oil LAND ROVER DISCOVERY 1995 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 99 of 873

12ENGINE

18

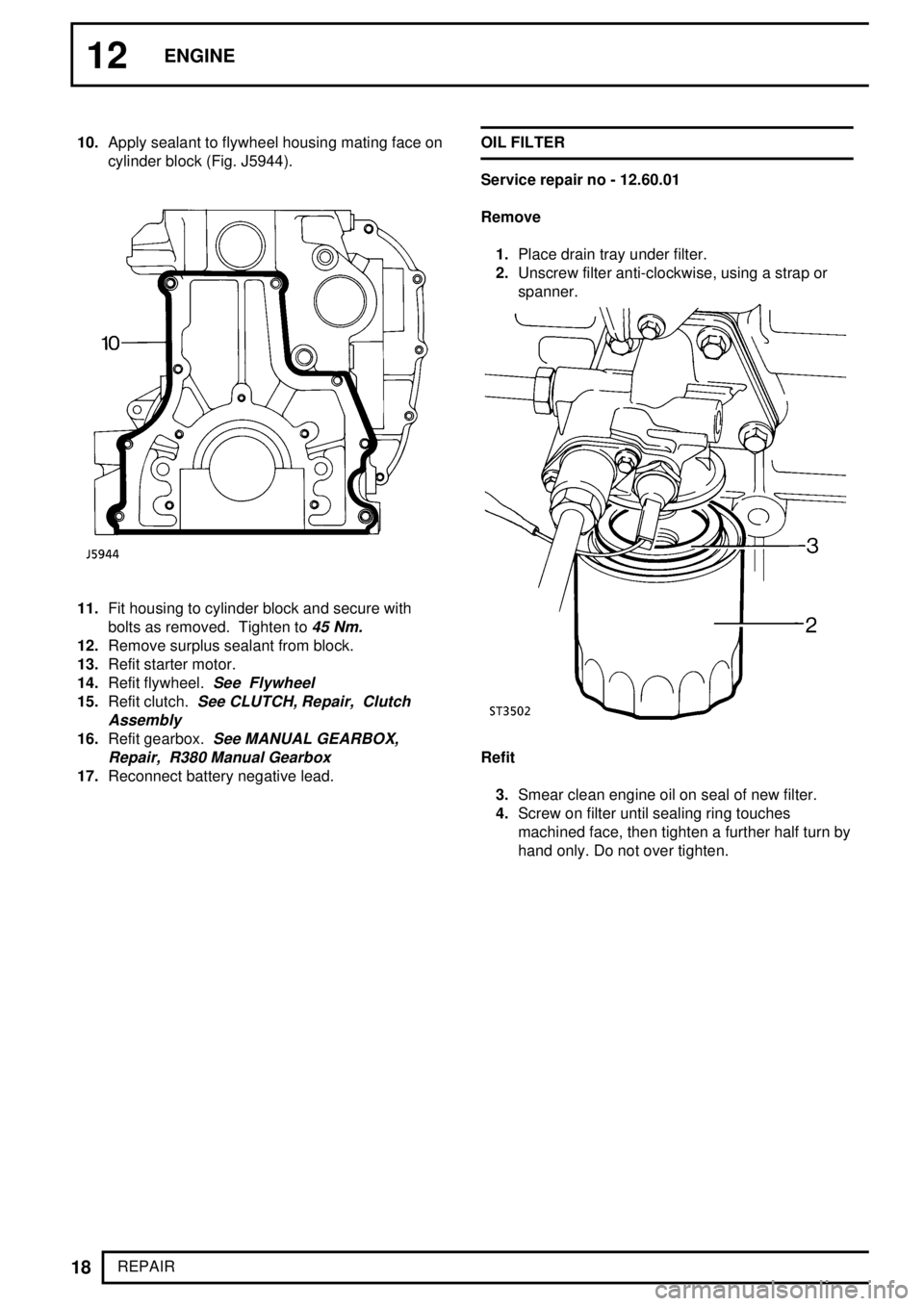

REPAIR 10.Apply sealant to flywheel housing mating face on

cylinder block (Fig. J5944).

