LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 341 of 873

19FUEL SYSTEM

4

REPAIR

NOTE: If rotary coupler is to be re-used a

piece of adhesive tape should be placed

around the moulding in position A to

prevent rotation. Failure to do this may result in

damage to the wires inside the coupler.

6.Release clips securing rotary coupler to column

stalk assembly.

7.Remove rotary coupler from column stalk

assembly.

CAUTION: Ensure front wheels are in the

straight ahead position before removal

and refitting. Store in a plastic bag. DO

NOT rotate mechanism whilst removed.

Refit

8.Reverse removal procedure. Ensuring that the

column harnesses are not trapped by the

column shroud.

NOTE: If original rotary coupler is to be

fitted and there is evidence of tampering, it

is imperative that the coupler is

centralised.

See SUPPLEMENTARY RESTRAINT

SYSTEM, Repair, Rotary Coupler

NOTE: If a new rotary coupler is to be

fitted and the sealing tape is broken it

MUST NOT be used. Ensure rotary coupler

lugs are correctly engaged in the rear of the

steering wheel.ACTUATOR - V8i

Service repair no - 19.75.12

NOTE: The actuator is non serviceable, fit

a new unit if failure or damage occurs.

Remove

1.Disconnect battery negative lead.

2.Disconnect vacuum hose from actuator.

3.Remove nut securing actuator to throttle bracket.

4.Remove actuator, and manoeuvre actuator

operating link off throttle lever.

5.Withdraw actuator.

Refit

6.Inspect rubber diaphragm. Fit a new actuator

assembly if diaphragm is damaged.

7.Reverse removal procedure. Fitting the hook

uppermost.

Page 342 of 873

CRUISE CONTROL

5

REPAIR ACTUATOR LINK-SETTING - V8i

Service repair no - 19.75.21

NOTE: Setting procedure is carried out at

minimum throttle condition only.

1.Ensure ignition is switched 'OFF'.

2.Check clearance between inside edge of

actuator link and recessed diameter of throttle

lever. Clearance should be 0.2 to 2.0 mm.

Link - adjust

3.Remove link from actuator.

4.Rotate socket joint adjuster as necessary.

5.Refit link to actuator and recheck clearance

between link and lever.

6.With throttle fully open, check a gap of at least

3mm exists between side of link ("A" in

illustration) and side of small spring ("B" in

illustration). Realign link by bending to achieve

correct gap. Recheck clearance at closed

throttle/open throttle. Check link slides smoothly

in groove of throttle lever.

Page 343 of 873

19FUEL SYSTEM

6

REPAIR VACUUM PUMP - TDI

Service repair no - 19.75.06

NOTE: The vacuum pump is non

serviceable, fit a new unit if failure or

damage occurs.

Remove

1.Release turnbuckle securing wheel chock and

remove.

2.Release strap securing jack and remove.

3.Release 3 pump mounting rubbers from vehicle

body.

4.Manoeuvre pump out of box section.

5.Release multiplug cover and disconnect

multiplug from pump.

6.Disconnect vacuum hose from pump.

7.Remove pump.

Refit

8.Reverse removal procedure. Ensure all hose

and electrical connections are secure.

