ECU LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1264 of 1529

WIPERS AND WASHERS

REPAIRS 84-29

Motor - wiper - rear screen

$% 84.35.12

Remove

1.Remove spare wheel from taildoor.

2.Remove tail door trim casing.

+ DOORS, REPAIRS, Trim casing - tail

door.

3.Remove tail door water shedder.

4.Disconnect washer tube

5.Raise nut cover, remove nut and release wiper

arm.

6.Remove spindle nut and flat washer and

discard rubber seal.

7.Disconnect taildoor harness multiplug from

wiper motor.

8.Remove 2 bolts securing wiper motor to tail

door.

9.Remove wiper motor. Refit

1.Position wiper motor to door and secure with

bolts.

2.Connect tail door harness multiplug to wiper

motor.

3.Fit rubber seal, flat washer and spindle nut.

Tighten spindle nut to 3 Nm (2.2 lbf.ft).

4.Position wiper arm to tail door and connect

washer tube.

5.Tighten wiper arm nut to 20 Nm (15 lbf.ft) and

fit nut cover.

6.Fit tail door water shedder.

7.Fit tail door trim casing.

+ DOORS, REPAIRS, Trim casing - tail

door.

8.Fit spare wheel to tail door.

Page 1265 of 1529

WIPERS AND WASHERS

84-30 REPAIRS

Switch - wiper - rear - up to 03MY

$% 84.35.33

Remove

1.Carefully remove switch from instrument cowl.

2.Disconnect multiplug and remove switch.

Refit

1.Position new switch and connect multiplug.

2.Carefully push switch into instrument cowl.

Switch - wiper - rear - from 03MY

$% 843533

Remove

1.Remove 2 screws securing instrument cowl to

fascia and release the cowl from the retaining

clips.

2.Disconnect multiplug from the rear wiper

switch.

3.Remove the rear wiper switch from the

instrument cowl.

Refit

1.Fit and secure the rear wiper switch to the

instrument cowl and connect the multiplug.

2.Fit the instrument cowl to the fascia and secure

with screws.

Page 1266 of 1529

CHARGING AND STARTING

REPAIRS 86-1-1

CHARGING AND STARTING REPAIRS

Alternator - diesel

$% 86.10.02

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Release cover and remove nut securing lead

to alternator.

3.Disconnect alternator multiplug.

4.Remove bolt (LH thread) and remove auxiliary

drive belt tensioner. 5.Remove bolt securing support stay to

alternator.

6.Release clip and disconnect oil drain hose from

vacuum pump.

7.Disconnect vacuum pump oil supply pipe from

cylinder head and discard 'O' ring.

8.Remove bolt securing alternator and release

from mounting bracket.

9.Disconnect vacuum hose from vacuum pump.

10.Remove alternator. Take care not to damage

radiator cooling fins.

11.Remove 4 bolts, and remove vacuum pump

from alternator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 1267 of 1529

CHARGING AND STARTING

86-1-2 REPAIRS

Refit

1.Clean mating faces of alternator and vacuum

pump.

2.Fit vacuum pump to alternator and tighten

bolts to 8 Nm (6 lbf.ft).

3.Position alternator to engine and connect

multiplug.

4.Connect vacuum hose and oil drain hose to

vacuum pump and secure clips.

5.With assistance align alternator to mounting

bracket and fit but do not tighten bolt.

6.Fit bolt securing support stay to alternator and

tighten to 25 Nm (18 lbf.ft) .

7.Tighten bolt securing alternator to mounting

bracket to 45 Nm (33 lbf.ft).

8.Using new 'O' ring, connect oil supply pipe to

cylinder head and tighten to 10 Nm (7 lbf.ft).

9.Connect lead to alternator and tighten nut to 6

Nm (4.4 lbf.ft).

10.Fit auxiliary drive belt tensioner and tighten bolt

to 50 Nm (37 lbf.ft).

11.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Page 1268 of 1529

CHARGING AND STARTING

REPAIRS 86-1-3

Alternator - V8

$% 86.10.02

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove 2 bolts securing alternator to

mounting bracket.

3.Release alternator from mounting bracket

4.Remove nuts securing alternator cables, and

release cables. 5.Remove alternator from mounting bracket.

6.Remove pulley from alternator.

Refit

1.Fit alternator pulley and tighten nut to 80 Nm

(59 lbf.ft).

2.Position alternator to mounting bracket.

3.Connect alternator cables and tighten B+ nut to

18 Nm (13 lbf.ft), and D+ nut to 5 Nm (3.7 lbf.ft).

4.Locate alternator in mounting bracket.

5.Fit alternator mounting bolts and tighten to 45

Nm (33 lbf.ft).

