ECU LAND ROVER DISCOVERY 1995 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 148 of 873

12ENGINE

12

REPAIR

12.Remove 4 bolts securing rocker cover to cylinder

head.

13.Remove rocker cover.

14.Remove and discard rocker cover gasket.Refit

15.Clean mating faces between rocker cover and

cylinder head using Bostick cleaner 6001 or

equivalent. Allow to dry.

NOTE: Gasket fits one way round only. It

must be fitted accurately, first time.

Subsequent movement will destroy

bonding.

16.Apply a thin coating of impact adhesive (Bostick

1775 or equivalent) to mating faces of rocker

cover seal face and new gasket. Use a brush to

ensure an even film. Allow adhesive to become

touch dry.

17.Place one end of gasket into cover recess with

edge firmly against recess wall, holding

remainder of gasket clear. Work around cover,

pressing gasket into place ensuring edge firmly

contacts recess wall.

CAUTION: Allow cover to stand for thirty

minutes before fitting.

18.Fit rocker cover to cylinder head, ensure short

screws are inboard. Tighten to

9 Nm.

19.Connect fuel feed and return hoses.

20.Refit ht leads into retaining brackets.

21.Secure engine harness to brackets.

22.Connect coolant pipes to hoses and secure

brackets.

23.Connect breather hose to rocker cover.

24.Connect purge hose to plenum chamber.

25.Connect bottom hose to radiator.

26.Refill cooling system.

See COOLING SYSTEM

V8, Adjustment, Coolant

27.Reconnect battery negative lead.

