LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 791 of 1529

FRONT SUSPENSION

60-46 REPAIRS

7.Remove 3 bolts securing valve block to

chassis.

8.Release front pipes and clamping plate from

valve block and remove valve block.

CAUTION: Always fit plugs to open

connections to prevent contamination.

NOTE: Keep pipes assembled to clamping

plate to maintain correct pipe positions for

refitting.

9.Remove 6 bushes from valve block. Refit

1.Fit 6 bushes to valve block.

2.Ensure valve block and pipe connections are

clean.

3.It is important that the pipe ends are in good

condition to achieve a seal.

4.Position valve block and connect front pipes

and clamping plate. To avoid damage to

seals, keep pipes square to valve block. Fit

and tighten bolts securing valve block to

chassis to 18 Nm (13 lbf.ft).

CAUTION: Ensure pipes are installed in

their correct ports or serious system

damage will occur.

5.Fit and tighten nuts securing front clamping

plate to valve block to 21 Nm (15 lbf.ft).

6.Fit bolt securing front pipe clip to chassis and

tighten to 6 Nm (4.4 lbf.ft).

7.Connect rear pipes and clamping plate to valve

block. To avoid damage to seals, keep pipes

square to valve block. Fit and tighten nuts

securing clamping plate to valve block to 21 Nm

(15 lbf.ft).

CAUTION: Ensure pipes are installed in

their correct ports or serious system

damage will occur.

8.Fit bolts securing rear pipe clips to chassis and

tighten to 6 Nm (4.4 lbf.ft) .

9.Connect 4 multiplugs to valve block.

10.If the same valve block has been refitted, renew

ACE high pressure filter.

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.

11.Bleed ACE hydraulic system.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

12.Lower vehicle.

