LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 301 of 873

19FUEL SYSTEM

18

REPAIRADD: 09/95

6.Fold back loadspace carpet and sound

insulation to reveal access panel.

7.Remove 6 screws securing fuel pump access

panel.

8.Remove access panel.

9.Disconnect multiplugs from fuel pump and

pressure sensor.

10.Release vent hose from pressure sensor body.

11.Noting their fitted positions, disconnect both fuel

connections by pressing the black release

latches on each connector and pushing the

connector back down the line. Care must be

taken to catch any excess fuel which may spill

from the fuel lines once removed.

Page 302 of 873

SFI

19

REPAIR ADD: 09/95

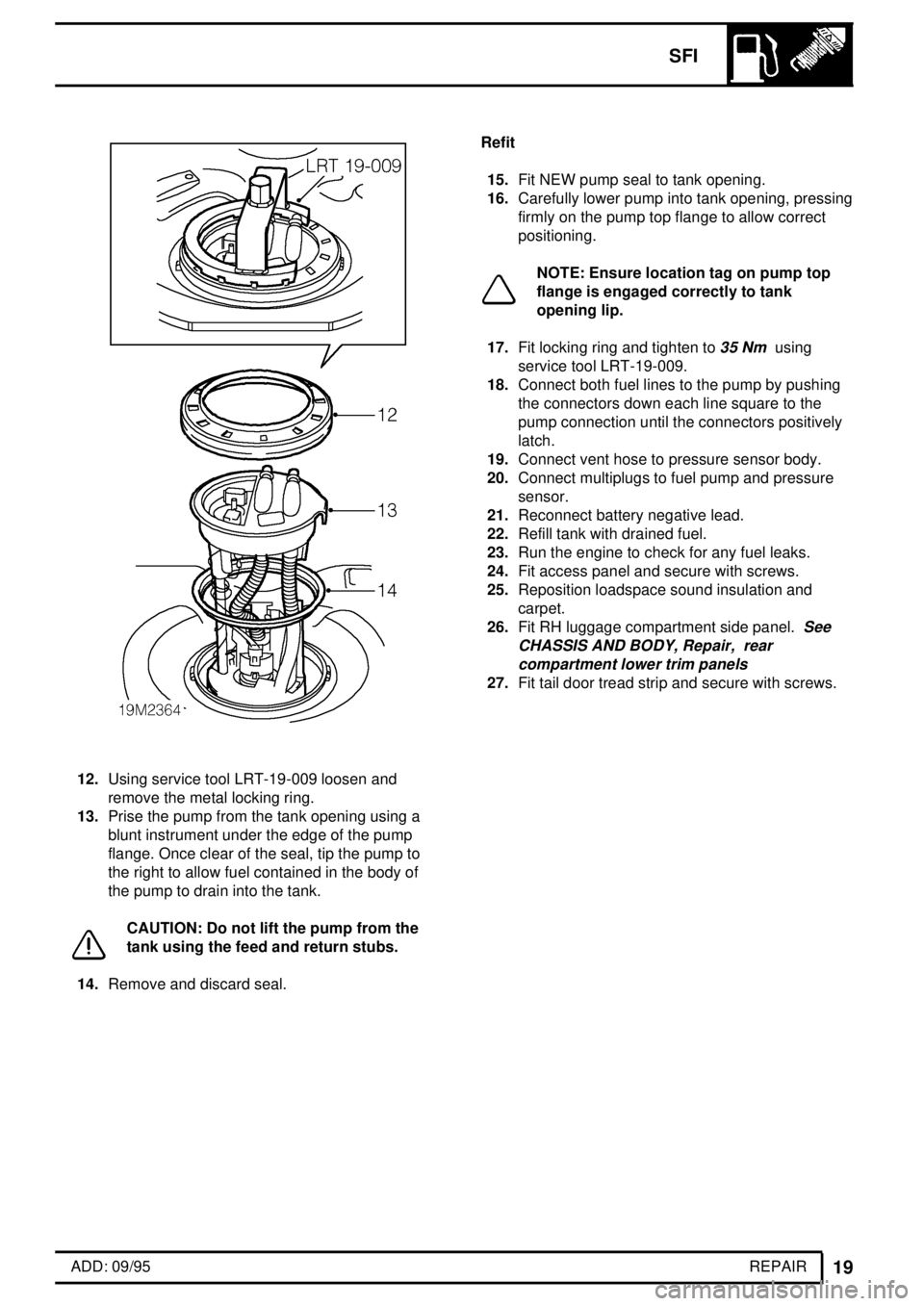

12.Using service tool LRT-19-009 loosen and

remove the metal locking ring.

13.Prise the pump from the tank opening using a

blunt instrument under the edge of the pump

flange. Once clear of the seal, tip the pump to

the right to allow fuel contained in the body of

the pump to drain into the tank.

CAUTION: Do not lift the pump from the

tank using the feed and return stubs.

14.Remove and discard seal.Refit

15.Fit NEW pump seal to tank opening.

16.Carefully lower pump into tank opening, pressing

firmly on the pump top flange to allow correct

positioning.

NOTE: Ensure location tag on pump top

flange is engaged correctly to tank

opening lip.

17.Fit locking ring and tighten to

35 Nmusing

service tool LRT-19-009.

18.Connect both fuel lines to the pump by pushing

the connectors down each line square to the

pump connection until the connectors positively

latch.

19.Connect vent hose to pressure sensor body.

20.Connect multiplugs to fuel pump and pressure

sensor.

21.Reconnect battery negative lead.

22.Refill tank with drained fuel.

23.Run the engine to check for any fuel leaks.

24.Fit access panel and secure with screws.

25.Reposition loadspace sound insulation and

carpet.

26.Fit RH luggage compartment side panel.

See

CHASSIS AND BODY, Repair, rear

compartment lower trim panels

27.Fit tail door tread strip and secure with screws.

Page 303 of 873