Page 344 of 873

CRUISE CONTROL

7

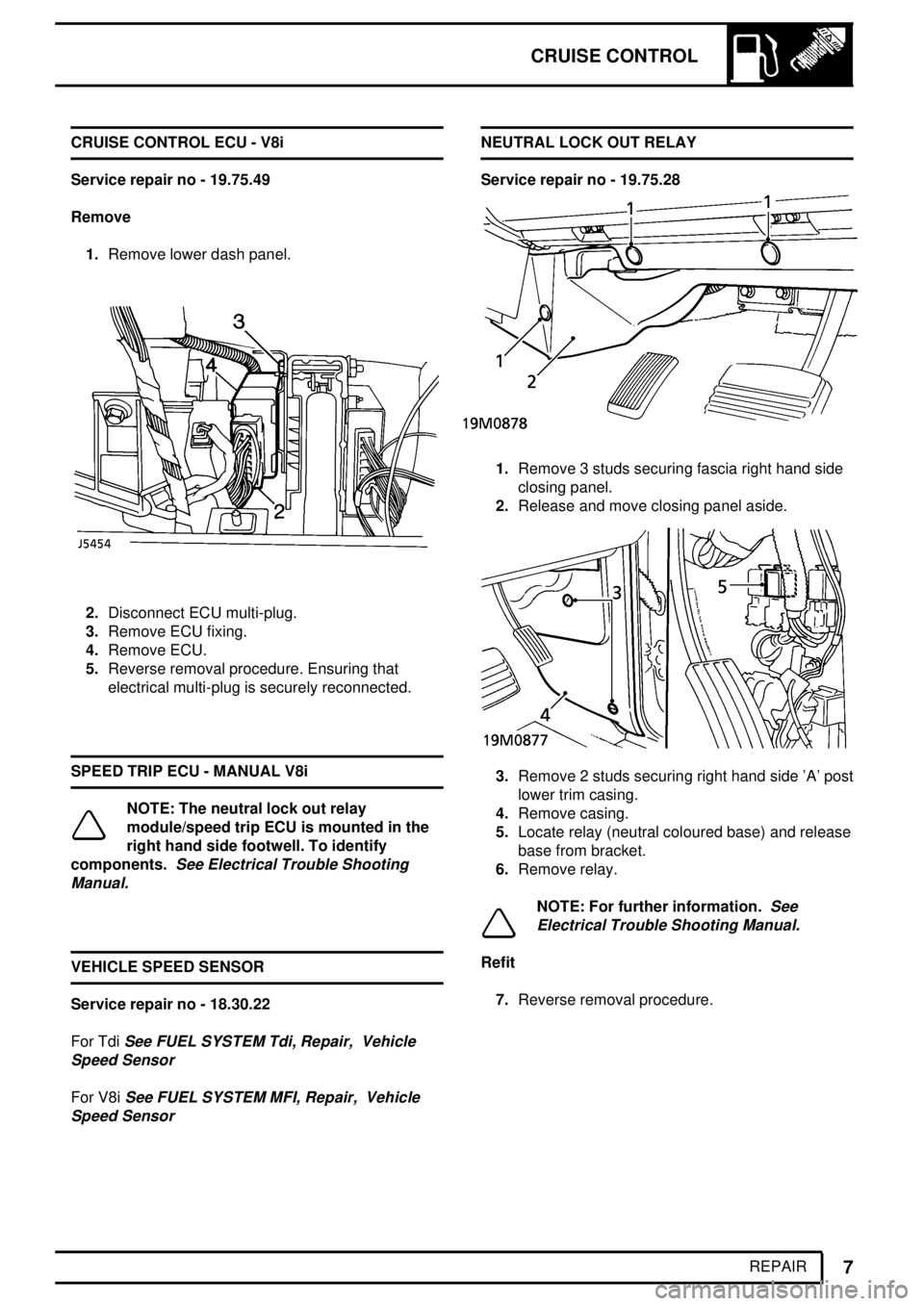

REPAIR CRUISE CONTROL ECU - V8i

Service repair no - 19.75.49

Remove

1.Remove lower dash panel.

2.Disconnect ECU multi-plug.

3.Remove ECU fixing.

4.Remove ECU.

5.Reverse removal procedure. Ensuring that

electrical multi-plug is securely reconnected.

SPEED TRIP ECU - MANUAL V8i

NOTE: The neutral lock out relay

module/speed trip ECU is mounted in the

right hand side footwell. To identify

components.

See Electrical Trouble Shooting

Manual.

VEHICLE SPEED SENSOR

Service repair no - 18.30.22

For Tdi

See FUEL SYSTEM Tdi, Repair, Vehicle

Speed Sensor

For V8iSee FUEL SYSTEM MFI, Repair, Vehicle

Speed Sensor

NEUTRAL LOCK OUT RELAY

Service repair no - 19.75.28

1.Remove 3 studs securing fascia right hand side

closing panel.

2.Release and move closing panel aside.

