LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 251 of 1529

EMISSION CONTROL - V8

17-2-18 DESCRIPTION AND OPERATION

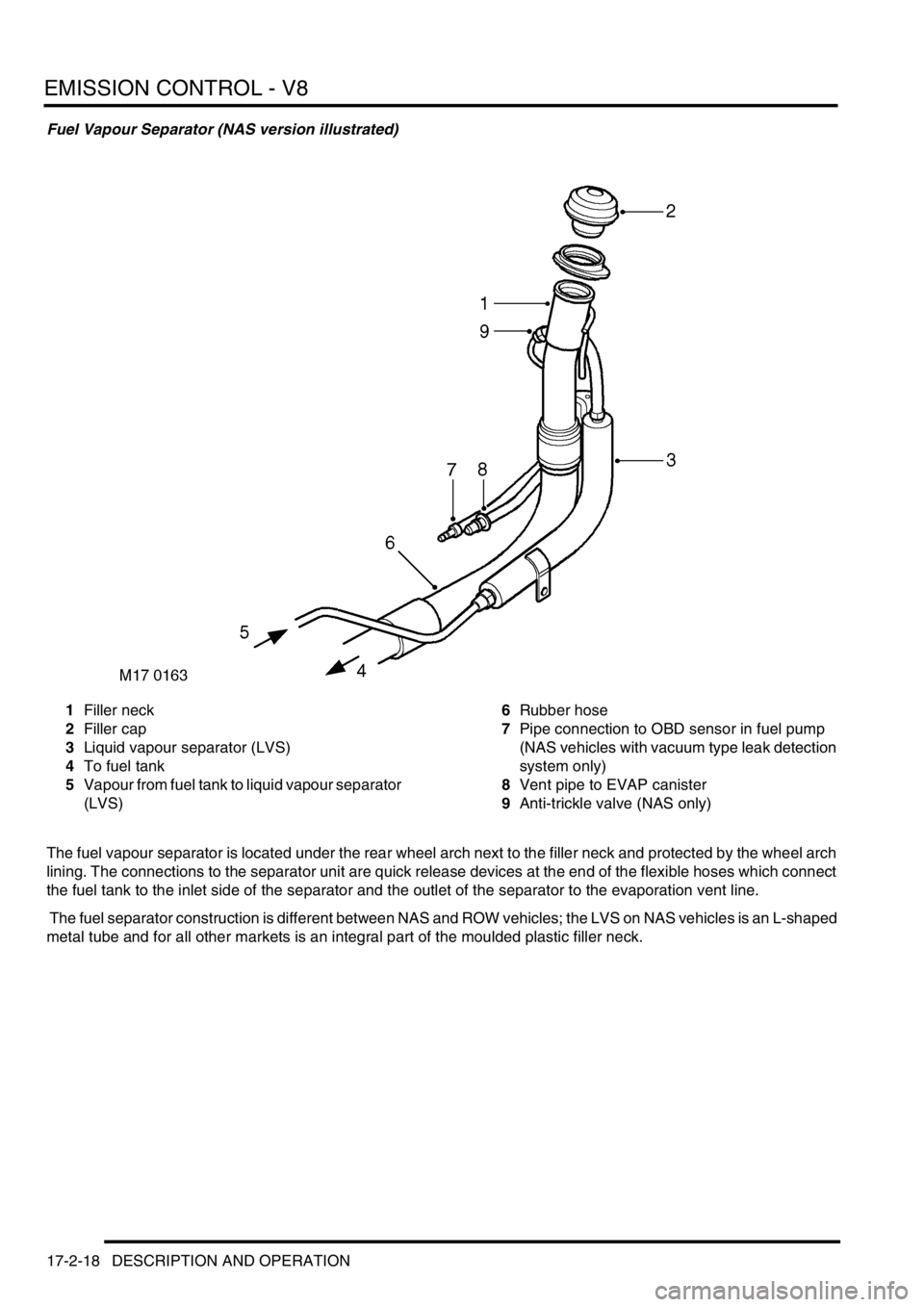

Fuel Vapour Separator (NAS version illustrated)

1Filler neck

2Filler cap

3Liquid vapour separator (LVS)

4To fuel tank

5Vapour from fuel tank to liquid vapour separator

(LVS)6Rubber hose

7Pipe connection to OBD sensor in fuel pump

(NAS vehicles with vacuum type leak detection

system only)

8Vent pipe to EVAP canister

9Anti-trickle valve (NAS only)

The fuel vapour separator is located under the rear wheel arch next to the filler neck and protected by the wheel arch

lining. The connections to the separator unit are quick release devices at the end of the flexible hoses which connect

the fuel tank to the inlet side of the separator and the outlet of the separator to the evaporation vent line.

