engine LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 617 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-20 DESCRIPTION AND OPERATION

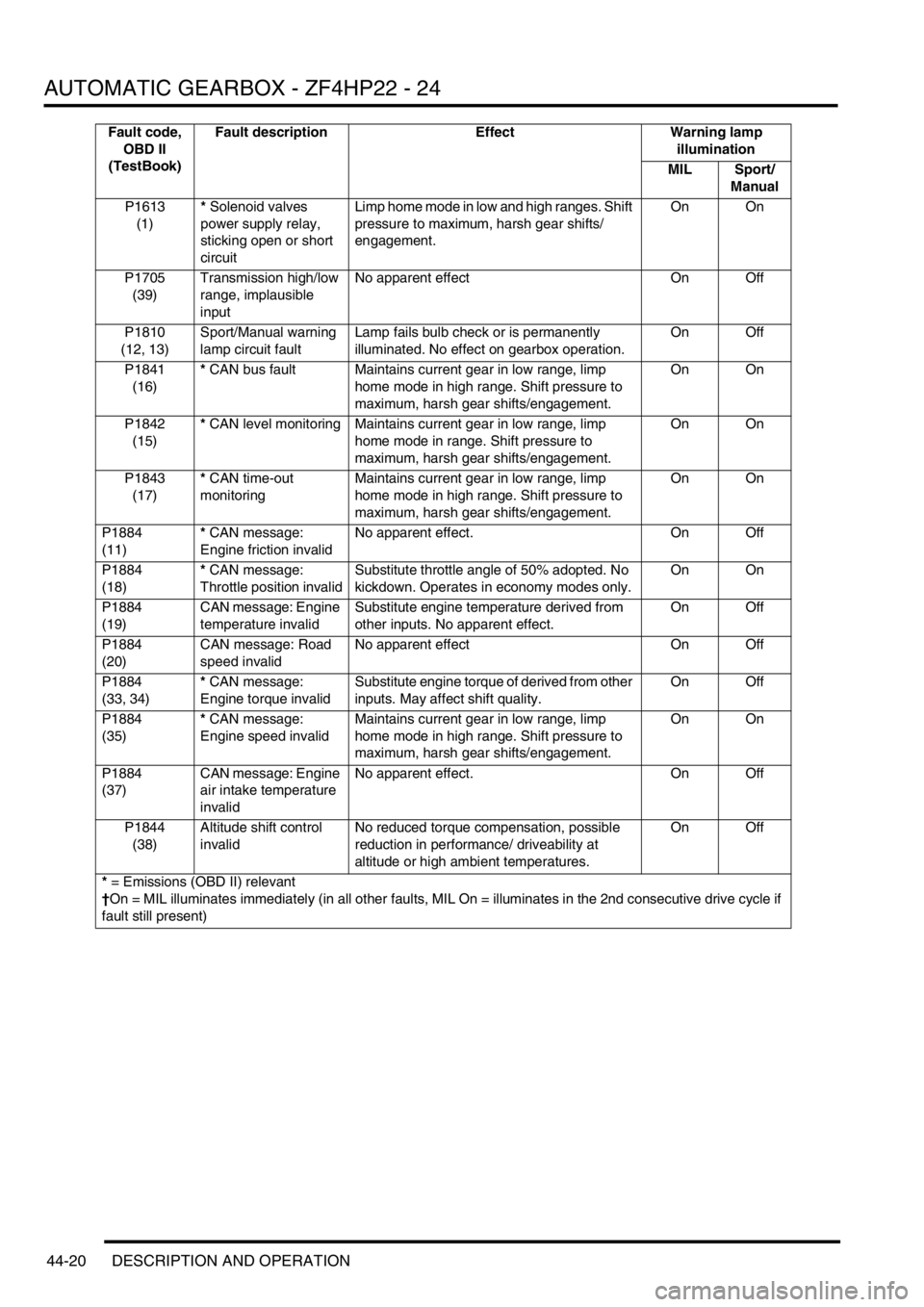

P1613

(1)* Solenoid valves

power supply relay,

sticking open or short

circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1705

(39)Transmission high/low

range, implausible

inputNo apparent effect On Off

P1810

(12, 13)Sport/Manual warning

lamp circuit faultLamp fails bulb check or is permanently

illuminated. No effect on gearbox operation.On Off

P1841

(16)* CAN bus fault Maintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1842