3.Remove 2 studs securing right hand side 'A' post

lower trim casing.

4.Remove casing.

5.Locate relay (neutral coloured base) and release

base from bracket.

6.Remove relay.

NOTE: For further information.See

Electrical Trouble Shooting Manual.

Refit

7.Reverse removal procedure.

Page 345 of 873

19FUEL SYSTEM

8

REPAIR ACTUATOR - Tdi

Service repair no - 19.75.05

NOTE: The actuator is non serviceable, fit

a new unit if failure or damage occurs.

Remove

1.Disconnect battery negative lead.

2.Remove split pin, withdraw clevis pin and

disconnect cable from lever.

3.Disconnect link ball end from cable lever.

4.Disconnect vacuum hose from actuator.

5.Remove nut securing actuator to bracket and

remove actuator.

6.Inspect rubber diaphragm. Fit a new actuator

assembly if diaphragm is damaged.Refit

7.Check that link setting distance (dimension 'A')

equals 16 mm and that the retainer is locked in

position. If correct, proceed to paragraph 9.

8.If dimension 'A' is not correct, proceed as

follows:

·Measure 16 mm from diaphragm collar and

mark the position.

·Position link and retainer to the mark and

rotate retainer half a turn to secure.

·Check measurement 'A' is still 16 mm, then

turn retainer a further quarter turn to lock.

9.Fit actuator and secure to bracket with nut.

10.Connect vacuum hose.

11.Connect link ball end to cable lever.

12.Connect cable to lever and secure with clevis pin

and split pin.

13.Adjust cable position to remove any free play

from link, setting dimension 'B' should be 103

mm.

