air filter LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1054 of 1672

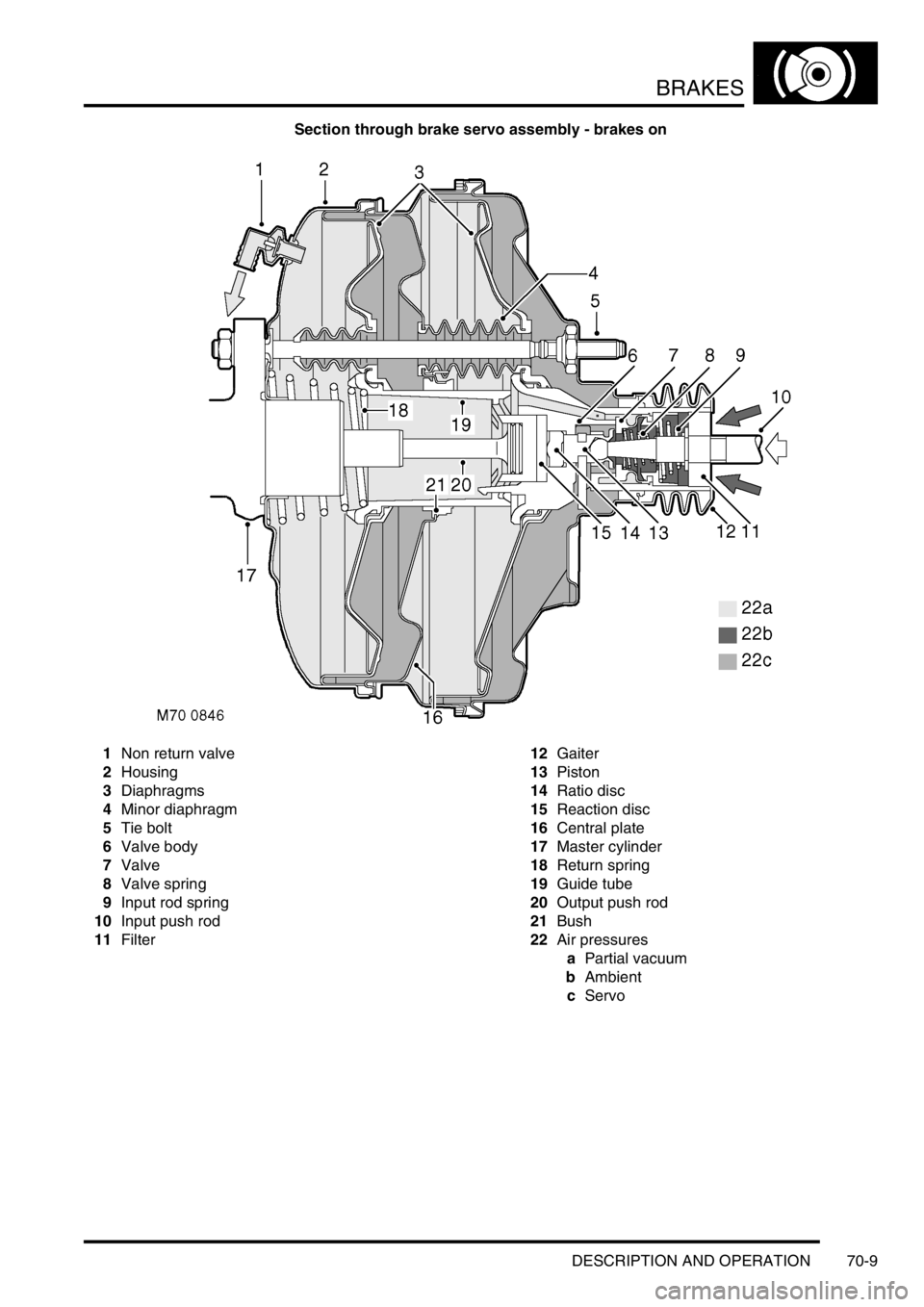

BRAKES

DESCRIPTION AND OPERATION 70-9

Section through brake servo assembly - brakes on

1Non return valve

2Housing

3Diaphragms

4Minor diaphragm

5Tie bolt

6Valve body

7Valve

8Valve spring

9Input rod spring

10Input push rod

11Filter12Gaiter

13Piston

14Ratio disc

15Reaction disc

16Central plate

17Master cylinder

18Return spring

19Guide tube

20Output push rod

21Bush

22Air pressures

aPartial vacuum

bAmbient

cServo

Page 1270 of 1672

PANEL REPAIRS

REPAIRS 77-2-21

REPAIRS

Front bulkhead assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

5. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

6. Diesel models: Remove gearbox fluid cooler.

7.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8.Release headlamp levelling motors and

position aside.