(15)* CAN level monitoring Maintains current gear in low range, limp

home mode in range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1843

(17)* CAN time-out

monitoringMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1884

(11)* CAN message:

Engine friction invalidNo apparent effect. On Off

P1884

(18)* CAN message:

Throttle position invalidSubstitute throttle angle of 50% adopted. No

kickdown. Operates in economy modes only.On On

P1884

(19)CAN message: Engine

temperature invalidSubstitute engine temperature derived from

other inputs. No apparent effect.On Off

P1884

(20)CAN message: Road

speed invalidNo apparent effect On Off

P1884

(33, 34)* CAN message:

Engine torque invalidSubstitute engine torque of derived from other

inputs. May affect shift quality.On Off

P1884

(35)* CAN message:

Engine speed invalidMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1884

(37)CAN message: Engine

air intake temperature

invalidNo apparent effect. On Off

P1844

(38)Altitude shift control

invalidNo reduced torque compensation, possible

reduction in performance/ driveability at

altitude or high ambient temperatures.On Off

* = Emissions (OBD II) relevant

†On = MIL illuminates immediately (in all other faults, MIL On = illuminates in the 2nd consecutive drive cycle if

fault still present)Fault code,

OBD II

(TestBook)Fault description Effect Warning lamp

illumination

MIL Sport/

Manual

Page 618 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

ADJUSTMENTS 44-21

ADJUST ME NTS

Cable - selector

$% 44.30.04

Check

1.Position vehicle on ramp.

2.Select position 'P'.

3.Loosen selector cable trunnion nut.

4.Ensure that gearbox selector lever is in 'P'

position, (fully forward) and tighten trunnion

nut.

5.Lower ramp.

Stall test

$% 44.30.13

Testing

1.Chock the wheels and fully apply the

handbrake.

2.Start the engine and run it until it reaches

normal operating temperature.

3.Apply the footbrake and select 'D'.

4.Fully depress the accelerator pedal and note

the tachometer reading. The figures should be

as given below. Do not carry out stall test for

longer than 10 seconds, and DO NOT repeat

until 30 minutes have elapsed.

lV8: 2200 to 2400 rev/min

lDiesel: 2600 to 2800 rev/min

5.A reading below 1300 rev/min indicates a

torque converter fault, ie stator free-wheel.

6.A reading between 1300 and 2200 rev/min (V8)

or between 1300 and 2600 rev/min (Diesel)

indicates reduced engine power.

7.A reading above 2400 rev/min (V8) or above

2800 rev/min (Diesel) indicates clutch slip.

NOTE: The figures quoted above were

measured at sea level with an ambient

temperature of 20

°C (68°F). At higher altitudes

or higher ambient temperatures, these figures

will be reduced.

Page 624 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-27

Gearbox - convertor and transfer

gearbox - Diesel

$% 44.20.04.99

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Raise vehicle on a ramp.

4.Remove starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

5.Remove 2 upper bolts securing gearbox

housing to engine.

6.Remove bolt securing closing plate to gearbox

housing.

7.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

8.Remove 3 nuts securing intermediate silencer

to tail pipe.

9.Release and remove silencer from rubber

mountings. 10.Drain automatic gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

11.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

12.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

13.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

14.Remove and discard 3 bolts securing torque

converter to drive plate.

Page 626 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-29

24. 03 Model Year onwards - If fitted: Release

and disconnect both differential lock warning

lamp switch multiplugs from main harness.

25.Remove cable tie and multiplug from bracket

on transfer box.

26.Release transfer and automatic gearbox

breather pipes from clip at rear of cylinder

block.

27.Position gearbox support jack and secure tool

LRT-99-008A to support plate on jack. 28.Position a second support jack under engine

using a block between engine sump and jack

to prevent damage to sump.

