LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 751 of 873

AIR CONDITIONING

1

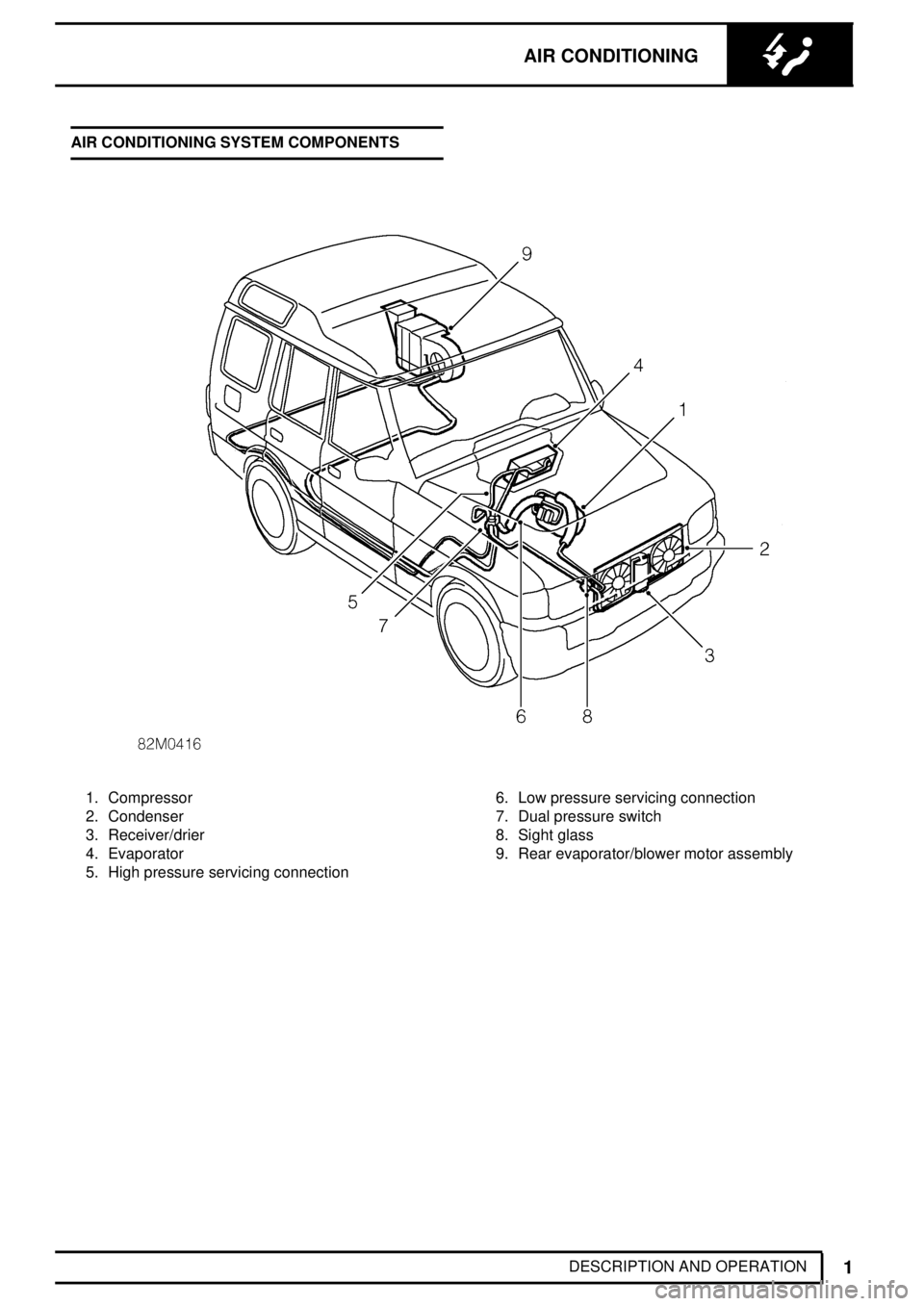

DESCRIPTION AND OPERATION AIR CONDITIONING SYSTEM COMPONENTS

1. Compressor

2. Condenser

3. Receiver/drier

4. Evaporator

5. High pressure servicing connection6. Low pressure servicing connection

7. Dual pressure switch

8. Sight glass

9. Rear evaporator/blower motor assembly

Page 752 of 873

82AIR CONDITIONING

2

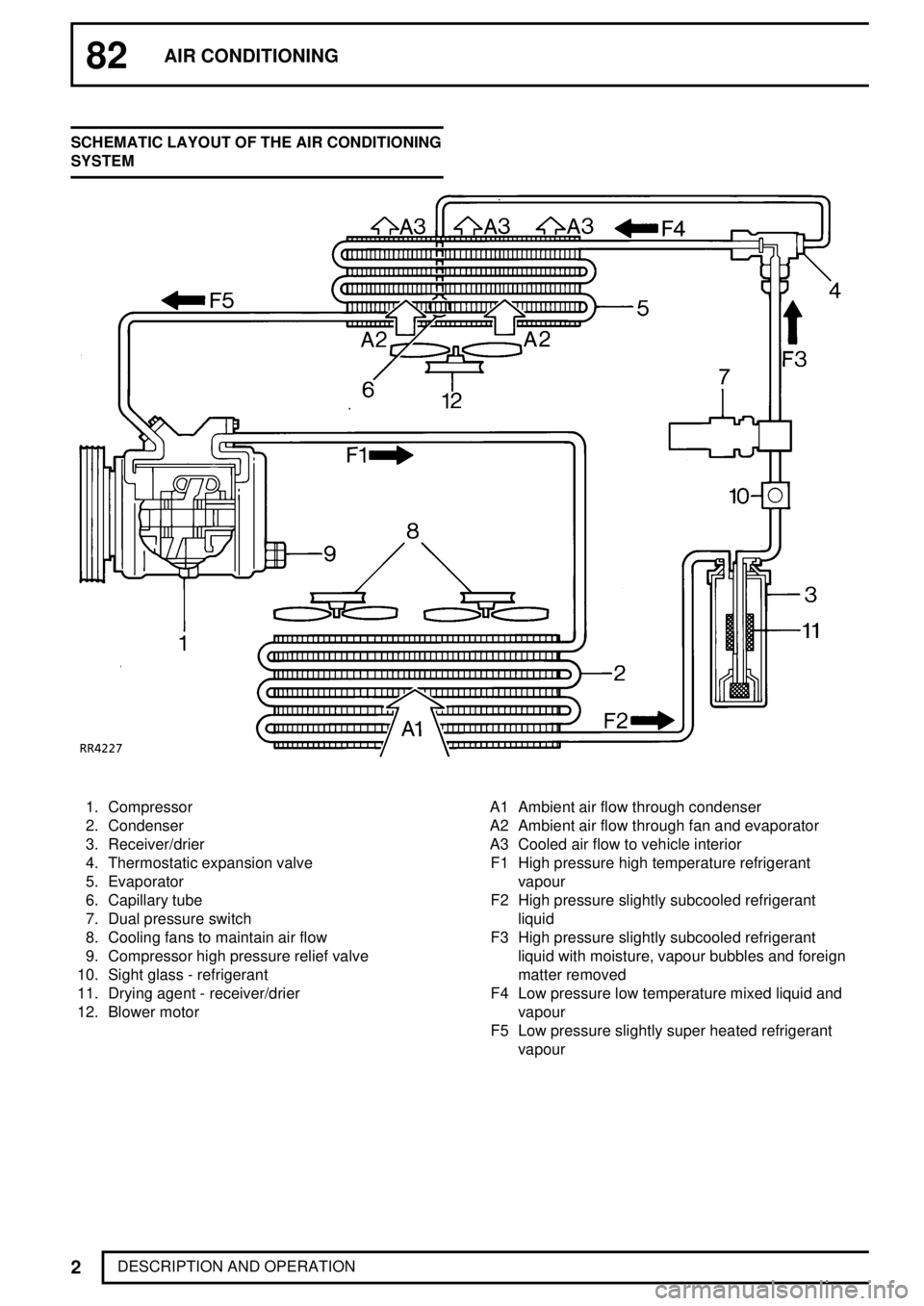

DESCRIPTION AND OPERATION SCHEMATIC LAYOUT OF THE AIR CONDITIONING

SYSTEM

1. Compressor

2. Condenser

3. Receiver/drier

4. Thermostatic expansion valve

5. Evaporator

6. Capillary tube

7. Dual pressure switch

8. Cooling fans to maintain air flow

9. Compressor high pressure relief valve

10. Sight glass - refrigerant

11. Drying agent - receiver/drier

12. Blower motorA1 Ambient air flow through condenser

A2 Ambient air flow through fan and evaporator

A3 Cooled air flow to vehicle interior

F1 High pressure high temperature refrigerant

vapour

F2 High pressure slightly subcooled refrigerant

liquid

F3 High pressure slightly subcooled refrigerant

liquid with moisture, vapour bubbles and foreign

matter removed

F4 Low pressure low temperature mixed liquid and

vapour

F5 Low pressure slightly super heated refrigerant

vapour

Page 753 of 873

AIR CONDITIONING

3

DESCRIPTION AND OPERATION AIR CONDITIONING SYSTEM OPERATION

The air conditioning system provides the means of