The fuel separator construction is different between NAS and ROW vehicles; the LVS on NAS vehicles is an L-shaped

metal tube and for all other markets is an integral part of the moulded plastic filler neck.

Page 252 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-19

EVAP (charcoal) Canister

1EVAP canister

2Port to breather tube3Port – vent line from fuel tank

4Port – purge line

The EVAP canister is mounted on a bracket fitted beneath the vehicle on the RH side of the chassis. The EVAP

canister ports face towards the front of the vehicle. The EVAP canister has inscriptions next to each port for

identification of the 'purge', 'tank' and 'air' connections.

The purge line from the EVAP canister is connected to the back of the inlet manifold plenum, after the throttle body

via a purge valve. The pipe between the EVAP canister and the purge valve is routed over the transmission and into

the LH side of the engine bay. The pipe clips to the purge port on the EVAP canister by means of a straight quick-fit

connector and the connection is covered by a rubber seal which is held in position on the port stub pipe.

The vent line from the fuel tank to the EVAP canister connects to the vent port on the canister by means of an elbowed

quick-fit connector. The line passes along the chassis behind the EVAP canister and terminates in a straight female

quick-fit connector to the fuel vent line at the fuel filler.

The plastic pipe to the atmosphere vent line connects to the port on the EVAP canister by means of a short rubber

hose and metal band clips. The atmosphere end of the plastic pipe terminates in a quick fit connector to the pipe

leading to the CVS unit on NAS vehicles with vacuum type, EVAP system leak detection and two snorkel tubes

situated behind the engine at the bulkhead on ROW vehicles. The bore of the plastic breather pipe is larger on NAS

vehicles than on ROW vehicles.

Page 253 of 1529

EMISSION CONTROL - V8

17-2-20 DESCRIPTION AND OPERATION

For NAS vehicles with positive pressure, EVAP system leak detection capability, the atmosphere vent line from the

EVAP canister connects to a port on the fuel leak detection pump via a short, large bore hose which is secured to the

component ports by crimped metal clips at each end. A large bore plastic hose from the top of the leak detection pump

is routed to the RH side of the engine bay where it connects to an air filter canister. Under normal operating conditions

(when the fuel leak detection solenoid valve is not energised), the EVAP canister is able to take in clean air via the

air filter, through the pipework and past the open solenoid valve to allow normal purge operation to take place and

release any build up of EVAP system pressure to atmosphere.

The EVAP system pipes are clipped at various points along the pipe runs and tied together with tie straps at suitable

points along the runs.

The NAS and ROW EVAP canisters are of similar appearance, but use charcoal of different consistency. The ROW

vehicles use granular charcoal of 11 bwc (butane working capacity) and NAS vehicles use pelletised charcoal with a

higher absorption capacity of 15 bwc. All canisters are of rectangular shape and have capacities of 1.8 litres (3 1/8

imp. pts) with purge foam retention.