9.Release headlamp wiring and position aside.

10.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11.Remove battery tray.

12.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

13.Remove 2 earth leads from LH of front

bulkhead.

14.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

15. Models with A/C: Release and remove A/C

pipes.

16.Remove RH and LH crush cans.

17.Remove bonnet release cable.

18.Support bonnet in open position

19.Remove bonnet locking mechanism.

20.Remove VIN plate.

21.Remove 2 bolts securing front bulkhead

assembly to chassis.

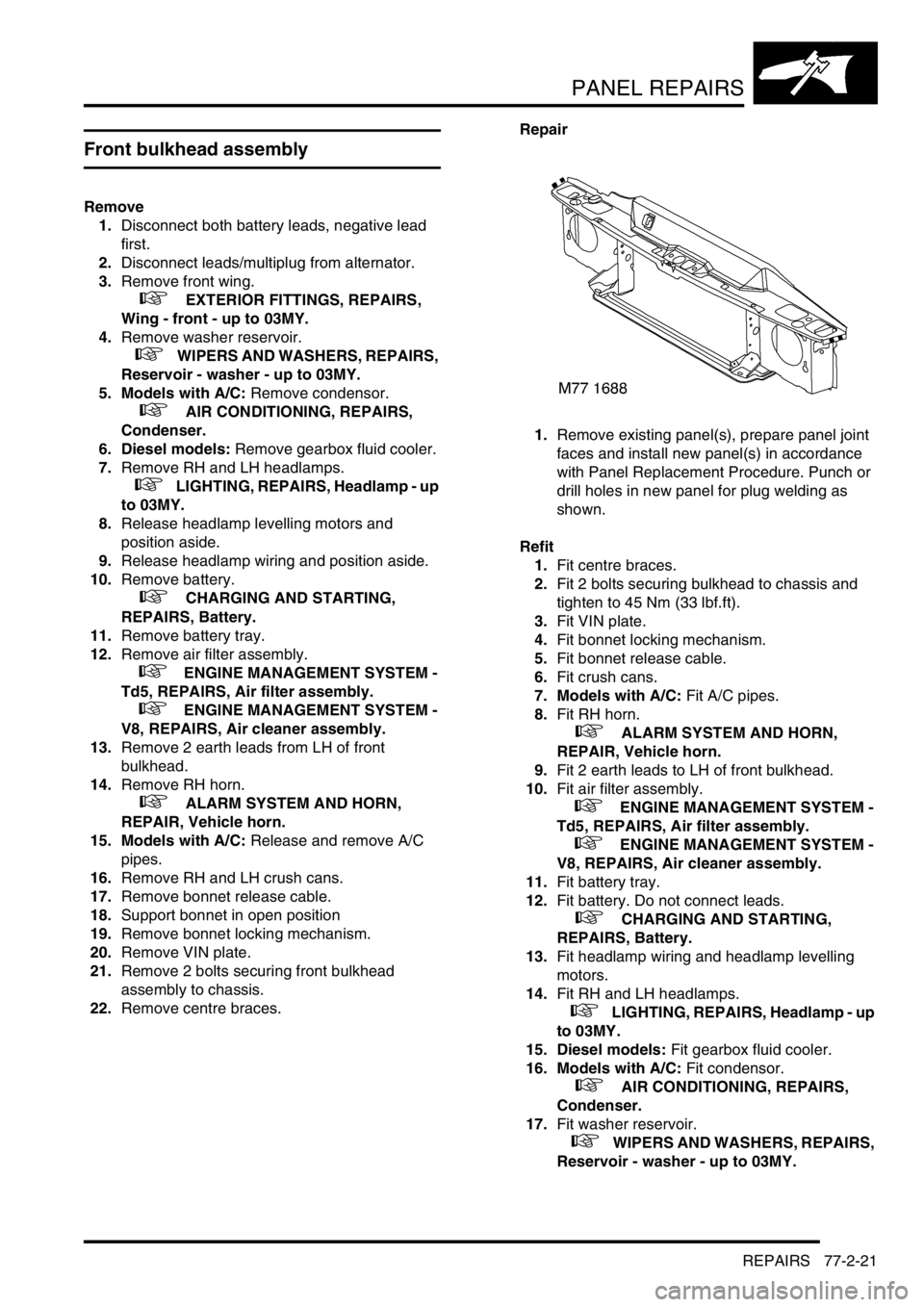

22.Remove centre braces.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten to 45 Nm (33 lbf.ft).

