sensor LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 969 of 1529

INTERIOR TRIM COMPONENTS

76-3-4 REPAIRS

Trim casing - 'D' post

$% 76.13.73

Remove

1.Fold rear seat forward.

2.Remove tail door aperture upper trim casing.

3.Release caps from end of grab handle.

4.Remove 2 bolts securing grab handle to body.

5.Remove grab handle and collect two spacers.

6.Remove 8 trim clips securing trim casing to

body.

7. Models with third row seats:

aRemove third row seat belt escutcheon.

bRemove cap from lower anchorage of third

row seat belt.

cRemove lower anchorage bolt.8. Models with volumetric alarm:

aRelease volumetric sensor from trim casing.

bDisconnect multiplug from volumetric

sensor.

cRemove volumetric sensor.

9.Remove rear seat belt blanking plate.

10.Release 2 clips securing trim casing to body.

11.Remove trim casing.

Refit

1.Fit trim casing and secure with clips.

2.Fit rear seat belt blanking plate.

3. Models with volumetric alarm:

aPosition volumetric sensor to trim casing

and connect multiplug.

bFit volumetric sensor to trim casing.

4. Models with third row seats:

aFit lower anchorage of third row seat belt

and tighten bolt to 32 Nm (24 lbf.ft).

bFit cap to lower anchorage bolt.

cFit third row seat belt escutcheon to trim

casing.

5.Fit trim clips securing trim casing to body.

6.Position grab handle and spacers to trim

casing.

7.Fit and tighten bolts securing grab handle to

body to 3 Nm (2.2 lbf.ft).

8.Close caps on ends of grab handle.

9.Fit tail door aperture upper trim casing.

10.Reposition rear seat.

Page 979 of 1529

INTERIOR TRIM COMPONENTS

76-3-14 REPAIRS

Panel - auxiliary switch

$% 76.46.38

Remove

1.Carefully remove electric exterior mirror switch

from auxiliary switch panel and disconnect

multiplug.

2. Models with headlamp levelling: Release

knob and remove nut securing headlamp

levelling switch to auxiliary switch panel.

3.Release 2 fasteners and open fascia access

panel.

4. Models with headlamp levelling: Remove

headlamp levelling switch from auxiliary switch

panel and disconnect multiplug.

5. Models with A/C: Remove 2 screws securing

in-car temperature sensor to auxiliary switch

panel.

6. Models with A/C: Disconnect multiplug from

in-car temperature sensor and remove from

auxiliary switch panel.

7.Release 2 clips securing auxiliary switch panel

to fascia and remove panel.Refit

1.Position auxiliary switch panel to fascia and clip

into position.

2. Models with A/C: Connect multiplug to in-car

temperature sensor.

3. Models with A/C: Position in-car temperature

sensor to auxiliary switch panel and secure with

screws.

4. Models with headlamp levelling: Position

headlamp levelling switch to auxiliary switch

panel and secure with nut.

5. Models with headlamp levelling: Replace

cap and connect multiplug to headlamp

levelling switch.

6.Connect multiplug to exterior mirror switch and

fit switch to auxiliary switch panel.

Page 986 of 1529

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-21

11.Remove access panel from front edge of front

stowage pocket.

12.Remove screw securing front stowage pocket

to headlining.

13.Remove lens from front interior lamp.

14.Remove 2 nuts securing front interior lamp to

headlining.

15.Disconnect multiplug from front interior lamp.

16.Remove front interior lamp.

17.Remove 10 screws securing front stowage

pocket to headlining.

18.Disconnect 3 multiplugs from sunroof switches.

19.Remove front stowage pocket.

20.Remove caps from sun visor clips.

21.Remove screws and release both sun visor

clips.

22.Remove tail door aperture upper trim casing.

23.Remove rear sunroof aperture trim. 24.Remove front sunroof aperture trim.

25.Release end caps from all grab handles.

26.Remove 2 bolts securing each grab handle to

roof.

