sensor LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1169 of 1529

HEATING AND VENTILATION

80-12DESCRIPTION AND OPERATION

Burner housing. The burner housing contains the burner insert and also incorporates connections for the exhaust

pipe, the coolant inlet from the circulation pump and the coolant outlet to the heater assembly. The exhaust pipe

directs exhaust combustion gases to atmosphere at the bottom of the engine compartment.

The burner insert incorporates the fuel combustion chamber, an evaporator and a glow plug/flame sensor. Fuel from

the FBH fuel pump is supplied to the evaporator, where it evaporates and enters the combustion chamber to mix with

air from the combustion air fan. The glow plug/flame sensor provides the ignition source of the fuel:air mixture and,

once combustion is established, monitors the flame.

ECU/heat exchanger. The ECU controls and monitors operation of the FBH system. Ventilation of the ECU is

provided by an internal flow of air from the combustion air fan. The heat exchanger transfers heat generated by

combustion to the coolant. A sensor in the heat exchanger provides the ECU with an input of heat exchanger casing

temperature, which the ECU relates to coolant temperature and uses to control system operation. The temperature

settings in the ECU are calibrated to compensate for the difference between coolant temperature and the heat

exchanger casing temperature detected by the sensor. Typically: as the coolant temperature increases, the coolant

will be approximately 7 °C (12.6 °F) hotter than the temperature detected by the sensor; as the coolant temperature

decreases, the coolant will be approximately 2 °C (3.6 °F) cooler than the temperature detected by the sensor.

Page 1170 of 1529

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-13

Operation

Air distribution

Turning the distribution knob on the control panel turns the control flaps in the heater assembly to direct air to the

corresponding fascia and footwell outlets.

Air temperature

Turning the LH or RH temperature knob on the control panel turns the related blend flaps in the heater assembly. The

blend flaps vary the proportion of air going through the cold air bypass and the heater matrix. The proportion varies,

between full bypass no heat and no bypass full heat, to correspond with the position of the temperature knob.

Blower speed

The blower can be selected off or to run at one of four speeds. While the ignition is on, when the blower switch is set

to positions 1, 2, 3, or 4, ignition power energises the blower relay, which supplies battery power to the blower. At

switch positions 1, 2 and 3, the blower switch also connects the blower to different earth paths through the resistor

pack, to produce corresponding differences of blower operating voltage and speed. At position 4, the blower switch

connects an earth direct to the blower, bypassing the resistor pack, and full battery voltage drives the blower at

maximum speed.

Fresh/Recirculated inlet air

When the recirculated air switch is latched in, the amber indicator LED in the switch illuminates and an earth is

connected to the recirculated air side of the fresh/recirculated air servo motor. The fresh/recirculated air servo motor

then turns the control flaps in the air inlet duct to close the fresh air inlet and open the recirculated air inlets.

When the latch of the recirculated air switch is released, the amber indicator LED in the switch extinguishes and the

earth is switched from the recirculated air side to the fresh air side of the fresh/recirculated air servo motor. The fresh/

recirculated air servo motor then turns the control flaps in the air inlet duct to open the fresh air inlet and close the

recirculated air inlets.

FBH system (where fitted)

The FBH system operates only while the engine is running and the ambient temperature is less than 5 °C (41 °F).

With the engine running and the ambient temperature below 5 °C (41 °F), the air temperature sensor connects the

alternator power supply to the ECU in the FBH unit. On receipt of the alternator power supply, the ECU starts the

circulation pump and, depending on the input from the temperature sensor in the heat exchanger, enters either a

standby or active mode of operation. If the heat exchanger casing temperature is 65 °C (149 °F) or above, the ECU

enters a standby mode of operation. If the heat exchanger casing temperature is below 65 °C (149 °F), the ECU enters

an active mode of operation. In the standby mode, the ECU monitors the heat exchanger casing temperature and

enters the active mode if it drops below 65 °C (149 °F). In the active mode, the ECU initiates a start sequence and

then operates the system at full or part load combustion to provide the required heat input to the coolant.