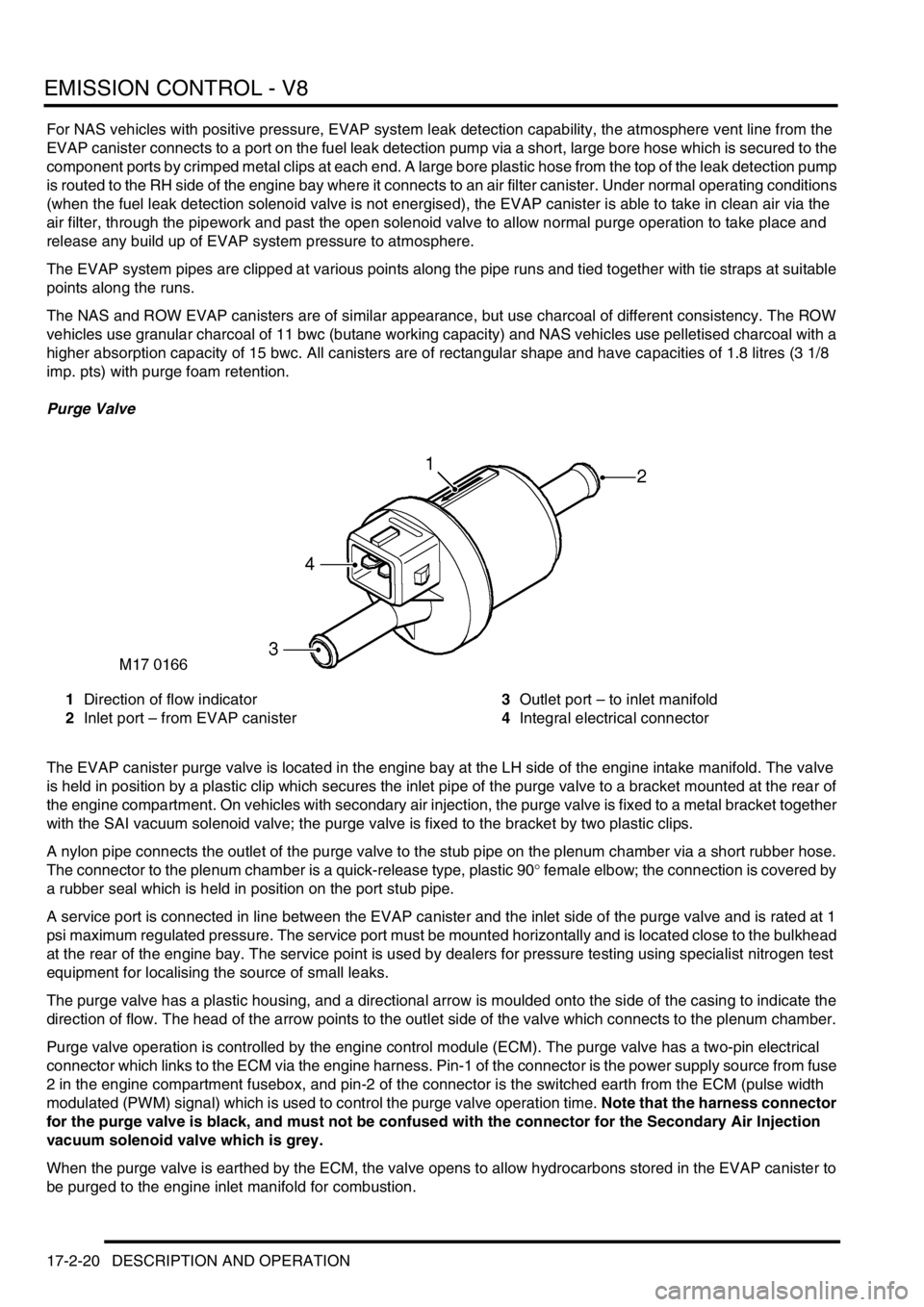

Purge Valve

1Direction of flow indicator

2Inlet port – from EVAP canister3Outlet port – to inlet manifold

4Integral electrical connector

The EVAP canister purge valve is located in the engine bay at the LH side of the engine intake manifold. The valve

is held in position by a plastic clip which secures the inlet pipe of the purge valve to a bracket mounted at the rear of

the engine compartment. On vehicles with secondary air injection, the purge valve is fixed to a metal bracket together

with the SAI vacuum solenoid valve; the purge valve is fixed to the bracket by two plastic clips.

A nylon pipe connects the outlet of the purge valve to the stub pipe on the plenum chamber via a short rubber hose.

The connector to the plenum chamber is a quick-release type, plastic 90° female elbow; the connection is covered by

a rubber seal which is held in position on the port stub pipe.

A service port is connected in line between the EVAP canister and the inlet side of the purge valve and is rated at 1

psi maximum regulated pressure. The service port must be mounted horizontally and is located close to the bulkhead

at the rear of the engine bay. The service point is used by dealers for pressure testing using specialist nitrogen test

equipment for localising the source of small leaks.

The purge valve has a plastic housing, and a directional arrow is moulded onto the side of the casing to indicate the

direction of flow. The head of the arrow points to the outlet side of the valve which connects to the plenum chamber.

Purge valve operation is controlled by the engine control module (ECM). The purge valve has a two-pin electrical

connector which links to the ECM via the engine harness. Pin-1 of the connector is the power supply source from fuse

2 in the engine compartment fusebox, and pin-2 of the connector is the switched earth from the ECM (pulse width

modulated (PWM) signal) which is used to control the purge valve operation time. Note that the harness connector

for the purge valve is black, and must not be confused with the connector for the Secondary Air Injection

vacuum solenoid valve which is grey.