3.Fit VIN plate.

4.Fit bonnet locking mechanism.

5.Fit bonnet release cable.

6.Fit crush cans.

7. Models with A/C: Fit A/C pipes.

8.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

9.Fit 2 earth leads to LH of front bulkhead.

10.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Fit battery tray.

12.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Fit headlamp wiring and headlamp levelling

motors.

14.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

15. Diesel models: Fit gearbox fluid cooler.

16. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

17.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

Page 1271 of 1672

PANEL REPAIRS

77-2-22 REPAIRS

18.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

19.Connect leads/multiplug to alternator.

20.Connect battery leads, negative lead last.Bonnet locking platform

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove RH and LH repeater lamps.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp wiring and position aside.

9.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

10.Remove battery tray.

11.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

12.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

13.Remove bonnet release cable.

14.Support bonnet in open position

15.Remove bonnet locking mechanism.

16.Remove VIN plate.

17.Remove centre braces.

Page 1272 of 1672

PANEL REPAIRS

REPAIRS 77-2-23

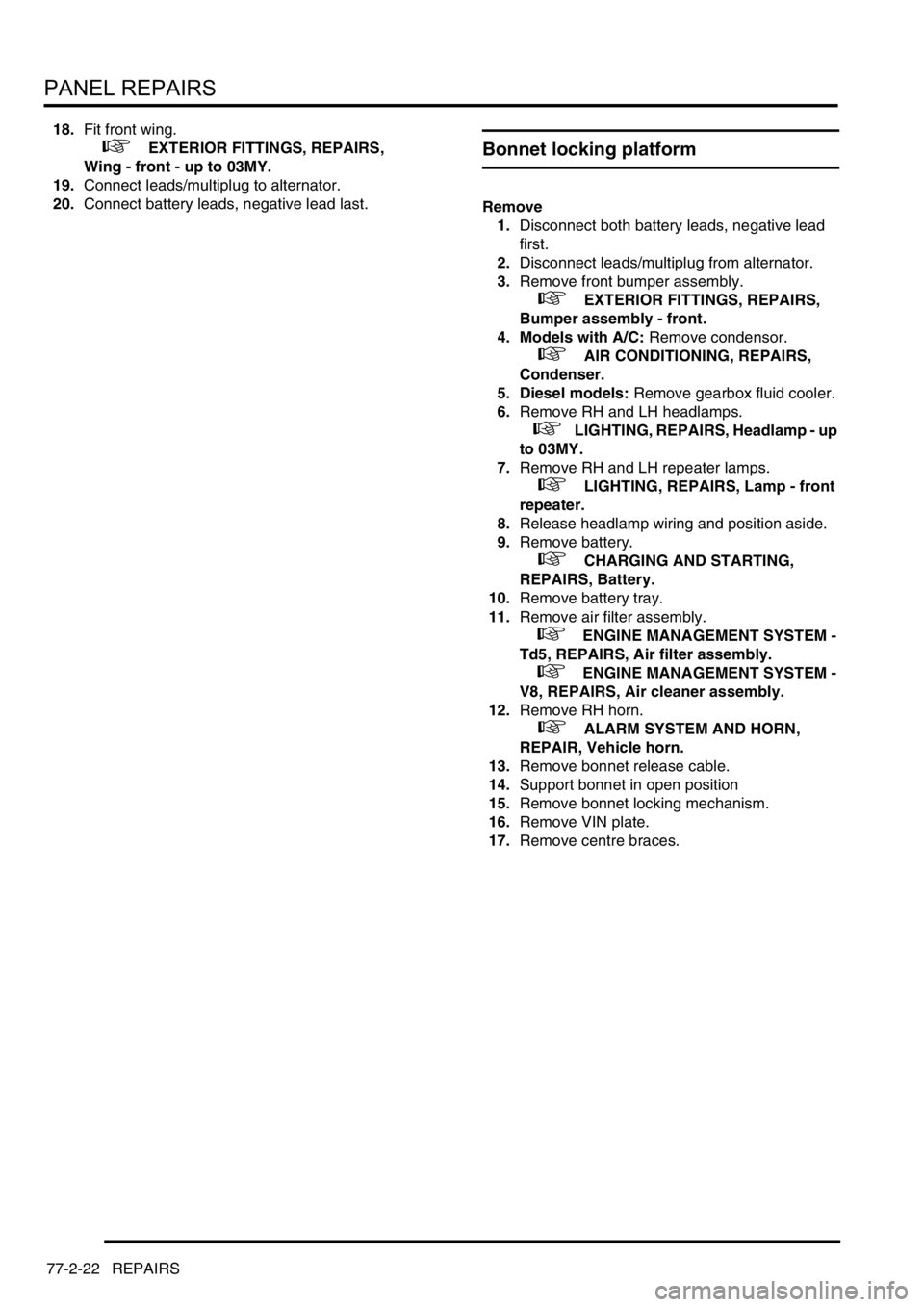

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit VIN plate.

3.Fit bonnet locking mechanism.

4.Fit bonnet release cable.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

7.Fit battery tray.

8.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

9.Fit headlamp wiring.

10.Fit RH and LH repeater lamps.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

11.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Front cross member

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Release headlamp levelling motors and

position aside.

8.Release headlamp wiring and position aside.

9.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

10. Models with A/C: Release and remove A/C

pipes.

11.Remove RH and LH crush cans.

12.Remove 2 bolts securing front bulkhead

assembly to chassis.

13.Remove centre braces.