Page 792 of 1529

FRONT SUSPENSION

REPAIRS 60-47

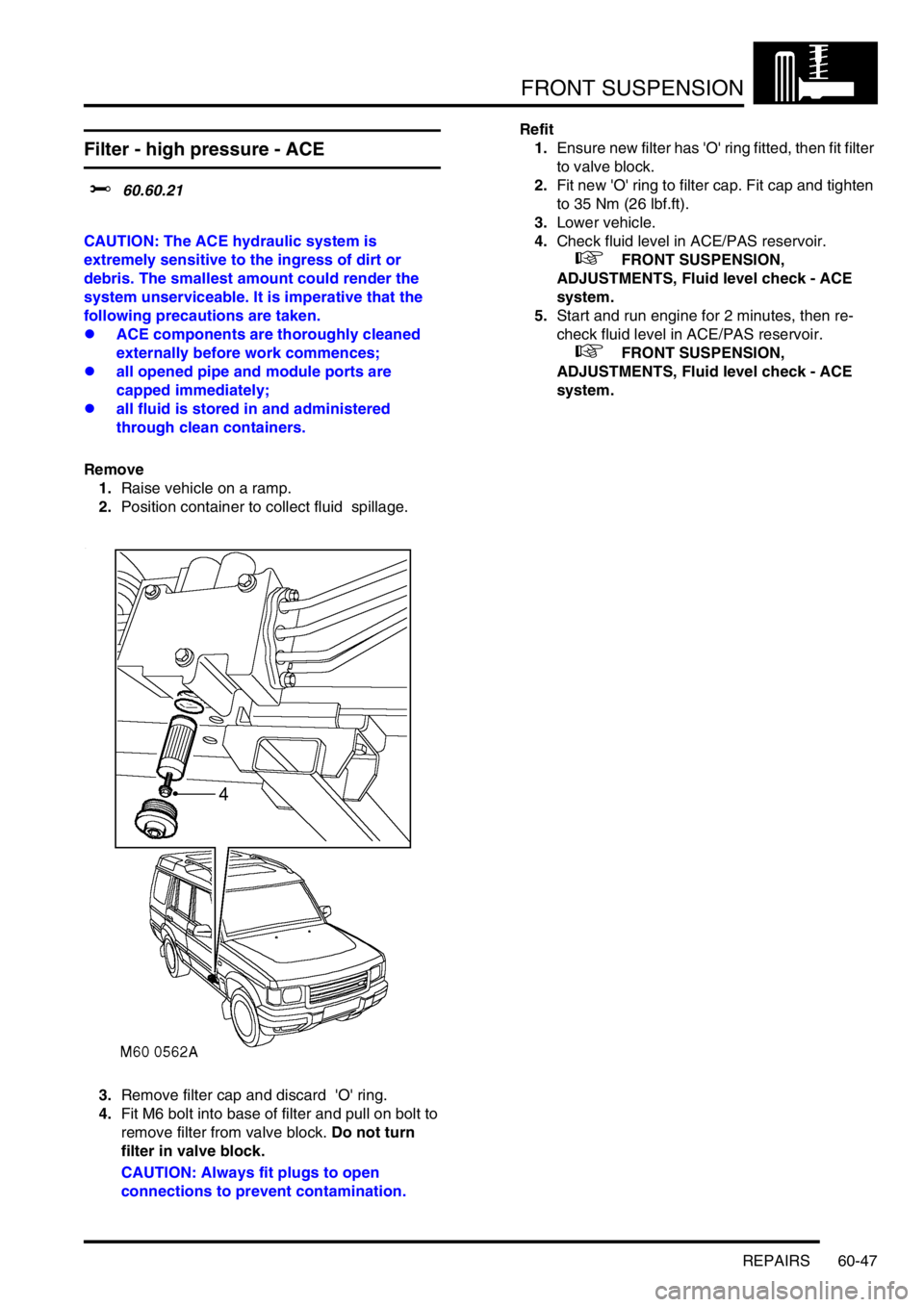

Filter - high pressure - ACE

$% 60.60.21

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Raise vehicle on a ramp.

2.Position container to collect fluid spillage.

3.Remove filter cap and discard 'O' ring.

4.Fit M6 bolt into base of filter and pull on bolt to

remove filter from valve block. Do not turn

filter in valve block.

CAUTION: Always fit plugs to open

connections to prevent contamination.Refit

1.Ensure new filter has 'O' ring fitted, then fit filter

to valve block.

2.Fit new 'O' ring to filter cap. Fit cap and tighten

to 35 Nm (26 lbf.ft).

3.Lower vehicle.

4.Check fluid level in ACE/PAS reservoir.

+ FRONT SUSPENSION,

ADJUSTMENTS, Fluid level check - ACE

system.

5.Start and run engine for 2 minutes, then re-

check fluid level in ACE/PAS reservoir.

+ FRONT SUSPENSION,

ADJUSTMENTS, Fluid level check - ACE

system.

Page 793 of 1529

FRONT SUSPENSION

60-48 REPAIRS

Pressure transducer - ACE

$% 60.60.22

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Raise vehicle on a ramp.

2.Disconnect multiplug from transducer.

3.Position container to collect fluid spillage.

4.Remove pressure transducer and discard 'O'

ring.

CAUTION: Always fit plugs to open

connections to prevent contamination.Refit

1.Ensure pressure transducer and port in valve

block is clean.

2.Fit new 'O' ring to pressure transducer. Fit and

tighten pressure transducer to 20 Nm (15

lbf.ft).

3.Connect multiplug to pressure transducer.

4.Renew ACE high pressure filter.

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.

5.Lower vehicle.

Page 794 of 1529

FRONT SUSPENSION

REPAIRS 60-49

Solenoid - pressure control valve - ACE

$% 60.60.23

Remove

1.Raise vehicle on a ramp.

2.Disconnect multiplug from solenoid.

3.Remove cap securing solenoid to pressure

control valve and discard 'O' ring.

4.Remove solenoid from pressure control valve

and discard 'O' ring from base of valve.

Refit

1.Ensure solenoid and pressure control valve are

clean.

2.Fit new 'O' ring to base of pressure control

valve.

3.Fit solenoid to pressure control valve, with

arrow on solenoid pointing away from valve

block and connector in correct position.

4.Fit new 'O' ring to solenoid securing cap. Fit cap

and tighten to 11 Nm (8 lbf.ft).

5.Connect multiplug to solenoid.

6.Lower vehicle.

Solenoid - directional control valve - ACE

$% 60.60.24

Remove

1.Raise vehicle on a ramp.

2.Disconnect multiplug from solenoid.

3.Loosen cap securing solenoid to directional

control valve.

4.Remove 3 bolts securing valve block to

chassis, lower block sufficiently only to remove

solenoid.

5.Remove cap securing solenoid to directional

control valve and discard 'O' ring.

6.Remove solenoid from directional control valve

and discard 'O' ring from base of valve.

Refit

1.Ensure solenoid and directional control valve

are clean.

2.Fit new 'O' ring to base of directional control

valve.

3.Fit solenoid to directional control valve, with

arrow on solenoid pointing up and connector in

correct position.

4.Fit new 'O' ring to solenoid securing cap. Fit cap

to solenoid but do not tighten at this stage.

5.Fit 3 bolts securing valve block to chassis and

tighten to 18 Nm (13 lbf.ft) .

6.Tighten solenoid securing cap to 11 Nm (8

lbf.ft) .

7.Connect multiplug to solenoid.