Start sequence

At the beginning of the start sequence the ECU energises the glow plug function of the glow plug/flame sensor, to

preheat the combustion chamber, and starts the combustion air fan at slow speed. After 30 seconds, the ECU

energises the FBH fuel pump at the starting sequence speed. The fuel delivered by the FBH fuel pump evaporates in

the combustion chamber, mixes with air from the combustion air fan and is ignited by the glow plug/flame sensor. The

ECU then progressively increases the speed of the FBH fuel pump and the combustion air fan to either part or full

load speed, as required by the system. Once full or part load speed is achieved, the ECU switches the glow plug/flame

sensor from the glow plug function to the flame sensing function to monitor combustion. From the beginning of the

start sequence to stable combustion takes approximately 90 seconds for a start to part load combustion and 150

seconds for a start to full load combustion.

Page 1171 of 1529

HEATING AND VENTILATION

80-14DESCRIPTION AND OPERATION

Coolant temperature control

When the ECU first enters the active mode, it initiates a start to full load combustion. Full load combustion continues

until the heat exchanger casing temperature reaches 60 °C (140 °F), when the ECU decreases the speed of the FBH

fuel pump and the combustion air fan to half speed, to produce part load combustion. The ECU maintains part load

combustion while the heat exchanger casing temperature remains between 54 and 65 °C (129 and 149 °F). If the heat

exchanger casing temperature decreases to 54 °C (129 °F), the ECU switches the system to full load combustion

again. If the heat exchanger casing temperature increases to 65 °C (149 °F), the ECU enters a control idle phase of

operation.

On entering the control idle phase, the ECU immediately switches the FBH fuel pump off, to stop combustion, and

starts a timer for the combustion air fan. After a 2 minute cooldown period, the ECU switches the combustion air fan

off and then remains in the control idle phase while the heat exchanger casing temperature remains above 59 °C (138

°F). If the heat exchanger casing temperature decreases to 59 °C (138 °F), within 15 minutes of the ECU entering the

control idle phase, the ECU initiates a start to part load combustion. If more than 15 minutes elapse before the heat

exchanger casing temperature decreases to 59 °C (138 °F), the ECU initiates a start to full load combustion.

In order to limit the build-up of carbon deposits on the glow plug/flame sensor, the ECU also enters the control idle

phase if the continuous part and/or full load combustion time exceeds 72 minutes. After the cooldown period, if the

heat exchanger casing is still in the temperature range that requires additional heat, the ECU initiates an immediate

restart to part or full load combustion, as appropriate.

Shutdown

The FBH system is de-activated when the alternator power supply to the FBH unit is disconnected, either by the

engine stopping or, if the ambient temperature increases to 5 °C (41 °F) or above, by the contacts in the air

temperature sensor opening. If the system is active when the alternator power supply is disconnected, the ECU de-

energises the FBH fuel pump to stop combustion, but continues operation of the combustion air fan and the circulation

pump to cool down the FBH unit. The cool down time depends on the combustion load at the time the alternator power

input is disconnected.