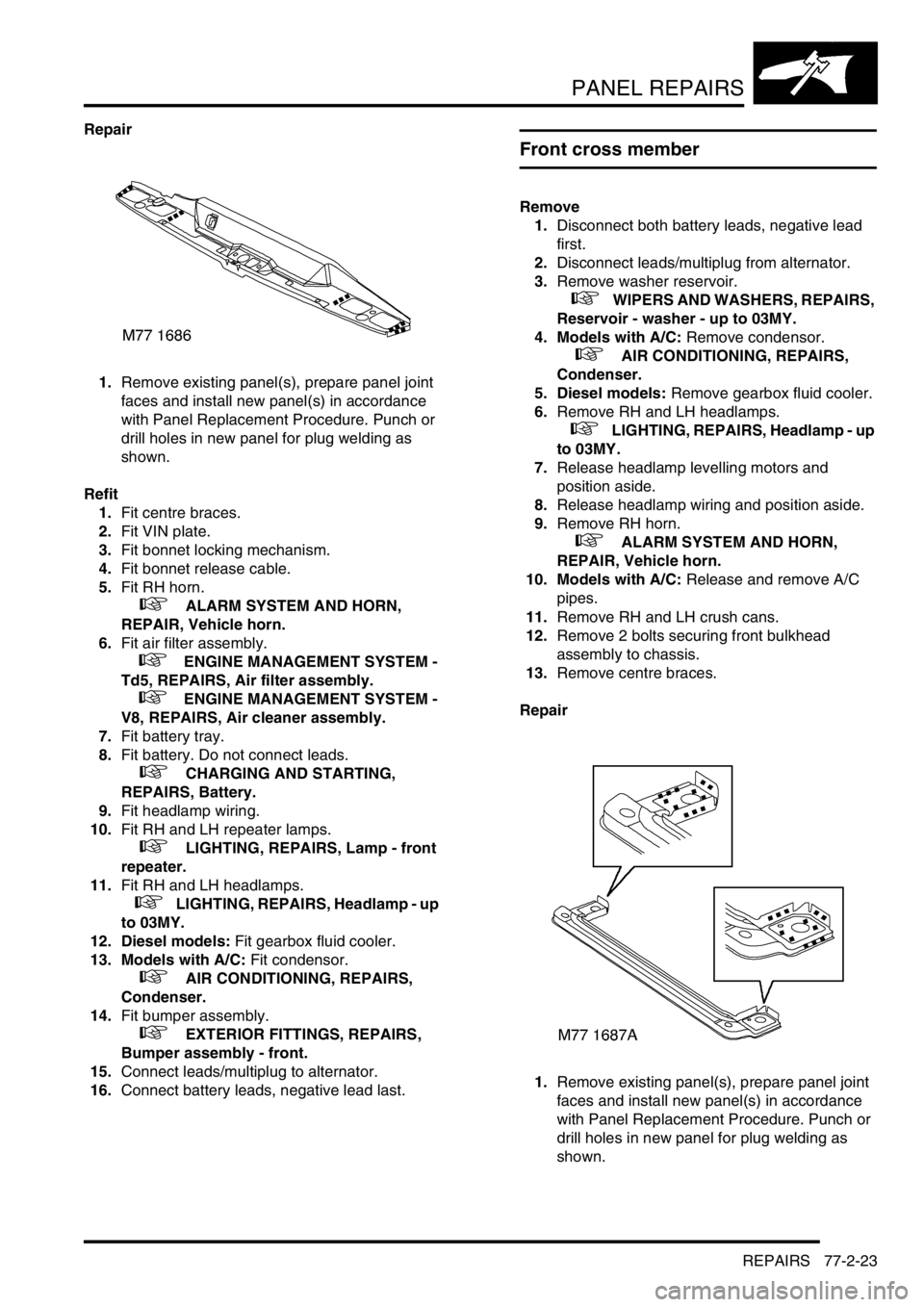

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Page 1275 of 1672

PANEL REPAIRS

77-2-26 REPAIRS

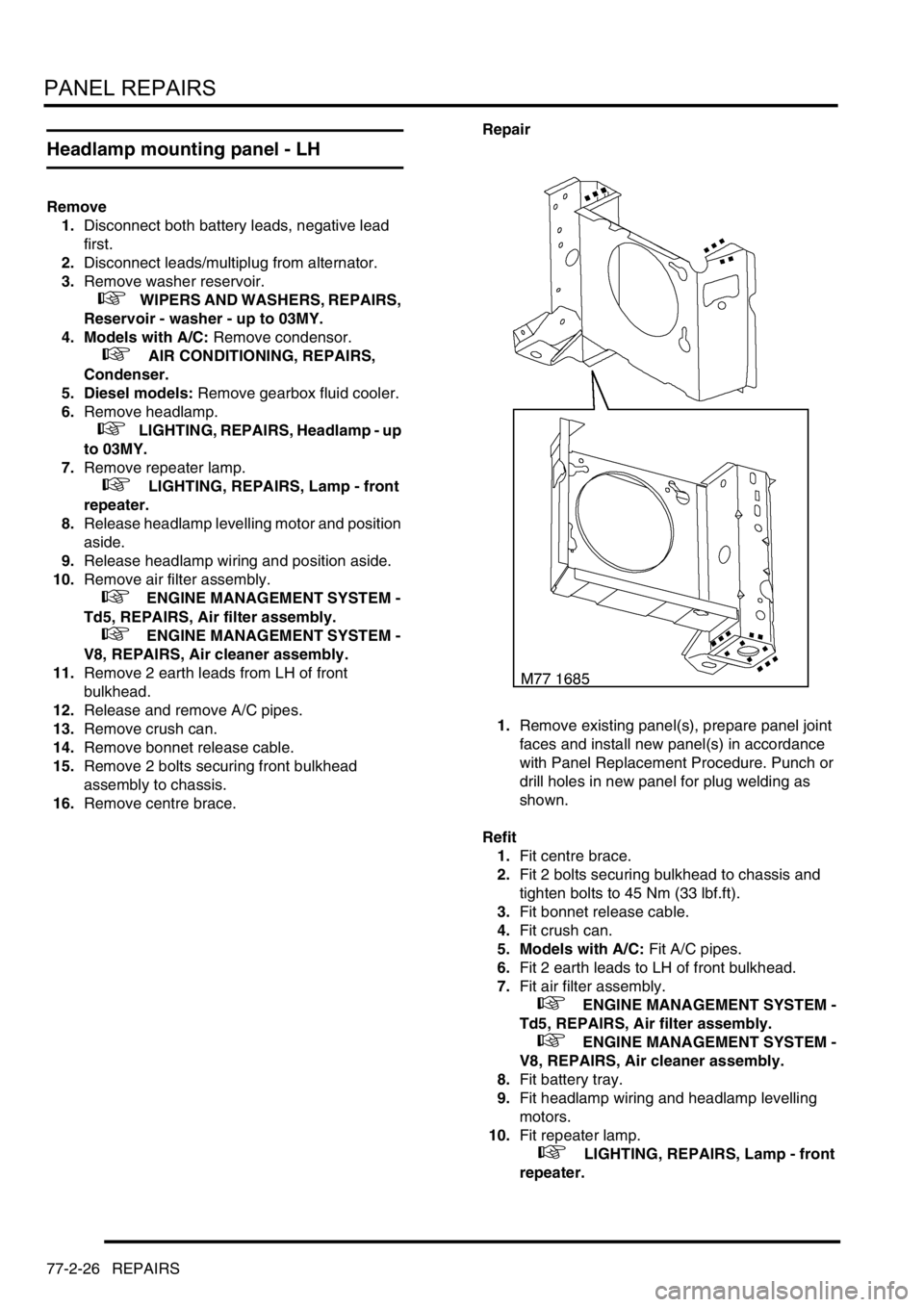

Headlamp mounting panel - LH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp levelling motor and position

aside.

9.Release headlamp wiring and position aside.

10.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Remove 2 earth leads from LH of front

bulkhead.

12.Release and remove A/C pipes.

13.Remove crush can.

14.Remove bonnet release cable.

15.Remove 2 bolts securing front bulkhead

assembly to chassis.

16.Remove centre brace.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre brace.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit bonnet release cable.

4.Fit crush can.

5. Models with A/C: Fit A/C pipes.

6.Fit 2 earth leads to LH of front bulkhead.

7.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

8.Fit battery tray.

9.Fit headlamp wiring and headlamp levelling

motors.