8.Lower vehicle.

Page 795 of 1529

FRONT SUSPENSION

60-50 REPAIRS

Pipe assembly - valve block to front

actuator - ACE

$% 60.60.31

Introduction

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove RH front road wheel.

3.Remove 7 screws securing RH front wheel arch

liner extension and remove extension.

4.Remove 3 screws securing splash shield and

remove shield. 5.Position containers under valve block and

actuator to collect fluid spillage.

6.Remove bolt securing pipe clamp to chassis

and remove clamp.

7.Release harness strap from suspension turret

and position harness aside.

8.Remove nut securing pipe clamp to bracket on

suspension turret and remove clamp.

Page 796 of 1529

FRONT SUSPENSION

REPAIRS 60-51

9.Remove 2 nuts securing pipe clamping plate to

valve block.

10.Release clamping plate and pipes from valve

block. Remove collets and release pipes from

clamping plate.

CAUTION: Always fit plugs to open

connections to prevent contamination.

11.Remove 2 cap nuts securing pipes to ACE

actuator. Disconnect pipes and discard sealing

washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

12.Release pipes from isolator above chassis RH

front outrigger.

13.Remove pipe assembly.Refit

1.Position pipe assembly.

2.Locate pipes in isolator above chassis RH front

outrigger. Fit cable tie around isolator to secure

pipes.

3.Ensure valve block and pipe connections are

clean.

4.Fit collets and pipes to clamping plate.

5.Connect pipes to valve block. To avoid seal

damage, keep pipes square to valve block.

Fit and tighten nuts securing clamping plate to

valve block to 21 Nm (15 lbf.ft).

CAUTION: Ensure pipes are installed in

their correct ports or serious system

damage will occur.

6.Fit pipe clamps. Secure to chassis with bolt and

to bracket on suspension turret with nut.

7.Connect pipes to ACE actuator with cap nuts

and new sealing washers Tighten cap nuts to

29 Nm (21 lbf.ft). Ensure pipes are not under

tension or kinked.

8.Secure harness to suspension turret.

9.Fit splash shield and secure with screws.

10.Fit RH wheel arch liner extension and secure

with screws.

11.Renew ACE high pressure filter.

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.

12.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

13.Refill and bleed ARC system.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

14.Lower vehicle.

