heater LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 423 of 1529

COOLING SYSTEM - V8

26-2-8 DESCRIPTION AND OPERATION

Coolant pump

1Pulley flange

2Body

3Impeller4Gallery

5Inlet connection

The coolant pump is attached to the front of the cylinder block with nine bolts and sealed between the pump housing

and the cylinder block with a gasket. The pump comprises a shaft which passes through an alloy housing. The outer

end of the shaft has a flange which allows for the attachment of the pump drive pulley which is secured with three

bolts. The drive pulley is driven by the grooved auxiliary drive belt and rotates at the same speed as the crankshaft.

The inner end of the shaft is fitted with an impeller which draws coolant from the thermostat housing and circulates it

through the galleries in the cylinder block and through the heater matrix.

The shaft is supported on bearings in the housing which are packed with grease and sealed for life. A seal is

positioned in the housing to further protect the bearings from the ingress of coolant. The seal is manufactured from a

synthetic material which will allow for expansion of the casing when hot coolant is present.

The cast alloy housing has a hose connection which provides the attachment for the coolant pump feed hose. The

cast housing connects with galleries in the cylinder block and distributes coolant from the pump impeller into the

galleries and water jackets.

Page 425 of 1529

COOLING SYSTEM - V8

26-2-10 DESCRIPTION AND OPERATION

Operation

Coolant flow - Engine warm up

Refer to illustration.

+ COOLING SYSTEM - V8, DESCRIPTION AND OPERATION, Cooling system coolant flow.

During warm-up the coolant pump moves fluid through the cylinder block and it emerges from the inlet manifold outlet

pipe. From the outlet pipe, the warm coolant flow is prevented from flowing through the radiator because the

thermostat is closed. The coolant is directed into the heater circuit.

Some coolant from the by-pass pipe can pass through small sensing holes in the flow valve. The warm coolant enters

a tube in the thermostat housing and surrounds 90% of the thermostat sensitive area. Cold coolant returning from the

radiator bottom hose conducts through 10% of the thermostat sensitive area. In cold ambient temperatures the engine

temperature can be raised by up to 10°C (50°F) to compensate for the heat loss of the 10% exposure to the cold

coolant returning from the radiator bottom hose.

At engine idle speed, the by-pass valve is closed only allowing the small flow through the sensing holes. As the engine

speed increases above idle, the greater flow and pressure from the pump overcomes the light spring and opens the

by-pass flow valve. The flow valve opens to meet the engines cooling needs at higher engine speeds and prevents

excess pressure in the system. With the thermostat closed, maximum flow is directed through the heater circuit.

The heater matrix acts as a heat exchanger reducing coolant temperature as it passes through the matrix. Coolant

emerges from the matrix and flows into the coolant pump feed pipe and recirculated around the heater circuit. In this

condition the cooling system is operating at maximum heater performance.

Coolant flow - Engine hot

As the coolant temperature increases the thermostat opens. This allows some coolant from the outlet housing to flow

through the top hose and into the radiator to be cooled. The hot coolant flows from the left tank in the radiator, along

the tubes to the right tank. The air flowing through the fins between the tubes cools the coolant as it passes through

the radiator.

A controlled flow of the lower temperature coolant is drawn by the pump and blended with hot coolant from the by-

pass and the heater return pipes in the pump feed pipe. The pump then passes this coolant into the cylinder block to

cool the cylinders.

Page 438 of 1529

MANIFOLDS AND EXHAUST SYSTEMS - V8

DESCRIPTION AND OPERATION 30-2-3

1Upper manifold

2Bolt 5 off

3Bolt 1 off

4Gasket

5IAC Valve

6IAC valve hose 2 off

7Bolt 4 off

8Bolt 4 off

9Schraeder valve

10Injector 8 off

11Retaining clip 8 off

12Bolt 12 off

13Bolt 2 off

14Clamp 2 off

15Seal 2 off

16Lower manifold/engine gasket

17Coolant pipe18Bolt 3 off

19Bolt

20Heater return pipe

21Pipe connection

22Lower manifold

23Gasket

24Hose clip 2 off

25Throttle housing coolant hose

26Fuel rail

27Throttle housing

28Gasket

29Bolt 4 off

30Plenum

31Rocker cover breather hose connection

32Brake servo vacuum pipe connection

33Hose clip 4 off

Page 440 of 1529

MANIFOLDS AND EXHAUST SYSTEMS - V8

DESCRIPTION AND OPERATION 30-2-5

Description

General

The inlet manifold on the V8 engine is located on the top of the engine, between the cylinders. The manifold directs

intake air into the cylinders. The intake air is mixed with fuel delivered by the injectors prior to ignition in the cylinders.

