tow LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 511 of 873

FRONT AXLE AND FINAL DRIVE

9

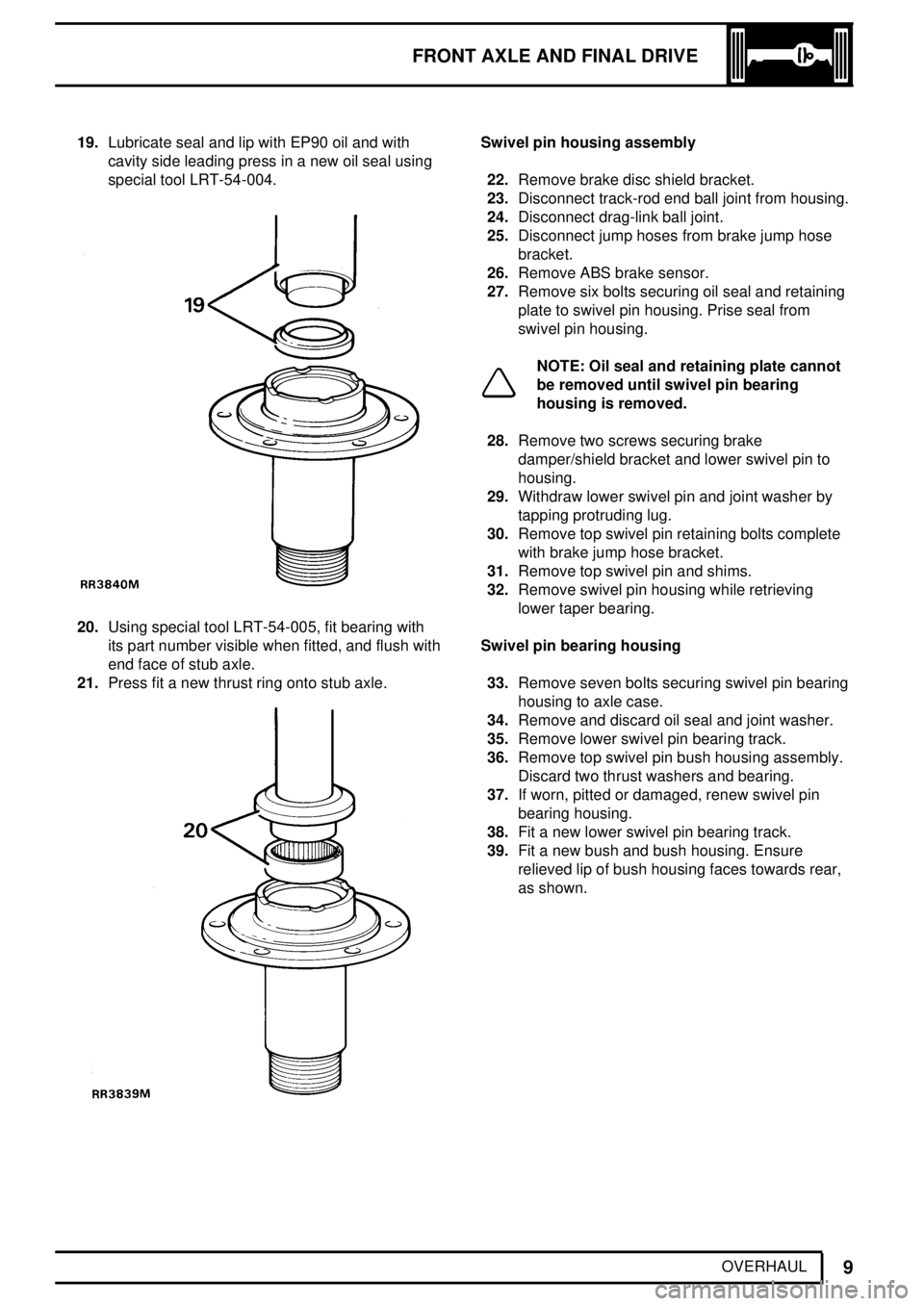

OVERHAUL 19.Lubricate seal and lip with EP90 oil and with

cavity side leading press in a new oil seal using

special tool LRT-54-004.

20.Using special tool LRT-54-005, fit bearing with

its part number visible when fitted, and flush with

end face of stub axle.

21.Press fit a new thrust ring onto stub axle.

Swivel pin housing assembly

22.Remove brake disc shield bracket.

23.Disconnect track-rod end ball joint from housing.

24.Disconnect drag-link ball joint.

25.Disconnect jump hoses from brake jump hose

bracket.

26.Remove ABS brake sensor.