6.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Page 1269 of 1529

CHARGING AND STARTING

86-1-4 REPAIRS

Belt - auxiliary drive

$% 86.10.03

Remove

1.Remove viscous fan:

l

+ COOLING SYSTEM - V8,

REPAIRS, Fan - viscous.

l

+ COOLING SYSTEM - Td5,

REPAIRS, Fan - viscous.

2.Turn drive belt tensioner using a 15 mm ring

spanner and release belt from pulleys.

Refit

1.Clean drive belt pulley grooves and ensure

grooves are not damaged.

2.Fit new drive belt around pulleys, ensure belt is

correctly aligned in pulley grooves.

3.With assistance, hold tensioner fully clockwise

and fit drive belt around remaining pulley.

Release tensioner.

4.Fit viscous fan:

l

+ COOLING SYSTEM - Td5,

REPAIRS, Fan - viscous.

l

+ COOLING SYSTEM - V8,

REPAIRS, Fan - viscous.

Battery

$% 86.15.01

Remove

1.Release fixings and remove battery cover.

2.Disconnect both battery leads, negative lead

first.

3.Remove lock nuts and retaining nuts securing

battery clamp.

4.Remove battery clamp.

5.Remove battery.

Refit

1.Clean battery terminals and coat with

petroleum jelly.

2.Fit battery.

3.Fit battery clamp and tighten retaining nuts and

lock nuts.

4.Fit both battery leads, negative lead last.

5.Fit battery cover and secure fixings.

Page 1270 of 1529

CHARGING AND STARTING

REPAIRS 86-1-5

Battery carrier

$% 86.15.11

Remove

1.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

2.Release strap and remove jack.

3.Release coolant hose from clip.

4. Diesel models: Remove screw securing ECM,

release ECM and position aside.

5.Remove 7 bolts securing battery carrier.

6.Remove battery carrier.

NOTE: Do not carry out further dismantling if

component is removed for access only.

7.Remove jack retaining strap, speed nut and

clip.Refit

1.Fit jack retaining strap, speed nut and clip.

2.Fit battery carrier, fit bolts and tighten to 28 Nm

(21 lbf.ft).

3. Diesel models: Fit ECM and secure with

screw.

4.Secure coolant hose.

5.Fit and secure jack.

6.Fit battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

Page 1271 of 1529

CHARGING AND STARTING

86-1-6 REPAIRS

Starter motor - diesel

$% 86.60.01

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

5.Disconnect Lucar connector from starter

solenoid.

6.Remove nut and disconnect battery lead from

starter solenoid.

7.Remove nut and 2 bolts securing starter motor

and remove starter motor from engine.Refit

1.Clean starter motor and mating face on engine.

2.Fit starter motor and tighten nut and 2 bolts to

27 Nm (20 lbf.ft).

3.Connect lead to starter solenoid and tighten nut

to 10 Nm (7 lbf.ft).

4.Connect Lucar connector to starter solenoid.

5.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Remove stand(s) and lower vehicle.

7.Connect battery earth lead.

8.Fit battery cover and secure the fixings.

Page 1272 of 1529

CHARGING AND STARTING

REPAIRS 86-1-7

Starter motor - V8

$% 86.60.01

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Remove 3 nuts securing exhaust flange to

front pipe, release front pipe and collect

gasket.

5.Remove bolt securing heat shield to engine

mounting bracket, release heat shield from

starter motor and remove from vehicle.

6.Remove nut securing battery lead to starter

solenoid and release lead.

7.Disconnect Lucar connector from starter

solenoid.

8.Remove 2 Allen bolts securing starter motor

and remove starter motor from engine. Refit

1.Clean starter motor and mating face on engine.

2.Fit starter motor and tighten Allen bolts to 44

Nm (32 lbf.ft).

3.Connect Lucar connector to starter solenoid.

4.Fit battery lead to solenoid and tighten nut.

5.Position heat shield to starter motor, locate tag

in engine mounting bracket, fit bolt and tighten

to 10 Nm (7 lbf.ft).

6.Clean exhaust manifold and front pipe mating

faces.

7.Using a new gasket, position front pipe, fit nuts

and tighten to 30 Nm (22 lbf.ft).

8.Remove stand(s) and lower vehicle.

9.Connect battery earth lead.

10.Fit battery cover and secure fixings.

Page 1274 of 1529

LIGHTING

ADJUSTMENTS 86-2-1

LIGHTING ADJUST ME NTS

Headlamps beam alignment - up to 03MY

$% 86.40.17

Check

1.Ensure vehicle is unladen and tyres are at

correct pressures.

2. Models with SLS: Ensure vehicle is at

standard ride height.

3. Models with headlamp levelling: Ensure

headlamp levelling switch is set to '0'.

4.Align suitable beam setting equipment to

headlamp.