Page 152 of 873

12ENGINE

2

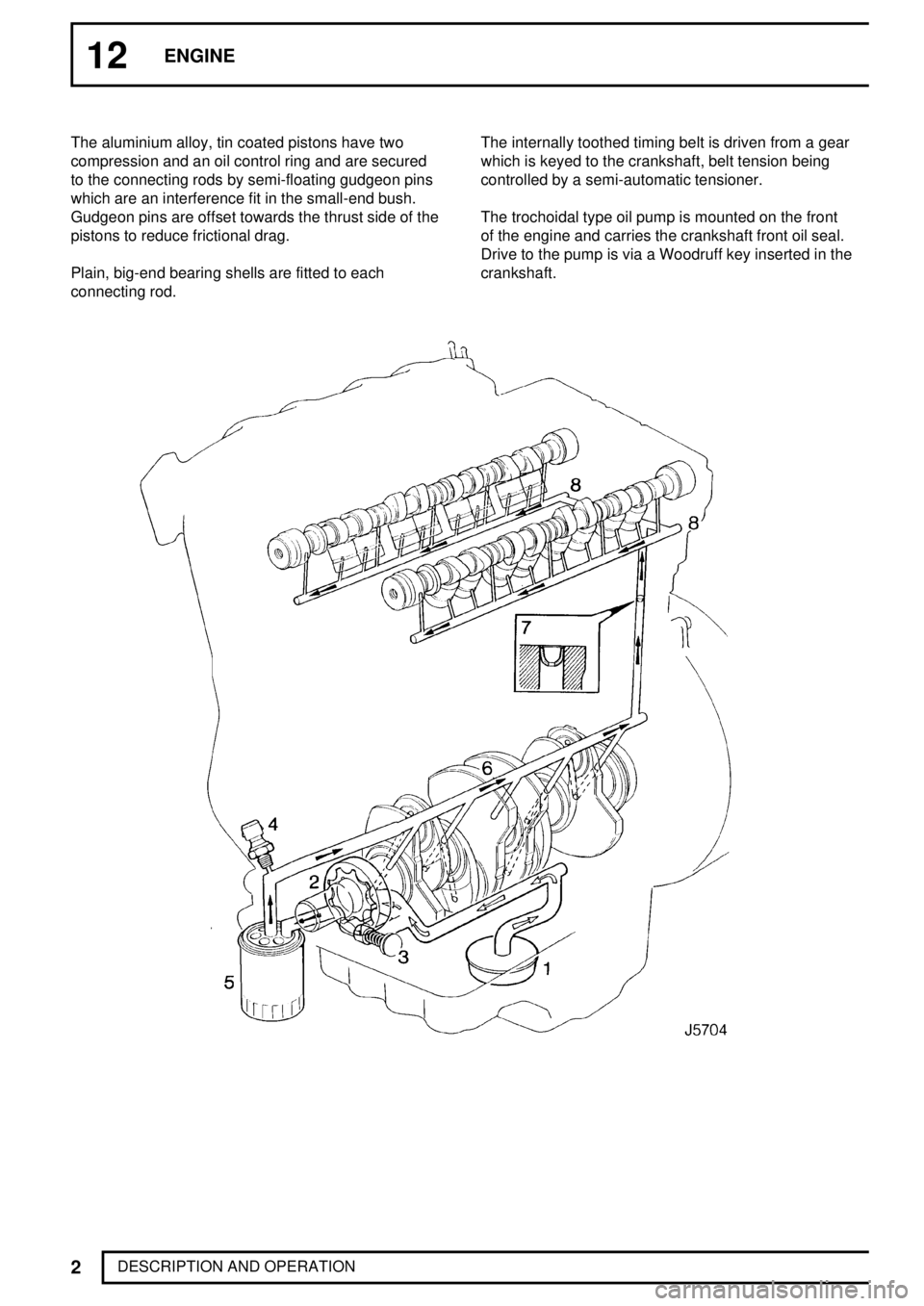

DESCRIPTION AND OPERATION The aluminium alloy, tin coated pistons have two

compression and an oil control ring and are secured

to the connecting rods by semi-floating gudgeon pins

which are an interference fit in the small-end bush.

Gudgeon pins are offset towards the thrust side of the

pistons to reduce frictional drag.

Plain, big-end bearing shells are fitted to each

connecting rod.The internally toothed timing belt is driven from a gear

which is keyed to the crankshaft, belt tension being

controlled by a semi-automatic tensioner.

The trochoidal type oil pump is mounted on the front

of the engine and carries the crankshaft front oil seal.

Drive to the pump is via a Woodruff key inserted in the

crankshaft.

Page 160 of 873

12ENGINE

2

REPAIR 13.Remove 2 bolts securing camshaft gears to

camshafts.

14.Remove tool LRT-12-060.

CAUTION: Do not rotate camshafts.

15.Remove gears noting the 'IN' and 'EXHAUST'

identifying marks.

16.Remove 5 bolts securing timing belt upper

backplate.

17.Remove belt upper backplate.

18.Remove seals using tool LRT-12-063 fit

thrustpad as shown.

Refit

1.Clean sealing area of cylinder head and

camshaft, ensure all traces of rubber are

removed - do not scrape.

2.Using tool LRT-12-064 and LRT-12-072 fit new

camshaft oil seals.

CAUTION: Ensure sealing lip of seal is not

distorted.