When the purge valve is earthed by the ECM, the valve opens to allow hydrocarbons stored in the EVAP canister to

be purged to the engine inlet manifold for combustion.

Page 254 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-21

If the purge valve breaks or becomes stuck in the open or closed position, the EVAP system will cease to function

and there are no default measures available. The ECM will store the fault in memory and illuminate the MIL warning

lamp if the correct monitoring conditions have been achieved (i.e. valve status unchanged for 45 seconds after engine

has been running for 15 minutes). If the purge valve is stuck in the open position, a rich air:fuel mixture is likely to

result at the intake manifold, this could cause the engine to misfire and the fuelling adaptions will change.

The following failure modes are possible:

lSticking valve

lValve blocked

lConnector or harness wiring fault (open or short circuit)

lValve stuck open

If the purge valve malfunctions, the following fault codes may be stored in the ECM diagnostic memory, which can be

retrieved using TestBook/T4:

Canister Vent Solenoid (CVS) Unit – (NAS with vacuum type, fuel evaporation leak detection system only)

1CVS unit

2Mounting bracket3Spring clips to pipe from EVAP canister

4Harness connector

The canister vent solenoid (CVS) valve is mounted on a slide-on bracket which is riveted to the cruise control bracket

at the right hand side of the engine compartment. The vent pipe from the EVAP canister is connected to a stub pipe

on the CVS unit via a hose and plastic pipe combination. A two-pin connector links to the engine management ECM

via the engine harness for solenoid control; one of the wires is the supply feed from fuse No.2 in the engine

compartment fusebox, the other wire is the valve drive line to the ECM. The solenoid is operated when the ECM

grounds the circuit.

P-code Description

P0440Purge valve not sealing

P0444Purge valve open circuit

P0445Purge valve short circuit to ground

P0443Purge valve short circuit to battery voltage

Page 255 of 1529

EMISSION CONTROL - V8

17-2-22 DESCRIPTION AND OPERATION

The valve is normally open, allowing any build up of air pressure within the evaporation system to escape, whilst

retaining the environmentally harmful hydrocarbons in the EVAP canister. When the ECM is required to run a fuel

system test, the CVS valve is closed to seal the system. The ECM is then able to measure the pressure in the fuel

evaporative system using the fuel tank pressure sensor.

The ECM performs electrical integrity checks on the CVS valve to determine wiring or power supply faults. The ECM

can also detect a valve blockage if the signal from the fuel tank pressure sensor indicates a depressurising fuel tank

while the CVS valve should be open to atmosphere.

The following failure modes are possible:

lConnector or harness wiring fault (open or short circuit)

lValve stuck open or shut

lValve blocked

If the CVS valve malfunctions, the following fault codes may be stored in the ECM diagnostic memory, which can be

retrieved using TestBook/T4:

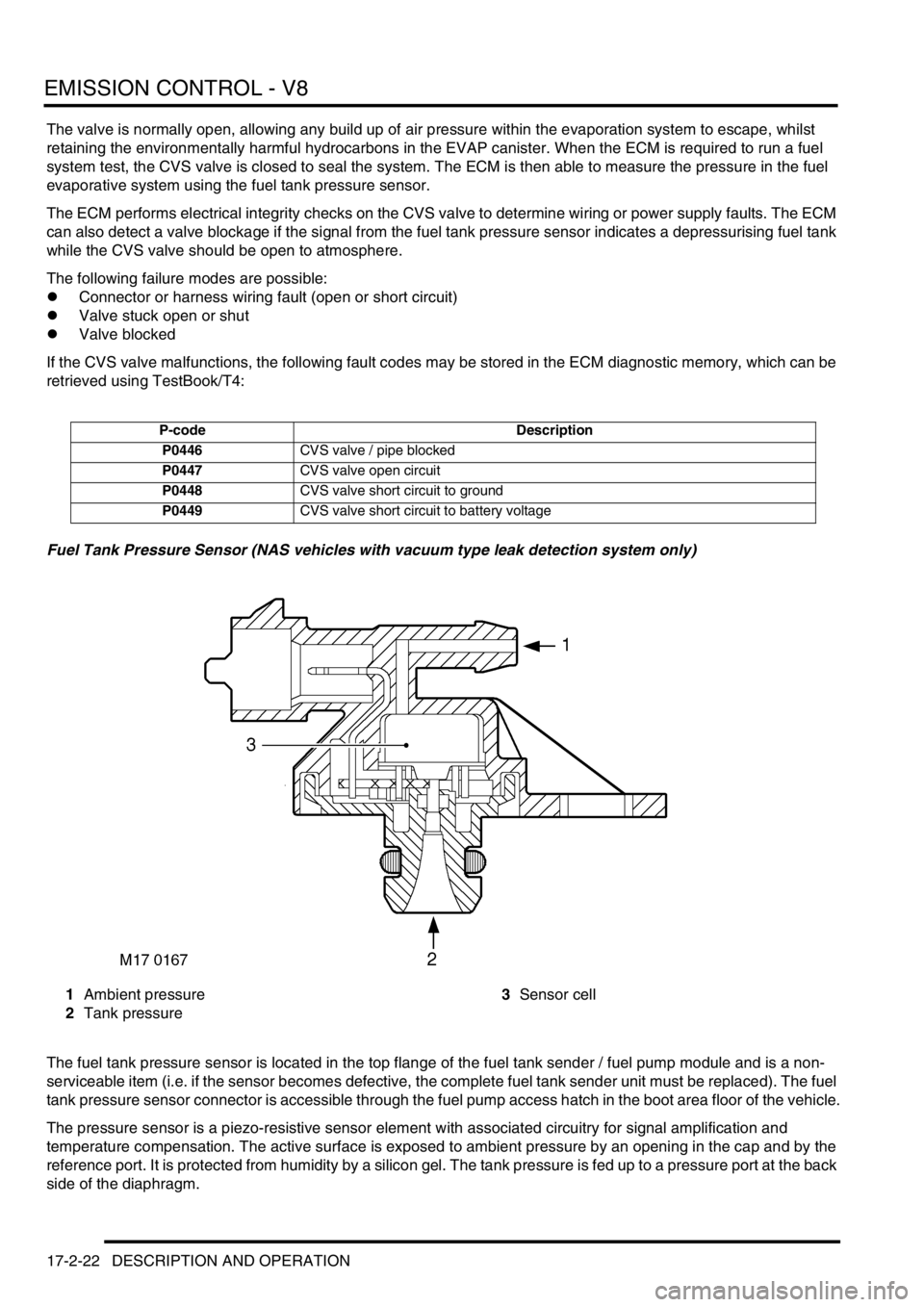

Fuel Tank Pressure Sensor (NAS vehicles with vacuum type leak detection system only)

1Ambient pressure

2Tank pressure3Sensor cell

The fuel tank pressure sensor is located in the top flange of the fuel tank sender / fuel pump module and is a non-

serviceable item (i.e. if the sensor becomes defective, the complete fuel tank sender unit must be replaced). The fuel

tank pressure sensor connector is accessible through the fuel pump access hatch in the boot area floor of the vehicle.

The pressure sensor is a piezo-resistive sensor element with associated circuitry for signal amplification and

temperature compensation. The active surface is exposed to ambient pressure by an opening in the cap and by the

reference port. It is protected from humidity by a silicon gel. The tank pressure is fed up to a pressure port at the back

side of the diaphragm.

P-code Description

P0446CVS valve / pipe blocked

P0447CVS valve open circuit

P0448CVS valve short circuit to ground

P0449CVS valve short circuit to battery voltage

Page 256 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-23

For systems utilising the vacuum method for determining evaporation leaks, the sensor is used to monitor for a drop

in vacuum pressure. The evaporation system is sealed by the CVS valve and purge valve after a vacuum has been

previously set up from the intake manifold while the purge valve is open and the CVS valve is closed. If any holes or

leaks are present at the evaporation system joints, the vacuum pressure will gradually drop and this change in

pressure will be detected by the fuel tank pressure sensor. This system is capable of determining leaks down to 1 mm

(0.04 in.) in diameter.

