LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 791 of 873

82AIR CONDITIONING

26

REPAIR ALPINE LIGHT DUCT

Service repair no - 82.26.21

Remove

1.Remove evaporator to alpine light duct.

See

evaporator to alpine light duct

2.Remove rear door upper trim panel.See

CHASSIS AND BODY, Repair, rear door

upper trim panel - with rear air conditioning

fitted

3.Remove clip securing alpine light duct to body

flange.

4.Remove screw securing alpine light duct.

5.Manoeuvre alpine light duct from headlining and

'D' post finishers and remove duct.

Refit

6.Position alpine duct and manoeuvre into

position.

7.Fit and tighten screw securing alpine duct to

body.

8.Fit clip securing alpine duct to body flange.

9.Fit rear door upper trim panel.

See CHASSIS

AND BODY, Repair, rear door upper trim

panel - with rear air conditioning fitted; Refit

10.Fit evaporator to alpine light duct.See

evaporator to alpine light duct; Refit

EVAPORATOR TO ALPINE LIGHT DUCT

Service repair no - 82.26.22

Remove

1.Remove rear compartment lower trim panel.

See CHASSIS AND BODY, Repair, rear

compartment lower trim panel - lh - with rear

air conditioning fitted

2.Remove 4 clips securing duct to evaporator.

3.Release duct from evaporator.

4.Remove duct from alpine light.

Refit

5.Fit duct to alpine light.

6.Position duct to evaporator ensuring rear of duct

flange is positioned beneath body panel flange.

7.Fit clips securing duct to evaporator.

8.Fit rear compartment lower trim panel.

See

CHASSIS AND BODY, Repair, rear

compartment lower trim panel - lh - with rear

air conditioning fitted; Refit

Page 792 of 873

AIR CONDITIONING

27

REPAIR BLOWER MOTOR RESISTOR - REAR

Service repair no - 82.26.23

Remove

1.Remove evaporator/blower motor assembly.

See evaporator/blower motor assembly -

rear

2.Disconnect multiplug from resistor.

3.Remove 2 screws securing resistor to blower

motor casing.

4.Remove resistor.

Refit

5.Fit resistor to blower motor casing and secure

with screws.

6.Connect multiplug to resistor.

7.Fit evaporator/blower motor assembly.

See

evaporator/blower motor assembly - rear;

Refit

Page 793 of 873

AIR CONDITIONING

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Air conditioning

Compressor flange bolts 10............................................................................

Receiver drier union bolts 6...........................................................................

Dual pressure switch 11..................................................................................

Pressure pipe union nuts - M16 14.................................................................

Discharge pipe union nuts - M22 22...............................................................

Suction pipe union nuts - M24 33...................................................................

AIR CONDITIONING CHARGE DATA

Total oil in system 180ml - 6.3Fl oz...........................................................................

Total refrigerant in system 0,90kg - 32Fl oz..............................................................

Total refrigerant in system with rear air conditioning 1,15kg - 40Fl oz.......................

Page 794 of 873

WIPERS AND WASHERS

1

DESCRIPTION AND OPERATION WINDSCREEN WIPER AND WASHER OPERATION

The illustration below locates and identifies the main

components of the windscreen and washer system

which is operated by a multi-switch on the right hand

side of the steering column.

All functions of the system are described in the

following paragraphs.