29.Remove 4 bolts and nut, remove engine LH

rear mounting.

30.Remove 4 bolts and nut, remove engine RH

rear mounting.

31.Remove 2 bolts securing gearbox oil cooler

pipe clips to engine sump and alternator

mounting bracket.

Page 627 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-30 REPAIRS

32.Remove bolt and 2 nuts securing clamps to oil

cooler pipes and remove clamps.

33.Loosen gearbox oil cooler pipe unions, release

pipes from gearbox and discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.34.Remove 'C' clip securing selector cable to

gearbox bracket.

35.Remove nut securing selector lever to inhibitor

switch and release lever.

36.Disconnect multiplug from inhibitor switch.

37.Loosen gearbox multi plug locking ring and

disconnect plug.

38.Remove 6 remaining gearbox housing bolts.

39.With assistance remove automatic gearbox

from engine.

Page 628 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-31

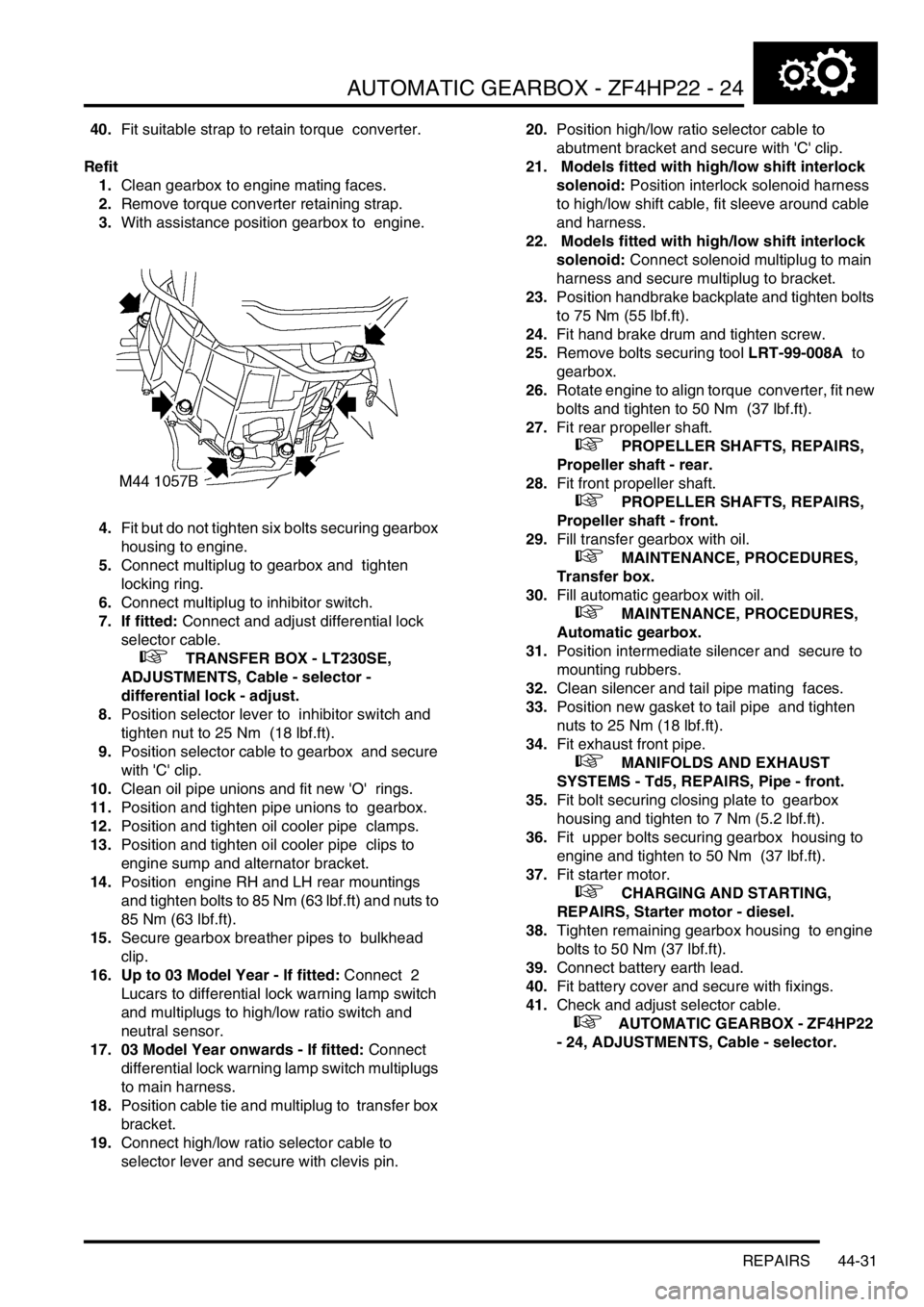

40.Fit suitable strap to retain torque converter.

Refit

1.Clean gearbox to engine mating faces.

2.Remove torque converter retaining strap.

3.With assistance position gearbox to engine.

4.Fit but do not tighten six bolts securing gearbox

housing to engine.

5.Connect multiplug to gearbox and tighten

locking ring.

6.Connect multiplug to inhibitor switch.

7. If fitted: Connect and adjust differential lock

selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.

8.Position selector lever to inhibitor switch and

tighten nut to 25 Nm (18 lbf.ft).

9.Position selector cable to gearbox and secure

with 'C' clip.

10.Clean oil pipe unions and fit new 'O' rings.

11.Position and tighten pipe unions to gearbox.

12.Position and tighten oil cooler pipe clamps.

13.Position and tighten oil cooler pipe clips to

engine sump and alternator bracket.

14.Position engine RH and LH rear mountings

and tighten bolts to 85 Nm (63 lbf.ft) and nuts to

85 Nm (63 lbf.ft).

15.Secure gearbox breather pipes to bulkhead

clip.

16. Up to 03 Model Year - If fitted: Connect 2

Lucars to differential lock warning lamp switch

and multiplugs to high/low ratio switch and

neutral sensor.

17. 03 Model Year onwards - If fitted: Connect

differential lock warning lamp switch multiplugs

