condition would be dangerous to use due to a

lowering of its boiling point.

7.Do not allow brake fluid to be contaminated with

mineral oil, or use a container which has

previously contained mineral oil.

8.Do not re-use brake fluid bled from system.

9.Always use clean brake fluid to clean hydraulic

components.

10.Fit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of dirt.

11.Absolute cleanliness must be observed with

hydraulic components at all times.

12.After any work on hydraulic systems, inspect

carefully for leaks underneath the vehicle while a

second operator applies maximum pressure to

the brakes (engine running) and operates the

steering.