Page 797 of 1529

FRONT SUSPENSION

60-52 REPAIRS

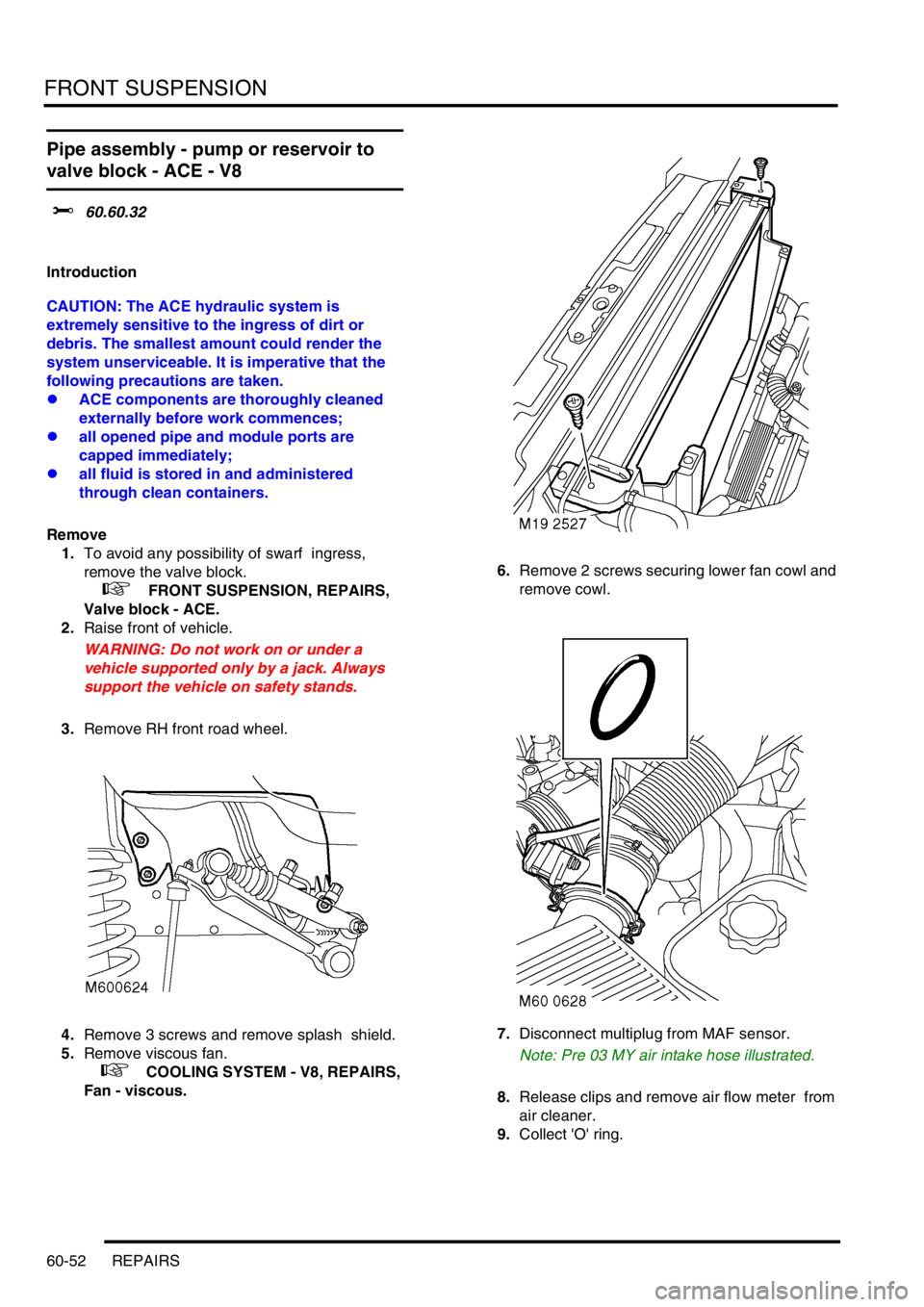

Pipe assembly - pump or reservoir to

valve block - ACE - V8

$% 60.60.32

Introduction

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.To avoid any possibility of swarf ingress,

remove the valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove RH front road wheel.

4.Remove 3 screws and remove splash shield.

5.Remove viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.6.Remove 2 screws securing lower fan cowl and

remove cowl.

7.Disconnect multiplug from MAF sensor.

Note: Pre 03 MY air intake hose illustrated.

8.Release clips and remove air flow meter from

air cleaner.

9.Collect 'O' ring.

Page 798 of 1529

FRONT SUSPENSION

REPAIRS 60-53

10.Loosen clip and disconnect air hose from

throttle body.

Note: Pre 03 MY air intake hose illustrated.

11.Position container to collect fluid loss.

12. Pump to valve block pipe:Remove banjo bolt

securing fluid hose to ACE pump and discard

sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.13. Valve block to reservoir pipe: Release clip,

disconnect hose from ACE fluid reservoir and

remove clip from hose.

CAUTION: Always fit plugs to open

connections to prevent contamination.

14.Remove bolts securing 2 pipe clamps to front

cross member and remove clamps.

15. Valve block to reservoir pipe: Release pipe

from clip on LH chassis member.