27.Remove six bolts securing oil seal and retaining

plate to swivel pin housing. Prise seal from

swivel pin housing.

NOTE: Oil seal and retaining plate cannot

be removed until swivel pin bearing

housing is removed.

28.Remove two screws securing brake

damper/shield bracket and lower swivel pin to

housing.

29.Withdraw lower swivel pin and joint washer by

tapping protruding lug.

30.Remove top swivel pin retaining bolts complete

with brake jump hose bracket.

31.Remove top swivel pin and shims.

32.Remove swivel pin housing while retrieving

lower taper bearing.

Swivel pin bearing housing

33.Remove seven bolts securing swivel pin bearing

housing to axle case.

34.Remove and discard oil seal and joint washer.

35.Remove lower swivel pin bearing track.

36.Remove top swivel pin bush housing assembly.

Discard two thrust washers and bearing.

37.If worn, pitted or damaged, renew swivel pin

bearing housing.

38.Fit a new lower swivel pin bearing track.

39.Fit a new bush and bush housing. Ensure

relieved lip of bush housing faces towards rear,

as shown.

Page 520 of 873

STEERING

1

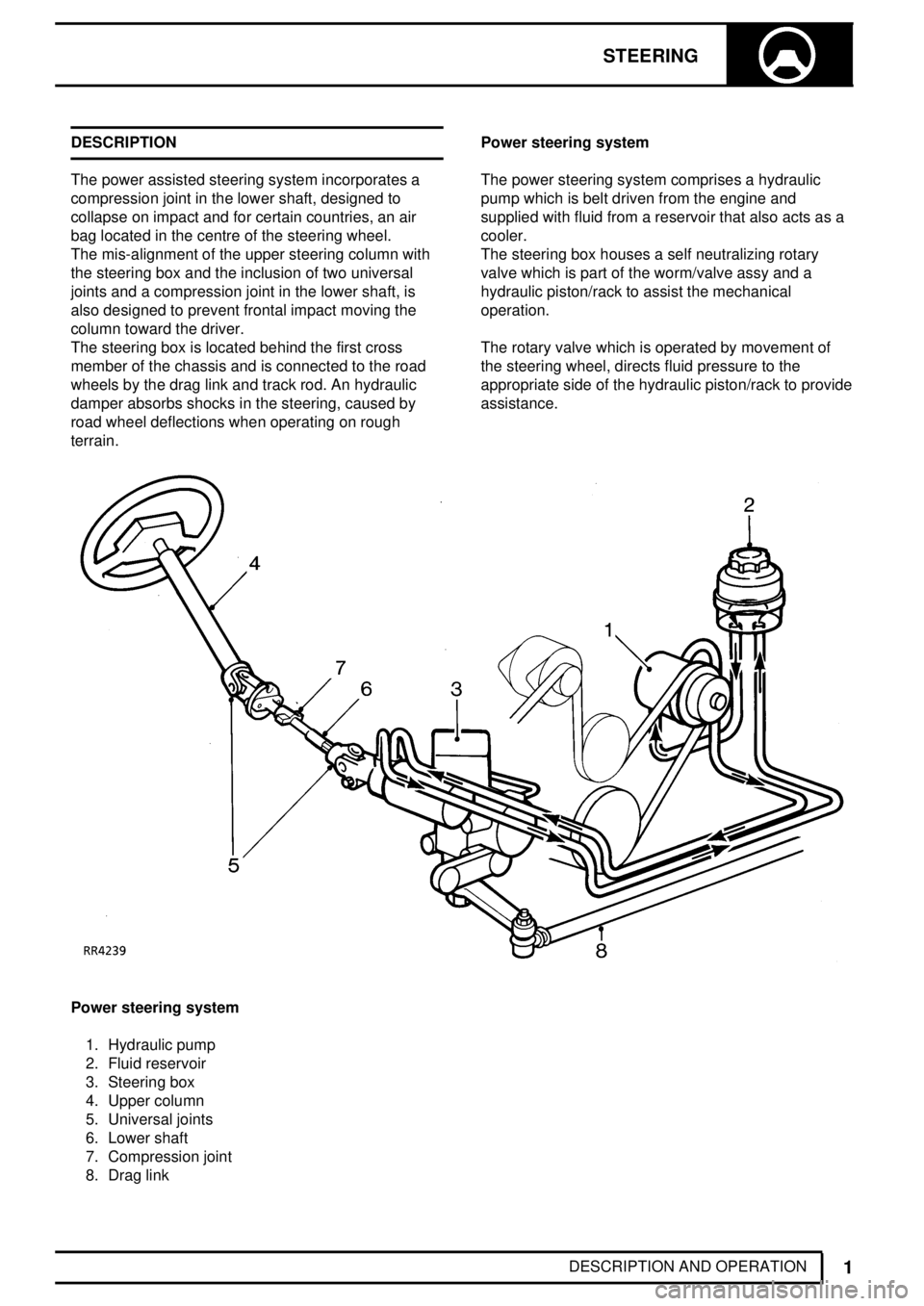

DESCRIPTION AND OPERATION DESCRIPTION

The power assisted steering system incorporates a

compression joint in the lower shaft, designed to

collapse on impact and for certain countries, an air

bag located in the centre of the steering wheel.