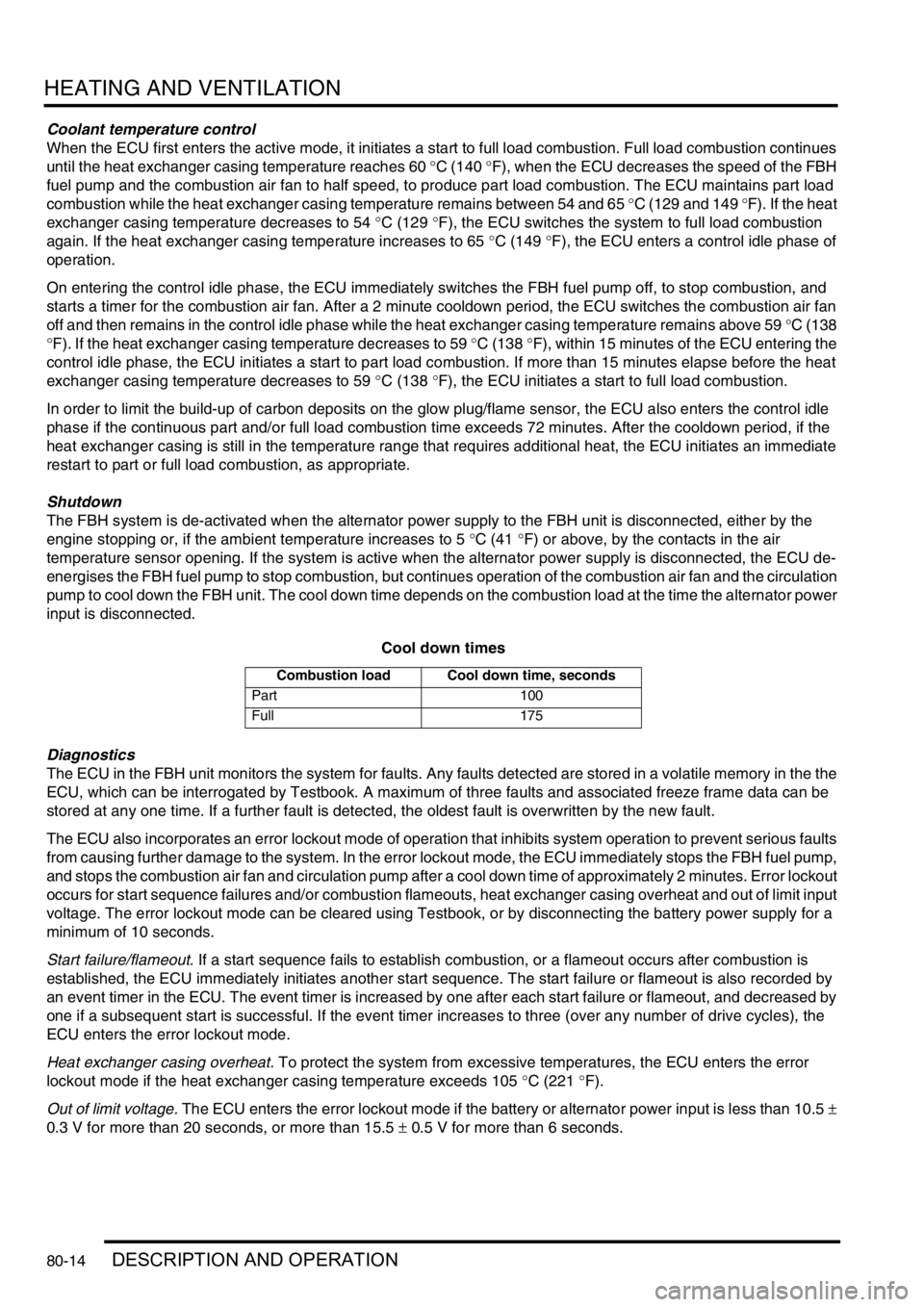

Cool down times

Diagnostics

The ECU in the FBH unit monitors the system for faults. Any faults detected are stored in a volatile memory in the the

ECU, which can be interrogated by Testbook. A maximum of three faults and associated freeze frame data can be

stored at any one time. If a further fault is detected, the oldest fault is overwritten by the new fault.

The ECU also incorporates an error lockout mode of operation that inhibits system operation to prevent serious faults

from causing further damage to the system. In the error lockout mode, the ECU immediately stops the FBH fuel pump,

and stops the combustion air fan and circulation pump after a cool down time of approximately 2 minutes. Error lockout

occurs for start sequence failures and/or combustion flameouts, heat exchanger casing overheat and out of limit input

voltage. The error lockout mode can be cleared using Testbook, or by disconnecting the battery power supply for a

minimum of 10 seconds.

