LAND ROVER DISCOVERY 1999 Workshop Manual

DISCOVERY 1999

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57247/w960_57247-0.png

LAND ROVER DISCOVERY 1999 Workshop Manual

Trending: seat memory, turn signal, fuel tank removal, oil type, window, parking brake, sport mode

Page 1071 of 1529

PANEL REPAIRS

77-2-4 REPLACEMENT PANELS

Body side panels

1Dash side assembly

2'A' post assembly

3'B/C' post assembly4Sill inner assembly

5Sill outer assembly

Page 1072 of 1529

PANEL REPAIRS

REPLACEMENT PANELS 77-2-5

Body side assembly

1Panel body side assembly

Page 1073 of 1529

PANEL REPAIRS

77-2-6 REPLACEMENT PANELS

'D'-post assembly

1'D' post outer assembly

2'D' post closing assembly3Wheelarch rear outer assembly

4Bodyside inner rear assembly

Page 1074 of 1529

PANEL REPAIRS

REPLACEMENT PANELS 77-2-7

Rear floor assembly.

1Rear floor assembly

M77 1673C

1

Page 1075 of 1529

PANEL REPAIRS

77-2-8 REPLACEMENT PANELS

Rear end panels

1'E' post assemblies

2'E' post closing assemblies

3Crossmember outer rear panel4Crossmember closing rear panel

5Crossmember rear assembly

6Crossmember closing rear brackets

Page 1076 of 1529

PANEL REPAIRS

REPLACEMENT PANELS 77-2-9

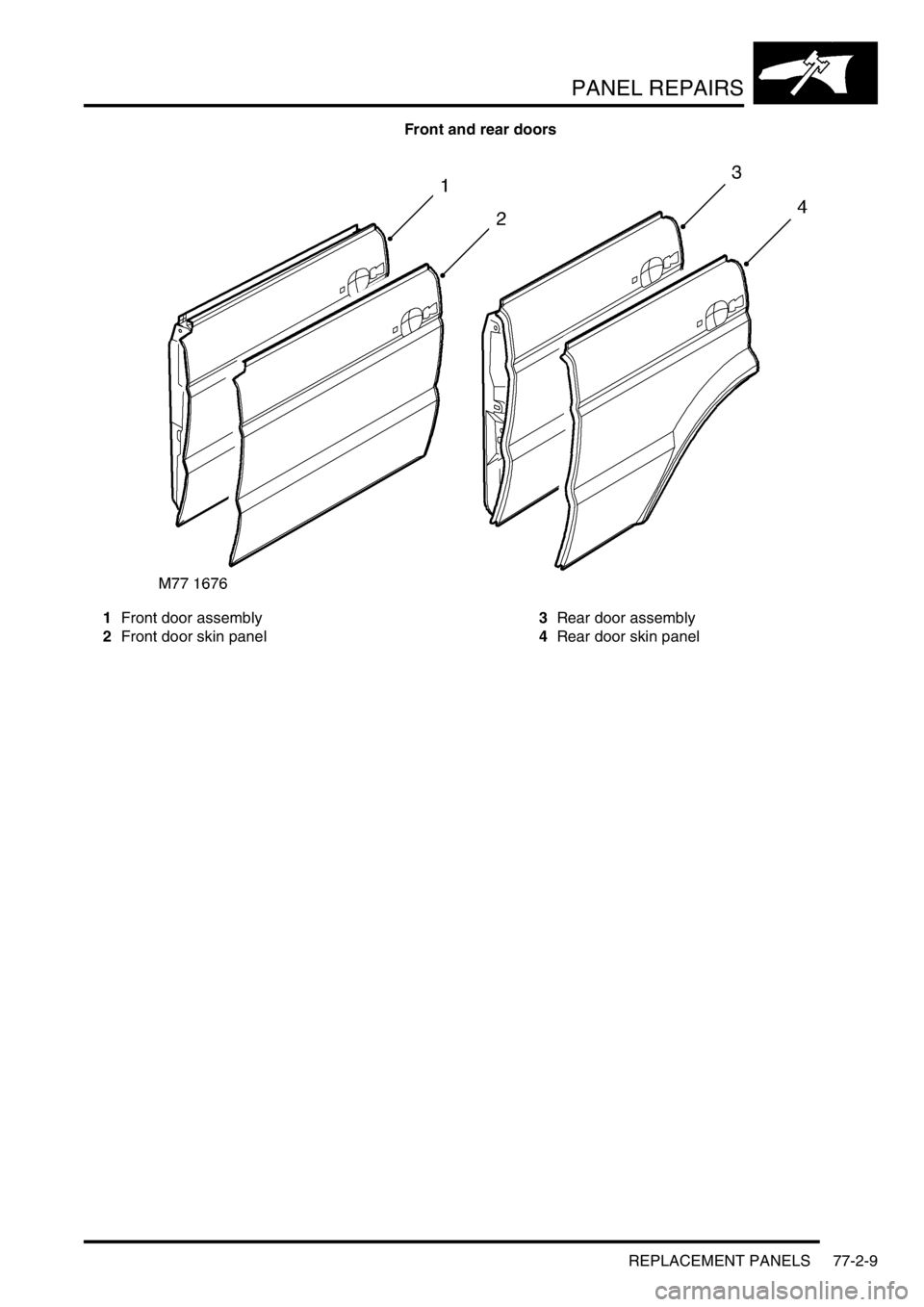

Front and rear doors

1Front door assembly

2Front door skin panel3Rear door assembly

4Rear door skin panel

Page 1077 of 1529

PANEL REPAIRS

77-2-10 REPLACEMENT PANELS

Taildoor

1Taildoor complete assembly

Page 1078 of 1529

PANEL REPAIRS

REPLACEMENT PANELS 77-2-11

Roof panels

1Roof panel with sunroofs and roof bar holes

2Roof panel with roof bar holes only3Roof panel with sunroofs only

4Roof panel

M77 1674A

1

2

3

4

Page 1079 of 1529

PANEL REPAIRS

77-2-12 REPLACEMENT PANELS

Replacement panels

The previous illustrations show some of the service panels which feature in the Body Repairs procedures. Additional

panels and full body shells are also available. See Parts Fiche for details.

Page 1080 of 1529

PANEL REPAIRS

PROCEDURES 77-2-13

PROCEDURES

General welding precautions

General

For ease of reference, the diagrams on the following pages show only the type of weld used in repair where it varies

from that used in production.

