tow LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 9 of 873

INTRODUCTION

7

INFORMATION DYNAMOMETER TESTING - VEHICLES WITH

ANTI-LOCK BRAKES (ABS)

WARNING: Do not attempt to test ABS

function on a dynamometer

Four wheel dynamometers

NOTE: Before testing a vehicle on a four

wheel dynamometer disconnect the valve

relay.

See Electrical Trouble Shooting

Manual.

The ABS function will not work, the ABS warning

light will illuminate. Normal braking will be

available.

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing except any that may apply to the tyres.

Two wheel dynamometers

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

NOTE: ABS will not function on a two

wheel dynamometer. The ABS light will

illuminate during testing. Normal braking

will be available.

If brake testing on a single rig is necessary it must be

carried out with propeller shaft to the rear axle

removed, AND neutral selected in BOTH main and

transfer boxes.

If checking engine performance, the transfer box must

be in high range and drive shaft to stationary axle

removed.

TOWING

CAUTION: The vehicle has permanent

four-wheel drive. The following towing

instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes.

1.Turn ignition key turn to position '1' to release

steering lock.

2.Select neutral in main gearbox and transfer

gearbox.

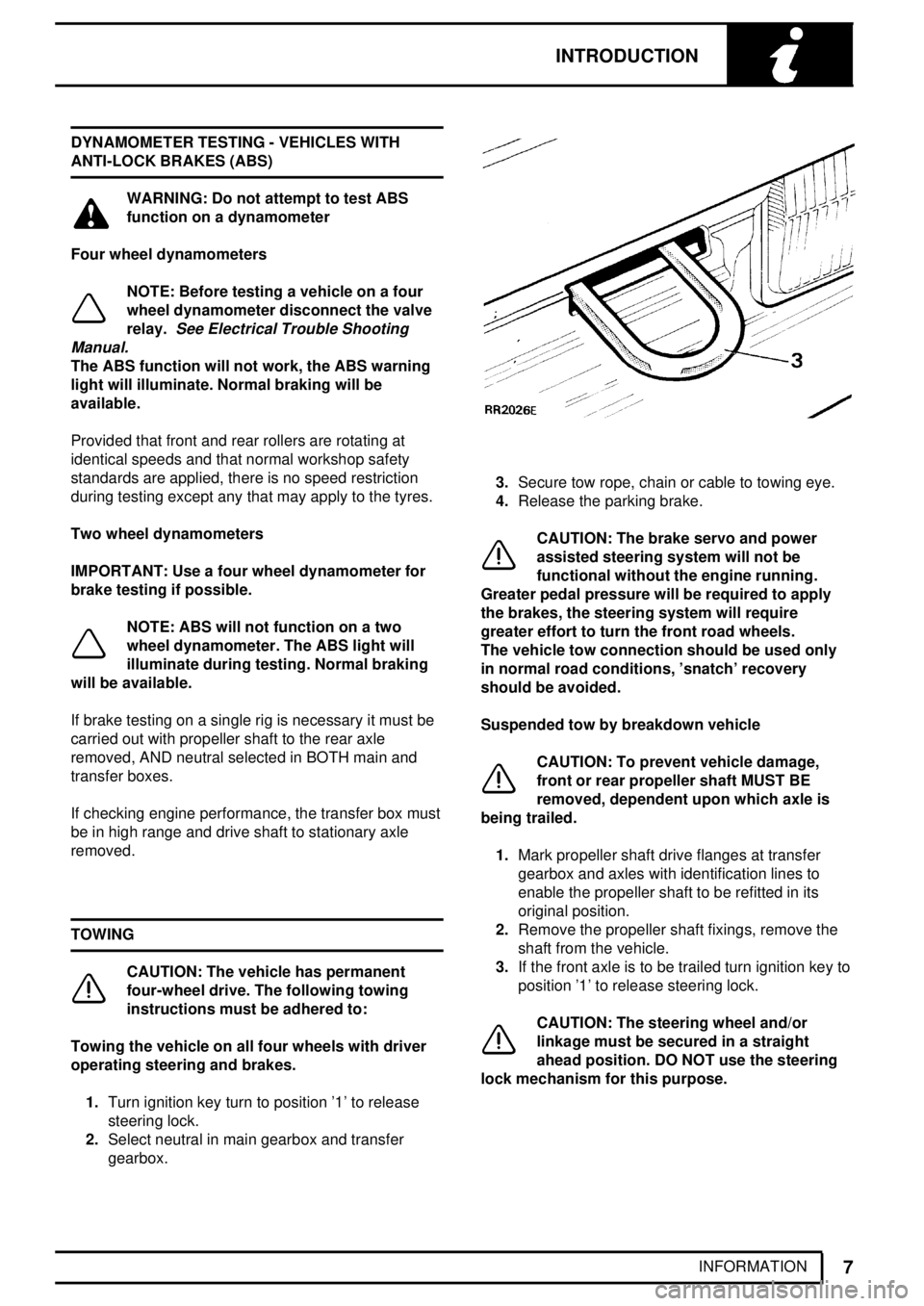

3.Secure tow rope, chain or cable to towing eye.