5.Switch headlamps on and measure main beam

settings. Beam must be 1.4% below the

horizontal and parallel to the vehicle centre line.

If necessary, adjust headlamp to get correct

beam settings.

6.Align beam setting equipment to 2nd headlamp

and repeat check.

7.Switch off headlamps and remove beam setting

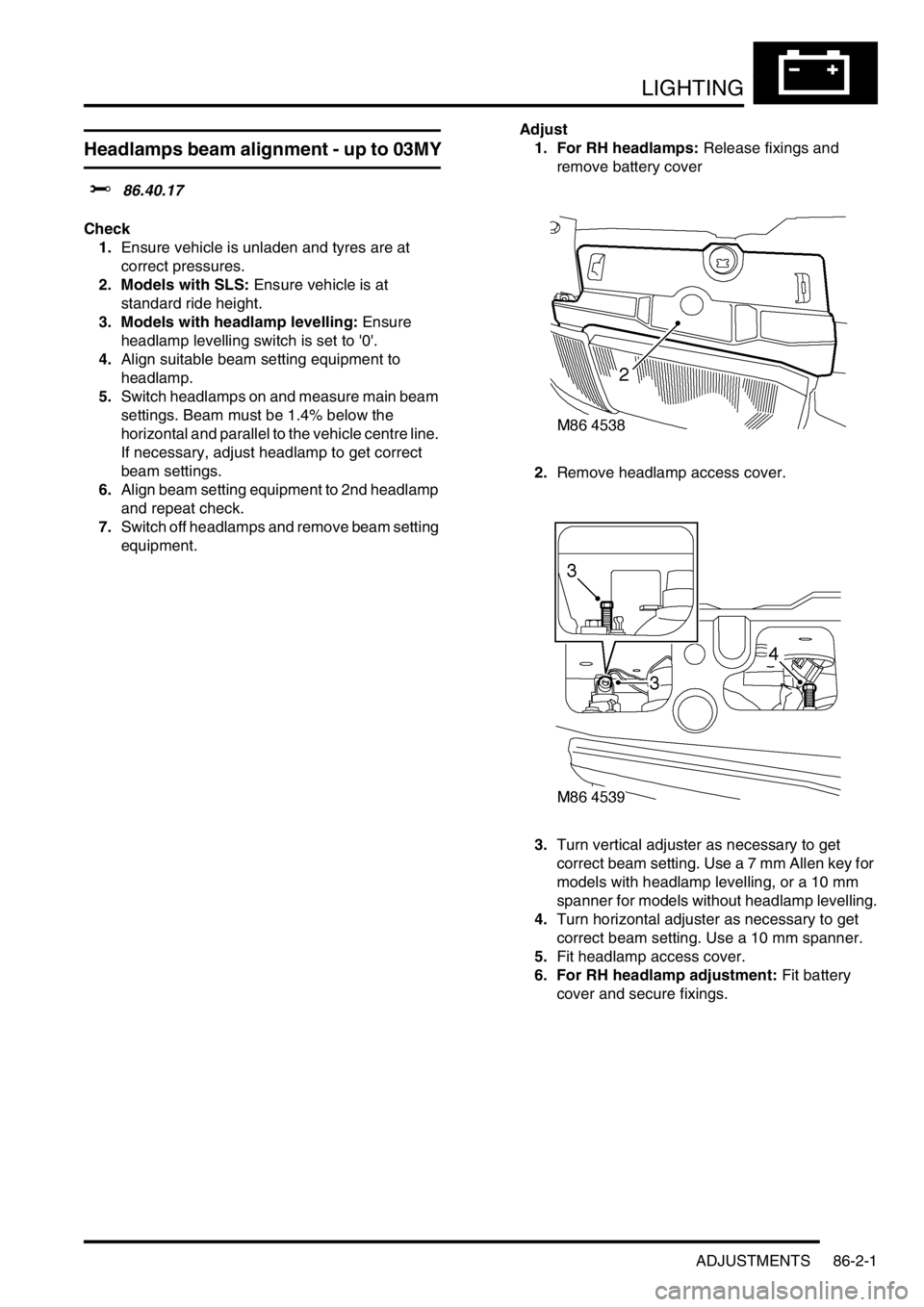

equipment.Adjust

1. For RH headlamps: Release fixings and

remove battery cover

2.Remove headlamp access cover.

3.Turn vertical adjuster as necessary to get

correct beam setting. Use a 7 mm Allen key for

models with headlamp levelling, or a 10 mm

spanner for models without headlamp levelling.

4.Turn horizontal adjuster as necessary to get

correct beam setting. Use a 10 mm spanner.

5.Fit headlamp access cover.

6. For RH headlamp adjustment: Fit battery

cover and secure fixings.