19FUEL SYSTEM

20

REPAIRADD: 09/95 FUEL SYSTEM - DEPRESSURISE - ADVANCED

EVAPS

Service repair no - 19.50.02

WARNING: Fuel pressure of up to 2.5 bar

will be present in the system, even if the

engine has not been run for some time.

Always depressurise the system before

disconnecting any components in the fuel feed

line (between fuel pump and pressure regulator).

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

NOTE: Fuel pressure can be relieved at

fuel filter unions.

1.Position cloth around relevant union to protect

against fuel spray.

2.Carefully loosen union.

CAUTION: Use two spanners when

loosening or tightening unions.

3.Tighten union once fuel pressure is relieved.

4.Remove cloth.FUEL TANK - ADVANCED EVAPS

Service repair no - 19.55.01

WARNING: Ensure fuel handling

precautions given in section 01

Introduction are strictly adhered to when

carrying out following instructions.

CAUTION: Before disconnecting any part

of fuel system, it imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign matter

into fuel system.

Remove

1.Disconnect battery negative lead.

2.Drain fuel tank completely.

See fuel tank -

draining - advanced evaps

3.Remove 6 screws securing tail door tread strip

and remove tread strip.

4.Remove RH luggage compartment side panel.

See CHASSIS AND BODY, Repair, rear

compartment lower trim panels

Page 304 of 873

SFI

21

REPAIR ADD: 09/95

5.Fold back loadspace carpet and sound

insulation to reveal access panel.

6.Remove 6 screws securing fuel pump access

panel.

7.Remove access panel.8.Disconnect multiplugs from fuel pump and

pressure sensor

9.Noting their fitted positions, disconnect both fuel

connections by pressing the black release

latches on each connector and pushing the

connector back down the line.

10.Care must be taken to catch any excess fuel

which may spill from the fuel lines once

removed.

11.Raise rear of vehicle.

WARNING: Support on safety stands.

Page 305 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 19FUEL SYSTEM

22

REPAIRADD: 09/95

12.Mark location of anti-roll [sway] bar straps.