Page 163 of 873

Mpi

5

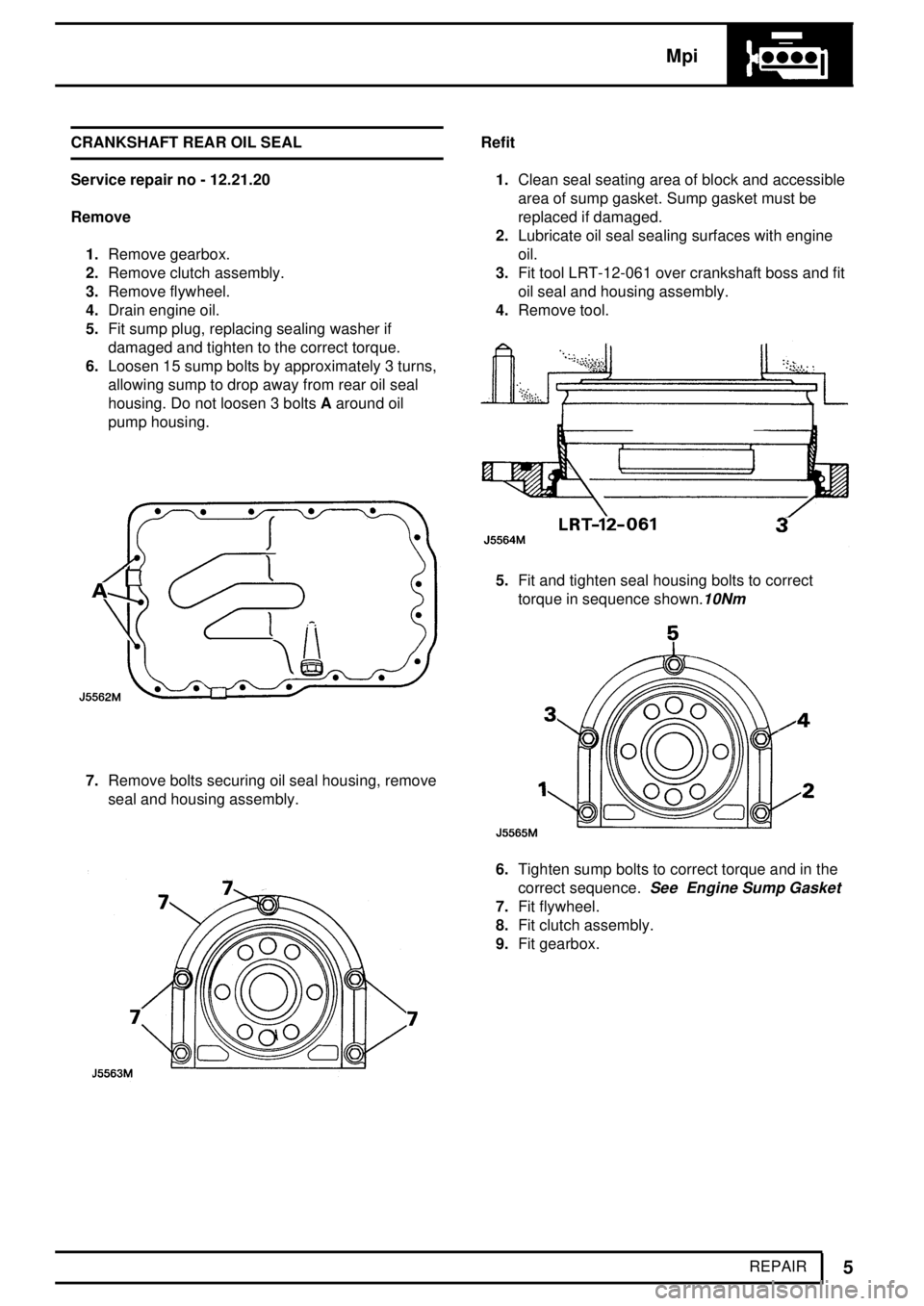

REPAIR CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

Remove

1.Remove gearbox.

2.Remove clutch assembly.

3.Remove flywheel.

4.Drain engine oil.

5.Fit sump plug, replacing sealing washer if

damaged and tighten to the correct torque.

6.Loosen 15 sump bolts by approximately 3 turns,

allowing sump to drop away from rear oil seal

housing. Do not loosen 3 boltsAaround oil

pump housing.

7.Remove bolts securing oil seal housing, remove

seal and housing assembly.

Refit

1.Clean seal seating area of block and accessible

area of sump gasket. Sump gasket must be

replaced if damaged.

2.Lubricate oil seal sealing surfaces with engine

oil.

3.Fit tool LRT-12-061 over crankshaft boss and fit

oil seal and housing assembly.

4.Remove tool.

5.Fit and tighten seal housing bolts to correct

torque in sequence shown.

10Nm

6.Tighten sump bolts to correct torque and in the

correct sequence.

See Engine Sump Gasket

7.Fit flywheel.

8.Fit clutch assembly.

9.Fit gearbox.

Page 165 of 873

Mpi

7

REPAIR

NOTE: On current models the generator

cover is omitted.

9.Remove 3 nuts securing generator rear cover.

10.Remove rear cover.

11.Remove 3 nuts securing harness to generator.

12.Remove harness.

13.Disconnect oxygen sensor multiplug.

14.Release multiplug from bracket.

15.Release harness from cable tie.

16.Disconnect 2 coolant temperature sensor

multiplugs.

17.Release clips and disconnect the bypass and

top hose.

18.Release harness lead from cable tie.

19.Release clip and disconnect breather hose from

inlet manifold.

20.Feed harness between inlet manifold and cam

cover.