4.Release the parking brake.

CAUTION: The brake servo and power

assisted steering system will not be

functional without the engine running.

Greater pedal pressure will be required to apply

the brakes, the steering system will require

greater effort to turn the front road wheels.

The vehicle tow connection should be used only

in normal road conditions, 'snatch' recovery

should be avoided.

Suspended tow by breakdown vehicle

CAUTION: To prevent vehicle damage,

front or rear propeller shaft MUST BE

removed, dependent upon which axle is

being trailed.

1.Mark propeller shaft drive flanges at transfer

gearbox and axles with identification lines to

enable the propeller shaft to be refitted in its

original position.

2.Remove the propeller shaft fixings, remove the

shaft from the vehicle.

3.If the front axle is to be trailed turn ignition key to

position '1' to release steering lock.

CAUTION: The steering wheel and/or

linkage must be secured in a straight

ahead position. DO NOT use the steering

lock mechanism for this purpose.

Page 43 of 873

GENERAL SPECIFICATION DATA

25

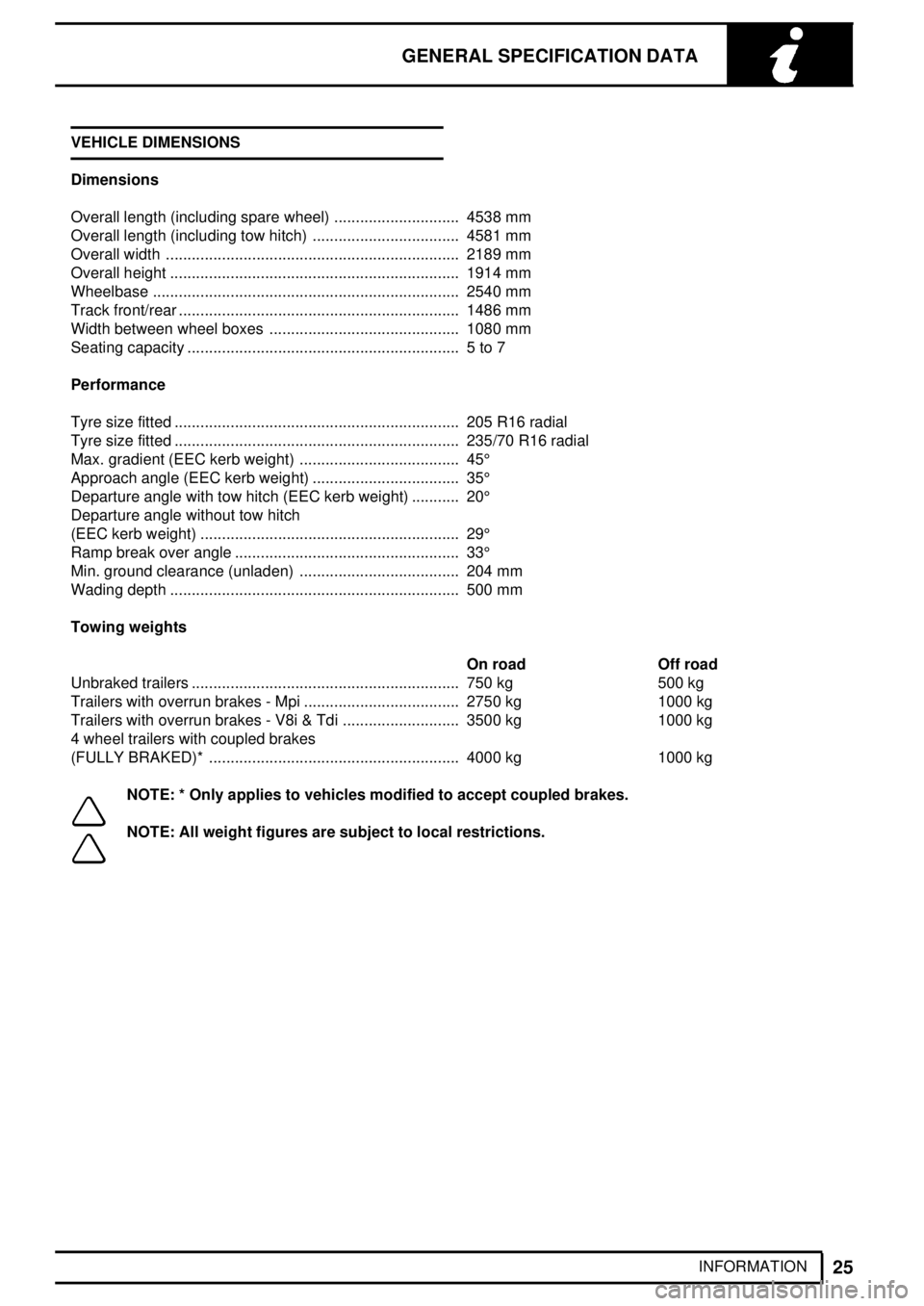

INFORMATION VEHICLE DIMENSIONS

Dimensions

Overall length (including spare wheel) 4538 mm.............................

Overall length (including tow hitch) 4581 mm..................................

Overall width 2189 mm....................................................................

Overall height 1914 mm...................................................................

Wheelbase 2540 mm.......................................................................

Track front/rear 1486 mm.................................................................

Width between wheel boxes 1080 mm............................................

Seating capacity 5 to 7...............................................................

Performance

Tyre size fitted 205 R16 radial..................................................................

Tyre size fitted 235/70 R16 radial..................................................................

Max. gradient (EEC kerb weight) 45° .....................................

Approach angle (EEC kerb weight) 35° ..................................

Departure angle with tow hitch (EEC kerb weight) 20° ...........

Departure angle without tow hitch

(EEC kerb weight) 29° ............................................................

Ramp break over angle 33° ....................................................

Min. ground clearance (unladen) 204 mm.....................................

Wading depth 500 mm...................................................................

Towing weights