The mis-alignment of the upper steering column with

the steering box and the inclusion of two universal

joints and a compression joint in the lower shaft, is

also designed to prevent frontal impact moving the

column toward the driver.

The steering box is located behind the first cross

member of the chassis and is connected to the road

wheels by the drag link and track rod. An hydraulic

damper absorbs shocks in the steering, caused by

road wheel deflections when operating on rough

terrain.Power steering system

The power steering system comprises a hydraulic

pump which is belt driven from the engine and

supplied with fluid from a reservoir that also acts as a

cooler.

The steering box houses a self neutralizing rotary

valve which is part of the worm/valve assy and a

hydraulic piston/rack to assist the mechanical

operation.

The rotary valve which is operated by movement of

the steering wheel, directs fluid pressure to the

appropriate side of the hydraulic piston/rack to provide

assistance.

Power steering system

1. Hydraulic pump

2. Fluid reservoir

3. Steering box

4. Upper column

5. Universal joints

6. Lower shaft

7. Compression joint

8. Drag link

Page 534 of 873

57STEERING

8

FAULT DIAGNOSIS 4. DIRECTIONAL STABILITY

From 1. GENERAL STEERING:

1.Is directional stability concern when vehicle is

towing?

YES - Check towing/vehicle loading parameters

in Owner's Handbook.

NO - go to 3.

2.Is problem resolved?

YES - end

NO - continue.

3.Check condition of rear trailing link/chassis

bushes.

4.Is problem resolved?

YES - end

NO - continue.

5.Check condition of front and rear shock

absorbers. If in doubt change units in pairs, side

to side.

6.Is problem resolved?

YES - end

NO - continue.

7.Check steering damper.

See Steering Damper

8.Is problem resolved?

YES - end

NO - continue.

9.Check wheel balance

10.Is problem resolved?

YES - end

NO - contact local technical office.POWER STEERING FLUID LEAKS

1.Is fluid level correct?

YES - go to 3.

NO - Refill or drain to correct level. Bleed

system, check for leaks.

See Repair,

Power Steering System - Bleed

2.Is problem resolved?

YES - end

NO - continue.

3.Are hoses or joints leaking? Check on full lock

with engine at 2000 rev/min.

YES - loosen and retorque joints.

NO - go to 6.

4.Does leak remain?

YES - change PAS pipe.

NO - end.

5.Does leak remain?

YES - suspect seal in component. Check and

replace as necessary.

NO - end.

6.Is oil escaping from filler cap?

YES - bleed system.

See Repair, Power

Steering System - Bleed

NO - go to 8.

7.Is oil still escaping from filler cap?

YES - go back to 1.

NO - end.

8.Is oil leaking from PAS pump?

YES - go to 10.

NO - continue.

9.Is oil leaking from PAS box?

YES - go to 10.

NO - end.

10.Clean unit, add tracer dye to system. Retest

11.Is oil still leaking?

YES - establish leak point. Repair or replace

unit as necessary.

NO - end.

Page 536 of 873

57STEERING

10

FAULT DIAGNOSIS VISUAL AND SAFETY CHECKS

WARNING: Before taking vehicle out on

the public highway for road test, it is

important that the following basic visual

checks are carried out to ensure that the vehicle

complies with legal requirements.

Tyres and wheel rims

1.Check and adjust tyre pressures.

See

GENERAL SPECIFICATION DATA,

Information, Tyre Pressures

Note that this information refers to standard tyres

fitted as original equipment.

2.Check condition of tyres. Inspect for signs of

uneven wear, damage and feathering. Check

tread depth.

3.Ensure that the tyre make, type and general

condition are common across each axle.

4.Check wheel rims for signs of damage and

excessive run out.

5.Carry out road test.

See Road Test Procedure

ROAD TEST PROCEDURE

General steering/handling problems can usually be

classified into one of the categories listed and ARE

GENERALLY RELATED TO THE AGE, CONDITION

AND USE OF THE VEHICLE.