Start failure/flameout. If a start sequence fails to establish combustion, or a flameout occurs after combustion is

established, the ECU immediately initiates another start sequence. The start failure or flameout is also recorded by

an event timer in the ECU. The event timer is increased by one after each start failure or flameout, and decreased by

one if a subsequent start is successful. If the event timer increases to three (over any number of drive cycles), the

ECU enters the error lockout mode.

Heat exchanger casing overheat. To protect the system from excessive temperatures, the ECU enters the error

lockout mode if the heat exchanger casing temperature exceeds 105 °C (221 °F).

Out of limit voltage. The ECU enters the error lockout mode if the battery or alternator power input is less than 10.5 ±

0.3 V for more than 20 seconds, or more than 15.5 ± 0.5 V for more than 6 seconds.

Combustion load Cool down time, seconds

Part 100

Full 175

Page 1191 of 1529

AIR CONDITIONING

82-2DESCRIPTION AND OPERATION

A/C control system component layout

RH drive shown, LH drive similar

1Air temperature control ECU

2Heater coolant temperature sensor

3Evaporator temperature sensor

4Dual pressure switch5Ambient temperature sensor

6Sunlight sensor

7In-car temperature sensor

Page 1198 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-9

Heater assembly

1Distribution servo motor

2Refrigerant inlet and outlet connector block

3RH blend flap servo motor4Thermostatic expansion valve

5LH blend flap servo motor

The heater assembly controls the temperature and distribution of air supplied to the distribution ducts, and is similar

to the heater assembly installed in non A/C vehicles.

+ HEATING AND VENTILATION, DESCRIPTION AND OPERATION, Description. The only differences from

the heater assembly in non A/C vehicles are as follows:

lThe thermostatic expansion valve, evaporator and evaporator temperature sensor are installed at the air inlet

side of the casing.

lThree servo motors operate the control flaps instead of control cables.

lA coolant temperature sensor is installed against the heater matrix.

The servo motors are controlled by the ATC ECU. Feedback potentiometers in the servo motors provide the ATC ECU

with flap position signals.

Page 1199 of 1529

AIR CONDITIONING

82-10DESCRIPTION AND OPERATION

Temperature and distribution control

Figure shows flaps set for medium heat to face level and footwell outlets

1Windscreen/Side windows outlet

2Heater assembly casing

3Air inlet

4Evaporator5Heater matrix

6Front footwells outlet

7Rear footwells outlet

8Face level outlet

Control system

The control system operates the refrigerant system and the control flaps in the heater assembly to control the

temperature and distribution of air in the vehicle interior. It also outputs signals to the fresh/recirculated air servo motor

and the blower to control the volume and source of inlet air. The control system consists of:

lAn Air Temperature Control (ATC) ECU.

lA dual pressure switch.

lAn evaporator temperature sensor.

lAn in-car temperature sensor.

lA sunlight sensor.

lA heater coolant temperature sensor.

lAn ambient temperature sensor.

Page 1200 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-11

ATC ECU

The ATC ECU is installed in the centre of the fascia, below the radio. An integral control panel on the ATC ECU

contains switches for system control inputs and a LCD to provide system status information.

Inputs from sensors and the control panel switches are processed by the ATC ECU, which then outputs the

appropriate control signals.

ATC ECU connectors

ATC ECU connector pin details

Connector/Pin

No.Description Input/Output

C0791

1 Battery power supply Input

2 Ignition power supply Input

3 Sensor power supply Output

4Earth -

5 Display illumination Input

6 Not used -

7 Not used -

8 Sensor earth -

C0792

1 Night lighting/dimming Input

2 Vehicle speed Input

3 Hand of drive Input

4 Distribution flaps position Input

5 Heater coolant temperature Input

6 External air temperature Input

7 In-car air temperature Input

8 Blower power transistor collector voltage Input

9 Not used -

10 Not used -

11 Windscreen heater status Input

12 Rear screen heater status Input

13 Rear air conditioning ON Input

Page 1204 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-15

Dual pressure switch

The dual pressure switch protects the refrigerant system from extremes of pressure. The normally closed switch is

installed in the top of the receiver drier. If minimum or maximum pressure limits are exceeded the switch contacts

open, causing the compressor clutch to be disengaged. The minimum pressure limit protects the compressor, by

preventing operation of the system unless there is a minimum refrigerant pressure (and thus refrigerant and

lubricating oil) in the system. The maximum pressure limit keeps the refrigerant system within a safe operating

pressure.