Page 346 of 873

CRUISE CONTROL

9

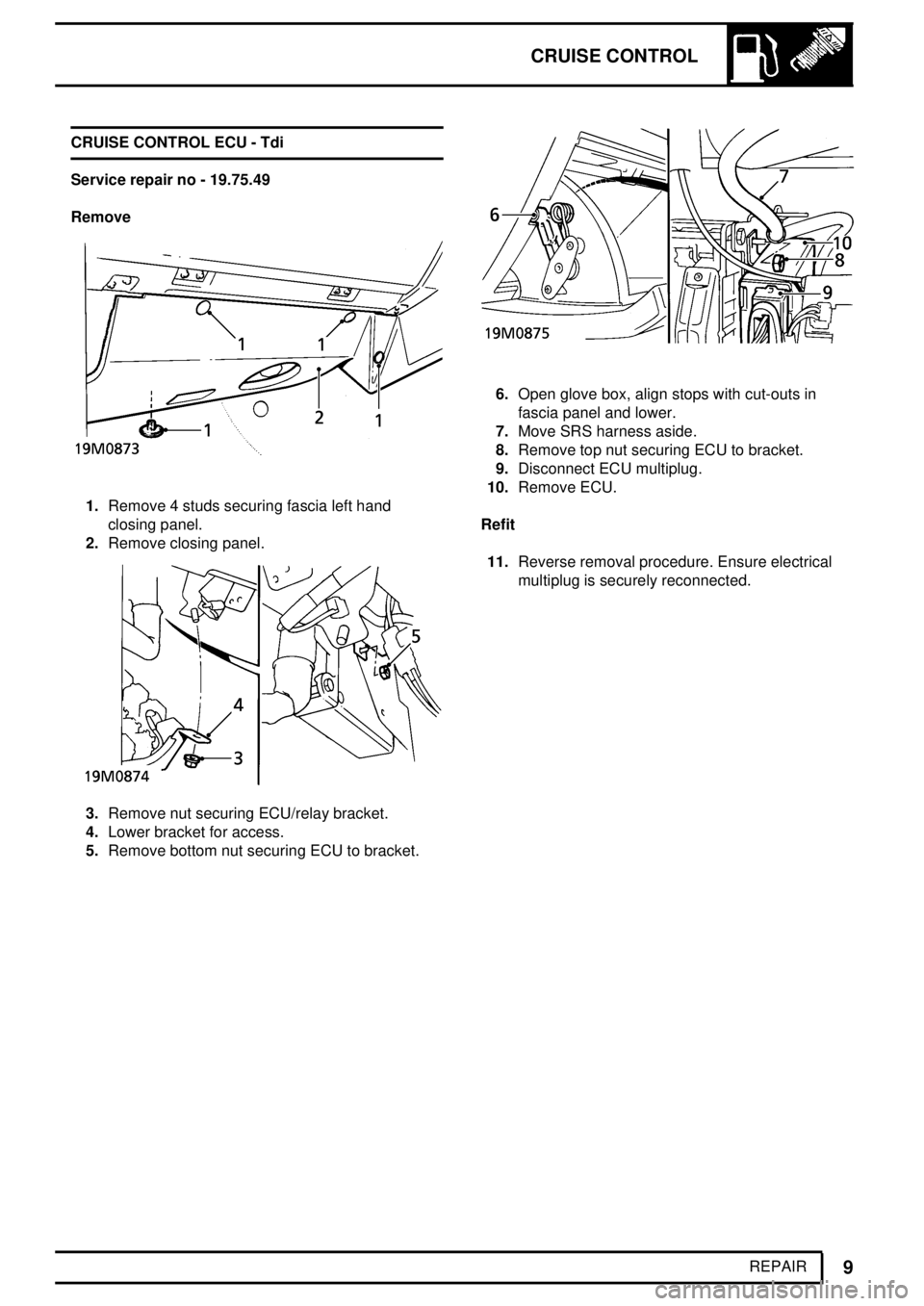

REPAIR CRUISE CONTROL ECU - Tdi

Service repair no - 19.75.49

Remove

1.Remove 4 studs securing fascia left hand

closing panel.

2.Remove closing panel.

3.Remove nut securing ECU/relay bracket.

4.Lower bracket for access.

5.Remove bottom nut securing ECU to bracket.

6.Open glove box, align stops with cut-outs in

fascia panel and lower.

7.Move SRS harness aside.

8.Remove top nut securing ECU to bracket.

9.Disconnect ECU multiplug.

10.Remove ECU.

Refit

11.Reverse removal procedure. Ensure electrical

multiplug is securely reconnected.

Page 347 of 873

Tdi

1

DESCRIPTION AND OPERATION ENGINE COOLING

Description

The Tdi engine uses a pressurized cooling system

and cross flow radiator which is supplied from a

separate header tank. The radiator assembly is in

three sections. The largest section is for engine

coolant and the other two sections which are cast in

aluminium, are the engine oil cooler and the turbo

charger intercooler.

A belt driven viscous fan and centrifugal water pump

is located in the front of the cylinder block. Hot coolant

is supplied to the heater through hoses. Two small

diameter air purge hoses connect the top of the

radiator and cylinder head water gallery, to the header

tank.

Coolant circulation (engine cold)

1. Cross flow radiator

2. Header tank

3. Viscous fan

4. Heater hoses

5. By pass hose and engine thermostat

6. Air purge hoses

7. Coolant pumpCOOLANT CIRCULATION

Operation

When the engine is started from cold the thermostat

prevents any coolant circulation through the radiator

by closing off the top hose. During the engine warm

up period, the water pump, pumps coolant towards

the rear of the cylinder block around each of the

cylinders. Coolant as it is heated rises through ports in

the cylinder block and head gasket, into the cylinder

head.The coolant flows forwards to the thermostat,

by-pass port and radiator top hose connection.

Start from cold (thermostat closed)

While the thermostat is closed, coolant circulates

around the cylinder block and cylinder head via the

by-pass.

Engine warm (thermostat open)

When the engine reaches normal running temperature

the thermostat closes off the by-pass and opens the

flow to the top of the radiator.

Page 348 of 873

26COOLING SYSTEM

2

DESCRIPTION AND OPERATION VISCOUS FAN

Description

The viscous drive unit for the engine cooling fan,

provides a means of controlling the speed of the fan

relative to the running temperature of the engine. The

viscous unit is a type of fluid coupling, which drives

the fan blades through the medium of a special

'silicone fluid' injected into the unit during

manufacture.