11.Fit housing to cylinder block and secure with

bolts as removed. Tighten to

45 Nm.

12.Remove surplus sealant from block.

13.Refit starter motor.

14.Refit flywheel.

See Flywheel

15.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

16.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

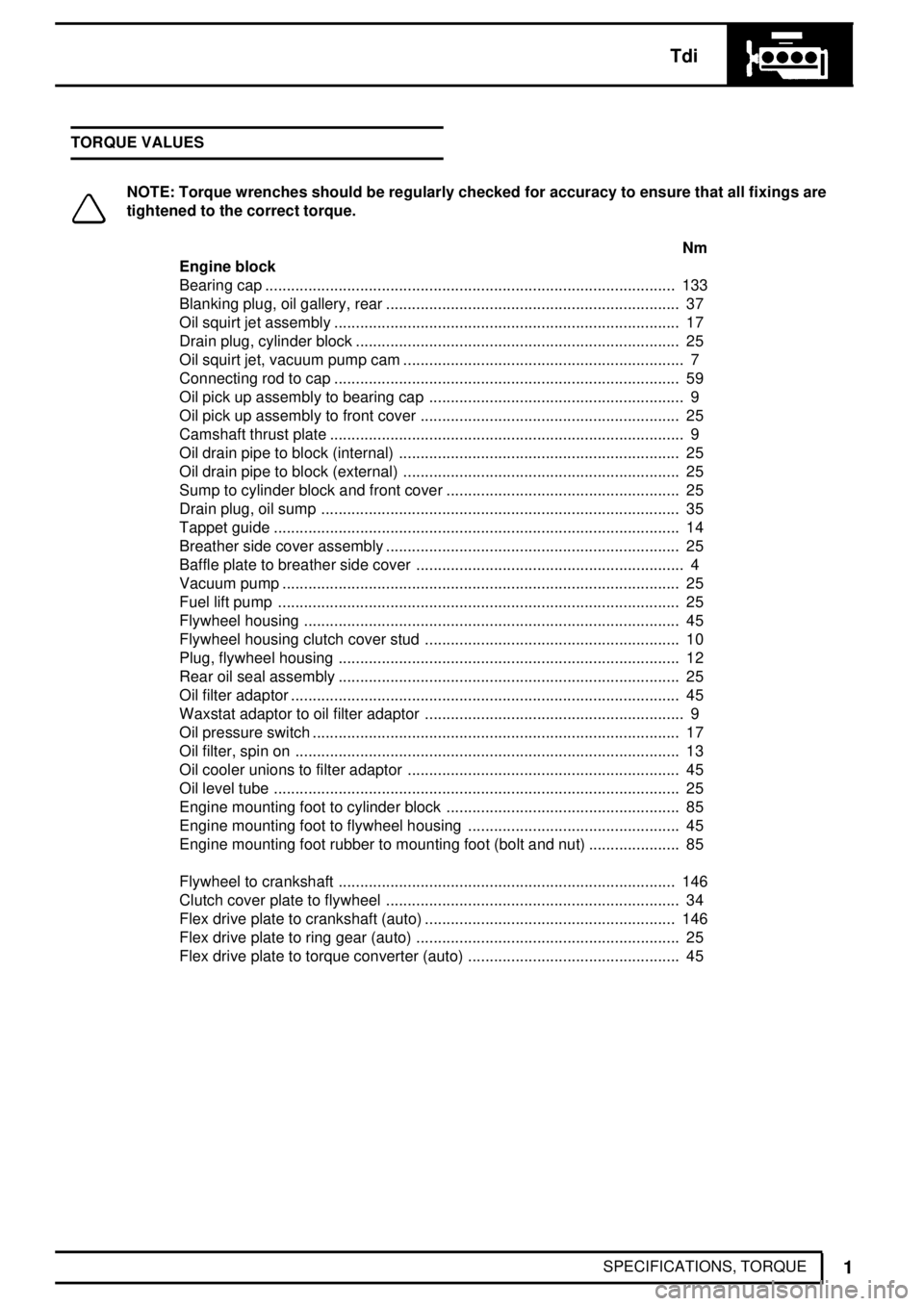

17.Reconnect battery negative lead.OIL FILTER

Service repair no - 12.60.01

Remove

1.Place drain tray under filter.