The inlet manifold comprises three separate aluminium castings.

Two exhaust manifolds are used, one for each bank of four cylinders. Each exhaust manifold allows combustion

gases from the cylinders to leave the engine and directs them into the exhaust system.

The exhaust system is connected to each exhaust manifold and merges into one pipe midway along the underside of

the vehicle. A catalytic converter (where fitted) is located in the front pipe from each manifold. A silencer is installed

midway along the system and a second tail silencer is located at the rear of the vehicle.

Inlet manifold

The inlet manifold comprises three aluminium castings; a lower manifold, an upper manifold and a plenum. The inlet

manifold is located on the top of the engine and feeds air into the cylinders.

Lower manifold

The lower manifold is a one piece machined aluminium casting which locates in the vee on the top of the engine and

is secured to each cylinder head with six bolts per head. A one piece coated metal gasket seals the lower manifold to

each cylinder head and also serves as a cover for the cylinder block.

Eight injectors are fitted into the lower manifold, four on each side. Each injector is sealed in the manifold with O-ring

seals and retained in position by the fuel rails. A fuel rail is attached to each side of the manifold and secured with two

bolts.

Eight air intake ports are cast and machined on the top of the manifold, each port directing intake air into one cylinder.

These ports mate with matching ports in the upper manifold and are sealed with a coated metal gasket between the

two manifolds.

A cavity at the front of the manifold collects coolant flow from the engine. A coolant outlet pipe is sealed and attached

to the front of the manifold and provides for coolant to flow through the cavity in the casting to the radiator top hose.

A smaller port in the manifold also allows coolant to flow from the cavity to the heater matrix. The lower manifold also

locates the Engine Coolant Temperature (ECT) sensor in a port in the front of the manifold.

Upper manifold

The upper manifold is a one piece machined aluminium casting. The manifold has eight ports on its lower face which

mate with the eight ports on the lower manifold. The joint between the upper and lower manifolds is sealed with a

coated metal gasket and secured with six bolts.

The manifold divides from the eight ports into eight branches, four on each side. Each set of four branches merge into

one gallery on each side of the manifold. Each gallery has an opening at its forward end which mates with the intake

plenum.

The upper manifold provides attachment for the Idle Air Control (IAC) valve and for brackets which retain pipes, plug

leads and throttle cables.

Inlet plenum

The plenum is mounted transversely on the front of the upper manifold. The plenum divides into two galleries which

connect with the galleries on the upper manifold. The plenum is secured to the upper manifold with four bolts and

sealed with a coated metal gasket.

The plenum provides attachment for the throttle housing, which is secured with four bolts and sealed with a coated

metal gasket. The plenum also has vacuum connections for brake servo, rocker cover breather and fuel vapour from

the charcoal canister. A port on the top of the plenum connects via a hose to the IAC valve.

Page 954 of 1529

EXTERIOR FITTINGS

REPAIRS 76-2-7

Panel - underbelly

$% 76.10.50

Remove

1.Raise front of vehicle, support underbody and

lower front axle

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing drag link to drop arm.

3.Using tool LRT-57-036 break taper joint and

release drag link from drop arm.

4.Remove nut and bolt securing steering damper

to chassis and remove damper.

5.Remove 7 screws securing underbelly panel.

6.Remove underbelly panel.

7.Remove 7 studs securing sound deadening to

underbelly panel.

8.Remove sound deadening.

Refit

1.Position sound deadening to underbelly panel

and secure with studs.

2.Fit underbelly panel and secure with screws.

3.Position steering damper, fit nut and bolt and

tighten to 125 Nm (92 lbf.ft)

4.Fit drag link to drop arm and tighten nut to 80

Nm (59 lbf.ft).

5.Lower front of vehicle.

Mirror - exterior - electric

$% 76.10.57

Remove

1.Release cheater panel from front door.

2.Remove anti-rattle foam pad from front door.

3.Release mirror multiplug from mounting plate.

4.Disconnect multiplug from mirror.

5.Remove 3 bolts securing mirror to door.

6.Remove mirror and collect mounting plate.

Refit

1.Fit mirror and mounting plate to door.

2.Fit bolts securing mirror to door and tighten to

4 Nm (3 lbf.ft).

3.Connect multiplug to mirror.

4.Secure multiplug to mounting plate.

5.Fit anti-rattle foam pad to front door.

6.Secure cheater panel to front door.