13.Remove nuts and bolts securing anti-roll [sway]

bar straps, and allow bar to swing down clear of

tank.14.Disconnec LAND ROVER DISCOVERY 1995 Workshop Manual 19FUEL SYSTEM

22

REPAIRADD: 09/95

12.Mark location of anti-roll [sway] bar straps.

13.Remove nuts and bolts securing anti-roll [sway]

bar straps, and allow bar to swing down clear of

tank.14.Disconnec](/img/64/57248/w960_57248-304.png)

19FUEL SYSTEM

22

REPAIRADD: 09/95

12.Mark location of anti-roll [sway] bar straps.

13.Remove nuts and bolts securing anti-roll [sway]

bar straps, and allow bar to swing down clear of

tank.14.Disconnect pressure sensor breather pipe

connection.

15.Disconnect vent line quickfit connector from

liquid/vapour separator.

16.Remove torque screw cap from hose to tank

filler neck clip.

17.Loosen clip screw securing hose to tank filler

neck.

18.Release hose from filler neck and internal filler

neck breather hose from fuel tank.

19.Remove and discard fuel filler neck clip.

Page 306 of 873

SFI

23

REPAIR ADD: 09/95

20.Remove nut and bolt securing RH side of upper

fuel tank strap to chassis.

21.Remove 4 nuts and bolts securing fuel tank

cradle.

22.Remove fuel tank cradle.

23.With assistance, tilt right hand side of tank

upwards and manoeuvre through chassis to

remove.

Do not carry out further dismantling if

component is removed for access only.

24.Release vent hose from tank pressure sensor.

25.Remove vent hose from 3 fuel tank clips.

26.Using service tool LRT-19-009 loosen and

remove the metal locking ring.

27.Prise the pump from the tank opening using a

blunt instrument under the edge of the lip of the

pump flange.

CAUTION: Do not lift the pump from the

tank using the feed and return stubs.

28.Remove and discard seal.

Page 307 of 873

19FUEL SYSTEM

24

REPAIRADD: 09/95 Refit

29.Fit NEW pump seal to tank opening.

30.Carefully lower pump into tank opening, pressing

firmly on the pump top flange to allow correct

positioning.

NOTE: Ensure location tag on pump top

flange is engaged correctly to tank

opening lip.

31.Fit locking ring and tighten to

35 Nmusing

service tool LRT-19-009.

32.Fit vent hose to fuel tank clips and connect to

pressure sensor.

33.With assistance, fit fuel tank into position.

34.Fit fuel tank cradle and secure with nuts and

bolts.

35.Align upper fuel tank strap and secure with nut

and bolt.

36.Fit NEW clip to fuel filler neck hose.

37.Connect fuel filler neck internal breather to tank.

38.Connect fuel filler neck hose to tank.

39.Position fuel filler neck hose clip and tighten until

head shears.

40.Connect vent line quickfit connector to

liquid/vapour separator.

41.Connect vent line hose connection.

42.Position anti-roll [sway] bar straps and secure

with nuts and bolts.

43.Remove stand(s) and lower vehicle.

44.Connect both fuel lines to the pump by pushing

the connectors down each line square to the

pump connection until the connectors positively

latches.

45.Connect multiplugs to fuel pump and pressure

sensor.

46.Reconnect battery negative lead.

47.Refill tank with drained fuel.

48.Run the engine to check for any fuel leaks.

49.Fit access panel and secure with screws.

50.Reposition loadspace sound insulation and

carpet.

51.Fit RH luggage compartment side panel.

See

CHASSIS AND BODY, Repair, rear

compartment trim panels

52.Fit tail door tread strip and secure with screws.FUEL TANK - DRAINING - ADVANCED EVAPS

Service repair no - 19.55.02

WARNING: Before removing the fuel tank

it must be drained.

WARNING: Petrol/gasoline vapour is

highly flammable and in confined spaces

is also explosive and toxic. Always have a

fire extinguisher containing FOAM, CO2, GAS or

POWDER close at hand when handling or draining

fuel. See Introduction

CAUTION: Before disconnecting any part

of fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign matter

into fuel system.