supplying cooled and dehumidified, fresh or

recirculated air to the interior of the vehicle. The

cooling effect is obtained by blowing air through the

matrix of an evaporator unit and when required,

mixing that air with heated air by means of the heater

distribution and blend unit, to provide the conditions

required inside the vehicle. The volume of conditioned

air being supplied is controlled by a variable speed

blower.

A sealed system, charged with Refrigerant R134a,

together with a blower unit, blend unit and control

system combine to achieve the cooled air condition.

For air conditioning air distribution system.

See

HEATING AND VENTILATION, Description and

operation, Heating and ventilation unit

The air conditioning system comprises five major

units:

1.An engine-mounted compressor.

2.A condenser mounted in front of the radiator.

3.A receiver/drier unit located in front of the

condenser.

4.Thermostatic expansion valve mounted above

the evaporator.

5.An evaporator unit mounted in front of the heater

matrix.

NOTE: Vehicles fitted with rear air

conditioning have an additional

evaporator/blower motor assembly located

behind the LH rear compartment lower trim panel.

These units are interconnected by hoses and pipes

carrying Refrigerant R134a, the evaporator is linked

into the vehicle ventilation system.

Refrigeration cycle

1. Compressor

The compressor (1), belt driven from the crankshaft

pulley, pressurises and circulates the refrigerant

through the system. Mounted on the compressor, an

electro-mechanical clutch maintains the correct

temperature and pressure by engaging or disengaging

to support the system's requirements. The clutch

action is normally controlled by a thermostat located

at the evaporator (5). The compressor is of the

swashplate type having fixed displacement.Should the temperature at the evaporator (5) fall low

enough for ice to begin to form on the fins, the

thermostat disengages the clutch and also isolates the

cooling fans relays. When the temperature at the

evaporator (5) rises to the control temperature, the

clutch is re-engaged.

Should the system pressure become excessive or

drop sufficiently to cause damage to the compressor

(1) a dual pressure switch (7), located in the high

pressure line, signals the relay unit to disengage the

clutch. The compressor also has an emergency high

pressure relief valve (9) fitted.

The cooling fans are controlled by engine temperature

when the air conditioning is not switched on.

2. Condenser

From the compressor, hot high pressure vaporised

refrigerant (F1) passes to the condenser (2), which is

mounted in front of the engine coolant radiator. Ram

air(A1) passing through the condenser (2),

supplemented by 2 cooling fans (8) mounted in front

of the condenser, cools the refrigerant vapour

sufficiently to form a high pressure slightly subcooled

liquid (F2).