Page 976 of 1529

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-11

13.Remove fascia access panel.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Panel - fascia access - driver's

side.

14.Remove 4 nuts securing fascia to steering

column bracket.

15.Disconnect 3 multiplugs connecting main body

harness to fascia harness.

16.Disconnect fascia harness multiplug from fuse

box.

17.Remove 4 bolts securing glove box and remove

glove box.18. Models with A/C: Disconnect multiplug from

heater controls.

19. Models without A/C: Release temperature

and air distribution control outer cables from

clips on heater casing and disconnect inner

cables from levers.

Page 977 of 1529

INTERIOR TRIM COMPONENTS

76-3-12 REPAIRS

20.Separate blue section from ICE multiplug.

21.Release coaxial cables from fascia panel.

22.Disconnect multiplug from passenger air bag.

23.Disconnect multiplug from blower motor.

24.Working through glove box aperture remove 2

bolts, or 4 bolts if passenger airbag module is

fitted, securing fascia to body.25.Remove 4 bolts securing lower edge of fascia

to mounting brackets on transmission tunnel.

26.Remove 4 bolts securing lower edge of fascia

to brackets on 'A' post.

27.With assistance carefully remove fascia from

vehicle.

28.If renewing fascia, transfer components to new

fascia as necessary.

Refit

1.With assistance carefully fit fascia and tighten

bolts securing lower edge of fascia to 26 Nm

(19 lbf.ft).

2.Tighten bolts securing fascia to body to 26 Nm

(19 lbf.ft).

3.Fit nuts securingfascia to steering column

bracket to 11 Nm (8 lbf.ft).

4.Secure coaxial cables to fascia and secure blue

multiplug to main ICE multiplug.

5. Models with A/C: Connect heater control

multiplug.

6. Models without A/C: Connect temperature

and air distribution inner cables to heater

control levers. Set temperature control knobs to

fully hot, distribution knob to demist position

and, with flap levers fully closed, secure outer

cables to clips on heater casing.

7.Connect multiplugs to blower motor and

passenger air bag (where fitted).

8.Fit glove box and secure with bolts.

9.Connect fascia harness multiplugs to main

harness and fuse box.

10.Position instrument pack and connect

multiplugs.