On road Off road

Unbraked trailers 750 kg.............................................................. 500 kg

Trailers with overrun brakes - Mpi 2750 kg.................................... 1000 kg

Trailers with overrun brakes - V8i & Tdi 3500 kg........................... 1000 kg

4 wheel trailers with coupled brakes

(FULLY BRAKED)* 4000 kg.......................................................... 1000 kg

NOTE: * Only applies to vehicles modified to accept coupled brakes.

NOTE: All weight figures are subject to local restrictions.

Page 53 of 873

07GENERAL FITTING REMINDERS

4

INFORMATION OIL SEALS

NOTE: Ensure that the seal running track

is free from pits, scores, corrosion and

general damage prior to fitting

replacement seal.

1.Always fit new oil seals when rebuilding an

assembly.

2.Carefully examine seal before fitting to ensure

that it is clean and undamaged.

3.Coat the sealing lips with clean grease; pack

dust excluder seals with grease, and heavily

grease duplex seals in cavity between sealing

lips.

4.Ensure that seal spring, if provided, is correctly

fitted.

5.Place lip of seal towards fluid to be sealed and

slide into position on shaft, using fitting sleeve

when possible to protect sealing lip from damage

by sharp corners, threads or splines. If fitting

sleeve is not available, use plastic tube or tape

to prevent damage to sealing lip.

6.Grease outside diameter of seal, place square to

housing recess and press into position, using

great care and if possible a 'bell piece' to ensure

that seal is not tilted. (In some cases it may be

preferable to fit seal to housing before fitting to

shaft). Never let weight of unsupported shaft rest

in seal.

7.If correct service tool is not available, use a

suitable drift approximately 0.4mm (0.015 in)

smaller than outside diameter of seal. Use a

hammerVERY GENTLYon drift if a press is not

suitable.

8.Press or drift seal in to depth of housing if

housing is shouldered, or flush with face of

housing where no shoulder is provided. Ensure

that the seal does not enter the housing in a

tilted position.

NOTE: Most cases of failure or leakage of

oil seals are due to careless fitting, and

resulting damage to both seals and

sealing surfaces. Care in fitting is essential if

good results are to be obtained. NEVER use a seal

which has been improperly stored or handled,

such as hung on a hook or nail.

Page 65 of 873

MAINTENANCE

3

MAINTENANCE VEHICLE EXTERIOR

CHECK/ADJUST HEADLAMP ALIGNMENT

Check/adjust headlamp and auxiliary alignment.

CHECK FRONT WHEEL ALIGNMENT

Use recognised wheel alignment equipment to

perform this check and adjustment.