WARNING: Ensure that all road tests are

conducted by suitably qualified drivers in

a safe and legal manner, and where local

traffic conditions allow.

1.Carry out visual and safety checks.

See Visual

and Safety Checks

Confirm general nature of complaint with customer,

simulating where possible the conditions under which

the problem occurs. Carry out following road test

procedure to establish the problem.2.Steering load assessment - drive at 16 km/h (10

mph). Put 90°turn input into steering wheel,

check self centering. The self centering should

be equal on each lock BUT not necessarily

return to exactly straight ahead without

assistance from the driver.

3.Steering assessment - drive at 64 km/h (40 mph)

on a staight FLAT road (no camber), check for

steering veer. The vehicle should follow a

straight path with NO tendency to follow a

curved path. If vehicle veers towards the kerb,

vehicle may be 'camber sensitive'. A small

amount of veer in direction of camber is

acceptable.

4.Directional stability assessment - drive at 112

km/h (70 mph) or maximum legal speed on a

straight flat road. Carry out a normal lane

change. Vehicle should quickly settle into a new

straight path.

5.Braking assessment (medium effort) - drive at 96

km/h (60 mph) on a straight flat road. Apply

steady medium braking effort, noting any

tendency to veer. Carry out brake test three

times, if a veer is consistently noted carry out a

braking efficiency test on a rolling road.

6.Braking assessment (full effort) - drive at 96

km/h (60 mph) on a straight flat road. Apply full

braking effort, noting any tendency to veer. Carry

out brake test three times, if a veer is

consistently noted carry out a braking efficiency

test on a rolling road.

If the symptom described by the customer is stiff

steering or steering niggle, carry out stiff steering

procedure.

See Stiff Steering Checklist

If not proceed with basic checks and adjustments.