1. Multi-switch

2. Wiper motor

3. Wiper arm/blade

4. Washer reservoir

5. Windscreen washer motor/pump

6. Non return valve

7. Washer jet

8. Rear window washer motor pump

9. Non return valve10. Headlamp power wash motor/pump

11. Headlamp power washer jet

12. Non return valve

13. Rear window wiper switch

14. Rear window washer switch

15. Rear window wiper motor, arm and blade

16. Washer jet

Page 795 of 873

84WIPERS AND WASHERS

2

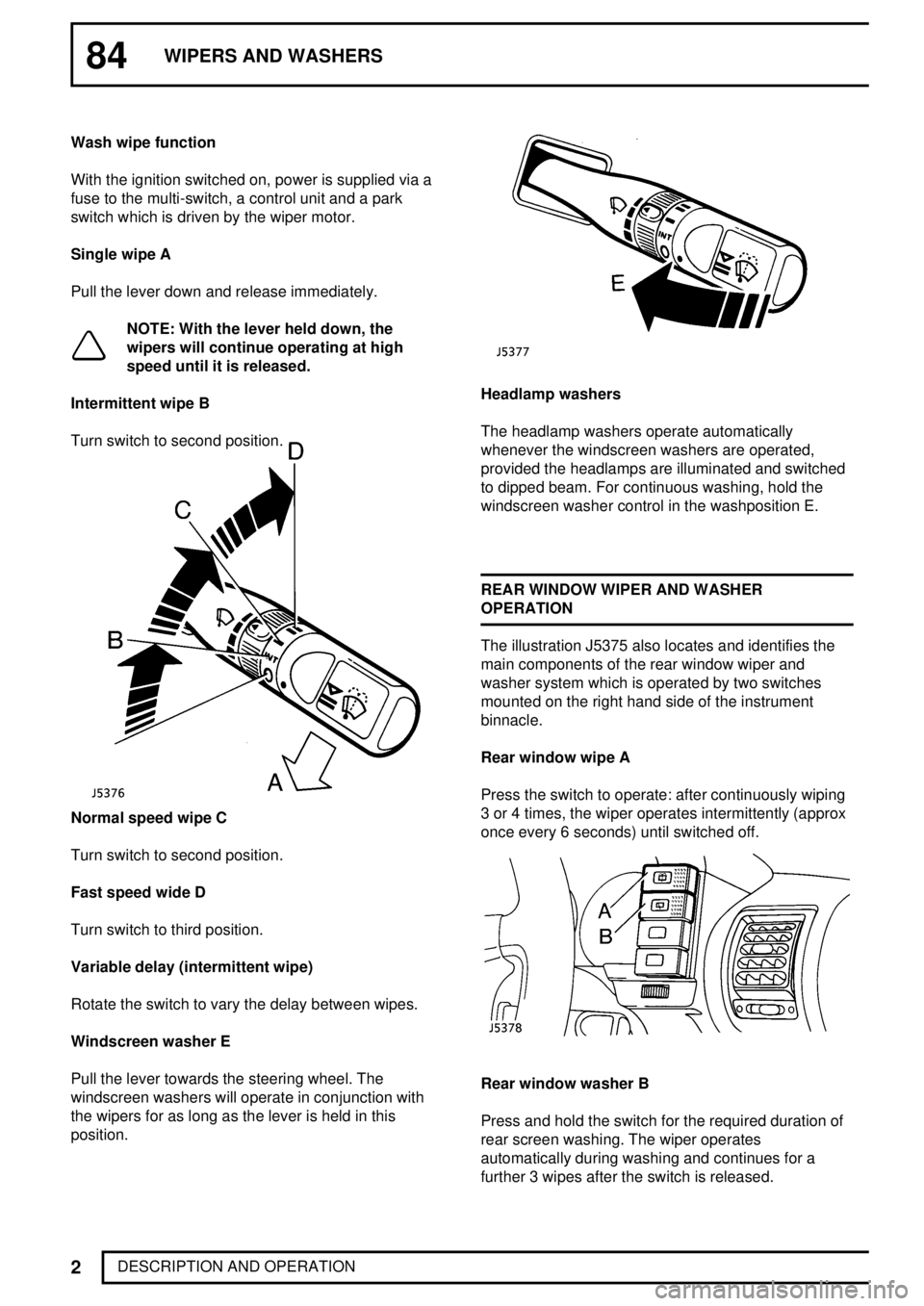

DESCRIPTION AND OPERATION Wash wipe function

With the ignition switched on, power is supplied via a

fuse to the multi-switch, a control unit and a park

switch which is driven by the wiper motor.

Single wipe A

Pull the lever down and release immediately.

NOTE: With the lever held down, the

wipers will continue operating at high

speed until it is released.

Intermittent wipe B

Turn switch to second position.

Normal speed wipe C

Turn switch to second position.

Fast speed wide D

Turn switch to third position.

Variable delay (intermittent wipe)

Rotate the switch to vary the delay between wipes.

Windscreen washer E

Pull the lever towards the steering wheel. The

windscreen washers will operate in conjunction with

the wipers for as long as the lever is held in this

position.

Headlamp washers

The headlamp washers operate automatically

whenever the windscreen washers are operated,

provided the headlamps are illuminated and switched

to dipped beam. For continuous washing, hold the

windscreen washer control in the washposition E.

REAR WINDOW WIPER AND WASHER

OPERATION

The illustration J5375 also locates and identifies the

main components of the rear window wiper and

washer system which is operated by two switches

mounted on the right hand side of the instrument

binnacle.

Rear window wipe A

Press the switch to operate: after continuously wiping

3 or 4 times, the wiper operates intermittently (approx

once every 6 seconds) until switched off.

Rear window washer B

Press and hold the switch for the required duration of

rear screen washing. The wiper operates

automatically during washing and continues for a

further 3 wipes after the switch is released.

Page 796 of 873

WIPERS AND WASHERS

1

FAULT DIAGNOSIS WIPER MOTOR CHECKING

NOTE: These instructions apply to

windscreen and rear window wiper motor.

If unsatisfactory operation of wiping equipment is

experienced, a systematic check to determine fault

should be carried out:

1.Check blades for signs of excessive friction. This

reduces wiping speed of motor and cause

increased current draw which may damage

armature. Check by substitution.