See STEERING,

Adjustment, Front Wheel Alignment

REMOVE WHEELS, CHECK TYRES

Check tyres (including spare) for compliance with

manufacturers' specification.

Check visually for cuts, lumps, bulges, uneven tread

wear and tread depth. Check road wheels for

damage.

Check/adjust tyre pressures.

CHECK/TIGHTEN TOWING BRACKET FITTINGSINSPECT BRAKE PADS FOR WEAR, CALIPERS

FOR LEAKS AND CONDITION

Check thickness of brake pads, fit new pads if

minimum thickness is less than 3,0mm. Check brake

pads for oil contamination. If new brake pads required.

See BRAKES, Repair, Front Brake Pads

or.See BRAKES, Repair, Rear Brake Pads

WARNING: When renewing brake pads, it

is essential that only genuine components

with correct grade of lining are used.

Always fit new pads as complete axle sets, NEVER

individually or as a single wheel set. Serious

consequences could result from out of balance

braking due to mixing of linings.

Refit road wheels

Fit road wheels in original hub position. Secure in

position with wheel nuts, do not fully tighten wheel

nuts at this stage, lower vehicle and finally tighten

wheel nuts to correct torque.

Alloy wheels:

130 Nm.

Steel wheels:130 Nm.

LUBRICATE ALL HINGES, DOOR CHECK

MECHANISMS, BONNET [HOOD] CATCHES AND

FUEL FILLER FLAP

Page 102 of 873

Tdi

21

REPAIR 23.Remove rocker cover.

24.Remove nuts and bolts and withdraw rocker

shaft assembly.

25.Remove push rods, store as an identified set to

allow refitment to same location.

26.Remove valve stem caps.

27.Evenly slacken, then remove, bolts retaining

cylinder head to block. Two of the bolts also

secure the air cleaner mounting bracket.

28.Lift off cylinder head and remove gasket.

Refit

29.Ensure face of cylinder block is thoroughly clean.

30.Select new gasket of correct thickness.

CAUTION: Three thicknesses of gasket are

available, different thicknesses are

identified by the number of small holes

punched in the right hand side of the gasket. One

hole identifies the thinnest gasket and three holes

the thickest. When renewing gaskets the gasket

being fitted must be of the same thickness as the

one removed. Therefore if the removed gasket had

two holes punched in the side the replacement

gasket must also have two holes punched in the

side.

31.Place gasket on cylinder block with identification

holes positioned towards rear on right hand side

and side marked TOP uppermost.

32.Clean mating face of cylinder head.

33.Lower cylinder head onto block ensuring correct

location with dowels.

Page 125 of 873

V8i

7

REPAIR ROCKER SHAFT RENEW

Service repair no - 12.29.29

1.Remove rocker covers as required.

See

Rocker Cover - Right Hand - Renew

or.See

Rocker Cover - Left Hand - Renew

2.Loosen four rocker shaft fixings.

3.Remove rocker shaft assembly.

NOTE: Each rocker shaft is notched at

ONE end. Notch must be uppermost and

towards front of engine on right hand side,

towards rear on left hand side.

4.Clean rocker pedestal locations on cylinder

head.

5.Fit rocker shaft assembly, locating push rods to

rockers.

6.Tighten rocker shaft fixings to

38 Nm.

7.Fit rocker covers.HYDRAULIC TAPPETS RENEW

Service repair no - 12.29.57

1.Remove rocker shafts.

See Rocker Shaft

Renew

2.Remove intake manifold.See FUEL SYSTEM,

Repair, Intake Manifold

3.Remove push rods, retain in removal sequence.

4.Remove hydraulic tappets

5.Fit tappets, push rods and rocker assemblies.

See V8i Overhaul Manual.

6.Fit inlet manifold.

7.Reverse removal procedure.

Page 128 of 873

12ENGINE

10

REPAIR TIMING CHAIN AND CHAINWHEELS

Service repair no - 12.65.12

Remove

1.Remove front cover.

See Front Cover Gasket

2.Remove retaining bolt and washer, remove

distributor drive gear and spacer.

3.Ensure number one piston is at TDC.

4.Remove chainwheels and chain as an assembly.

See V8i Overhaul Manual.

Refit

5.Clean chainwheels and chain.

6.Fit chainwheels to chain, aligning timing marks.

7.Ensure camshaft key is fitted parallel to shaft

axis to ensure adequate lubrication to distributor

drive gear.

8.Engage chainwheel assembly on camshaft and

crankshaft keys, ensure chain wheels are fully

located.

9.Check alignment of timing marks with straight

edge.