2.Unscrew filter anti-clockwise, using a strap or

spanner.

Refit

3.Smear clean engine oil on seal of new filter.

4.Screw on filter until sealing ring touches

machined face, then tighten a further half turn by

hand only. Do not over tighten.

Page 100 of 873

Tdi

19

REPAIR OIL TEMPERATURE CONTROL VALVE

Service repair no - 12.60.69

Remove

1.Disconnect oil cooler pipes.

2.Remove two bolts and carefully withdraw

thermostat extension housing (1) complete with

O ring seal (2), thermostat (3), two washers (4)

and spring (5).

3.Clean adaptor housing.

4.Inspect all parts and renew as necessary.

Refit

5.Fit thermostat to extension housing ensuring pin

locates in hole.

6.Fit two washers and spring to thermostat.

7.Fit a new 'O' ring to extension housing.

8.Insert spring into adaptor and secure extension

housing to adaptor with bolts. Tighten to

9 Nm.

OIL FILTER HEAD GASKET

Service repair no - 12.60.03

Renew

1.Disconnect oil cooler pipes.

2.Disconnect pressure switch lead.

3.Remove securing bolts and withdraw head

complete with gasket.

4.Clean mating faces.

5.Refit head with new gasket.

6.Secure with bolts. Tighten to

45 Nm.

7.Refit pipes and reconnect pressure switch.

Page 103 of 873

12ENGINE

22

REPAIR

NOTE: Cylinder head retaining bolts can

be used up to a maximum of five times.

34.Lubricate threads of bolts with light oil and fit to

positions illustrated.

Bolt sizes:

M10 x 117mm locations 3, 5, 12, and 13.

M12 x 140mm locations 1, 2, 7, 8, 9, 10, 15, 16, 17,

and 18.

M12 x 100mm locations 4, 6, 11, 14.

35.Tighten bolts so that underside of heads just

make contact with cylinder head.

36.Following the sequence illustrated tighten all

bolts to

40 Nm.

37.Attach degree disc special tool LRT-12-007 to a

power bar.

38.Make a suitable pointer from welding rod and

attach to a bolt screwed into a rocker shaft

securing bolt hole.

39.Tighten all bolts through 60°strictly in sequence

illustrated.

40.Repeat 60°tightening procedure, again strictly in

sequence illustrated.

41.Tighten the ten longer bolts (M12 x 140mm) a

further 20°, again following the sequence

illustrated.

NOTE: Repositioning of the pointer will be

necessary to reach all bolts, the pointer

can be fitted to the rocker shaft securing

studs using two nuts.

CAUTION: The double tightening

procedure must be carried out, on no

account should tightening be performed in

one operation, otherwise damage to the cylinder

head may occur.

42.Fit valve stem caps.

43.Fit push rods to locations from which they were

removed.

44.Fit rocker shaft assembly evenly tightening

securing nuts and bolts to correct torque.

45.Fit rocker cover ensuring oil seal is satisfactory

for continued use.

NOTE: Rocker cover seals can be re-used

up to a maximum of five times.

46.Secure rocker cover with special seal washers

and nuts tightened to correct torque.

47.Refit remainder of items by reversing operations

1 to 22 tightening securing bolts to correct torque

where applicable.