10.Fit repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

Page 1276 of 1672

PANEL REPAIRS

REPAIRS 77-2-27

11.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

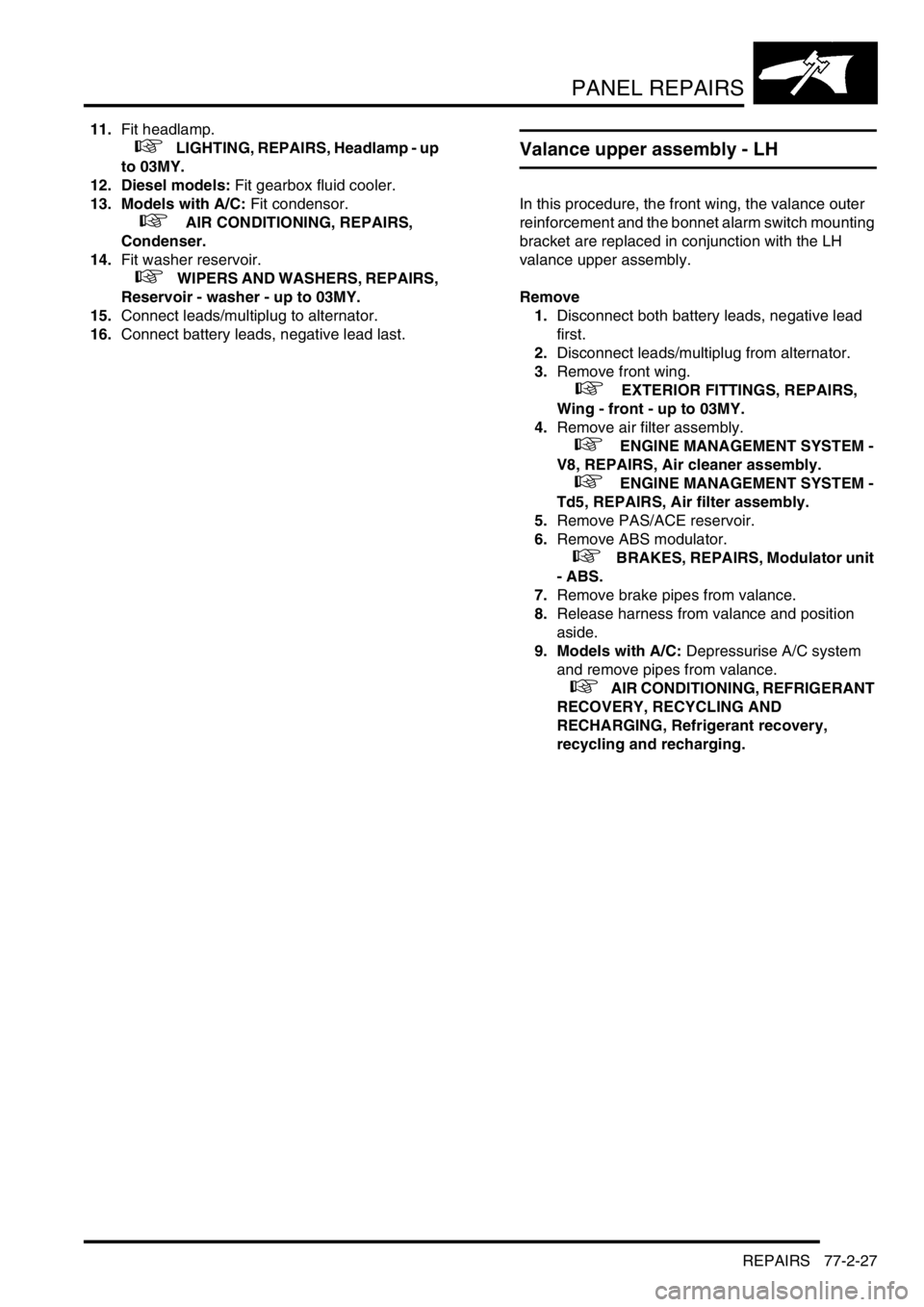

Valance upper assembly - LH

In this procedure, the front wing, the valance outer

reinforcement and the bonnet alarm switch mounting

bracket are replaced in conjunction with the LH

valance upper assembly.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

5.Remove PAS/ACE reservoir.

6.Remove ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

7.Remove brake pipes from valance.

8.Release harness from valance and position

aside.

9. Models with A/C: Depressurise A/C system

and remove pipes from valance.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

Page 1277 of 1672

PANEL REPAIRS

77-2-28 REPAIRS

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. Models with A/C: Fit A/C pipes and recharge

A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Fit harness to valance.

3.Fit brake pipes to valance.

4.Fit ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

5.Fit PAS/ACE reservoir, refill fluids to correct

levelsand bleed ACE system.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Fluids.6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

7.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

8.Connect leads/multiplug to alternator.

9.Connect battery leads, negative lead last.