The fuel tank pressure sensor is part of the NAS OBD system, a component failure will not be noticed by the driver,

but if the ECM detects a fault, it will be stored in the diagnostic memory and the MIL light will be illuminated on the

instrument pack. Possible failures are listed below:

lDamaged or blocked sensor

lHarness / connector faulty

lSensor earthing problem

lOpen circuit

lShort circuit to battery voltage

lShort circuit to ground

lECM fault

Possible failure symptoms of the fuel tank pressure sensor are listed below:

lFuel tank pressure sensor poor performance

lFuel tank pressure sensor low range fault

lFuel tank pressure sensor high range fault

If the fuel tank pressure sensor should malfunction, the following fault codes may be stored in the ECM diagnostic

memory, which can be retrieved using TestBook/T4:

P-code Description

P0451Fuel tank pressure signal stuck high within range

P0452Fuel tank pressure signal short circuit to battery voltage (out of range - High)

P0453Fuel tank pressure signal short circuit to ground or open circuit (out of range - Low)

Page 257 of 1529

EMISSION CONTROL - V8

17-2-24 DESCRIPTION AND OPERATION

Leak Detection Pump (NAS vehicles with positive pressure EVAP system leakage test only)

1Harness connector

2Leak detection pump motor

3Atmosphere connection to/from EVAP canister4Atmosphere connection to/from air filter

5Leak detection pump solenoid valve

The fuel evaporation leak detection pump is mounted forward of the EVAP canister on a bracket fitted beneath the

vehicle on the RH side of the vehicle chassis. The leak detection pump is fixed to the bracket by three screws through

the bottom of the bracket.

A short hose connects between the atmosphere vent port of the EVAP canister and a port at the rear of the fuel

evaporation leak detection pump. The hose is secured to the ports at each end by crimped metal band clips.

An elbowed quick fit connector on the top of the fuel evaporation leak detection pump connects to atmosphere via a

large bore pipe. The pipe is routed along the underside of the vehicle chassis and up into the RH side of the engine

compartment where it connects to an air filter canister.

The leak detection pump incorporates a 3–pin electrical connector. Pin-1 is the earth switched supply to the ECM for

control of the pump solenoid valve. Pin-2 is the earth switched supply to the ECM for the operation of the pump motor.

Pin-3 is the power supply to the pump motor and solenoid valve and is switched on at system start up via the main

relay and fuse 2 in the engine compartment fusebox.

Under normal circumstances (i.e. when the leak detection pump is not operating and the solenoid is not energised),

the EVAP canister vent port is connected to atmosphere via the open solenoid valve.

The pump is operated at the end of a drive cycle when the vehicle is stationary and the ignition is switched off.

The leak detection pump module contains an integral air by-pass circuit with restrictor (reference-leak orifice) which

is used for providing a reference value for the leak detection test. The restrictor corresponds to an air leak equivalent

to 0.5 mm (0.02 in) diameter. With the solenoid valve open and the purge valve closed, the pump forces pressurised

air through the orifice while the current drawn by the leak detection pump motor is monitored to obtain the reference

value. The orifice must be kept free from contamination, otherwise the reference restriction may appear less than for

a 0.5 mm leak and consequently adversely affect the diagnostic results.

M17 0213

3

4

5

1

2

Page 258 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-25

During the leakage test, the solenoid valve is energised, closing the atmosphere vent line between the EVAP canister

and atmosphere and opening a path to the pressurised air supplied from the leak detection pump motor. Air is pumped

into the EVAP system, while the current drawn by the pump motor is monitored. The current drawn during the leakage

test is compared against the value obtained during the reference check, to determine if an EVAP system leak is

present.

The fuel leak detection pump is powered from a 12V supply and operates at a working pressure of 3 kPa.

Air Filter – (NAS vehicles with positive pressure leak detection system only)

1Air vents through canister lid

2Air filter canister3To fuel leak detection pump

(EVAP canister atmosphere vent)

A paper element air filter (40 µm) is located in a plastic canister at the RH side of the engine compartment. The air

filter canister is fixed to the cruise control mounting bracket by a single nut and bolt. A large bore plastic pipe is

connected to a port at the base of the air filter canister and is secured to the port by a short nylon hose and two crimped

metal band clips.

The air filter is used to prevent particulate contaminants down to 40 µm from entering the fuel leak detection pump.

A press-fit lid on top of the canister contains slots to allow the passage of air into and out of the EVAP system.

The bottom end of the paper element is sealed to the canister and is non-serviceable (i.e fit for life). If necessary, the

canister and paper filter must be replaced as a single, complete assembly.

M17 0203

2

1

3

Page 259 of 1529

EMISSION CONTROL - V8

17-2-26 DESCRIPTION AND OPERATION

Secondary Air Injection System

The secondary air injection (SAI) system comprises the following components:

lSecondary air injection pump

lSAI vacuum solenoid valve

lSAI control valves (2 off, 1 for each bank of cylinders)

lSAI pump relay

lVacuum reservoir

lVacuum harness and pipes

The secondary air injection system is used to limit the emission of carbon monoxide (CO) and hydrocarbons (HCs)

that are prevalent in the exhaust during cold starting of a spark ignition engine. The concentration of hydrocarbons

experienced during cold starting at low temperatures are particularly high until the engine and catalytic converter

reach normal operating temperature. The lower the cold start temperature, the greater the prevalence of

hydrocarbons emitted from the engine.