10.Fit spacer with flange to front,

11.Fit distributor drive gear with groove towards

spacer.

12.Fit retaining bolt and washer. Tighten to

58 Nm.

13.Fit front cover.See Front Cover Gasket

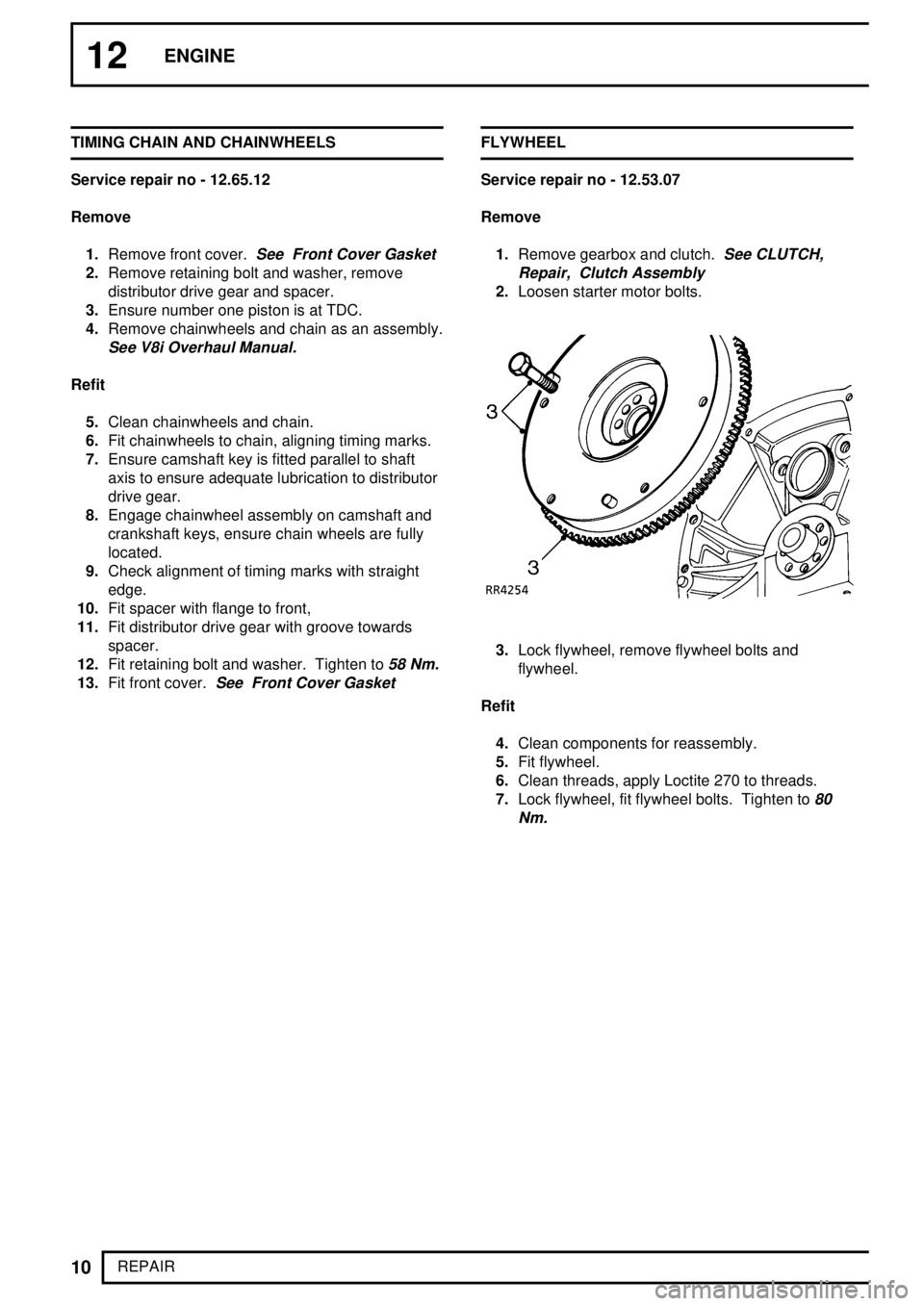

FLYWHEEL

Service repair no - 12.53.07

Remove

1.Remove gearbox and clutch.

See CLUTCH,

Repair, Clutch Assembly

2.Loosen starter motor bolts.

3.Lock flywheel, remove flywheel bolts and

flywheel.

Refit

4.Clean components for reassembly.

5.Fit flywheel.

6.Clean threads, apply Loctite 270 to threads.