3. Receiver/drier

This liquid then passes to a receiver/drier (3) which

fulfils two functions. It acts as a reservoir and moisture

extractor (11).

A sight glass (10), in the high pressure line, provides a

method of determining the state of the refrigerant

without breaking into the system.

4. Expansion valve

From the receiver/drier (3) the moisture free high

pressure liquid refrigerant (F3) passes through a

thermostatic expansion valve (4). A severe pressure

drop occurs across the valve and as the refrigerant

enters the evaporator space at a temperature of

approximately -5°C it boils and vaporises.

Page 754 of 873

82AIR CONDITIONING

4

DESCRIPTION AND OPERATION 5. Evaporator

As this change of state occurs, a large amount of

latent heat is absorbed. The evaporator is therefore

cooled and as a result heat is extracted from the air

flowing across the evaporator. The air flow is

controlled by the ventilation fan which can be

operated at anyone of four speeds.

To prevent liquid passing through to the compressor,

a capillary tube (6), attached to the outlet pipe of the

evaporator (5) and connected to the thermostatic

expansion valve (4), controls the amount that the

valve opens and closes in relation to the temperature

of the low pressure high temperature refrigerant

vapour (F4) at the outlet. The atomised refrigerant

then passes through the evaporator (5). Fan blown air

(A2) passes through the matrix (A3) of the evaporator

and is cooled by absorption due to the low

temperature refrigerant passing through the

evaporator.

A thermostat is fitted in the airflow out of the

evaporator to sense the temperature of the exterior

fins. Should ice begin to form, due to a too cold

condition, it will signal to disengage the

electro-mechanical clutch on the compressor (1).

From the evaporator, low pressure slightly

superheated refrigerant (F5) passes to the

compressor to complete the cycle.AIR CONDITIONING CONTROL SYSTEM

The air conditioning control system comprises relays,

thermostat, pressure switches, and a control panel.

Inputs from outside the air conditioning system

comprise temperature information from the engine

cooling system. Together these controls, in

conjunction with the cooling fans, compressor clutch,

blower and heater distribution and blend unit enable

minimal input to maintain the required environment

inside the vehicle.

When air conditioning is not selected, air is supplied

by ram effect or blower to the areas selected by the

controls. The air mix flap on the blend unit controls the

temperature of the air being supplied. No cooled air is

available.

Selecting air conditioning provides the added facility of

cooled air available to be mixed as before. When

required a fully cold condition can be selected by

turning the temperature controls to cold, which

automatically closes the heated coolant access to the

heater matrix. Mixtures of cooled, fresh, and hot air

can be selected to give required interior environmental

conditions by selection at the control panel.

Dual pressure switch

This switch, located in the high pressure line between

the receiver drier and the expansion valve, monitors

refrigerant pressure and by means of the relay module

controls the following system functions:

1.Refrigerant pressure drops below 2.0 bar, 29

lbf/in

2(due to possible leakage), the

compressor's electro-mechanical clutch is

dis-engaged.

When pressure rises above 2.0 bar, 29 lbf/in

2the

compressor's clutch is re-engaged.

2.Refrigerant pressure rises above 32 bar, 455

lbf/in

2(due to possible blockage), even with

cooling fan operation, the compressor's

electro-mechanical clutch is dis-engaged.

When the pressure drops below 26 bar, 375

lbf/in

2the compressor clutch is re-engaged.

Page 755 of 873

AIR CONDITIONING

5

DESCRIPTION AND OPERATION Condenser cooling fans

The condenser cooling fans operate automatically

whenever the air conditioning system is switched on.

Fan timer unit

The thermostatically controlled timer will continue to

operate the cooling fans after the air conditioning or

ignition is switched off. When the system temperature

is excessive, the fans will operate for 10 minutes to

reduce condenser and underbonnet temperature.

Blower control

The blower can be operated at any one of four speeds

by sliding the blower switch to the required position.