Page 167 of 873

Mpi

9

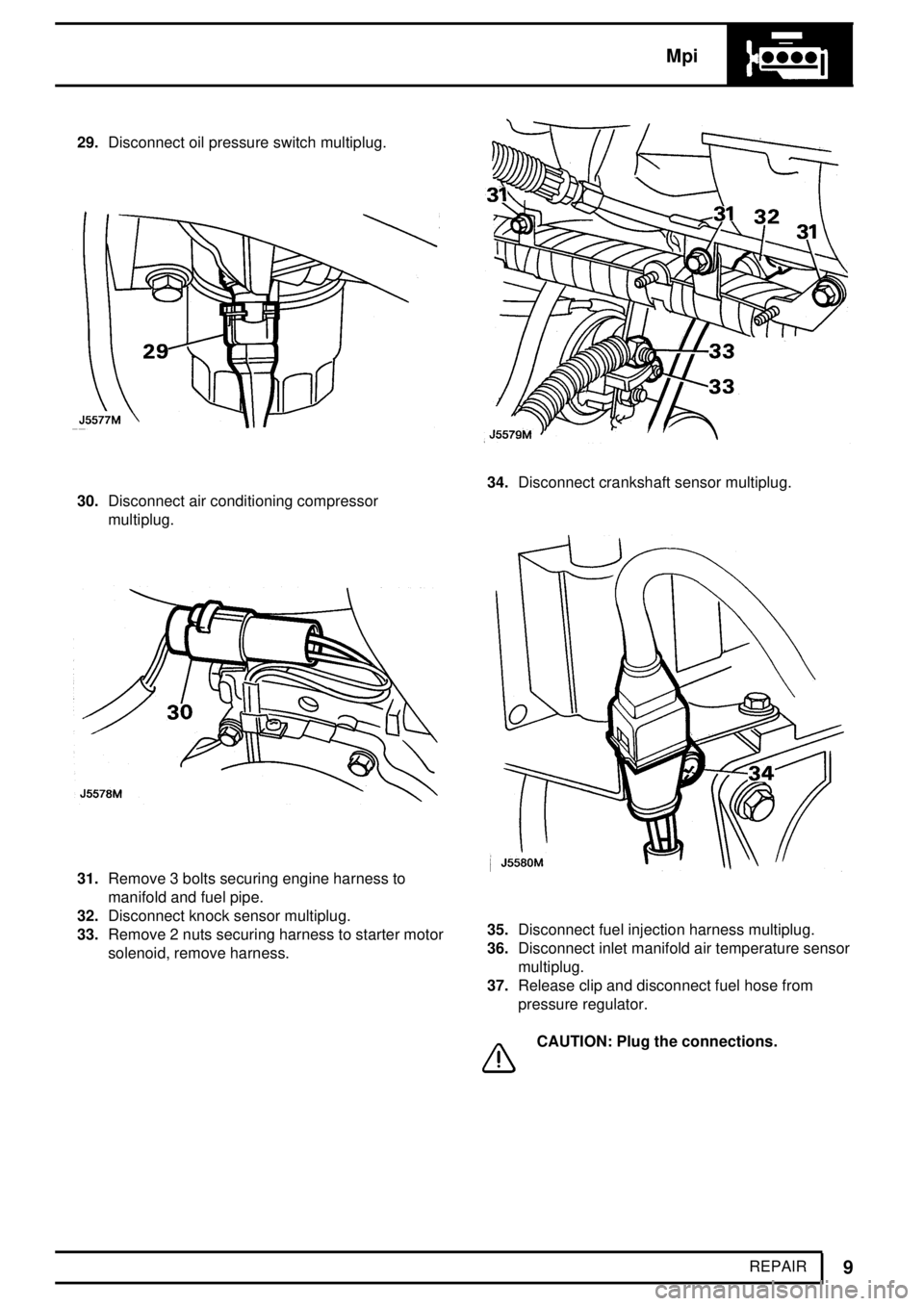

REPAIR 29.Disconnect oil pressure switch multiplug.

30.Disconnect air conditioning compressor

multiplug.

31.Remove 3 bolts securing engine harness to

manifold and fuel pipe.

32.Disconnect knock sensor multiplug.

33.Remove 2 nuts securing harness to starter motor

solenoid, remove harness.