7.Lock flywheel, fit flywheel bolts. Tighten to

80

Nm.

Page 130 of 873

12ENGINE

12

REPAIR

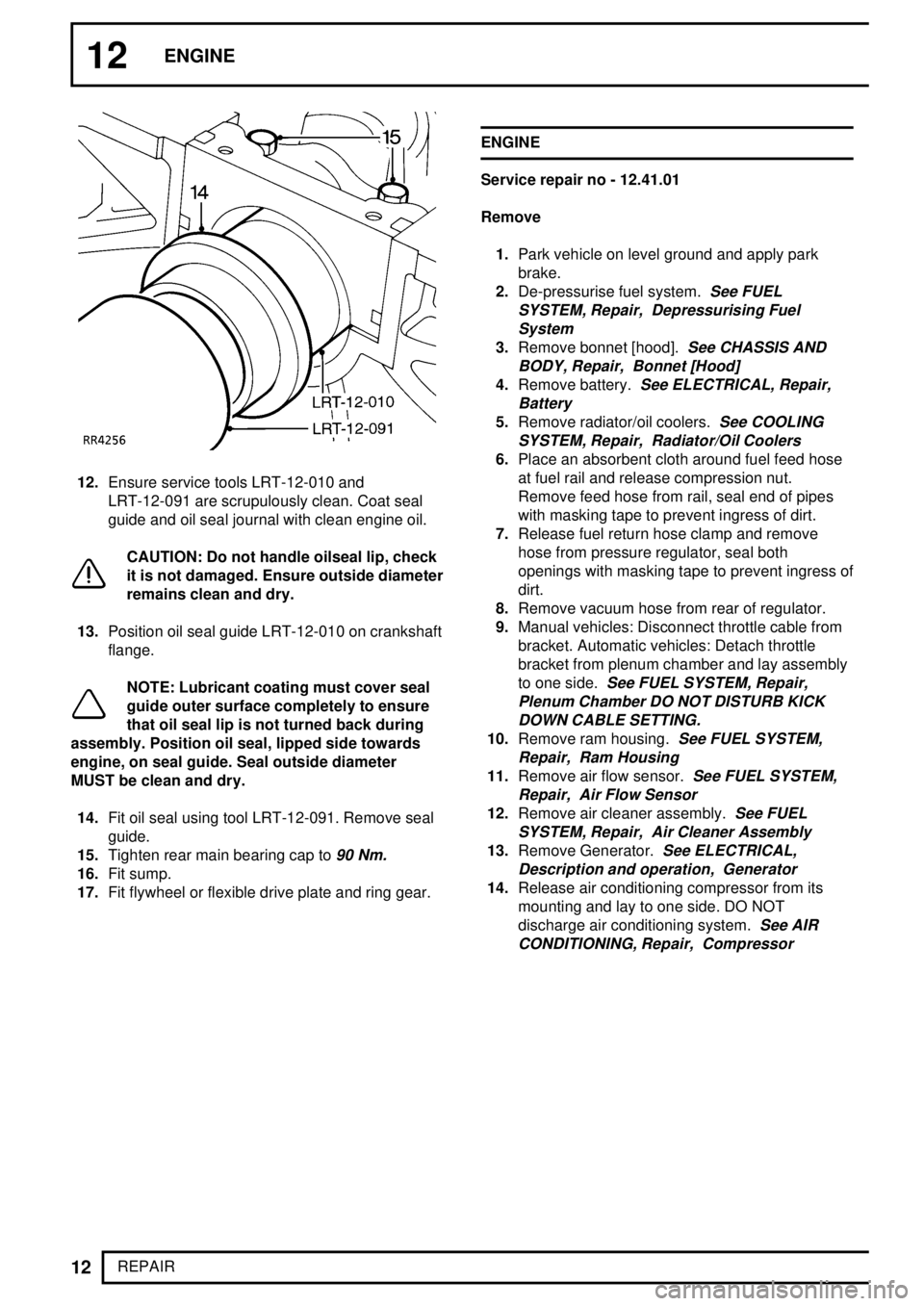

12.Ensure service tools LRT-12-010 and

LRT-12-091 are scrupulously clean. Coat seal

guide and oil seal journal with clean engine oil.

CAUTION: Do not handle oilseal lip, check

it is not damaged. Ensure outside diameter

remains clean and dry.

13.Position oil seal guide LRT-12-010 on crankshaft

flange.

NOTE: Lubricant coating must cover seal

guide outer surface completely to ensure

that oil seal lip is not turned back during

assembly. Position oil seal, lipped side towards

engine, on seal guide. Seal outside diameter

MUST be clean and dry.