27.Remove all 4 grab handles.

28. Models with volumetric alarm: Release front

volumetric sensor from headlining and

disconnect multiplug.

29. Models with rear A/C:

aRelease rear A/C control panel from

headlining.

bDisconnect 2 multiplugs and 2 Lucar

connectors from rear A/C control panel.

cRemove rear A/C control panel.

30.Release rear interior lamp from headlining and

disconnect multiplug.

31.Remove rear interior lamp.

Page 988 of 1529

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-23

11.Position rear interior lamp to headlining and

connect multiplug.

12.Fit rear interior lamp to headlining.

13. Models with rear A/C:

aPosition rear A/C control panel to headlining

and connect multiplugs and Lucar

connectors.

bFit rear A/C control panel to headlining.

14. Models with volumetric alarm: Connect

multiplug to front volumetric sensor and fit

sensor to headlining.

15.Fit grab handles to headlining and secure with

bolts.

16.Fit end caps to grab handles.

17.Fit front sunroof aperture trim.

18.Fit rear sunroof aperture trim.

19.Fit tail door aperture upper trim casing.

20.Fit sun visor clips to headlining and secure with

screws.

21.Fit caps to sun visor clips.

22.Position front stowage pocket to headlining and

connect multiplugs to sunroof switches.

23.Fit and tighten 10 screws securing front

stowage pocket to headlining.

24.Connect multiplug to front interior lamp.

25.Fit front interior lamp to headlining and secure

with nuts.

26.Fit lens to front interior lamp.

27.Fit and tighten screw securing front stowage

pocket to headlining.

28.Fit access panel to front edge of front stowage

pocket.

29.Position sun visor to headlining and secure to

clip.

30.Connect multiplug to sun visor.

31.Fit and tighten screws securing sun visor to

headlining.

32.Repeat process for second sun visor.

33. Models with premium ICE: Position both 'A'

post trim casings and connect multiplugs to

speakers.

34.Fit both trim casings to 'A' posts and secure

with clips.

35.Fit both 'B' post upper trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - upper - 'B' post.

36.Fit both 'D' post trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - 'D' post.

Page 1008 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-11

Description - heated seats

Heated seats

The heated seat system is available on both manual seats and electric seats. The electrical sub-system consists of

the following components:

lSeat heater switches.

lSeat heater elements.

lTemperature control unit (if electric seats are fitted).

lTemperature sensor (if electric seats are fitted).

lThermostat (if manual seats are fitted).

Seat heater switches

The seat heater switches supply an ignition feed to either the temperature control unit (vehicles with electric seats) or

directly to the seat heater elements (vehicles with manual seats). When a seat heater switch is operated, current flows

to the seat heater elements causing them to heat the seat.

The ignition feed comes from fuse 15 in the passenger compartment fuse box.

Seat heater elements

The seat heater elements are located in the seat cushion and squab. The cushion and squab heater elements are

wired in series. Total power consumption at 13.5 volts is approximately 115 Watts.

The cushion heater element has an input feed from the temperature control unit or heater switch and an output to the

squab heater element, which outputs to earth.

Page 1009 of 1529

SEATS

76-5-12 DESCRIPTION AND OPERATION

Temperature control unit

The temperature control unit is only fitted to vehicles with electric seats. Feed back of the seat temperature is via a

Negative Temperature Coefficient (NTC) sensor within the seat cushion. Resistance of this sensor changes with the

temperature of the seat cushion allowing the temperature control unit to lower or raise the voltage to the seat heater

elements to raise or lower their temperature.

An ignition feed is supplied via the seat heater switch. The temperature sensor supplies an input. Output is a supply

to the cushion heater element and an earth.

Thermostat

On vehicles with non electric seats, the temperature is controlled by a thermostat located in the seat cushion. The

thermostat interrupts the power supply when it reaches a pre-determined temperature.