34.Disconnect crankshaft sensor multiplug.

35.Disconnect fuel injection harness multiplug.

36.Disconnect inlet manifold air temperature sensor

multiplug.

37.Release clip and disconnect fuel hose from

pressure regulator.

CAUTION: Plug the connections.

Page 168 of 873

12ENGINE

10

REPAIR

38.Disconnect 2 ignition coil multiplugs.

39.Disconnect 3 vacuum hoses from manifold.

40.Release cover and remove bolt securing earth

lead to cylinder block.

41.Move earth lead aside.

42.Remove 4 bolts securing air conditioning

compressor, move compressor aside.

Page 169 of 873

Mpi

11

REPAIR 43.Remove engine mounting heat shield. Remove

upper nuts from engine L.H. and R.H.

mountings.

44.Release 4 screws and remove spark plug cover.

45.Fit tool LRT-12-056, support engine using

suitable hoist.

46.Raise vehicle.

47.Loosen 2 nuts securing downpipe to silencer.

48.Remove 4 nuts securing downpipe to exhaust

manifold.

49.Release downpipe from exhaust manifold.

50.Collect gasket.

Page 170 of 873

12ENGINE

12

REPAIR 51.Remove engine L.H. and R.H. mounting lower

nuts.

52.Lower vehicle.

53.Raise engine.

54.Remove engine mountings.

55.Lower engine.

56.Remove bell housing top nut.

57.Raise engine and support gearbox.58.Remove 12 remaining bell housing nuts.

59.Remove engine.

Refit

NOTE: For torque values.See

Specifications, torque, Torque Values

1.Using assistance, lower engine into position.

2.Fit bell housing nuts, tighten to the correct

torque.

3.Remove gearbox support.

4.Lower engine.

5.Fit bell housing top nut, tighten to the correct

torque.

6.Raise engine.

7.Position engine mountings, partially tighten nuts.

8.Lower engine.

9.Remove hoist and chains.

10.Tighten L.H. and R.H. mounting nuts to the

correct torque. Fit engine mounting heatshield.

11.Fit new gasket to exhaust downpipe.

12.Fit exhaust manifold to downpipe nuts and

tighten to the correct torque.

13.Tighten exhaust downpipe to silencer box nuts

to the correct torque.

14.Position air conditioning compressor and secure

with bolts. Tighten to the correct torque.

15.Connect coil multiplugs.

16.Connect harness to starter solenoid and secure

with nuts.

17.Connect earth lead to cylinder block and secure

with nut.

18.Position engine harness to manifold, secure with

bolts.

Page 171 of 873

Mpi

13

REPAIR 19.Connect crankshaft sensor, knock sensor, air

conditioning compressor, fuel injector harness,

inlet manifold air temperature and fuel

temperature sensor multiplugs.

20.Connect fuel hose to pressure regulator and

secure with clip.

21.Fit and tighten fuel pipe to fuel rail union.

22.Connect multiplugs to throttle housing.

23.Connect vacuum hose to manifold.

24.Connect oil pressure switch multiplug.

25.Connect brake servo hose to manifold, secure

with clip.

26.Connect throttle cable to cam.

27.Position engine harness and connect breather

hose to inlet manifold, secure with clip.

28.Connect coolant temperature sensor multiplugs,

secure harness with cable tie.

29.Connect oxygen sensor multiplug, secure

harness with cable tie.

30.Connect alternator harness.

31.Connect heater hose to heater rail and secure

with clip.

32.Connect hose to coolant pump and secure with

clip.

33.Connect inlet hose to power steering pump and

secure with clip.

34.Fit and tighten outlet pipe union to power

steering pump.

35.Connect bypass and top hose, secure with clip.

36.Connect air cleaner to throttle housing hose and

secure with clip.

37.Remove engine lifting bracket.

38.Position spark plug cover and secure with

screws.

39.Fill engine with oil.

40.Fit bonnet [hood].