Dual pressure switch nominal operating pressures

Evaporator temperature sensor

The evaporator temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of the

evaporator air outlet temperature. The evaporator temperature sensor is installed in a clip which locates in the

evaporator matrix in the heater assembly. The ATC ECU uses the input to prevent the formation of ice on the

evaporator.

In-car temperature sensor

The in-car temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of cabin air

temperature. The sensor is integrated into the inlet of an electric fan, which is installed behind a grille in the fascia

outboard of the steering column. The fan runs continuously, while the ignition is on, to draw air through the grille and

across the sensor.

Sunlight sensor

The sunlight sensor consists of two diodes that provide the ATC ECU with inputs of light intensity, one as sensed

coming from the left of the vehicle and one as sensed coming from the right. The inputs are used as a measure of the

solar heating effect on vehicle occupants. The sensor is installed in the centre of the fascia upper surface.

Heater coolant temperature sensor

The heater coolant temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input related

to heater matrix coolant temperature. The sensor is installed in the casing of the heater assembly and presses against

the end tank of the heater matrix.

Ambient temperature sensor

The ambient temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of external

air temperature. The sensor is attached to the cooling fan mounting bracket in front of the condenser.

Limit Opening pressure, bar (lbf.in2) Closing pressure, bar (lbf.in2)

Minimum 2.0 (29.0), pressure decreasing 2.3 (33.4), pressure increasing

Maximum 32 (464), pressure increasing 26 (377), pressure decreasing

Page 1205 of 1529

AIR CONDITIONING

82-16DESCRIPTION AND OPERATION

Operation

General

While the system is on, the ATC ECU operates the refrigerant system and the inlet air, blower speed, air temperature

and air distribution functions to produce the conditions requested on the control panel. When the system is first

switched on, the ATC ECU resumes the control outputs in use when the system was last switched off. If conditions

have changed, or a different mode is selected to switch the system on, the control outputs are then changed to

produce the required new settings.

The system operates in automatic, economy and defrost modes, with manual overrides of the inlet air source, blower

speed and air distribution. The air temperature is automatically controlled in all operating modes.

In the automatic mode, the ATC ECU operates the system to warm-up or cool down the cabin to establish and

maintain the temperature selections on the control panel, while directing the air to those outlets most comfortable for

the occupant(s). If a difference between the LH and RH temperature selections causes a conflict of the required inlet

air source, blower speed or air distribution settings, priority is given to achieving the temperature requested on the

driver's side of the control panel.

The ATC ECU enters the economy mode when the refrigerant compressor is selected off while the system is in the

automatic mode, which reduces the load on the engine. Economy mode operation is similar to the automatic mode,

but without the ability to cool the cabin if the ambient temperature is higher than the temperature selections made on

the control panel, or to dehumidify the air in the cabin.

In the defrost mode, the ATC ECU sets the inlet air source to fresh air, the blower to maximum speed, the air

distribution to windscreen and side windows, and outputs signals to the BCU to operate the rear window heater and

(where fitted) the windscreen heater. The BCU starts or, if the heaters are already on, resets the heater timers and

energises the rear window and windscreen heaters for a complete on cycle.