NOTE: Assuming the fuel tank is FULL

drain the following quantities:

Renew Fuel pump = 9 Litres (2.4 US Gallons)

Renew Fuel filler neck = 22 Litres (6 US Gallons)

Renew Fuel tank = COMPLETE DRAIN

1.Depressurise fuel system.

See fuel system -

depressurise - advanced evaps

2.Disconnect battery negative lead.

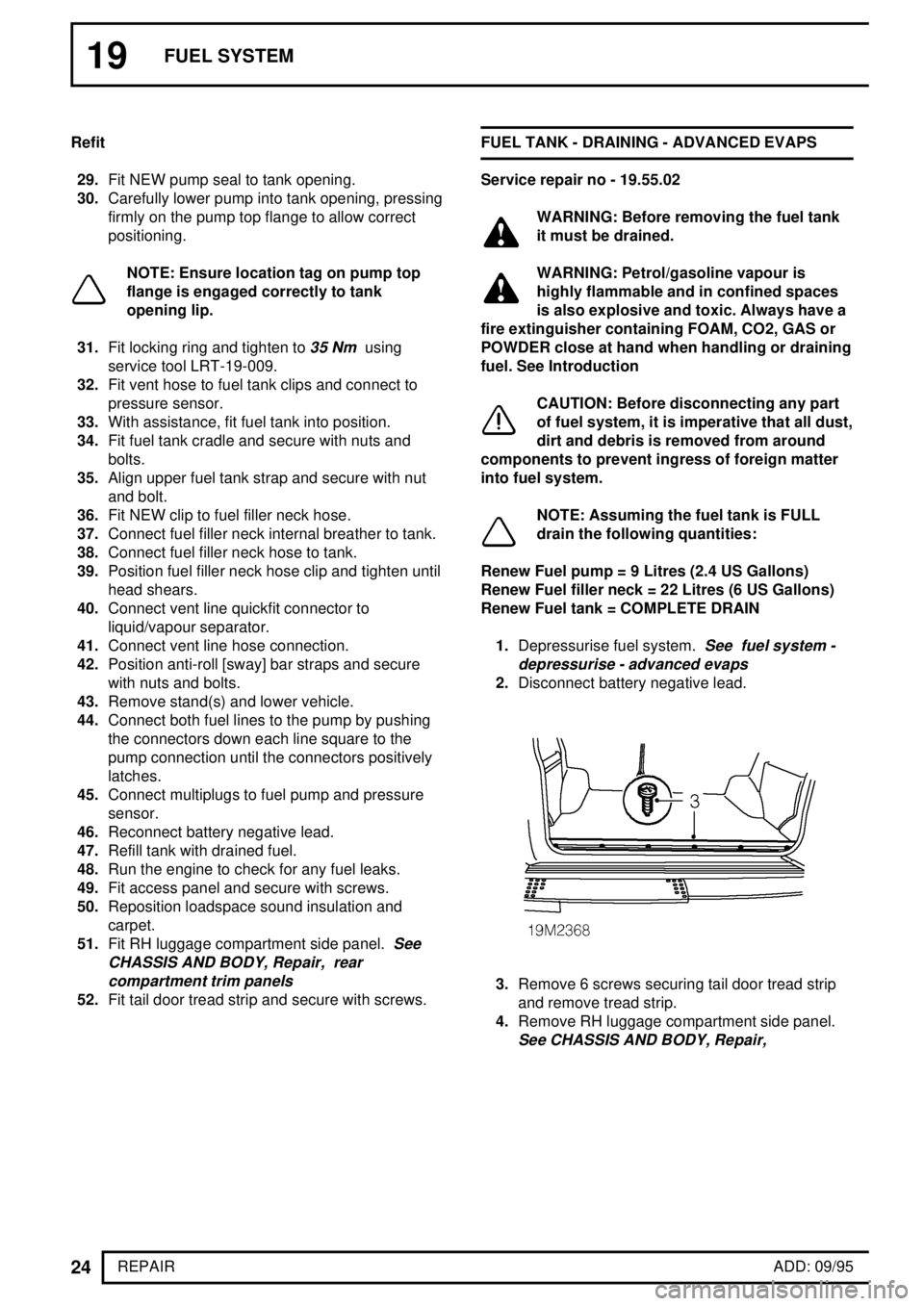

3.Remove 6 screws securing tail door tread strip

and remove tread strip.