14.Fit oil seal using tool LRT-12-091. Remove seal

guide.

15.Tighten rear main bearing cap to

90 Nm.

16.Fit sump.

17.Fit flywheel or flexible drive plate and ring gear.ENGINE

Service repair no - 12.41.01

Remove

1.Park vehicle on level ground and apply park

brake.

2.De-pressurise fuel system.

See FUEL

SYSTEM, Repair, Depressurising Fuel

System

3.Remove bonnet [hood].See CHASSIS AND

BODY, Repair, Bonnet [Hood]

4.Remove battery.See ELECTRICAL, Repair,

Battery

5.Remove radiator/oil coolers.See COOLING

SYSTEM, Repair, Radiator/Oil Coolers

6.Place an absorbent cloth around fuel feed hose

at fuel rail and release compression nut.

Remove feed hose from rail, seal end of pipes

with masking tape to prevent ingress of dirt.

7.Release fuel return hose clamp and remove

hose from pressure regulator, seal both

openings with masking tape to prevent ingress of

dirt.

8.Remove vacuum hose from rear of regulator.

9.Manual vehicles: Disconnect throttle cable from

bracket. Automatic vehicles: Detach throttle

bracket from plenum chamber and lay assembly

to one side.

See FUEL SYSTEM, Repair,

Plenum Chamber DO NOT DISTURB KICK

DOWN CABLE SETTING.

10.Remove ram housing.See FUEL SYSTEM,

Repair, Ram Housing

11.Remove air flow sensor.See FUEL SYSTEM,

Repair, Air Flow Sensor

12.Remove air cleaner assembly.See FUEL

SYSTEM, Repair, Air Cleaner Assembly

13.Remove Generator.See ELECTRICAL,

Description and operation, Generator

14.Release air conditioning compressor from its

mounting and lay to one side. DO NOT

discharge air conditioning system.