2.Check windscreen wiper motor light running

current and speed with motor coupling link

disconnected from wiper shaft transmission

linkage.

Check rear window glass wiper motor with wiper

connected and glass wet. Connect an ammeter in

series with motor supply. Measure current

consumption when motor is switched on. Check

operating speed by timing speed of rotation of motor

coupling link. The results should compare with figures

given in 'General Specification Data'.

NOTE: If vehicle wiring connections are

disconnected and an alternative supply

source is applied it is essential that

correct polarity is observed. Failure to observe

this will cause motor to rotate in reverse direction,

which may result in limit switch contacts being

damaged.

3.If motor does not run satisfactorily or takes

higher than normal current, a fault exists and

must be remedied.

4.If current consumption and speed of motor are

satisfactory. A check should be carried out for

proper functioning of transmission linkage and

wiper arm shafts.

NOTE: Service parts are not available for

windscreen and rear window wiper motors

with exception of windscreen wiper rotary

connecting link.

Page 797 of 873

WIPERS AND WASHERS

1

REPAIR WASHER RESERVOIR

Service repair no - 84.10.03.

Remove

1.Remove two bolts securing top of reservoir.

2.From underneath the wheelarch remove two

bolts securing base of reservoir.

3.Withdraw reservoir and disconnect tubing from

washer pumps and power wash.

4.Disconnect electrical leads from pumps.

Refit

5.Reverse removal procedure. 1 to 4.WASHER PUMP - WINDSCREEN, REAR WINDOW

OR POWER WASH

Service repair no - 84.20.21.

Remove

1.Remove washer reservoir.See Washer

reservoir

2.Disconnect washer tubing from pump.

3.Disconnect electrical leads from pump.

4.Pull top of pump away from its location in

reservoir and remove pump.

Note position of sealing gasket in reservoir.

Refit

5.Reverse removal procedure. 1 to 4.

Page 798 of 873

84WIPERS AND WASHERS

2

REPAIR WINDSCREEN WASHER JETS

Service repair no - 84.10.09.

Remove

1.Disconnect washer tube from jet.

2.Remove nut and washer securing washer jet to

air intake cowl.

3.Remove jet.

Refit

4.Reverse removal procedure. 1 to 3.WINDSCREEN WASHER TUBES

Service repair no - 84.10.15.

Remove

1.Disconnect tubing from reservoir pump.

2.Disconnect tubing from washer jets.

3.Disconnect tubing from three-way tee piece.

4.Release tubing from retaining clip and withdraw.

Refit

5.Reverse removal procedure. 1 to 4. Ensuring the

tubing is not pinched or restricted.

Page 799 of 873

WIPERS AND WASHERS

3

REPAIR WIPER ARMS - WINDSCREEN

Service repair no - 85.15.01.

Remove

1.Lift wiper arm end cap to gain access to securing

nut.

2.Remove nut and withdraw wiper arm from

splined boss.

Refit

3.Allow wiper motor to move to 'park' position.

4.Push arm onto splined boss, locating it so that

wiper blades are clear of windscreen rail.

5.Fit and tighten securing nut.

6.Push end cap over securing nut.

7.Operate wiper on a wet windscreen to ensure

blades do not over travel.WIPER ARM - REAR WINDOW

Service repair no - 84.35.01.

Remove

1.Remove plastic nut cover and wiper arm

securing nut.

2.Withdraw wiper arm and grommet from splined

boss.

Refit

3.Allow wiper motor to move to 'park' position.

4.Fit spacer and wiper arm to splined boss so that

the wiper blade is clear of rear window surround.

5.Fit and tighten securing nut.

6.Push plastic nut cover into position.

7.Check operation of wiper.

Page 800 of 873

84WIPERS AND WASHERS

4

REPAIR WIPER BLADES

Service repair no - 84.15.05

Remove

1.Pull wiper blade away from screen.

2.Depress spring clip and withdraw blade from

hooked end of wiper arm.

Refit

3.Reverse removal procedure. 1 and 2.REAR WINDOW WASHER JET

Service repair no - 84.30.09

Remove

1.Turn washer jet in a clockwise direction to

release it from the rear quarter panel.

2.Remove rear quarter/speaker trim panel.

3.Feed washer tubing through rear quarter panel

to allow removal of washer jet.

4.Remove washer jet from tubing.

Refit

5.Reverse removal procedure. 1 to 4.

NOTE: The tubing run from the reservoir to

rear door washer jet differs between left

and right hand drive vehicles. On right

hand vehicles the tubing run is on the left hand

side of the roof. On left hand drive vehicles, the

right side.

See Description and operation,

Windscreen Wiper and Washer Operation