Page 1010 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-13

Operation - heated seats

When the seat heater switch is operated, power is supplied to the heater elements in the seat, causing the seat to

heat up. On vehicles fitted with non electric seats, the thermostat switches the power supply to the heater elements

on and off. On vehicles fitted with electric seats, the temperature control unit senses seat temperature via the sensor

in the cushion and regulates voltage to the seat heater elements to maintain a constant temperature.

On both electric and non electric seats, the heater elements increase and then maintain the seat at a temperature

between 26 and 36 °C (79 and 97 °F).

Page 1159 of 1529

HEATING AND VENTILATION

80-2DESCRIPTION AND OPERATION

Fuel burning heater component layout

RH drive shown, LH drive similar

1FBH fuel line connection

2FBH unit3Air temperature sensor

4FBH pump

Page 1165 of 1529

HEATING AND VENTILATION

80-8DESCRIPTION AND OPERATION

Control panel

The controls for heating and ventilation are installed on a control panel in the centre of the fascia, below the radio.

Three rotary knobs control the LH and RH outlet temperatures and distribution. A slider switch controls blower speed.

A latching pushswitch controls the selection of fresh/recirculated air; an amber LED in the switch illuminates when

recirculated air is selected.

Graphics on the panel and the controls indicate the function and operating positions of the controls.

Outlet vent

The outlet vent promotes the free flow of heating and ventilation air through the cabin. The outlet vent is installed in

the RH rear quarter body panel and vents cabin air into the sheltered area between the rear quarter body panel and

the outer body side panel. The vent consists of a grille covered by soft rubber flaps and is effectively a non-return

valve. The flap opens and closes automatically depending on the differential between cabin and outside air pressures.

FBH system (diesel models only)

The FBH system is an auxiliary heating system that compensates for the relatively low coolant temperatures inherent

in the diesel engine. At low ambient temperatures, the FBH system heats the coolant supply to the heater assembly,

and maintains it within the temperature range required for good in-car heating performance. Operation is fully

automatic, with no intervention required by the driver.

The system consists of an air temperature sensor, a FBH fuel pump and a FBH unit. Fuel for the FBH system is taken

from the fuel tank, through a line attached to the fuel tank's fuel pump, and supplied via the FBH fuel pump to the FBH

unit. The connection on the fuel tank's fuel pump incorporates a tube which extends down into the tank. At the FBH

unit connection, the fuel line incorporates a self-sealing, quick disconnect coupling. In the FBH unit, the fuel delivered

by the FBH fuel pump is burned and the resultant heat output is used to heat the coolant. An ECU integrated into the

FBH unit controls the operation of the system at one of two heat output levels, 2.5 kW at part load and 5 kW at full load

Ambient temperature sensor

The ambient temperature sensor controls a power supply from the alternator to the FBH unit. The sensor is installed

on the RH support strut of the bonnet closing panel and contains a temperature sensitive switch that is closed at

temperatures below 5 °C (41 °F) and open at temperatures of 5 °C (41 °F) and above.