When the blower is switched off the air conditioning

system will not operate.

The fresh air/recirculation flaps can move between

two positions. One position covers the outside air

inlet, leaving open an inlet from the inside of the

vehicle clear, when recirculated air is required. In the

other position they will cover the inlet from the inside

of the vehicle leaving open the outside air inlet when

fresh air is required.Heater distribution and blend unit control

Blower unit air flow, having passed through the

evaporator passes into the heater blend unit to be

heated, if required. It is then directed into the vehicle

interior in accordance with the flap positions

designated by the air distribution control. Heater flaps

control the amount of air flowing through the heater

matrix. These flaps are controlled individually by the

driver's and passenger's temperature controls.

When the temperature control is in the cold position, a

micro switch actuates a vacuum control to close the

coolant valve on the engine. As the temperature

control is moved away from cold, the coolant valve is

opened allowing heated engine coolant to flow

throught the heater matrix. The temperature of the

heated air flow into the vehicle interior is controlled by

the blend flaps.

The distribution control moves the flaps which control

the direction of the air flow into the interior of the

vehicle.

Page 756 of 873

AIR CONDITIONING

1

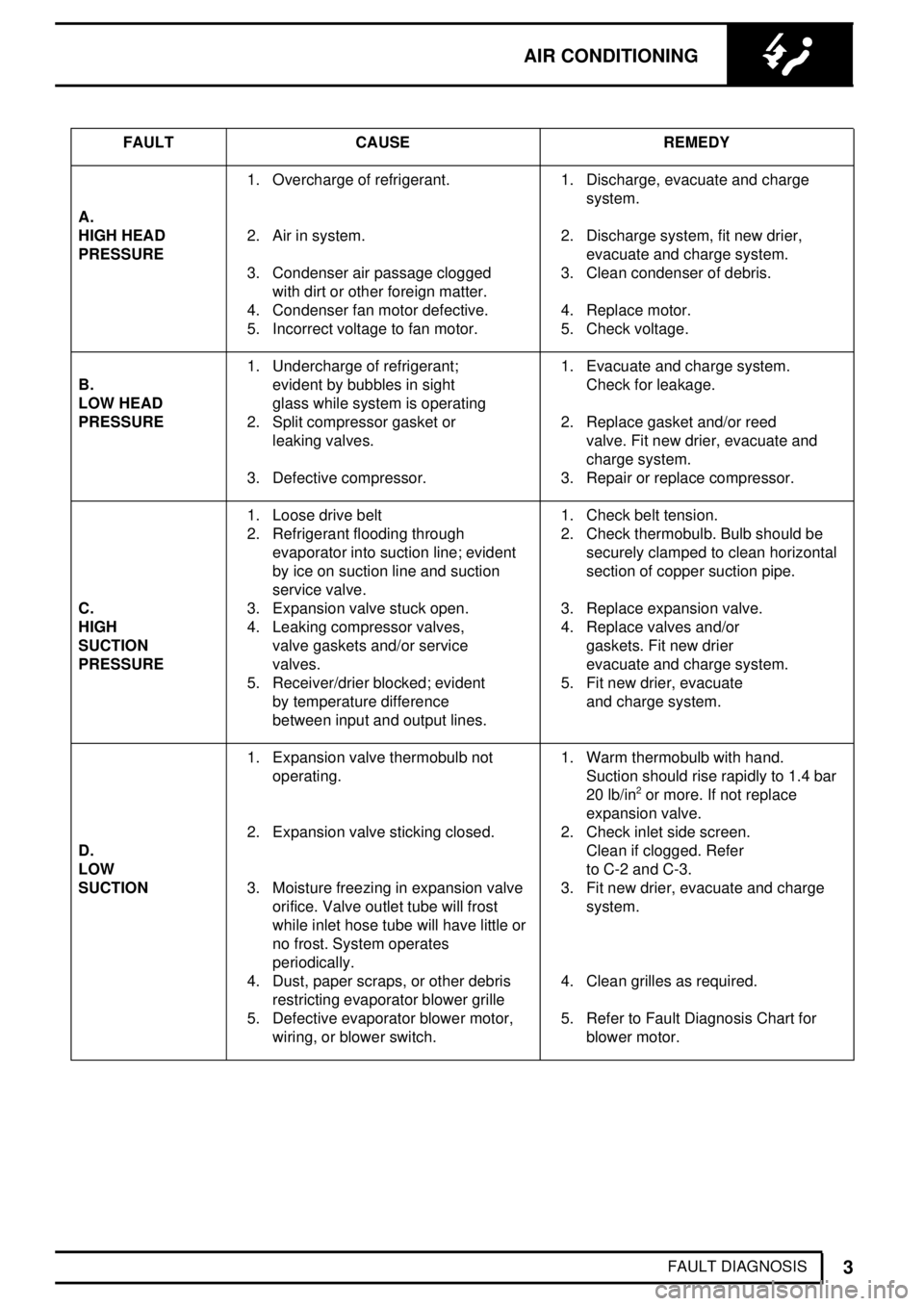

FAULT DIAGNOSIS AIR CONDITIONING FAULTS

FAULT CAUSE REMEDY

1. Incorrect voltage. 1. Check voltage.

A.2. Open or defective fuse or relay. 2. Check and replace as necessary.

BLOWER3. Loose wire connection including 3. Check system wires; tighten

MOTORground. all connections.

INOPERATIVE4. Switch open or defective. 4. Replace switch.

OR SLOW5. Tight, worn, or burnt motor 5. Replace motor.

RUNNINGbearings.

6. Open rotor windings. 6. Replace motor.

7. Worn motor brushes. 7. Replace motor.