See CHASSIS AND BODY,

Repair, Bonnet [Hood]

41.Fit radiator.See COOLING SYSTEM, Repair,

Radiator - Mpi

42.Adjust throttle cable.See FUEL SYSTEM,

Adjustment, Throttle Cable Adjustment

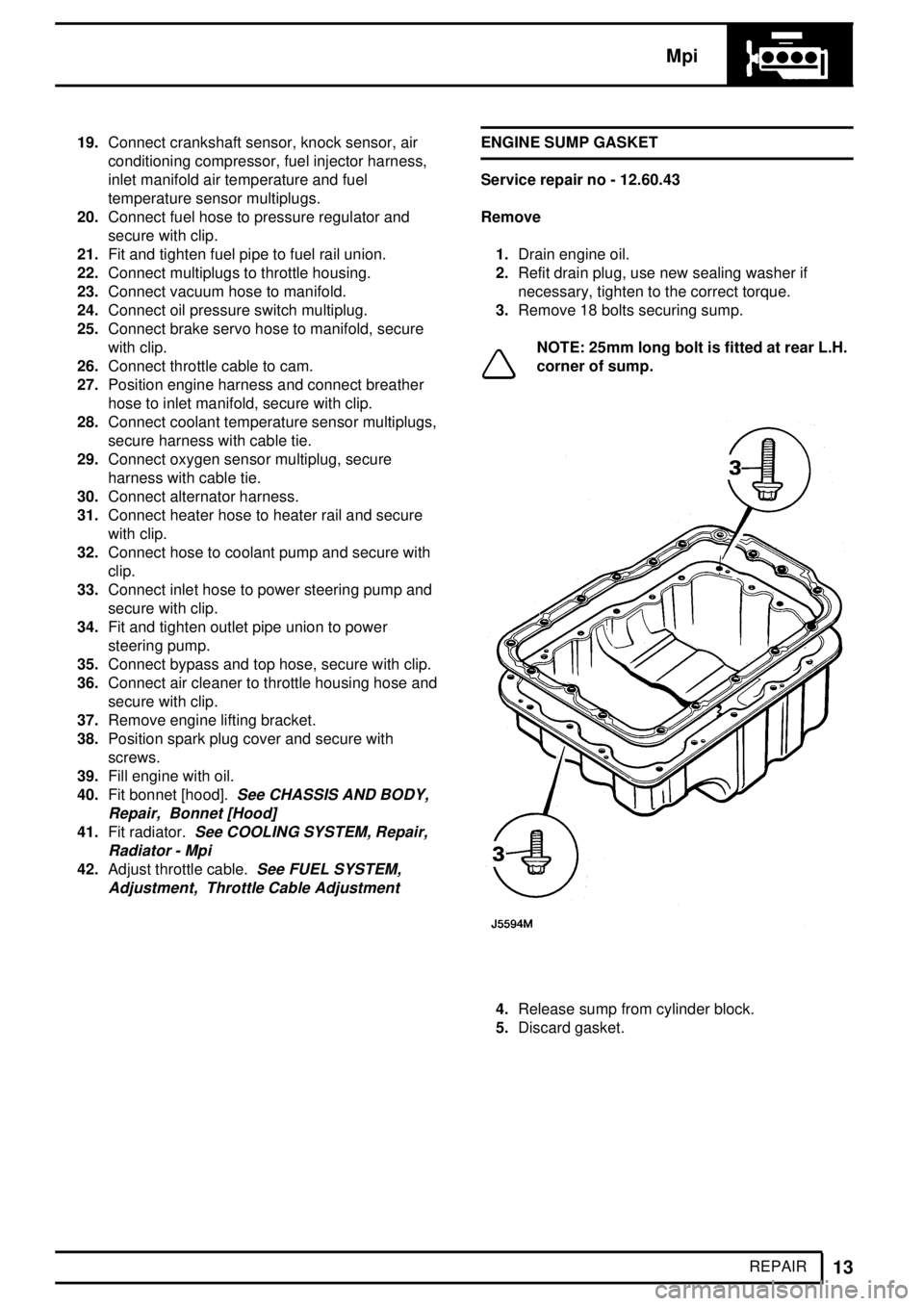

ENGINE SUMP GASKET

Service repair no - 12.60.43

Remove

1.Drain engine oil.

2.Refit drain plug, use new sealing washer if

necessary, tighten to the correct torque.

3.Remove 18 bolts securing sump.

NOTE: 25mm long bolt is fitted at rear L.H.

corner of sump.

4.Release sump from cylinder block.

5.Discard gasket.