See Visual Check and Basic Adjustments

Page 568 of 873

STEERING

7

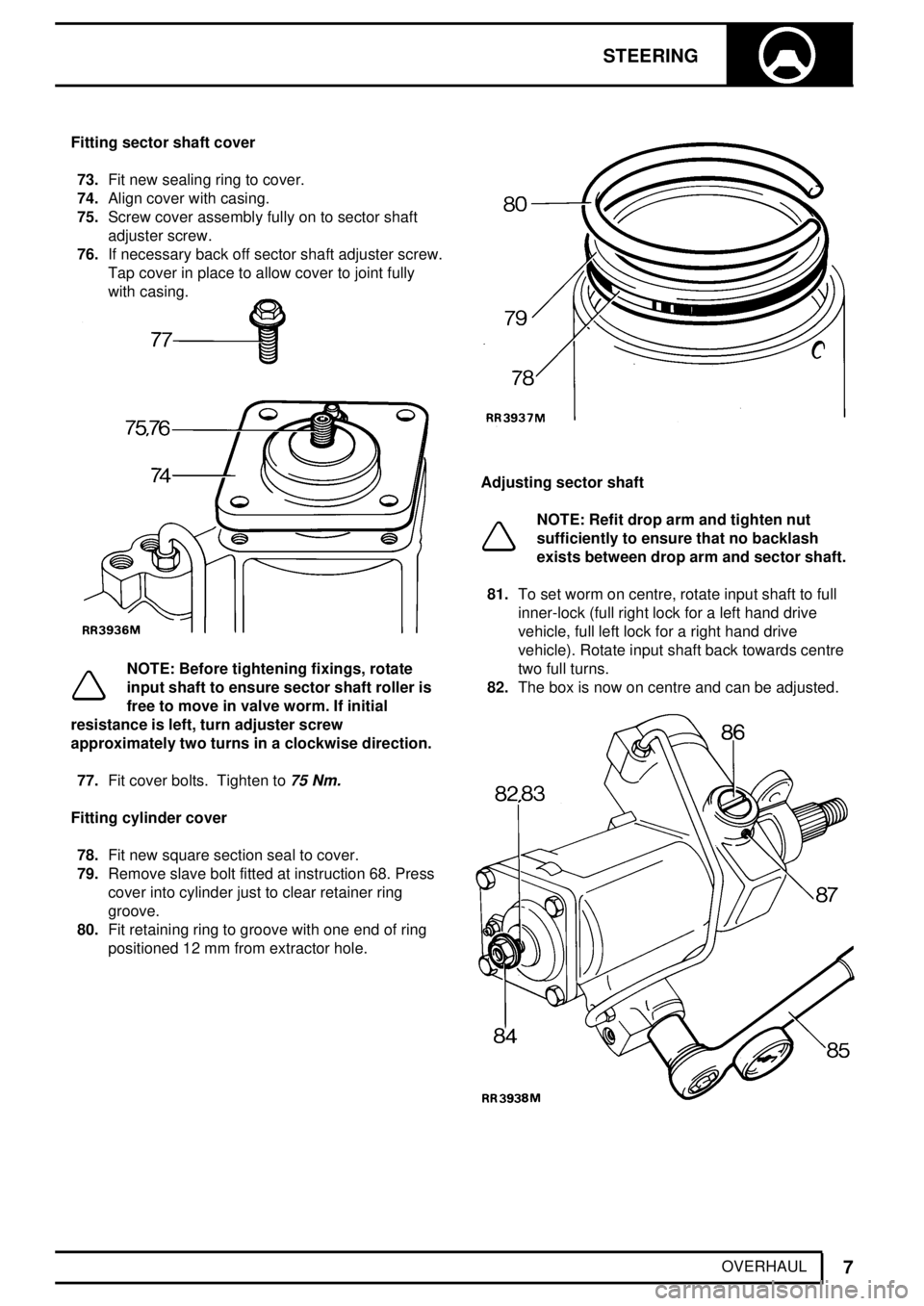

OVERHAUL Fitting sector shaft cover

73.Fit new sealing ring to cover.

74.Align cover with casing.

75.Screw cover assembly fully on to sector shaft

adjuster screw.

76.If necessary back off sector shaft adjuster screw.

Tap cover in place to allow cover to joint fully

with casing.

NOTE: Before tightening fixings, rotate

input shaft to ensure sector shaft roller is

free to move in valve worm. If initial

resistance is left, turn adjuster screw

approximately two turns in a clockwise direction.

77.Fit cover bolts. Tighten to

75 Nm.

Fitting cylinder cover

78.Fit new square section seal to cover.

79.Remove slave bolt fitted at instruction 68. Press

cover into cylinder just to clear retainer ring

groove.

80.Fit retaining ring to groove with one end of ring

positioned 12 mm from extractor hole.

Adjusting sector shaft

NOTE: Refit drop arm and tighten nut

sufficiently to ensure that no backlash

exists between drop arm and sector shaft.

81.To set worm on centre, rotate input shaft to full

inner-lock (full right lock for a left hand drive

vehicle, full left lock for a right hand drive

vehicle). Rotate input shaft back towards centre

two full turns.

82.The box is now on centre and can be adjusted.