Page 105 of 873

Tdi

1

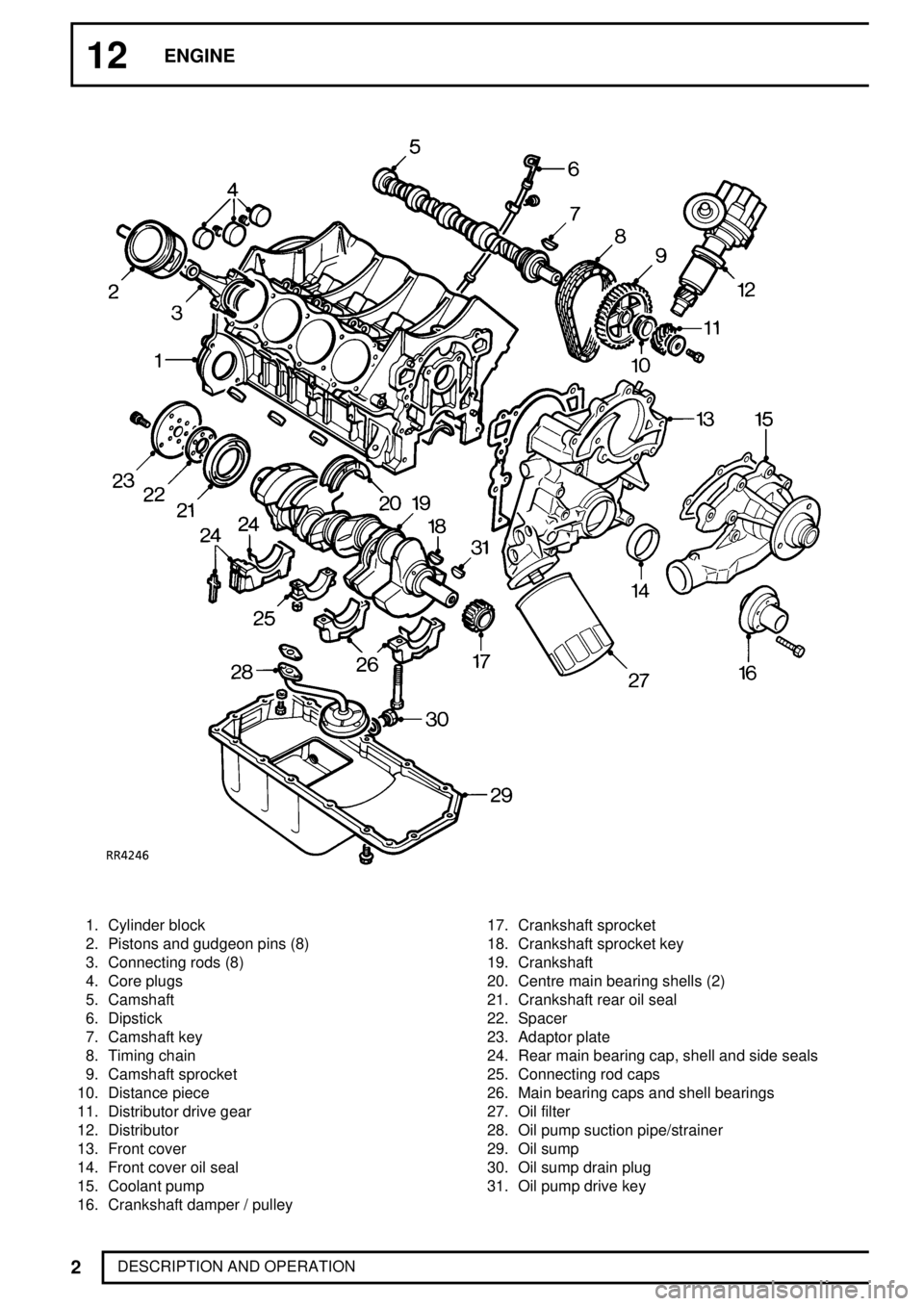

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Engine block

Bearing cap 133...............................................................................................

Blanking plug, oil gallery, rear 37....................................................................

Oil squirt jet assembly 17................................................................................

Drain plug, cylinder block 25...........................................................................

Oil squirt jet, vacuum pump cam 7.................................................................

Connecting rod to cap 59................................................................................

Oil pick up assembly to bearing cap 9...........................................................

Oil pick up assembly to front cover 25............................................................

Camshaft thrust plate 9..................................................................................

Oil drain pipe to block (internal) 25.................................................................

Oil drain pipe to block (external) 25................................................................

Sump to cylinder block and front cover 25......................................................

Drain plug, oil sump 35...................................................................................

Tappet guide 14..............................................................................................

Breather side cover assembly 25....................................................................