8. Shaft binding-blade misaligned. 8. Check alignment. Repair or replace

as necessary.

9. Defective resistors 9. Rectify or replace.

1. Incorrect voltage. 1. Check voltage.

2. Open or defective fuse or relay. 2. Check and replace as necessary.

B.3. Defective thermostat control or 3. Replace thermostat or

COMPRESSORpressure switch. pressure switch.

CLUTCH4. Shorted or open field coil. 4. Replace coil.

INOPERATIVE5. Bearing seized (clutch will not 5. Replace clutch pulley assembly.

disengage).

6. Refrigeration circuit problem causing

heavy load and excessive drive

torque.6. Check and rectify.

1. Incorrect alignment. 1. Check alignment; repair as

necessary.

2. Loose belt. 2. Adjust to proper tension.

C.3. Compressor not mounted securely. 3. Repair as necessary.

COMPRESSOR4. Bearing in clutch-pulley 4. Remove clutch and replace

CLUTCHassembly not pressed in. clutch pulley assembly.

NOISY5. Low voltage to clutch. 5. Check connections and voltage.

6. Clutch will not spin freely. 6. Refer to B5 above.

7. Oil on clutch face. 7. Check compressor seals for leaks.

8. Slipping clutch. 8. Refer to C5 above. Then check air

gap.

9. Overloaded or locked compressor. 9. Repair or replace compressor.

10. Icing. 10. Check for suction line frosting.

Replace expansion valve if

necessary.

Replace receiver/drier if necessary.

D.1. Motor and/or blades improperly 1. Check mountings, adjust as

CONDENSERmounted. necessary.

VIBRATION2. Foreign matter build-up on 2. Clean blades with a suitable

blades. non-inflammable cleaner.

3. Excessive wear of motor bearings. 3. Replace motor.

Page 757 of 873

82AIR CONDITIONING

2

FAULT DIAGNOSIS REFRIGERATION SYSTEM FAULTS

For any refrigeration system to function properly all

components must be in good working order. The unit

cooling cycle and the relationship between air

discharge temperature and ambient temperature and

the pressures at the compressor can help to

determine proper operation of the system.