to main harness.

18.Position cable tie and multiplug to transfer box

bracket.

19.Connect high/low ratio selector cable to

selector lever and secure with clevis pin. 20.Position high/low ratio selector cable to

abutment bracket and secure with 'C' clip.

21. Models fitted with high/low shift interlock

solenoid: Position interlock solenoid harness

to high/low shift cable, fit sleeve around cable

and harness.

22. Models fitted with high/low shift interlock

solenoid: Connect solenoid multiplug to main

harness and secure multiplug to bracket.

23.Position handbrake backplate and tighten bolts

to 75 Nm (55 lbf.ft).

24.Fit hand brake drum and tighten screw.

25.Remove bolts securing tool LRT-99-008A to

gearbox.

26.Rotate engine to align torque converter, fit new

bolts and tighten to 50 Nm (37 lbf.ft).

27.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

28.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

29.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

31.Position intermediate silencer and secure to

mounting rubbers.

32.Clean silencer and tail pipe mating faces.

33.Position new gasket to tail pipe and tighten

nuts to 25 Nm (18 lbf.ft).

34.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

35.Fit bolt securing closing plate to gearbox

housing and tighten to 7 Nm (5.2 lbf.ft).

36.Fit upper bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

37.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

38.Tighten remaining gearbox housing to engine

bolts to 50 Nm (37 lbf.ft).

39.Connect battery earth lead.

40.Fit battery cover and secure with fixings.

41.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, ADJUSTMENTS, Cable - selector.

Page 631 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-34 REPAIRS

25.Position gearbox support jack and secure tool

LRT-99-008A to support plate on jack.

26.Position a second support jack under engine

using a block between engine sump and jack to

prevent damage to sump.

27.Remove 4 bolts and nut, remove engine LH

rear mounting.

28.Remove 4 bolts and nut, remove engine RH

rear mounting. 29.Remove bolt securing gearbox oil cooler pipe

clips to engine.

30.Remove bolt and 2 nuts securing clamps to oil

cooler pipes and remove clamps.