Page 569 of 873

57STEERING

8

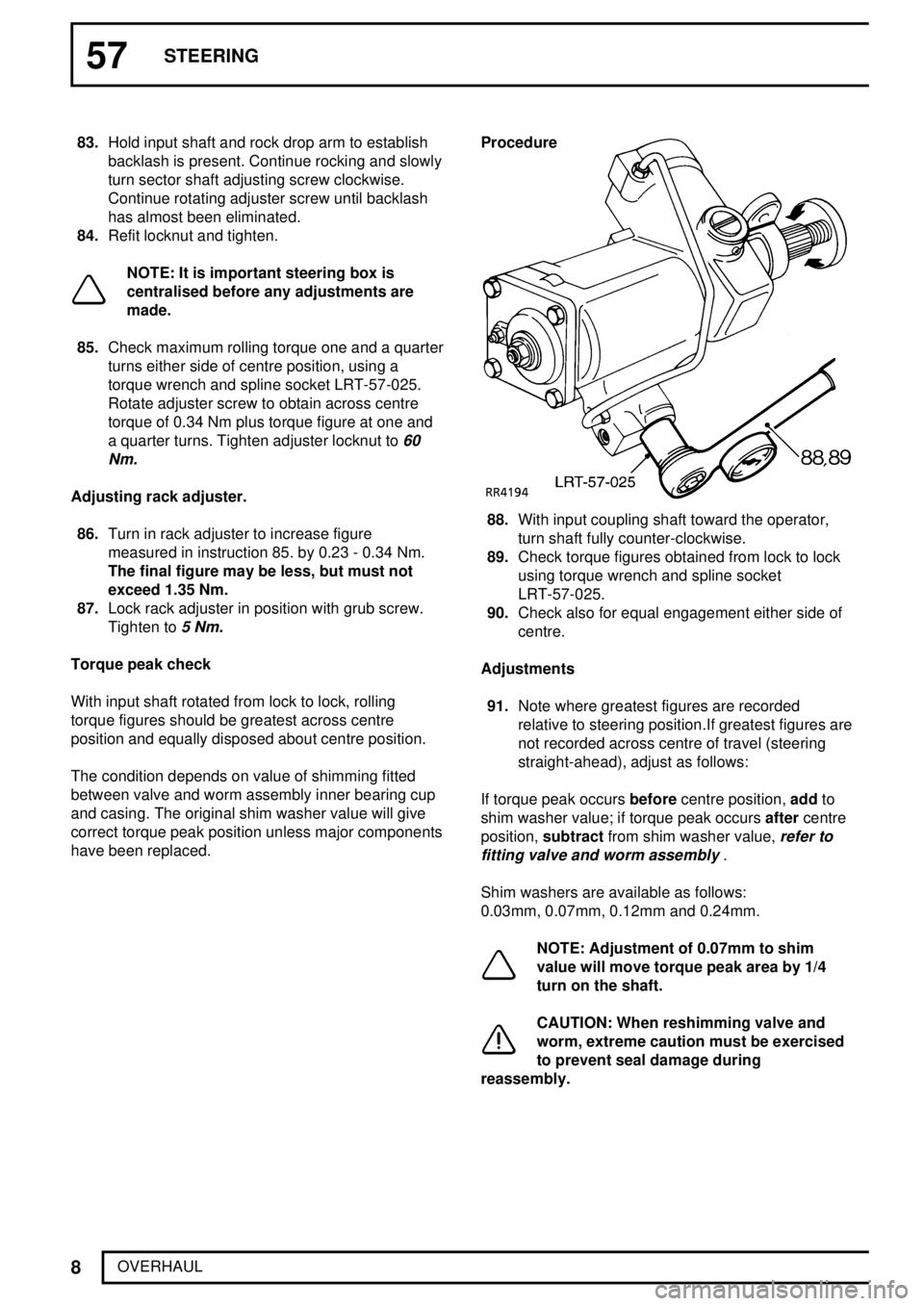

OVERHAUL 83.Hold input shaft and rock drop arm to establish

backlash is present. Continue rocking and slowly

turn sector shaft adjusting screw clockwise.

Continue rotating adjuster screw until backlash

has almost been eliminated.

84.Refit locknut and tighten.

NOTE: It is important steering box is

centralised before any adjustments are

made.

85.Check maximum rolling torque one and a quarter

turns either side of centre position, using a

torque wrench and spline socket LRT-57-025.

Rotate adjuster screw to obtain across centre

torque of 0.34 Nm plus torque figure at one and

a quarter turns. Tighten adjuster locknut to

60

Nm.

Adjusting rack adjuster.

86.Turn in rack adjuster to increase figure

measured in instruction 85. by 0.23 - 0.34 Nm.

The final figure may be less, but must not

exceed 1.35 Nm.

87.Lock rack adjuster in position with grub screw.

Tighten to

5 Nm.

Torque peak check

With input shaft rotated from lock to lock, rolling

torque figures should be greatest across centre

position and equally disposed about centre position.

The condition depends on value of shimming fitted

between valve and worm assembly inner bearing cup

and casing. The original shim washer value will give

correct torque peak position unless major components

have been replaced.Procedure

88.With input coupling shaft toward the operator,

turn shaft fully counter-clockwise.

89.Check torque figures obtained from lock to lock

using torque wrench and spline socket

LRT-57-025.

90.Check also for equal engagement either side of

centre.

Adjustments

91.Note where greatest figures are recorded

relative to steering position.If greatest figures are

not recorded across centre of travel (steering

straight-ahead), adjust as follows:

If torque peak occursbeforecentre position,addto

shim washer value; if torque peak occursaftercentre

position,subtractfrom shim washer value,

refer to

fitting valve and worm assembly

.

Shim washers are available as follows:

0.03mm, 0.07mm, 0.12mm and 0.24mm.

NOTE: Adjustment of 0.07mm to shim

value will move torque peak area by 1/4

turn on the shaft.

CAUTION: When reshimming valve and

worm, extreme caution must be exercised

to prevent seal damage during

reassembly.

Page 582 of 873

![LAND ROVER DISCOVERY 1995 Owners Manual FRONT SUSPENSION

5

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY FRONT

Service repair no - 60.10.01

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Castellated nut an LAND ROVER DISCOVERY 1995 Owners Manual FRONT SUSPENSION

5

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY FRONT

Service repair no - 60.10.01

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Castellated nut an](/img/64/57248/w960_57248-581.png)

FRONT SUSPENSION

5

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY FRONT

Service repair no - 60.10.01

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Castellated nut and cotter pin

7. Ball joint link arm

Remove

1.Mark for reassembly position of rubber bushes

on anti- roll[sway] bar.

2.Remove four nuts, bolts and washers securing

two bush straps.

