gearbox LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 763 of 1672

TRANSFER BOX - LT230SE

41-30 REPAIRS

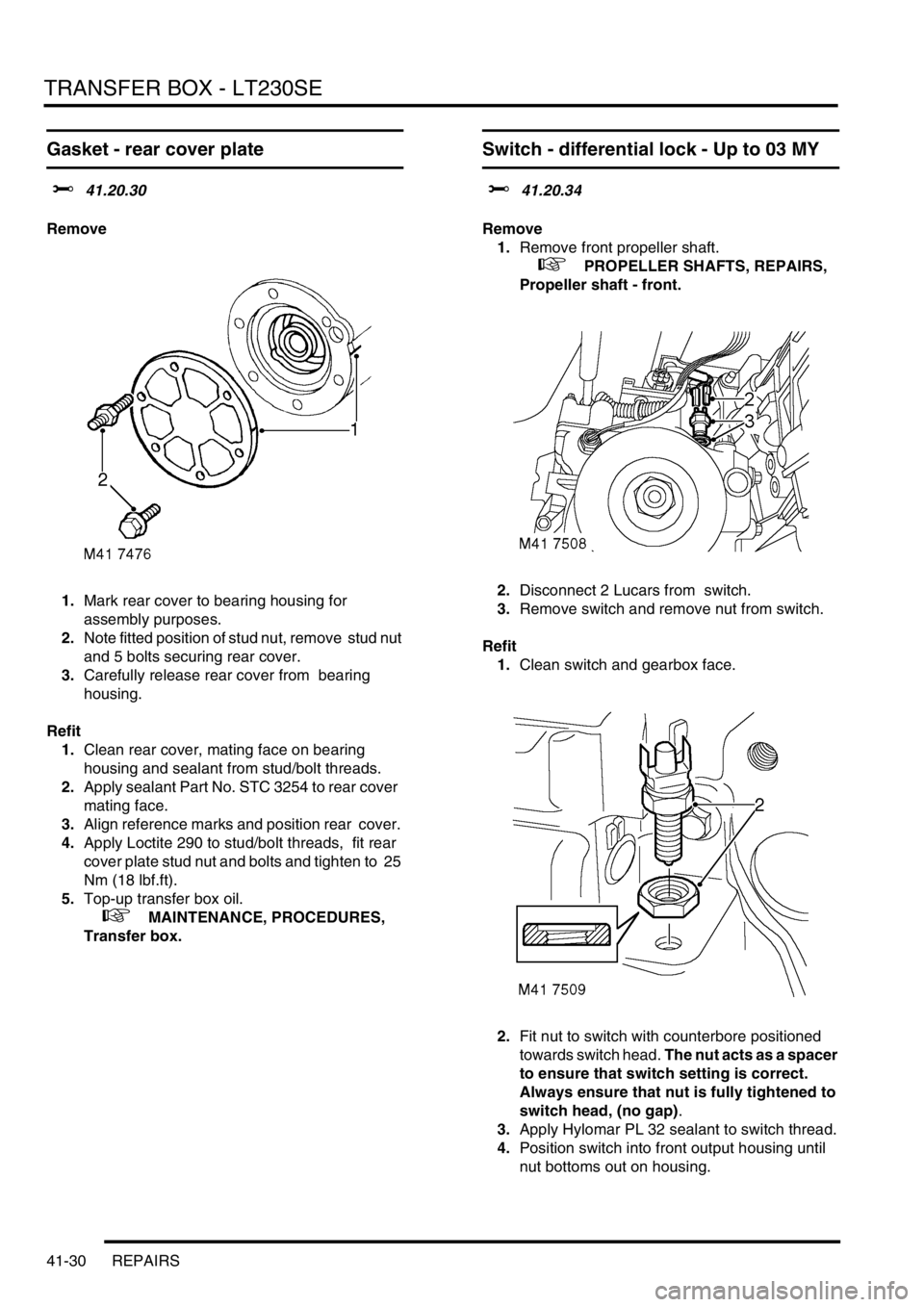

Gasket - rear cover plate

$% 41.20.30

Remove

1.Mark rear cover to bearing housing for

assembly purposes.

2.Note fitted position of stud nut, remove stud nut

and 5 bolts securing rear cover.

3.Carefully release rear cover from bearing

housing.

Refit

1.Clean rear cover, mating face on bearing

housing and sealant from stud/bolt threads.

2.Apply sealant Part No. STC 3254 to rear cover

mating face.

3.Align reference marks and position rear cover.