Page 981 of 1529

INTERIOR TRIM COMPONENTS

76-3-16 REPAIRS

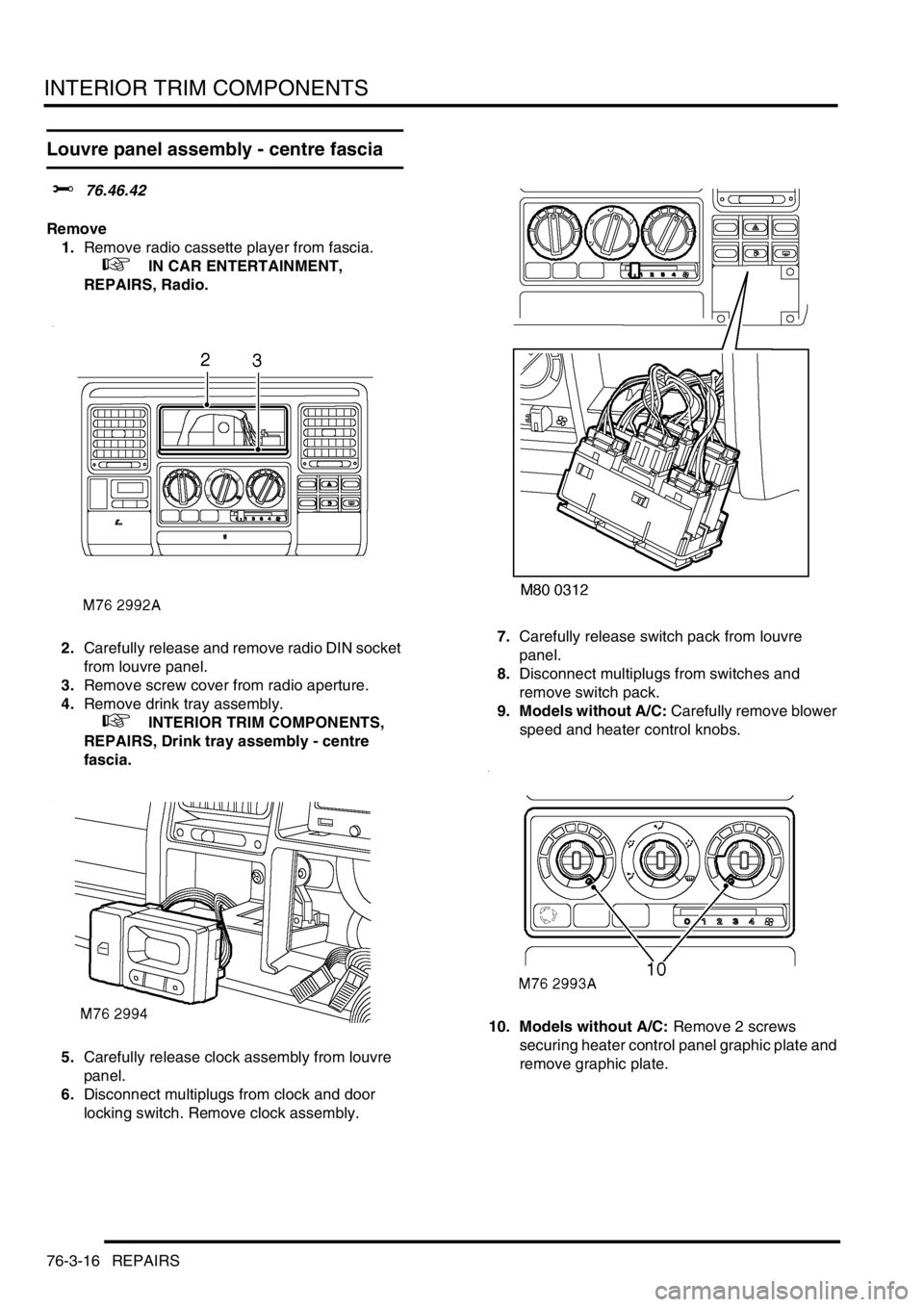

Louvre panel assembly - centre fascia

$% 76.46.42

Remove

1.Remove radio cassette player from fascia.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio.

2.Carefully release and remove radio DIN socket

from louvre panel.

3.Remove screw cover from radio aperture.

4.Remove drink tray assembly.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Drink tray assembly - centre

fascia.

5.Carefully release clock assembly from louvre

panel.

6.Disconnect multiplugs from clock and door

locking switch. Remove clock assembly.7.Carefully release switch pack from louvre

panel.

8.Disconnect multiplugs from switches and

remove switch pack.

9. Models without A/C: Carefully remove blower

speed and heater control knobs.

10. Models without A/C: Remove 2 screws

securing heater control panel graphic plate and

remove graphic plate.