Baffle plate to breather side cover 4..............................................................

Vacuum pump 25............................................................................................

Fuel lift pump 25.............................................................................................

Flywheel housing 45.......................................................................................

Flywheel housing clutch cover stud 10...........................................................

Plug, flywheel housing 12...............................................................................

Rear oil seal assembly 25...............................................................................

Oil filter adaptor 45..........................................................................................

Waxstat adaptor to oil filter adaptor 9............................................................

Oil pressure switch 17.....................................................................................

Oil filter, spin on 13.........................................................................................

Oil cooler unions to filter adaptor 45...............................................................

Oil level tube 25..............................................................................................

Engine mounting foot to cylinder block 85......................................................

Engine mounting foot to flywheel housing 45.................................................

Engine mounting foot rubber to mounting foot (bolt and nut) 85.....................

Flywheel to crankshaft 146..............................................................................

Clutch cover plate to flywheel 34....................................................................

Flex drive plate to crankshaft (auto) 146..........................................................

Flex drive plate to ring gear (auto) 25.............................................................

Flex drive plate to torque converter (auto) 45.................................................

Page 107 of 873

Tdi

3

SPECIFICATIONS, TORQUE Turbo charger oil drain adaptor to block 42....................................................

Oil drain pipe to turbocharger 25....................................................................

Turbocharger oil drain pipe to adaptor 38.......................................................

Turbocharger oil feed pipe adaptor to block 25...............................................

Turbocharger oil feed pipe to adaptor 25........................................................

Oil feed pipe to turbocharger 19.....................................................................

Turbocharger to cylinder head (stud) 10.........................................................

Turbocharger to cylinder head (nut) 45...........................................................

Turbocharger to blanking plate 25..................................................................

Turbocharger to EGR valve 25.......................................................................

EGR delivery tube to valve 25........................................................................

EGR delivery tube to mixing tube 25..............................................................

Fuel lift pump to filter (union) 15.....................................................................

Fuel filter from lift pump (banjo bolt) 33...........................................................

Fuel filter to fuel injection pump (banjo bolt) 33..............................................

Fuel injection pump from fuel filter (banjo bolt) 25..........................................

Injector pipes to injectors and fuel injection pump 29.....................................

Spill rail to injectors (banjo bolt) 10.................................................................

Spill rail to injection pump (banjo bolt) 25.......................................................

Boost pipe injection pump (banjo bolt) 10.......................................................

Plug, rear of injection pump 29.......................................................................

PAS pump to mounting plate 25.....................................................................

PAS pump mounting plate to auxiliaries mounting bracket 25........................

PAS pump pulley to hub 25............................................................................

Generator to auxiliaries mounting bracket 25.................................................

Starter motor (bolt and nut) 45........................................................................

Tachometer electrical connection 4...............................................................

Air conditioning compressor

Compressor mounting bracket to front cover 45.............................................

Compressor to mounting bracket (stud) 8......................................................

Compressor to mounting bracket (nut) 25......................................................

Belt tensioner pulley to tensioner arm 45........................................................

Belt tensioner assembly to front cover plate 25..............................................

Idler pulley to front cover plate 45...................................................................

Compressor belt guard (nut) 25......................................................................

Sensors to water outlet elbow (air/con) 25......................................................

Blanking plug, water outlet elbow (air/con) 25................................................

Generator mounting bracket to front cover 45................................................

Generator to mounting bracket 85..................................................................

Generator pulley to hub 95.............................................................................

Generator belt guard 25..................................................................................

Page 109 of 873

V8i

1

DESCRIPTION AND OPERATION DESCRIPTION

The V8i engine has cast aluminium cylinder heads

and cylinder block. The two banks of steel cylinder

liners which are pressed down to stops in the block,

are set at 90°to one another. The three ringed

aluminium pistons transmit the power through the

connecting rods to a cast iron five bearing crankshaft,

which drives the centrally located camshaft via a

duplex type chain.

The electronic ignition distributor is driven by a gear

off the front of the camshaft and the lubrication oil

pump is driven by a gear off the front of the

crankshaft. The overhead inlet and exhaust valves are

operated by rocker shafts, pushrods and self adjusting

hydraulic tappets.