There are several reasons for the increase of HC emissions at low cold start temperatures, including the tendency for

fuel to be deposited on the cylinder walls, which is then displaced during the piston cycle and expunged during the

exhaust stroke. As the engine warms up through operation, the cylinder walls no longer retain a film of fuel and most

of the hydrocarbons will be burnt off during the combustion process.

The SAI pump is used to provide a supply of air into the exhaust ports in the cylinder head, onto the back of the

exhaust valves, during the cold start period. The hot unburnt fuel particles leaving the combustion chamber mix with

the air injected into the exhaust ports and immediately combust. This subsequent combustion of the unburnt and

partially burnt CO and HC particles help to reduce the emission of these pollutants from the exhaust system. The

additional heat generated in the exhaust manifold also provides rapid heating of the exhaust system catalytic

converters. The additional oxygen which is delivered to the catalytic converters also generate an exothermic reaction

which causes the catalytic converters to 'light off' quickly.

The catalytic converters only start to provide effective treatment of emission pollutants when they reach an operating

temperature of approximately 250°C (482°F) and need to be between temperatures of 400°C (752°F) and 800°C

(1472°F) for optimum efficiency. Consequently, the heat produced by the secondary air injection “afterburning”,

reduces the time delay before the catalysts reach an efficient operating temperature.

The ECM checks the engine coolant temperature when the engine is started in addition to the elapsed time since the

engine was last started. The engine coolant temperature must be below 55°C (131°F) for the SAI pump to run.

NOTE: The ambient air temperature must also be above 8

°C (46°F) for the SAI pump to run.

Also, depending on the long term 'modelled' ambient temperature determined by the ECM, the minimum elapsed time

required since the last engine start can be up to 8.25 hours. The period of time that the SAI pump runs for depends

on the starting temperature of the engine and varies from approximately 96 seconds at 8°C (46°F) to 30 seconds at

55°C (131°F).

Air from the SAI pump is supplied to the SAI control valves via pipework and an intermediate T-piece which splits the

air flow evenly to each bank.

At the same time the secondary air pump is started, the ECM operates a SAI vacuum solenoid valve, which opens to

allow vacuum from the reservoir to be applied to the vacuum operated SAI control valves on each side of the engine.

When the vacuum is applied to the SAI control valves, they open simultaneously to allow the air from the SAI pump

through to the exhaust ports. Secondary air is injected into the inner most exhaust ports on each bank.

When the ECM breaks the ground circuit to de-energise the SAI vacuum solenoid valve, the vacuum supply to the

SAI control valves is cut off and the valves close to prevent further air being injected into the exhaust manifold. At the

same time as the SAI vacuum solenoid valve is closed, the ECM opens the ground circuit to the SAI pump relay, to

stop the SAI pump.

A vacuum reservoir is included in the vacuum line between the intake manifold and the SAI vacuum solenoid valve.

This prevents changes in vacuum pressure from the intake manifold being passed on to cause fluctuations of the

secondary air injection solenoid valve. The vacuum reservoir contains a one way valve and ensures a constant

vacuum is available for the SAI vacuum solenoid valve operation. This is particularly important when the vehicle is at

high altitude.

Page 260 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-27

The ECM connector and pins pertinent for secondary air injection are listed in the following table:

Secondary Air Injection System Components

The secondary air injection (SAI) system components (where fitted) are described below:

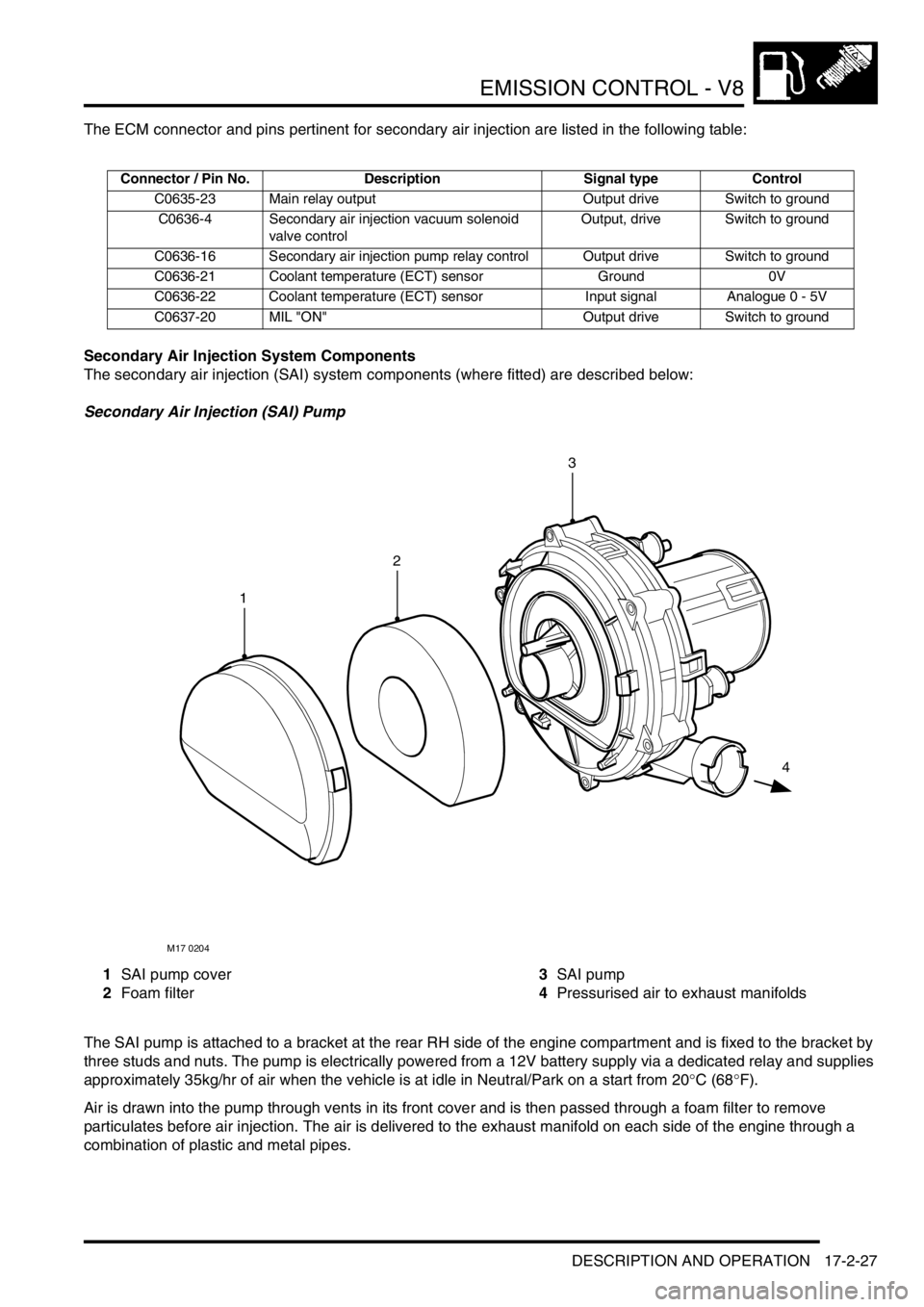

Secondary Air Injection (SAI) Pump

1SAI pump cover

2Foam filter3SAI pump

4Pressurised air to exhaust manifolds

The SAI pump is attached to a bracket at the rear RH side of the engine compartment and is fixed to the bracket by

three studs and nuts. The pump is electrically powered from a 12V battery supply via a dedicated relay and supplies

approximately 35kg/hr of air when the vehicle is at idle in Neutral/Park on a start from 20°C (68°F).

Air is drawn into the pump through vents in its front cover and is then passed through a foam filter to remove

particulates before air injection. The air is delivered to the exhaust manifold on each side of the engine through a

combination of plastic and metal pipes.

Connector / Pin No. Description Signal type Control

C0635-23 Main relay output Output drive Switch to ground

C0636-4 Secondary air injection vacuum solenoid

valve controlOutput, drive Switch to ground

C0636-16 Secondary air injection pump relay control Output drive Switch to ground

C0636-21 Coolant temperature (ECT) sensor Ground 0V

C0636-22 Coolant temperature (ECT) sensor Input signal Analogue 0 - 5V

C0637-20 MIL "ON" Output drive Switch to ground

M17 0204

1

4

2

3