See AIR

CONDITIONING, Repair, Compressor

Page 152 of 873

12ENGINE

2

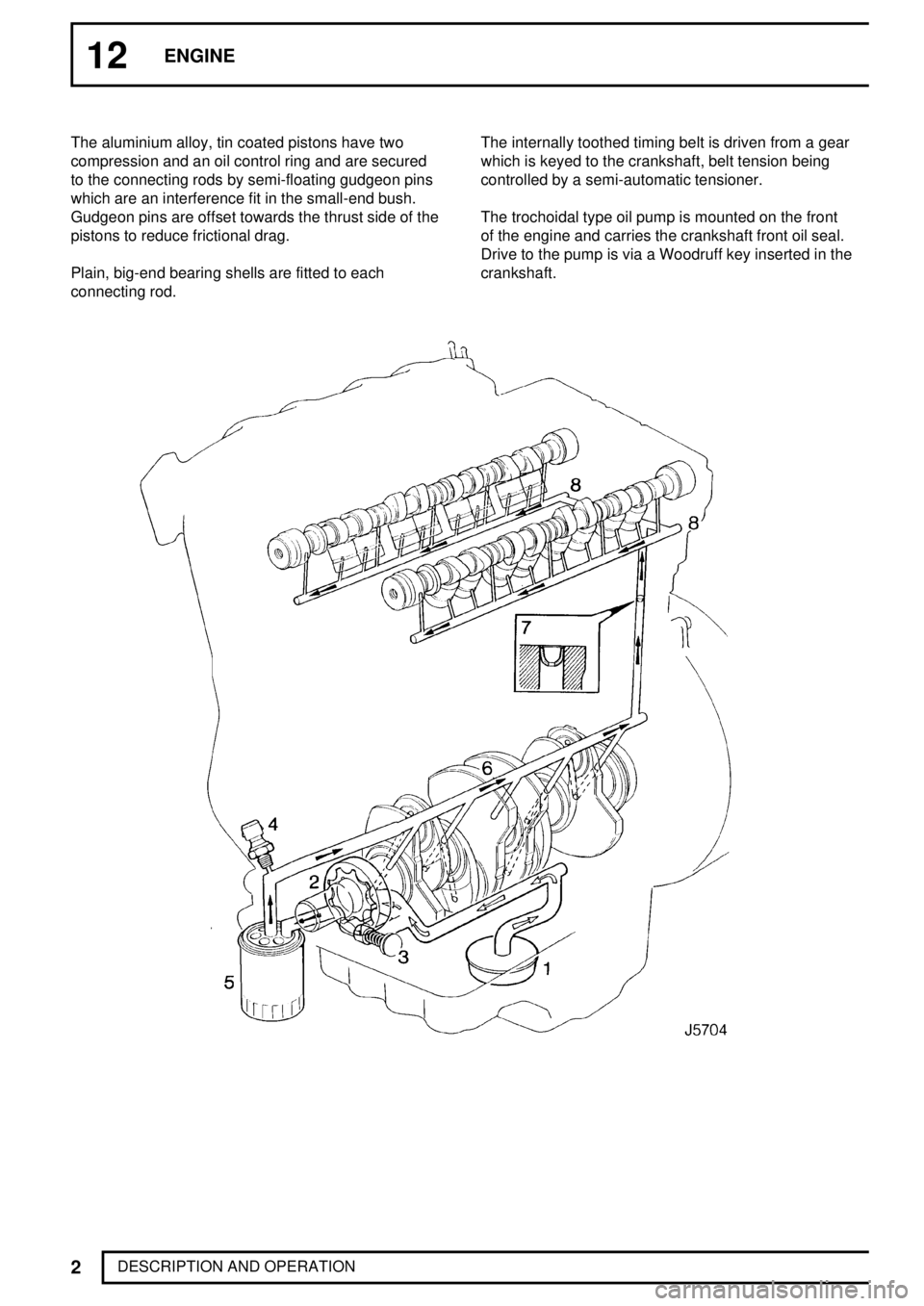

DESCRIPTION AND OPERATION The aluminium alloy, tin coated pistons have two

compression and an oil control ring and are secured

to the connecting rods by semi-floating gudgeon pins

which are an interference fit in the small-end bush.

Gudgeon pins are offset towards the thrust side of the

pistons to reduce frictional drag.

Plain, big-end bearing shells are fitted to each

connecting rod.The internally toothed timing belt is driven from a gear

which is keyed to the crankshaft, belt tension being

controlled by a semi-automatic tensioner.

The trochoidal type oil pump is mounted on the front

of the engine and carries the crankshaft front oil seal.

Drive to the pump is via a Woodruff key inserted in the

crankshaft.

Page 209 of 873

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION OPERATION

Diesel engines operate by compression ignition. The

rapid compression of air in the cylinder during the

compression cycle heats the injected fuel, causing it

to self ignite. During cold starting, automatically

controlled glow plugs assist in raising the temperature

of the compressed air to ignition point.

A cold start advance unit advances the injection timing

to further assist starting. Idle quality is improved by

the high idle setting.

The engine is supplied with pre-compressed air by a

single stage turbocharger.

Exhaust gases passing over a turbine cause it to

rotate, driving a compressor mounted on the turbine

shaft. Air drawn from the cold air intake passes, via

the air cleaner, to the turbocharger where it is

compressed. The compressed air passes to the

cylinders via an intercooler, which reduces the

temperature of the compressed air, increasing its

density.

Fuel is drawn from the tank by a mechanical lift pump

and passes to the injection pump via a filter. In

addition to removing particle contamination from the

fuel, the filter incorporates a water separator, which

removes and stores both bound and unbound water.

The injection pump meters a precisely timed, exact

quantity of fuel to the injectors in response to throttle

variations, injection timing varying with engine speed.

Any excess fuel delivered to the injection pump is not

injected, passing back to the tank via the fuel return

line.

Fuel is injected in a finely atomised form into a

pre-combustion chamber in the cylinder head where it

ignites. The burning fuel expands rapidly into the main

combustion chamber, creating extreme turbulence

which mixes the burning fuel thoroughly with the

compressed air, providing complete combustion.

Cold Starting is assisted by glow plugs, a cold start

advance unit and a high idle setting.Glow plugs

Glow plug operation is controlled by a timer unit, start

relay and resistor. When the ignition is turned on the

timer unit is energised, the glow plugs start to operate

and a warning light on the dashboard illuminates,

remaining illuminated until the glow plugs are

automatically switched off.

The length of time the glow plugs will operate is

dependent on under bonnet temperature, which is

monitored by a sensor located in the timer unit.

Starting the engine results in the power supply to the

glow plugs passing through the resistor, which

reduces their operating temperature. The glow plugs

are cut out either by the temperature sensor in the

timer, or by a microswitch on the injection pump which

operates when the throttle is depressed.

Cold start advance

The cold start advance unit is connected to the engine

cooling system via hoses. It contains a temperature

sensitive element which is retracted when cold and

pulls the advance lever, via cable, towards the rear of

the pump against spring pressure. As coolant

temperature rises, the cold start element expands

releasing tension on the cable and allowing spring

pressure to move the advance lever forwards.