4.Remove RH luggage compartment side panel.

See CHASSIS AND BODY, Repair,

Page 308 of 873

SFI

25

REPAIR ADD: 09/95

5.Fold back loadspace carpet and sound

insulation to reveal access panel.

6.Remove 6 screws securing fuel pump access

panel.

7.Remove access panel.

8.Disconnect the fuel return connection by

pressing the black release latch on connector

and pushing the connector back down the line.

Care must be taken to catch any excess fuel

which may spill from the fuel line once removed.

9.Using a bowser, with a 7 mm inside diameter

hose connection attach to fuel pump return stub,

drain fuel into a sealed container. Follow the

manufacturers instructions for the connection

and safe use of the bowser.

10.Continue draining until air bubbles appear and

fuel ceases to flow.

11.Disconnect bowser from fuel pump return stub.

12.Connect fuel return line to pump by pushing the

connector down line square to the pump

connection until the connector positively latches.

13.Fit access panel and secure with screws.

14.Reposition loadspace sound insulation and

carpet.

15.Fit RH luggage compartment side panel.

See

CHASSIS AND BODY, Repair, rear

compartment trim panels

16.Fit tail door tread strip and secure with screws.

17.Reconnect battery negative lead.

Page 309 of 873

19FUEL SYSTEM

26

REPAIRADD: 09/95 FUEL FILLER NECK - ADVANCED EVAPS

Service repair no - 19.55.07

WARNING: Ensure that fuel handling

precautions given in 1 - Introduction are

strictly adhered to when carrying out

following instructions.

CAUTION: Before disconnecting any part

of fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign matter

into fuel system.

Remove

1.Depressurise fuel system.

See fuel system -

depressurise - advanced evaps

2.Disconnect battery negative lead.

3.Check the amount of fuel in the tank. If the tank

is full drain 6 US gallons (22 litres) minimum.

See fuel tank - draining.

4.Remove 6 screws securing tail door tread strip

and remove tread strip.

5.Remove RH luggage compartment side panel.

See CHASSIS AND BODY, Repair, rear

compartment trim panels

6.Fold back loadspace carpet and sound

insulation to gain access to RH mudflap fixing.

7.Raise rear of vehicle.

WARNING: Support on safety stands.

8.Remove nut and bolt securing filler neck support

bracket to mud flap bracket.

NOTE: This fixing also retains the filler

neck earth strap.

9.Remove 5 nuts and bolts securing mud flap to

body.

10.Remove mud flap.

Page 310 of 873

SFI

27

REPAIR ADD: 09/95

11.Disconnect vent line quickfit connector from

liquid/vapour separator.

12.Remove torque screw cap from hose to tank

filler neck clip.

13.Loosen clip screw securing hose to tank filler

neck.

14.Release hose from filler neck and internal filler

neck breather hose from fuel tank.

15.Remove and discard fuel filler neck clip.

16.Disconnect the pressure sensor breather pipe

connection.

17.Disconnect the vent line hose connection.

18.Fit ignition key to fuel filler flap lock and open

flap.

19.Release fuel filler cap from filler neck.

20.Remove filler neck assembly from vehicle.

Do not carry out further dismantling if

component is removed for access only.

21.Remove torque screw cap from hose to filler

neck clip.

22.Loosen clip screw securing hose to filler neck.

23.Remove hose from filler neck.

24.Remove and discard fuel filler hose clip.

25.Remove vent line from filler neck.