1. Drive in from water pump spindle

2. Drive out to fan blades

3. Bi-metalOperation

The viscous unit consists of two principal components:

An inner member 1 which is secured to water pump

spindle and is driven by the fan belt.

An outer member 2 which has the fan blades

attached, houses the working parts and is driven

through the medium of the viscous fluid.

The inner and outer members have interlocking

annular grooves machined in each, with a small

running clearance 3 to allow the silicone fluid to

circulate through the valve plate 4.

The unit also contains a valve 5 which is controlled by

an external bi-metal thermostat 6.

Starting engine from cold

During the time the engine is at rest the silicone fluid

drains down, half filling chambers A and B. Thus when

the engine is first started sufficient fluid is present in

chamber A to provide a positive drive between the

members, as is evident by the initial noise of the fan.

However within a very short period of time, after

starting the engine, the fan speed and noise will

decline indicating that the fluid is being centrifuged

into chamber B (as seen in RR3757M) causing the

drive to slip.

Page 349 of 873

Tdi

3

DESCRIPTION AND OPERATION

Viscous unit slipping (Engine at normal running

temperature)

1. Inner member (drive in fast)

2. Outer member (drive out slow)

3. Running clearance

4. Valve plate

5. Valve (closed)

6. Bi-metal

7. Fluid seals

8. Ball race

AFluid chamber

BFluid chamber

If the engine speed is increased the degree of slip will

also increase to limit the maximum fan speed.Hot conditions

When operating in high ambient temperatures or

when stationary in traffic, the bi-metel thermostat will

operate and open the valve port between chambers A

and B.

Opening the valve (as shown in RR3758M) allows the

fluid to circulate between the two members, causing

the unit to couple, thus increasing the fan speed and

cooling effect.

Viscous unit coupled (Hot running conditions)

Bi-metal expanded, valve (open)

Page 350 of 873

Tdi

1

FAULT DIAGNOSIS ENGINE OVERHEATING

Before conducting any cooling system diagnosis:

See

Description and operation, Engine Cooling

1.Is coolant level correct?

NO - Allow engine to cool, top up level to

expansion tank seam.

YES - Continue.

2.Is drive belt tension correct?

NO -

See ENGINE, Repair, Compressor

Drive Belt

YES - Continue.

3.Is coolant in radiator frozen?

YES - Slowly thaw and drain system.

See

Adjustment, Coolant

NO - Continue.

4.Is air flow through radiator restricted or blocked?

YES - Apply air pressure from engine side of

radiator to clear obstruction.

NO - Continue.

5.Are there any external leaks, from water pump,

engine gaskets, fast idle thermostat or the heater

unit?

YES - Investigate and rectify.

See Adjustment,

Coolant

NO - Continue.

6.Are fan blades fitted correct way round, concave

side towards engine?

NO - Rectify.

YES - Continue

7.Is viscous unit operating correctly?

See

Description and operation, Viscous Fan

NO - Renew.See Repair, Viscous

Coupling, Fan Blades, Pulley and Fan

Cowl

YES - Carry out a pressure test on radiator cap

and system. Check thermostat type,

operation and correct fitting.

See Repair,

Thermostat

If pressure test leads you to suspect coolant

leakage across gaskets, go to check 10,

otherwise: Continue.8.Are the air conditioning fans operating correctly?

See Electrical Trouble Shooting Manual.

NO - Rectify.

YES - Continue.

9.Is temperature sender and gauge giving

accurate readings?

NO - Sustitute parts and compare readings.

YES - Continue.

10.Carry out cylinder pressure test to determine if

pressure is leaking into cooling system causing

over pressurising and loss of coolant.

If problem is not diagnosed, check the coolant system

for engine oil contamination and engine lubrication

system for coolant contamination.

If only the coolant system is contaminated suspect a

cylinder head gasket.

If both systems are contaminated, suspect the

radiator.

If only the lubrication system is contaminated with

coolant, suspect leakage past cylinder liner seals or

cylinder head gasket.