31.Loosen gearbox oil cooler pipe unions, release

pipes from gearbox and discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 632 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-35

32.Remove 'C' clip securing selector cable to

gearbox bracket.

33.Remove nut securing selector lever to inhibitor

switch and release lever.

34.Disconnect multiplug from inhibitor switch.

35.Loosen gearbox multiplug locking ring and

disconnect plug.

36.Lower gearbox sufficiently to access bell

housing bolts, take care not to trap any pipes or

cables when lowering gearbox.

37.Remove 14 bolts securing gearbox to engine.

38.With assistance remove gearbox from engine.39.Fit suitable strap to retain torque converter.

Refit

1.Clean gearbox to engine mating faces.

2.Remove torque converter retaining strap.

3.With assistance position gearbox to engine.

4.Fit gearbox bell housing bolts and tighten to 46

Nm (34 lbf.ft)..

5.Connect multiplug to gearbox and tighten

locking ring.

6.Connect inhibitor switch multiplug.

7. If fitted: Connect and adjust differential lock

selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.

8.Position selector lever to inhibitor switch and

tighten nut to 25 Nm (18 lbf.ft).

9.Position selector cable to gearbox and secure

with 'C' clip.

10.Clean oil pipe unions and fit new 'O' rings.

11.Position and tighten pipe unions to gearbox.

12.Position and tighten oil cooler pipe clamps.

13.Position and tighten oil cooler pipe clip to

engine sump.

14.Position engine RH and LH rear mountings

and tighten bolts to 85 Nm (63 lbf.ft) and nuts to

85 Nm (63 lbf.ft).

15.Secure gearbox breather pipes to bulkhead

clip.

16. Up to 03 Model Year - If fitted: Connect 2

Lucars to differential lock warning lamp switch

and multiplugs to high/low ratio switch and

neutral sensor.

17. 03 Model Year onwards - If fitted: Connect

differential lock warning lamp switch multiplugs

to main harness.

18.Position cable tie and multiplug to transfer

gearbox bracket.

19.Connect high/low ratio selector cable to

selector lever and secure with clevis pin.

20.Position high/low ratio selector cable to

abutment bracket and secure with 'C' clip.

Page 633 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-36 REPAIRS

21. Models fitted with high/low shift interlock

solenoid: Position interlock solenoid harness

to high/low shift cable, fit sleeve around cable

and harness, secure sleeve.

22. Models fitted with high/low shift interlock

solenoid: Connect solenoid multiplug to main

harness and secure multiplug to bracket.

23.Position hand brake back plate and tighten

bolts to 75 Nm (55 lbf.ft).

24.Fit hand brake drum and tighten screw.

25.Remove bolts securing tool LRT-99-008A to

gearbox.

26.Rotate engine to align torque converter, fit new

bolts and tighten to 50 Nm (37 lbf.ft).

27.Fit access plug to torque converter housing.

28.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

29.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

30.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

31.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

32.Position intermediate silencer and secure to

mounting rubbers.

33.Clean silencer and tail pipe mating faces.

34.Position new gasket to tail pipe and tighten nuts

to 40 Nm (30 lbf.ft).

35.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

36.Position centre cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

37.Connect battery earth lead.

38.Fit battery cover and secure fixings.

39.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, ADJUSTMENTS, Cable - selector.

Page 646 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-49

Cooler - fluid - Td5

$% 44.24.10

Remove

1.Remove intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

2.Disconnect fluid temperature sensor multiplug.

3.Position absorbent cloth under each gearbox

cooler hose connection to collect spillage.

4.Push against coupling release ring and

disconnect both fluid hoses from cooler.

5.Remove screw and release cooler from

radiator.

6.Carefully remove cooler.7.Remove temperature sensor and discard

sealing washer.

Refit

1.Use new sealing washer and tighten

temperature sensor to 14 Nm (10 lbf.ft).

2.Fit cooler, engage with radiator and secure with

screw.

3.Connect temperature sensor multiplug.

4.Ensure connections are clean and fit hoses to

cooler.

5.Fit intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

6.Check and if necessary top up gearbox fluid.