Page 1168 of 1529

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-11

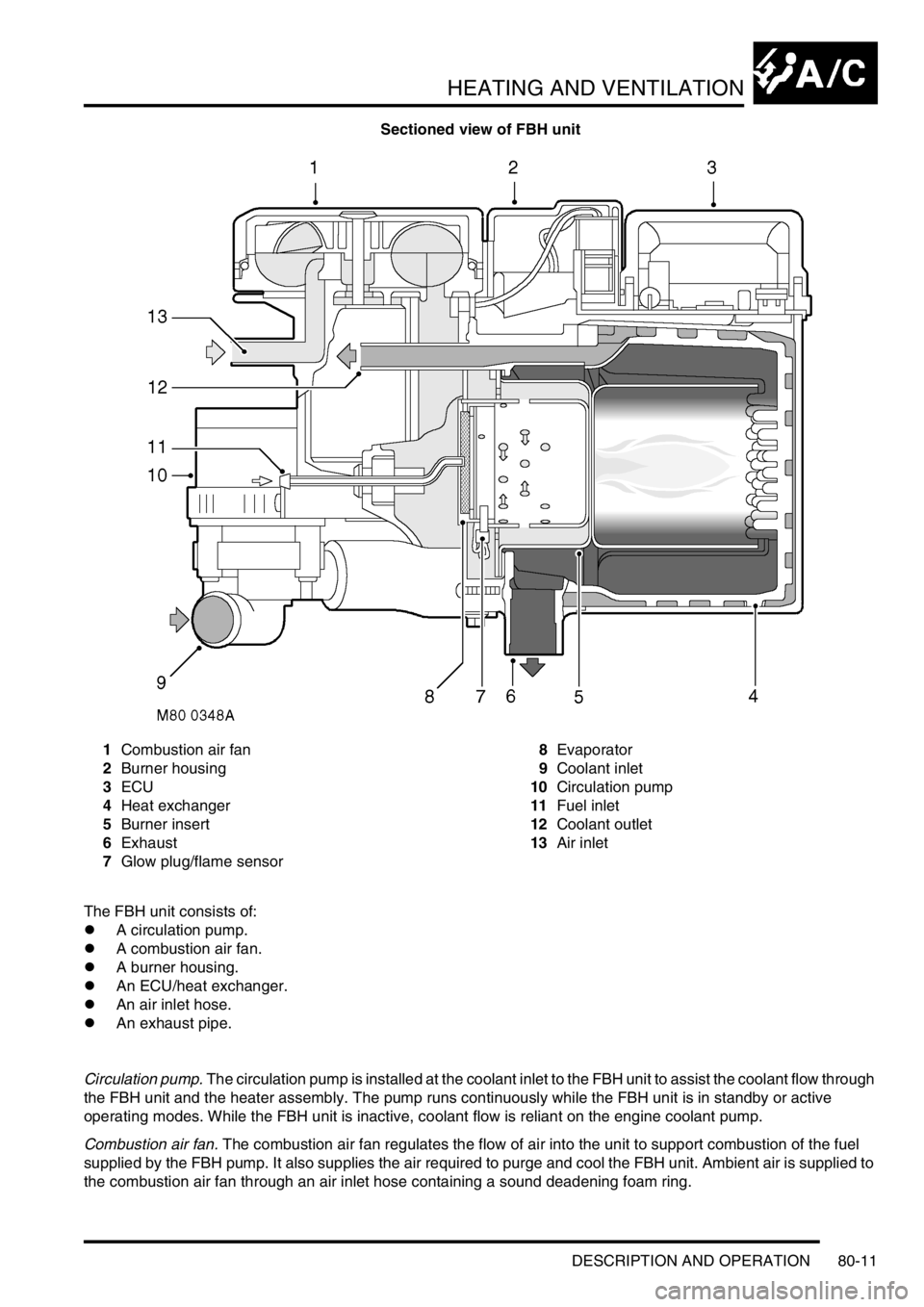

Sectioned view of FBH unit

1Combustion air fan

2Burner housing

3ECU

4Heat exchanger

5Burner insert

6Exhaust

7Glow plug/flame sensor8Evaporator

9Coolant inlet

10Circulation pump

11Fuel inlet

12Coolant outlet

13Air inlet

The FBH unit consists of:

lA circulation pump.

lA combustion air fan.

lA burner housing.

lAn ECU/heat exchanger.

lAn air inlet hose.

lAn exhaust pipe.

Circulation pump. The circulation pump is installed at the coolant inlet to the FBH unit to assist the coolant flow through

the FBH unit and the heater assembly. The pump runs continuously while the FBH unit is in standby or active

operating modes. While the FBH unit is inactive, coolant flow is reliant on the engine coolant pump.

Combustion air fan. The combustion air fan regulates the flow of air into the unit to support combustion of the fuel

supplied by the FBH pump. It also supplies the air required to purge and cool the FBH unit. Ambient air is supplied to

the combustion air fan through an air inlet hose containing a sound deadening foam ring.