Page 799 of 1529

FRONT SUSPENSION

60-54 REPAIRS

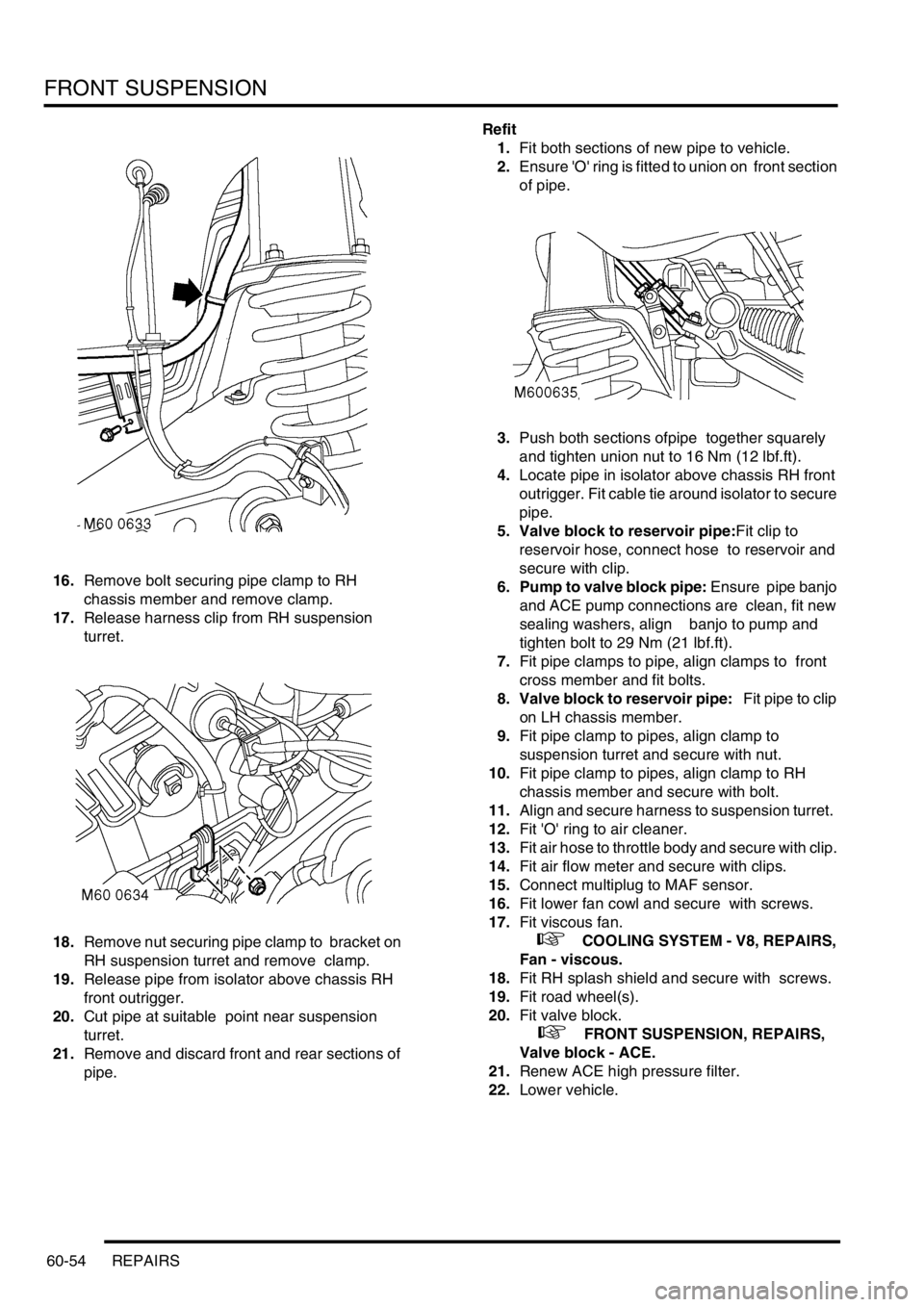

16.Remove bolt securing pipe clamp to RH

chassis member and remove clamp.

17.Release harness clip from RH suspension

turret.

18.Remove nut securing pipe clamp to bracket on

RH suspension turret and remove clamp.

19.Release pipe from isolator above chassis RH

front outrigger.

20.Cut pipe at suitable point near suspension

turret.

21.Remove and discard front and rear sections of

pipe. Refit

1.Fit both sections of new pipe to vehicle.

2.Ensure 'O' ring is fitted to union on front section

of pipe.

3.Push both sections ofpipe together squarely

and tighten union nut to 16 Nm (12 lbf.ft).

4.Locate pipe in isolator above chassis RH front

outrigger. Fit cable tie around isolator to secure

pipe.

5. Valve block to reservoir pipe:Fit clip to

reservoir hose, connect hose to reservoir and

secure with clip.

6. Pump to valve block pipe: Ensure pipe banjo

and ACE pump connections are clean, fit new

sealing washers, align banjo to pump and

tighten bolt to 29 Nm (21 lbf.ft).

7.Fit pipe clamps to pipe, align clamps to front

cross member and fit bolts.

8. Valve block to reservoir pipe: Fit pipe to clip

on LH chassis member.

9.Fit pipe clamp to pipes, align clamp to

suspension turret and secure with nut.

10.Fit pipe clamp to pipes, align clamp to RH

chassis member and secure with bolt.

11.Align and secure harness to suspension turret.

12.Fit 'O' ring to air cleaner.

13.Fit air hose to throttle body and secure with clip.

14.Fit air flow meter and secure with clips.

15.Connect multiplug to MAF sensor.

16.Fit lower fan cowl and secure with screws.

17.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

18.Fit RH splash shield and secure with screws.

19.Fit road wheel(s).

20.Fit valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

21.Renew ACE high pressure filter.

22.Lower vehicle.

Page 800 of 1529

FRONT SUSPENSION

REPAIRS 60-55

Pipe assembly - pump or reservoir to

valve block - ACE - diesel

$% 60.60.32

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.To avoid any possibility of swarf ingress,

remove valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

2.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Remove RH front road wheel.

5.Remove 3 screws and remove splash shield.

6.Remove viscous fan.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.7.Remove 2 screws securing lower half of fan

cowl and remove cowl.

8.Disconnect multiplug from air flow meter.

9.Release clips and remove air flow meter from

air cleaner.

10.Collect 'O' ring.