The length of any cooling cycle is determined by such

factors as ambient temperature and humidity,

thermostat setting, compressor speed and air leakage

into the cooled area, etc. With these factors constant,

any sudden increase in the length of the cooling cycle

would be indicative of abnormal operation of the air

conditioner.

The low and high side pressures at the compressor

will vary with changing ambient temperature, humidity,

in-car temperature and altitude.

The following items should be checked before

operating the system:

1.Compressor drive belt tension.

2.Compressor magnetic clutch operation.

3.Condenser fan operation.

4.Condenser fins, dirt will cause poor cooling and

higher operating temperatures.The following conditions should be checked after

operating the system for several minutes:

1.All high pressure lines and components should

be hot to the touch.

2.All low pressure lines should be cool to the

touch.

3.Inlet and outlet temperatures at the receiver/drier

should be at the same temperature (warm). Any

very noticeable temperature difference indicates

a blocked receiver/drier.

4.Heavy frost on the inlet to the expansion valve

may indicate a defective valve or moisture in the

system.

5.Evaporation air temperature will vary with

ambient temperature and humidity. As humidity

increases the outlet temperature will be higher.

Page 758 of 873

AIR CONDITIONING

3

FAULT DIAGNOSIS FAULT CAUSE REMEDY

1. Overcharge of refrigerant. 1. Discharge, evacuate and charge

system.

A.

HIGH HEAD2. Air in system. 2. Discharge system, fit new drier,

PRESSUREevacuate and charge system.

3. Condenser air passage clogged 3. Clean condenser of debris.

with dirt or other foreign matter.

4. Condenser fan motor defective. 4. Replace motor.

5. Incorrect voltage to fan motor. 5. Check voltage.

1. Undercharge of refrigerant; 1. Evacuate and charge system.

B.evident by bubbles in sight Check for leakage.

LOW HEADglass while system is operating

PRESSURE2. Split compressor gasket or 2. Replace gasket and/or reed

leaking valves. valve. Fit new drier, evacuate and

charge system.

3. Defective compressor. 3. Repair or replace compressor.

1. Loose drive belt 1. Check belt tension.

2. Refrigerant flooding through

evaporator into suction line; evident

by ice on suction line and suction

service valve.2. Check thermobulb. Bulb should be

securely clamped to clean horizontal

section of copper suction pipe.

C.3. Expansion valve stuck open. 3. Replace expansion valve.

HIGH4. Leaking compressor valves, 4. Replace valves and/or

SUCTIONvalve gaskets and/or service gaskets. Fit new drier

PRESSUREvalves. evacuate and charge system.

5. Receiver/drier blocked; evident 5. Fit new drier, evacuate

by temperature difference and charge system.

between input and output lines.

1. Expansion valve thermobulb not 1. Warm thermobulb with hand.

operating. Suction should rise rapidly to 1.4 bar

20 lb/in

2or more. If not replace

expansion valve.

2. Expansion valve sticking closed. 2. Check inlet side screen.

D.Clean if clogged. Refer

LOWto C-2 and C-3.

SUCTION3. Moisture freezing in expansion valve

orifice. Valve outlet tube will frost

while inlet hose tube will have little or

no frost. System operates

periodically.3. Fit new drier, evacuate and charge

system.

4. Dust, paper scraps, or other debris

restricting evaporator blower grille4. Clean grilles as required.

5. Defective evaporator blower motor,

wiring, or blower switch.5. Refer to Fault Diagnosis Chart for

blower motor.

Page 759 of 873

82AIR CONDITIONING

4

FAULT DIAGNOSISFAULT CAUSE REMEDY

E.

NOISY

EXPANSION

VALVE

(steady hissing)1. Low refrigerant charge; evident by

bubbles in sight glass.1. Leak test. Repair or replace

components as required.

F.1. Expansion valve not operating 1. Refer to C-2, C-3, D-1

INSUFFICIENTproperly. and E.

COOLING2. Low refrigerant charge-evident 2. Refer to B-1 and E.

by bubbles in sight glass.