3.Remove nuts, bolts, washers and rubber bushes

from ball joint links and remove anti-roll[sway]

bar.Refit

4.Position bushes on anti-roll[sway] bar. Ensure

split points towards axle on RH bush and away

from axle on LH bush.

5.Fit anti-roll[sway] bar with two straps. To ensure

correct fit angled sides of bar should point down

as shown. Loosely fit the bolts, washers and

nyloc nuts.

6.Fit bolt, washers and rubber bushes. Using new

nuts fit anti-roll[sway] bar to ball joint links.

Tighten to

68Nm.

7.Tighten nuts securing straps to30Nm

Page 589 of 873

![LAND ROVER DISCOVERY 1995 Owners Manual 64REAR SUSPENSION

4

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY REAR

Service repair no - 64.35.08.

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Ball joint link a LAND ROVER DISCOVERY 1995 Owners Manual 64REAR SUSPENSION

4

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY REAR

Service repair no - 64.35.08.

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Ball joint link a](/img/64/57248/w960_57248-588.png)

64REAR SUSPENSION

4

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY REAR

Service repair no - 64.35.08.

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Ball joint link arm

7. Bolt and washer

8. Castellated nut and cotter pin

Remove

1.Note for reassembly, position of rubber bushes

on anti-roll bar.

2.Remove four nuts, bolts and washers securing

two bush straps.

3.Remove nuts, bolts, washers and rubber bushes

from the ball joint links and remove anti-roll bar.Refit

4.Position rubber bushes on anti-roll bar. Fit joint

towards axle.

5.Fit anti-roll bar with two straps. Ensure ball joint

link arms point down as shown. Loosely fit, bolts,

washers and new nyloc nuts.

6.Fit bolt, washers and rubber bushes. Fit anti-roll

bar to ball joint links. Tighten to

68Nm.

7.Tighten nuts securing straps to30Nm.

Page 609 of 873

BRAKES

7

REPAIR 19.Coat new seals in unused brake fluid. Fit 'L' seal

to plunger.

20.Fit washer followed by recuperating seal. Fit seal

retainer and springs, ensure springs are

correctly seated.

Assembling master cylinder

CAUTION: It is important that following

instructions are carried out precisely,

otherwise damage could be caused to new

seals when inserting plungers into cylinder bore.

Generous amounts of new brake fluid should be

used to lubricate parts during assembly.

21.Fit new swirl tube to bottom of cylinder bore.

22.Lubricate secondary plunger and cylinder bore.

Offer plunger assembly to cylinder until

recuperation seal is resting centrally in mouth of

bore. Gently introduce plunger with a circular

rocking motion, as illustrated. Ensuring that seal

does not become trapped, ease seal into bore

and slowly push plunger down bore in one

continuous movement.

23.Fit new primary plunger assembly using same

method as for secondary plunger.

24.Fit original guide ring to support primary plunger.

25.Coat a new 'O' ring with brake fluid and fit to its

respective groove on outer location surface of

master cylinder.

CAUTION: Do not roll 'O' ring down outer

location surface of master cylinder. It

should be slightly stretched and eased

down cylinder and into its groove. Do not over

stretch seal.

26.Fit new retaining ring on outer surface of master

cylinder ensuring that serrations of ring are

facing mounting flange.

27.Fit two new reservoir seals in respective ports.

28.Fit a new vacuum seal to either primary plunger

or to bottom of transfer housing bore, open face

of seal towards primary plunger.

29.Lubricate vacuum seal with brake fluid. Fit

transfer housing to master cylinder, push

housing fully up to cylinder mounting flange, Do

not adjust transfer housing after fitting.

30.Lubricate new water ingress seal with brake

fluid, Slightly stretch seal and ease down

housing until it is in position between housing

and flange.

31.Roll reservoir into top of master cylinder,

reversing procedure described in instruction 10.

Refit

NOTE: Ensure O ring seal between master

cylinder and servo unit is fitted correctly.

32.Fit master cylinder to servo. Secure in position

with two nuts, plain and spring washers. Tighten

to

26 Nm.

33.Fit brake pipes to master cylinder. Tighten to

15Nm.

34.Top-up master cylinder with correct grade of

brake fluid.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

35.Bleed system.See Brake System Bleed

36.Fit cap, reconnect electrical lead to fluid level

switch. Reconnect battery negative lead.