M77 1743

M77 1690A

Page 1279 of 1672

PANEL REPAIRS

77-2-30 REPAIRS

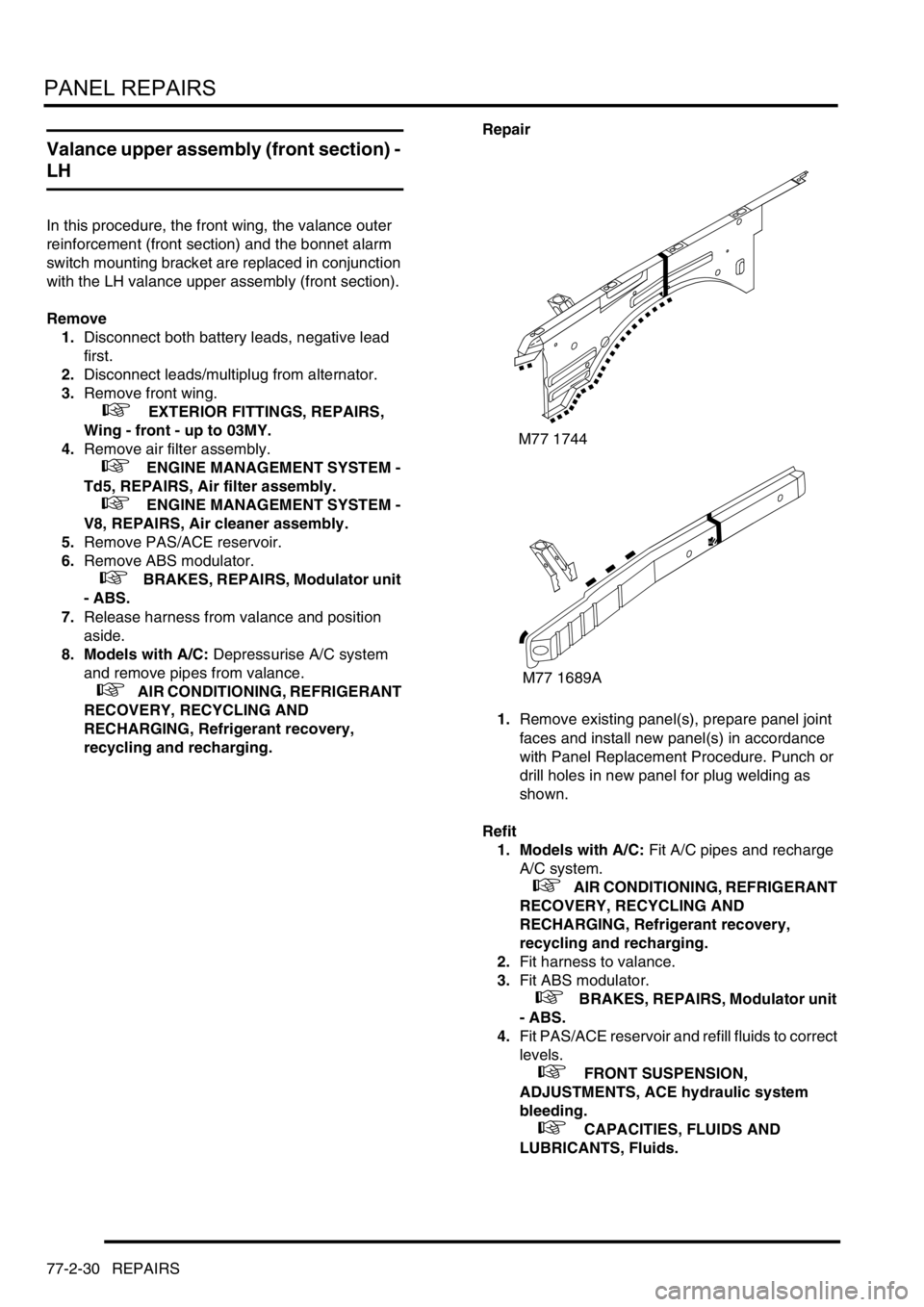

Valance upper assembly (front section) -

LH

In this procedure, the front wing, the valance outer

reinforcement (front section) and the bonnet alarm

switch mounting bracket are replaced in conjunction

with the LH valance upper assembly (front section).

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

5.Remove PAS/ACE reservoir.

6.Remove ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

7.Release harness from valance and position

aside.

8. Models with A/C: Depressurise A/C system

and remove pipes from valance.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. Models with A/C: Fit A/C pipes and recharge

A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Fit harness to valance.

3.Fit ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

4.Fit PAS/ACE reservoir and refill fluids to correct

levels.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Fluids.

M77 1744

M77 1689A

Page 1280 of 1672

PANEL REPAIRS

REPAIRS 77-2-31

5.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

6.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

7.Connect leads/multiplug to alternator.

8.Connect battery leads, negative lead last.

Valance upper assembly (front section) -

RH

In this procedure, the front wing and the valance

outer reinforcement (front section) are replaced in

conjunction with the RH valance upper assembly

(front section).

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

5.Remove battery tray.

6.Remove fuse box.

7.Release expansion tank from fixings and

position aside.

8.Release harness from valance and position

aside.