4.Apply Loctite 290 to stud/bolt threads, fit rear

cover plate stud nut and bolts and tighten to 25

Nm (18 lbf.ft).

5.Top-up transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Switch - differential lock - Up to 03 MY

$% 41.20.34

Remove

1.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

2.Disconnect 2 Lucars from switch.

3.Remove switch and remove nut from switch.

Refit

1.Clean switch and gearbox face.

2.Fit nut to switch with counterbore positioned

towards switch head. The nut acts as a spacer

to ensure that switch setting is correct.

Always ensure that nut is fully tightened to

switch head, (no gap).

3.Apply Hylomar PL 32 sealant to switch thread.

4.Position switch into front output housing until

nut bottoms out on housing.

Page 765 of 1672

TRANSFER BOX - LT230SE

41-32 REPAIRS

6.Remove bolt securing outer cable clip to cross

shaft housing, remove cable.

Refit

1.Clean change levers, abutment bracket and

clevis pins.

2.Apply Mobilith SHC 100 grease to inner cable

ends and clevis pins.

3.Position cable and secure to high/low lever

abutment bracket with 'C' clip.

4.Secure inner cable to high/low lever with clevis

pin.

5.Position outer cable clip to cross shaft housing,

tighten bolt to 15 Nm (11 lbf.ft).

6.Adjust high/low selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - high/low selector.

Oil seal - input shaft

$% 41.20.50

Remove

1.Remove transfer box.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

2.Lever input shaft oil seal from transfer box.

Refit

1.Clean oil seal recess in transfer gearbox.

2.Lubricate new input shaft oil seal with gearbox

oil.

3.Using tool LRT-37-014 fit input shaft seal to

transfer box.

4.Fit transfer box.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

Page 766 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-33

Seal - front output shaft

$% 41.20.51

Remove

1.Position vehicle on 4 post ramp.

2.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

3.Restrain transfer box drive flange using tool

LRT-51-003. Remove and discard drive flange

nut, remove and discard steel and felt washers.

4.Using tool LRT-99-500 if necessary, remove

drive flange from transfer box.

5.Remove seal from transfer box. Refit

1.Clean seal mating faces.

2.Lubricate seal with gearbox oil.

3.Fit new seal using tool LRT-41-012.

4.Position drive flange, fit new felt and steel

washers.

5.Position tool LRT-51-003 and tighten new

drive flange nut to 148 Nm (109 lbf.ft).

6.Fit propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

7.Top-up transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Page 767 of 1672

TRANSFER BOX - LT230SE

41-34 REPAIRS

Seal - rear output shaft

$% 41.20.54

Remove

1.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

2.Loosen brake shoe adjuster bolt.

3.Remove screw securing handbrake drum. 4.Remove handbrake drum.

5.Restrain transfer box drive flange using tool

LRT-51-003. Remove and discard drive flange

nut, remove and discard steel and felt washers.

6.Using tool LRT-99-500 if necessary, remove

drive flange from transfer box.

7.Remove seal from transfer box.

Refit

1.Clean seal mating faces.

2.Lubricate seal with gearbox oil.

Page 768 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-35

3.Fit new seal using tool LRT-41-012.

4.Position drive flange, fit new felt and steel

washers.

5.Position tool LRT-51-003 and tighten new

drive flange nut to 148 Nm (109 lbf.ft).

6.Position handbrake drum and tighten screw.

7.Tighten brake shoe adjuster bolt to 25 Nm (18

lbf.ft) then loosen one and a half turns.

8.Check that brake drum is free to rotate.

9.Fit propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

10.Top-up transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Gasket - rear output shaft housing

$% 41.20.55

Remove

1.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

2.Remove rear output shaft seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Seal - rear output shaft.

3.Mark output shaft housing to main casing for

assembly purposes.

4.Note position of shoulder bolt, remove 6 bolts

securing housing to main casing.

Refit

1.Clean output shaft housing, mating face on

main casing and sealant from bolt threads.

2.Apply sealant, Part No. STC 3254 to mating

flange on output shaft housing.

3.Fit output shaft housing to main casing.

4.Apply Loctite 290 to bolt threads.

5.Fit output shaft housing bolts and tighten by

diagonal selection to 45 Nm (33 lbf.ft).

6.Fit rear output shaft seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Seal - rear output shaft.