Multiport fuel injection ensures that engine

performance, economy and exhaust emissions are

automatically correct for the demands of highway and

off road operation.

Page 110 of 873

12ENGINE

2

DESCRIPTION AND OPERATION

1. Cylinder block

2. Pistons and gudgeon pins (8)

3. Connecting rods (8)

4. Core plugs

5. Camshaft

6. Dipstick

7. Camshaft key

8. Timing chain

9. Camshaft sprocket

10. Distance piece

11. Distributor drive gear

12. Distributor

13. Front cover

14. Front cover oil seal

15. Coolant pump

16. Crankshaft damper / pulley17. Crankshaft sprocket

18. Crankshaft sprocket key

19. Crankshaft

20. Centre main bearing shells (2)

21. Crankshaft rear oil seal

22. Spacer

23. Adaptor plate

24. Rear main bearing cap, shell and side seals

25. Connecting rod caps

26. Main bearing caps and shell bearings

27. Oil filter

28. Oil pump suction pipe/strainer

29. Oil sump

30. Oil sump drain plug

31. Oil pump drive key

Page 111 of 873

V8i

3

DESCRIPTION AND OPERATION

1. Cylinder heads (2)

2. Rocker covers (2)

3. PCV filter

4. Rocker shafts (2)

5. Hydraulic tappets (8)

6. Pushrods (8)

7. Rocker brackets (8)

8. Rocker arms (4) left and (4) right

9. Rocker shaft springs (6)

10. Inlet manifold

11. Plenum chamber lower