Page 1312 of 1672

BODY SEALING MATERIALS

MATERIALS AND APPLICATIONS 77-3-5

Cooper Pegler Falcon Junior Pneumatic Gun (Airless)

Intended primarily for applying transit wax, this pneumatic sprayer has a 5-litre container with integral hand pump and

provides an effective means of wax spraying without the need for compressed air or additional services.

A selection of nozzles, lances, hose lengths and a trigger valve assembly with integral filter allows flexibility in use.

Additional applications include general maintenance, wax injection and paint application. Heavy-bodied materials

may also be applied. All parts are fully replaceable and a wide range of nozzle configurations is available.

SATA Schutz Gun Model UBE

The SATA Schutz Gun is approved for the retreatment of vehicle underbody areas with protective coatings as

supplied in 1 litre, purpose-designed 'one-way' containers. The screw thread fitting (female on the gun) is standard

to most Schutz-type packs.

SATA HKD1 Wax Injection Injection Equipment

This equipment is approved for carrying out cavity wax re-treatment. The SATA HKD1 set comprises a high quality

forged gun with 1-litre pressure feed container, a flexible nylon lance, a straight 1100 mm (43.307 in) steel lance and

hooked- wand lance. A quick-change coupling is provided as a standard fitting to allow lances to be easily

interchanged. Each lance has an integral, machined nozzle with specialised spray characteristics to suit the type of

box section to be treated.

NOTE: Always clean gun after use with appropriate solvent to maintain efficiency.

Specifications of Model UBE:

Air consumption 7 ft

3/min (200 litres/min) @ 45 lbf.in2

Weight: 23.3oz (220 grams)