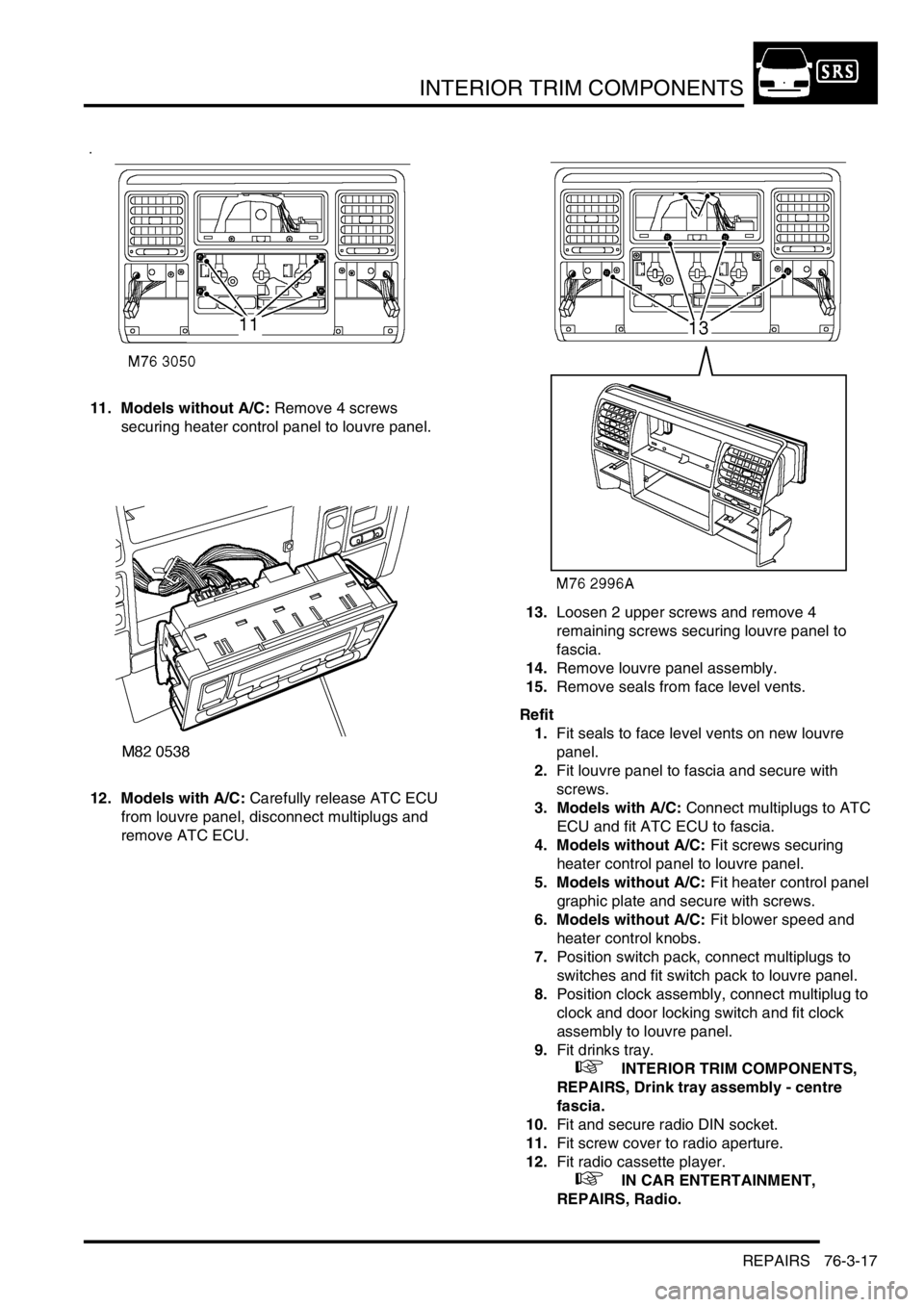

Page 982 of 1529

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-17

11. Models without A/C: Remove 4 screws

securing heater control panel to louvre panel.

12. Models with A/C: Carefully release ATC ECU

from louvre panel, disconnect multiplugs and

remove ATC ECU.13.Loosen 2 upper screws and remove 4

remaining screws securing louvre panel to

fascia.

14.Remove louvre panel assembly.

15.Remove seals from face level vents.

Refit

1.Fit seals to face level vents on new louvre

panel.

2.Fit louvre panel to fascia and secure with

screws.

3. Models with A/C: Connect multiplugs to ATC

ECU and fit ATC ECU to fascia.

4. Models without A/C: Fit screws securing

heater control panel to louvre panel.

5. Models without A/C: Fit heater control panel

graphic plate and secure with screws.

6. Models without A/C: Fit blower speed and

heater control knobs.

7.Position switch pack, connect multiplugs to

switches and fit switch pack to louvre panel.

8.Position clock assembly, connect multiplug to

clock and door locking switch and fit clock

assembly to louvre panel.

9.Fit drinks tray.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Drink tray assembly - centre

fascia.

10.Fit and secure radio DIN socket.

11.Fit screw cover to radio aperture.

12.Fit radio cassette player.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio.

Page 990 of 1529

SCREENS

REPAIRS 76-4-1

SCREENS REPAIRS

Glass/sealing rubber - tail door

$% 76.31.22

Remove

1.Remove spare wheel from rear door.

2.Remove centre high mounted stop lamp.

+ LIGHTING, REPAIRS, Lamp - stop -

centre high mounted (CHMSL).

3.Pull the rear wiper arm away from the glass.

4.Disconnect leads from rear window heater.

5.Ease glass sealing rubber from tail door flange

and with assistance, from inside push the glass

and sealing rubber out.

6.Remove sealing rubber from glass. Refit

1.Thoroughly clean the tail door glass mounting

flange.

2.Clean glass and fit sealing rubber. Ensure

sealing rubber is fully located onto glass.

3.Fit a draw cord into the outside groove of the

sealing rubber with cord ends situated on top

corner of bend at bottom of glass.

4.To aid assembly, lubricate the tail door glass

mounting flange with liquid soap.

5.Position the assembled glass and rubber to

outside of flange.

6.With assistance from second operator pushing

glass into door, hold one end of cord and pull

the other end carefully around the aperture,

easing the rubber seal over the flange.

7.Connect leads to rear window heater.

8.Fit centre high mounted stop lamp.

+ LIGHTING, REPAIRS, Lamp - stop -

centre high mounted (CHMSL).

9.Fit rear wiper onto glass.

10.Fit spare wheel.