12. Ram pipes (8)13. Plenum chamber upper

14. PCV air intake filter

15. Oil filler

16. Thermostat

17. Thermostat cover

18. Inlet valve seal, spring, cap and collets (8)

19. Exhaust valve seal, spring, cap and collets (8)

20. Inlet valve and seat (8)

21. Exhaust valve and seat (8)

22. Inlet manifold gasket and seals

23. Cylinder head gaskets (2)

24. Valve guides (16)

Page 112 of 873

12ENGINE

4

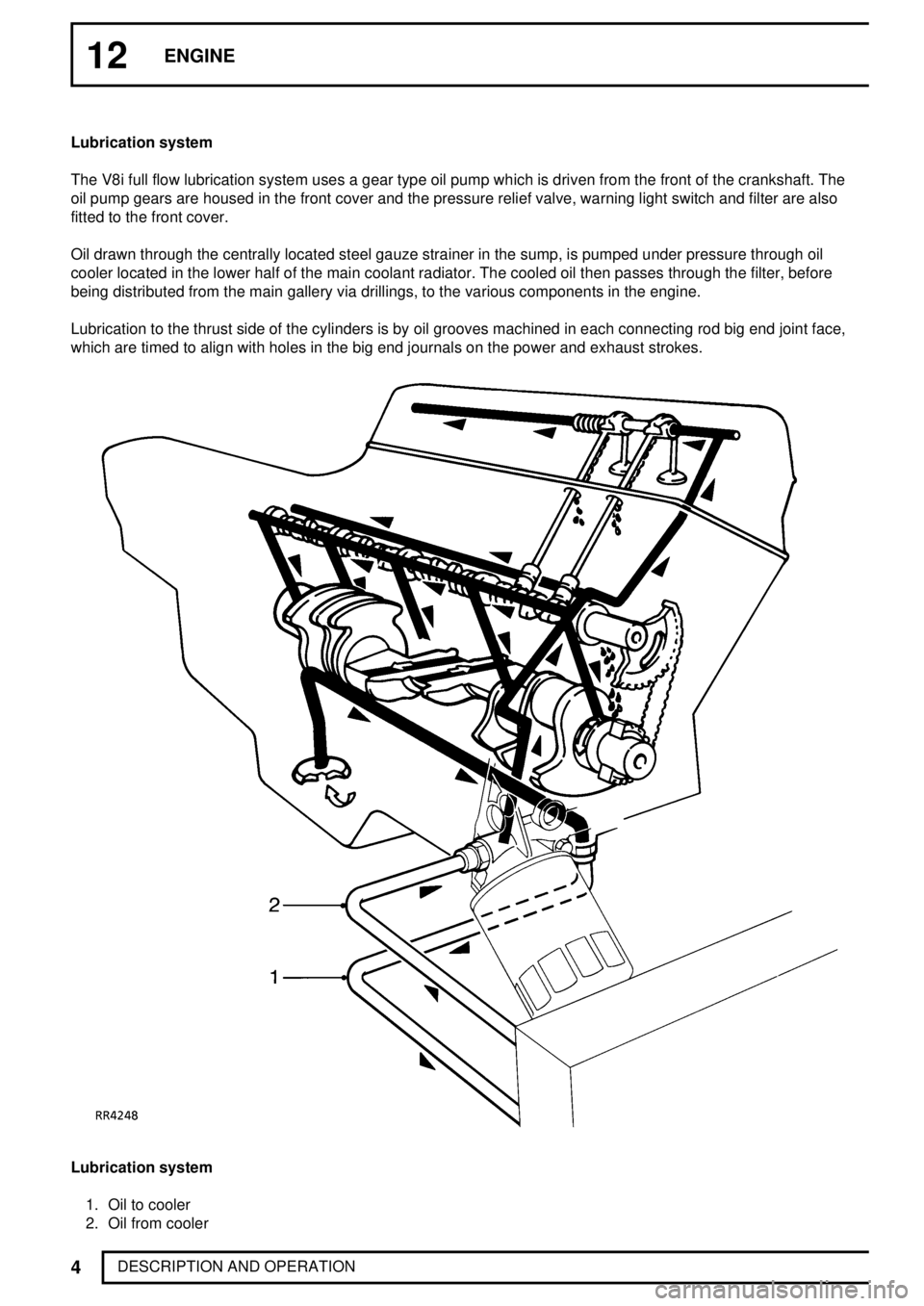

DESCRIPTION AND OPERATION Lubrication system

The V8i full flow lubrication system uses a gear type oil pump which is driven from the front of the crankshaft. The

oil pump gears are housed in the front cover and the pressure relief valve, warning light switch and filter are also

fitted to the front cover.

Oil drawn through the centrally located steel gauze strainer in the sump, is pumped under pressure through oil

cooler located in the lower half of the main coolant radiator. The cooled oil then passes through the filter, before

being distributed from the main gallery via drillings, to the various components in the engine.

Lubrication to the thrust side of the cylinders is by oil grooves machined in each connecting rod big end joint face,

which are timed to align with holes in the big end journals on the power and exhaust strokes.