Page 641 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

5

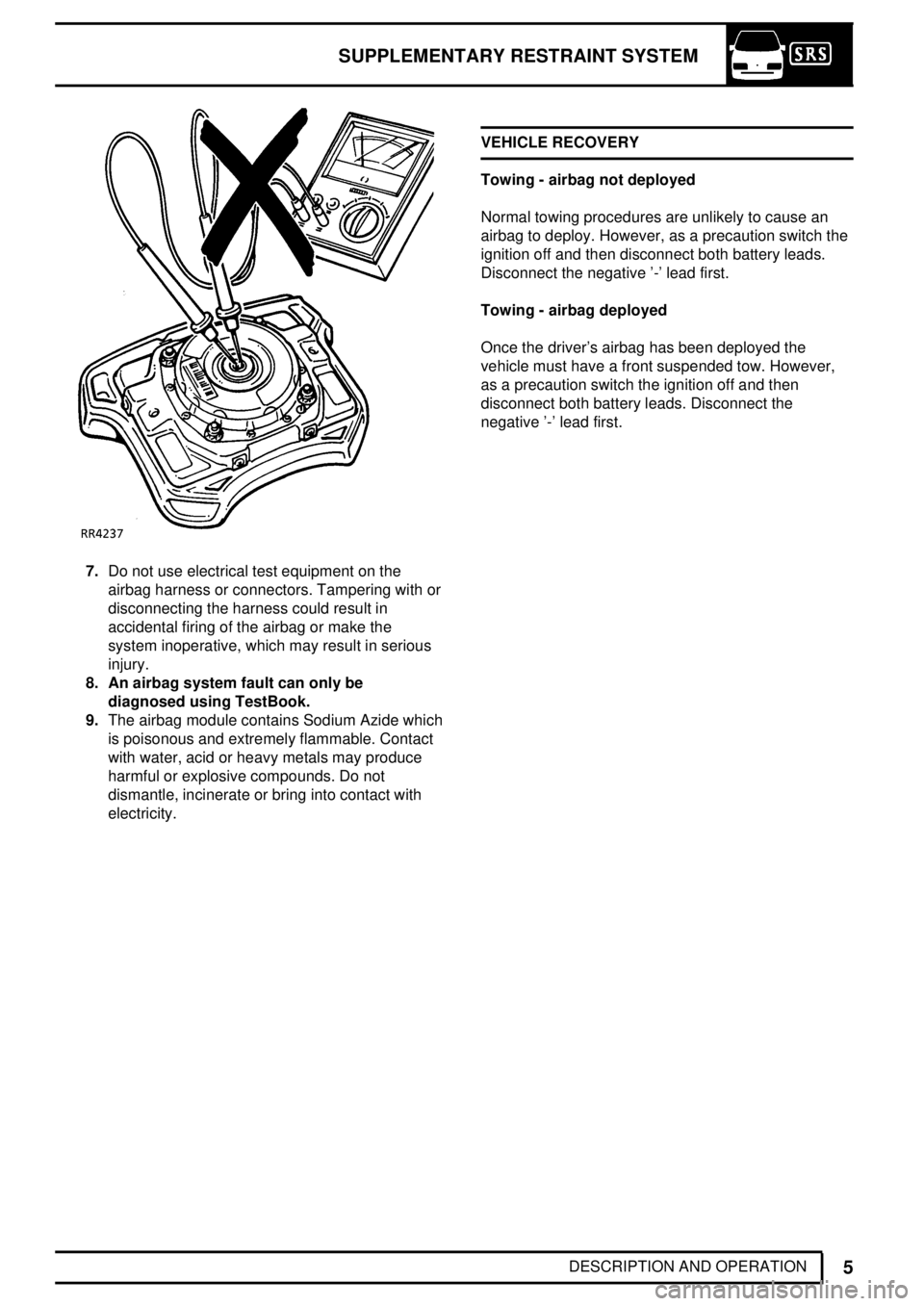

DESCRIPTION AND OPERATION

7.Do not use electrical test equipment on the

airbag harness or connectors. Tampering with or

disconnecting the harness could result in

accidental firing of the airbag or make the

system inoperative, which may result in serious

injury.

8. An airbag system fault can only be

diagnosed using TestBook.

9.The airbag module contains Sodium Azide which

is poisonous and extremely flammable. Contact

with water, acid or heavy metals may produce

harmful or explosive compounds. Do not

dismantle, incinerate or bring into contact with

electricity.VEHICLE RECOVERY

Towing - airbag not deployed

Normal towing procedures are unlikely to cause an

airbag to deploy. However, as a precaution switch the

ignition off and then disconnect both battery leads.

Disconnect the negative '-' lead first.

Towing - airbag deployed

Once the driver's airbag has been deployed the

vehicle must have a front suspended tow. However,

as a precaution switch the ignition off and then

disconnect both battery leads. Disconnect the

negative '-' lead first.