3. Compressor not pumping. 3. Refer to B-2 and B-3

G.1. Belt tension. 1. Adjust belt tension.

COMPRESSOR2. Excessive head pressure. 2. Refer to A-1 through

BELTA-4 and C-6.

SLIPPING3. Incorrect alignment of pulleys 3. Repair as needed.

or worn belt not riding properly.

4. Nicked or broken pulley. 4. Replace as needed.

5. Seized compressor. 5. Replace compressor.

1. Loose or missing mounting bolts. 1. Repair as necessary.

2. Broken mounting bracket. 2. Replace bracket.

3. Loose flywheel or clutch 3. Repair as necessary.

retaining bolt.

H.4. Rough idler pulley bearing. 4. Replace bearing.

ENGINE5. Bent, loose, or improperly 5. Repair as necessary.

NOISEmounted engine drive pulley.

AND/OR6. Defective compressor bearing. 6. Replace bearing.

VIBRATION7. Insecure mountings of 7. Repair as necessary.

accessories; generator, power

steering, air filter, etc.

8. Excessive head pressure. 8. Refer to A-1, A-2, A-3

A-4 and C-6.

9. Incorrect compressor oil level. 9. Refer to compressor Oil

Level Check.

HEATER AND AIR CONDITIONING - CIRCUIT

DIAGRAMS

1.For details of heating and air conditioning

electrics

See Electrical Trouble Shooting

Manual.

Page 760 of 873

AIR CONDITIONING

1

ADJUSTMENT GENERAL PRECAUTIONS

The refrigerant used in the air conditioning system is

HFC (Hydrofluorocarbon) R134a.

WARNING: R134a is a hazardous liquid

and when handled incorrectly can cause

serious injury. Suitable protective clothing

must be worn when carrying out servicing

operations on the air conditioning system.

WARNING: R134a is odourless and

colourless. Do not handle or discharge in

an enclosed area, or in any area where the

vapour or liquid can come in contact with naked

flame or hot metal. R134a is not flammable but

can form a highly toxic gas.

WARNING: Do not smoke or weld in areas

where R134a is in use. Inhalation of

concentrations of the vapour can cause

dizziness, disorientation. uncoordination,

narcosis, nausea or vomiting.

WARNING: Do not allow fluids other than

R134a or compressor lubricant to enter the

air conditioning system. Spontaneous

combustion may occur.

WARNING: R134a splashed on any part of

the body will cause immediate freezing of

that area. Also refrigerant cylinders and

replenishment trolleys when discharging will

freeze skin to them if contact is made.

WARNING: The refrigerant used in an air

conditioning system must be reclaimed in

accordance with the recommendations

given with a Refrigerant Recovery Recycling

Recharging Station.

NOTE: Suitable protective clothing

comprises: Wrap around safety glasses or

helmet, heatproof gloves, rubber apron or

waterproof overalls and rubber boots.REMEDIAL ACTIONS

1.If liquid R134a strikes the eye, do not rub it.

Gently run large quantities of eyewash over the

eye to raise the temperature. If eyewash is not

available cool, clean water may be used. Cover

eye with clean pad and seek immediate medical

attention.

2.If liquid R134a is splashed on the skin run large

quantities of water over the area as soon as

possible to raise the temperature. Carry out the

same actions if skin comes into contact with

discharging cylinders. Wrap affected parts in

blankets or similar material and seek immediate

medical attention.

3.If suspected of being overcome by inhalation of

R134a vapour seek fresh air. If unconscious

remove to fresh air. Apply artificial respiration

and/or oxygen and seek immediate medical

attention.

NOTE: Due to its low evaporating

temperature of -30°C, R134a should be

handled with care.

WARNING: Do not allow a refrigerant

container to be heated by a direct flame or

to be placed near any heating appliance. A

refrigerant container must not be heated above

50°C.

WARNING: Do not leave a container of

refrigerant without its cap fitted. Do not

transport a container of refrigerant that is

unrestrained, especially in the boot of a car.