Air temperature control

To determine the amount of heat or cooling required by the cabin, the ATC ECU uses the sensor inputs and the

temperatures selected on the control panel to calculate target air outlet temperatures for the driver's and the front

passenger's side of the heater assembly. The ATC ECU then signals the servo motors controlling the respective blend

flaps in the heater assembly to move to the flaps to the appropriate position. The target temperatures are constantly

updated and, in the automatic mode, also used in further calculations to determine the inlet air source, the blower

speed and the air distribution.

Inlet air control

The inlet air source is automatically controlled while the system is off or on. While the system is on, the inlet air source

can also be manually controlled to give timed recirculated air or latched recirculated air.

While the system is off, the ATC ECU uses vehicle speed to determine the inlet air source. With the vehicle at rest,

the inlet air source is set to recirculated air. When vehicle speed reaches 17.5 mph (28 km/h), the inlet air source

changes to fresh air. The inlet air source then remains at fresh air until the vehicle speed decreases to 5 mph (8 km/

h), when it returns to recirculated air.

While the system is on, the ATC ECU uses the LH and RH temperature selections, vehicle speed, ambient air

temperature and coolant temperature to determine the inlet air source. In the automatic mode:

lIf one temperature selection is set to LO and one is set to a specific temperature or HI, the inlet air is set to

recirculated air.

lIf one temperature selection is set to HI and one is set to a specific temperature or HI, the inlet air is set to fresh

air.

lWhen specific LH and RH temperature selections are set, the inlet air source remains at fresh air except when

the air distribution function is set to face level only or face level and footwell outlets. If the air distribution function

is set to face level only or face level and footwell outlets, at 56 mph (90 km/h) the inlet air source changes to

recirculated air (to exclude ram effect, which becomes excessive at speed). When the vehicle speed decreases

to 37.5 mph (60 km/h), the inlet air source returns to fresh air.

In the defrost mode, the inlet air source is set to fresh air except at low ambient air and coolant temperatures. If, within

5 minutes of the ignition being switched on, the vehicle speed is less than 5 mph (8 km/h) while the external air

temperature is −16 °C (3 °F) or less and the heater coolant temperature is −10 °C (14 °F) or less, then the inlet air

source is automatically set to the timed recirculated air mode. The timed recirculated air mode is cancelled

immediately the vehicle speed reaches 8 km/h or more .

Page 1208 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-19

Diagnostics

The ATC ECU performs a diagnostic check each time the ignition is switched on. To avoid nuisance fault indications

at low light levels, the sunlight sensor is omitted from the diagnostic check. If a fault is detected, the audible warning

sounds three times and the AUTO window on the control panel display flashes for 20 seconds. The ATC ECU then

reverts to normal control but uses a default value or strategy for the detected fault. Faults are identified by performing

a manual diagnostic check of the system.

A manual diagnostic check includes a check of the sunlight sensor, and is initiated by pressing and holding the AUTO

switch and the air distribution switch, then turning the ignition switch from off to on. The audible warning sounds once

and the indications on the control panel display illuminate. FC is shown in the LH temperature window and the results

of the check are shown as a two digit fault code in the RH temperature window. If a fault is detected, the audible

warning sounds three times and the AUTO window on the display flashes on and off for 20 seconds. If more than one

fault is detected, the fault codes cycle in numerical order, at 1 Hz. The audible warning sounds as each fault code is

shown. In low light conditions, to avoid false sunlight sensor fault indications, the sunlight sensor should be illuminated

with a strong light source.

Diagnostic fault codes and fault descriptions

Code Component Fault Default value/strategy

00 - No fault found -

11 In-car temperature sensor Open or short circuit 25°C (77°F)

12 Ambient temperature sensor Open or short circuit 10°C (50°F)

Cooling fan permanently on

Display shows "- -" if external air

temperature selected

13 Thermistor Open or short circuit 0°C (32°F)

14 Heater coolant temperature sensor Open or short circuit 70°C (158°F)

21 Sunlight sensor, left output Open or short circuit No solar heating correction

22 Sunlight sensor, right output Open or short circuit No solar heating correction

31 LH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

32 RH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

33 Distribution servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position