Lubrication system

1. Oil to cooler

2. Oil from cooler

Page 113 of 873

V8i

5

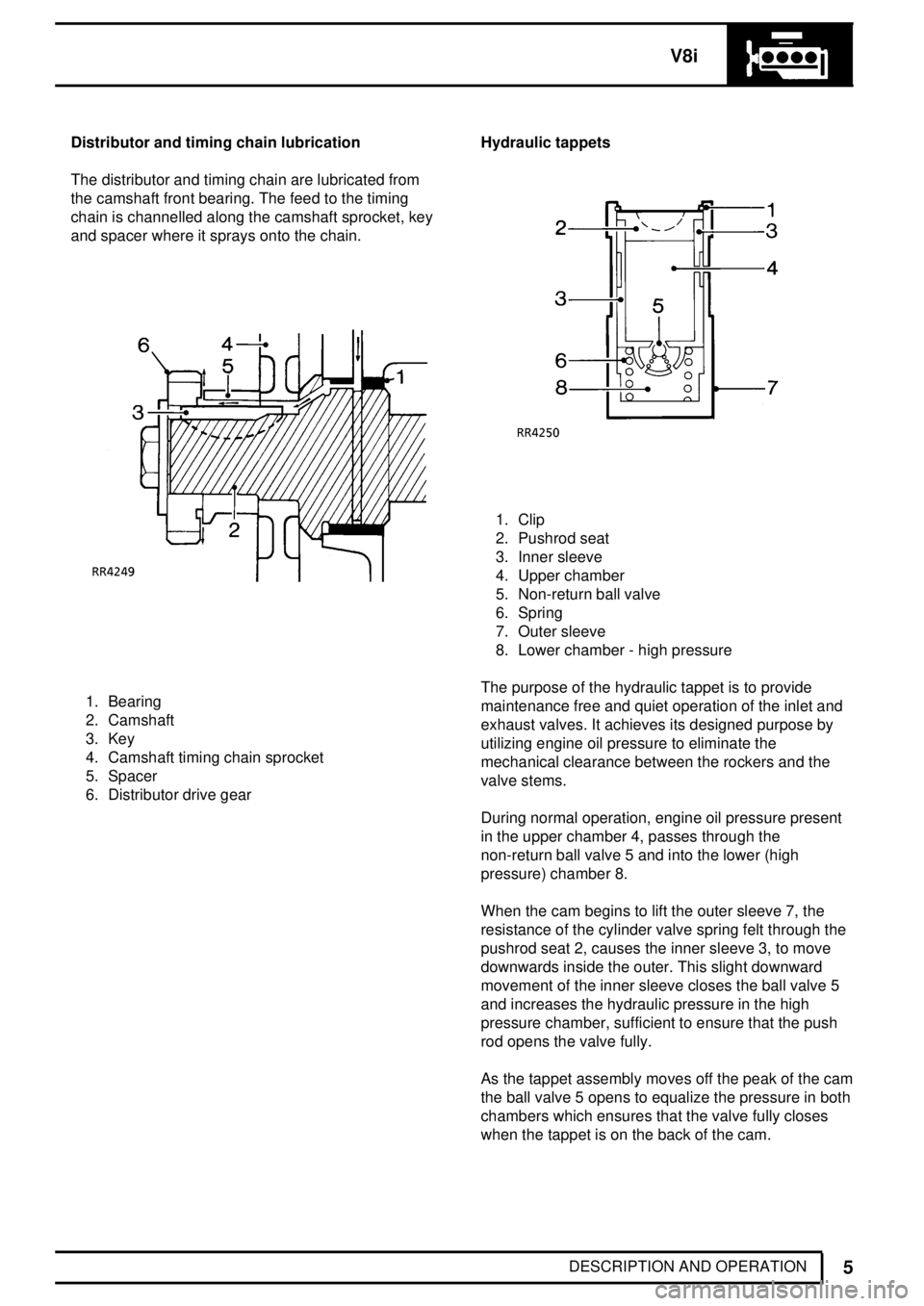

DESCRIPTION AND OPERATION Distributor and timing chain lubrication

The distributor and timing chain are lubricated from

the camshaft front bearing. The feed to the timing

chain is channelled along the camshaft sprocket, key

and spacer where it sprays onto the chain.

1. Bearing

2. Camshaft

3. Key

4. Camshaft timing chain sprocket

5. Spacer

6. Distributor drive gearHydraulic tappets

1. Clip

2. Pushrod seat

3. Inner sleeve

4. Upper chamber

5. Non-return ball valve

6. Spring

7. Outer sleeve

8. Lower chamber - high pressure

The purpose of the hydraulic tappet is to provide

maintenance free and quiet operation of the inlet and

exhaust valves. It achieves its designed purpose by

utilizing engine oil pressure to eliminate the

mechanical clearance between the rockers and the

valve stems.

During normal operation, engine oil pressure present

in the upper chamber 4, passes through the

non-return ball valve 5 and into the lower (high

pressure) chamber 8.

When the cam begins to lift the outer sleeve 7, the

resistance of the cylinder valve spring felt through the

pushrod seat 2, causes the inner sleeve 3, to move

downwards inside the outer. This slight downward

movement of the inner sleeve closes the ball valve 5

and increases the hydraulic pressure in the high

pressure chamber, sufficient to ensure that the push

rod opens the valve fully.

As the tappet assembly moves off the peak of the cam

the ball valve 5 opens to equalize the pressure in both

chambers which ensures that the valve fully closes

when the tappet is on the back of the cam.