The replacement welds in the welding diagrams are denoted by the following symbols:

a = Single/Multiple thickness plug welds

b = MIG seam weld

When NOT carrying out welding operations the following criteria must be observed:

lWhere resistance spot welds have been used in production, these must be reproduced with new spot welds in

replacement where possible. All such reproduction spot welds must be spaced 30 mm (1.181 in) apart;

lWhen spot welding, it is recommended that test coupons of the same metal gauges and materials are produced

to carry out peel tests to ensure that welding equipment being used can produce a satisfactory joint. Plug welds

must be used if a satisfactory spot weld cannot be produced;

lThe electrode arms on hand-held spot welding guns must not exceed 300 mm (11.811 in) in length;

lSingle-side spot welding is not acceptable;

lBrazing and gas welding are not acceptable EXCEPT where they have been specified in production;

lWhere 3 metal thicknesses or more are to be welded together it is imperative to use MIG plug welds to ensure

joint strength;

lMIG plug welds must be used in repair joints where there is no access for a resistance spot welder. To replace

each production spot weld a hole must be drilled and/or punched, and a MIG plug weld then made in its place.

The number of plug welds must match exactly the number of spot welds which have been removed;

lWhere holes are left in an existing panel after removal of the spot welds, a single MIG plug weld will be made in

each hole as appropriate.

Seat belt anchorages

Seat belt anchorages are safety critical. When making repairs in these areas, it is essential to follow design

specifications. Note that High Strength Low Alloy (HSLA) steel may be used for seat belt anchorages.

Where possible, the original production assembly should be used, complete with its seat belt anchorages, or the cut

line should be so arranged that the original seat belt anchorage is not disturbed.

All welds within 250 mm (9.842 in) of seat belt anchorages must be carefully checked for weld quality, including

spacing of spot welds.

Trending: fuel cap, gearbox, suspension, width, four wheel drive, change time, trailer