7.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Page 785 of 1672

TRANSFER BOX - LT230SE

41-52 OVERHAUL

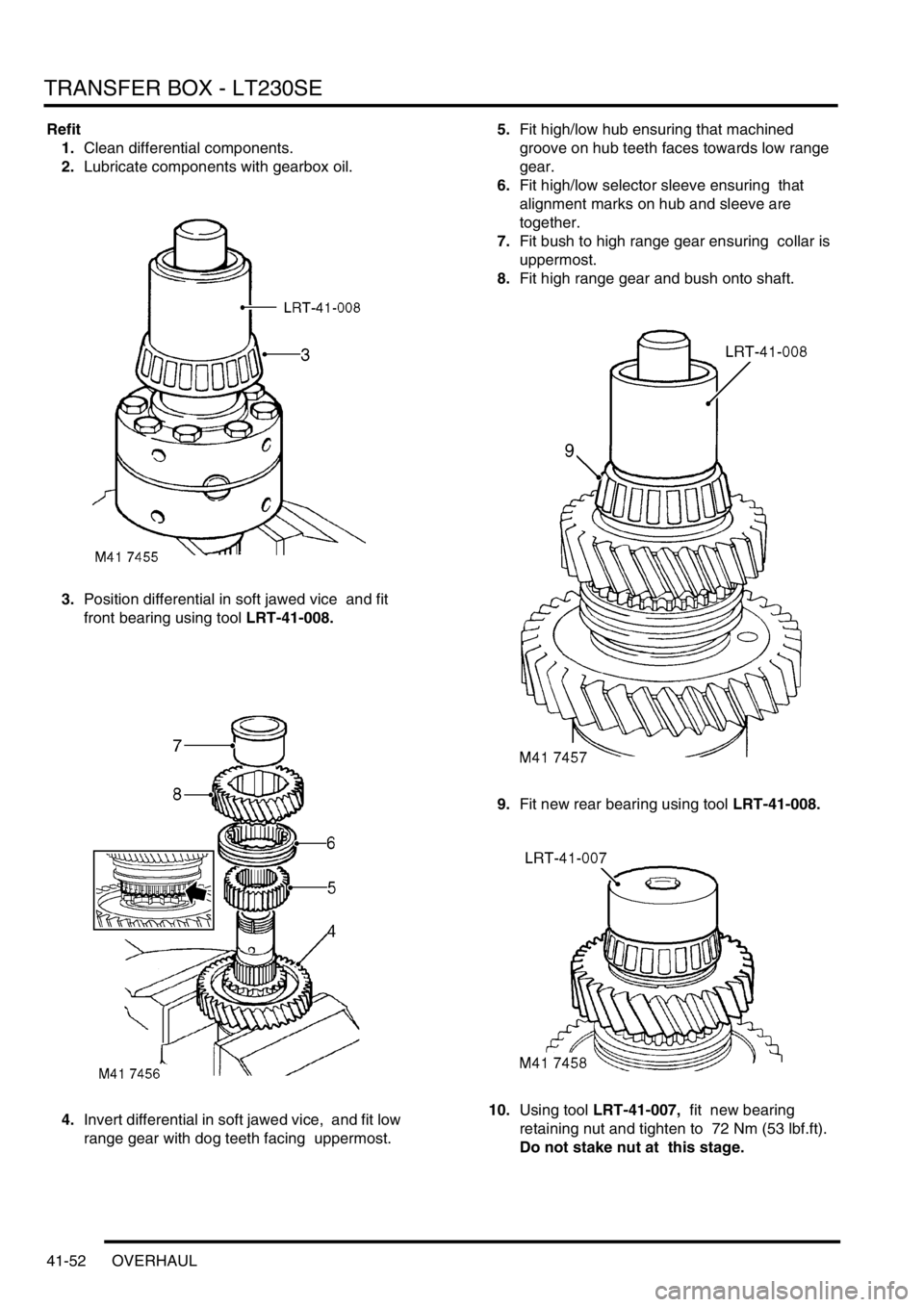

Refit

1.Clean differential components.

2.Lubricate components with gearbox oil.

3.Position differential in soft jawed vice and fit

front bearing using tool LRT-41-008.

4.Invert differential in soft jawed vice, and fit low

range gear with dog teeth facing uppermost. 5.Fit high/low hub ensuring that machined

groove on hub teeth faces towards low range

gear.

6.Fit high/low selector sleeve ensuring that

alignment marks on hub and sleeve are

together.

7.Fit bush to high range gear ensuring collar is

uppermost.

8.Fit high range gear and bush onto shaft.

9.Fit new rear bearing using tool LRT-41-008.

10.Using tool LRT-41-007, fit new bearing

retaining nut and tighten to 72 Nm (53 lbf.ft).

Do not stake nut at this stage.

Page 791 of 1672

TRANSFER BOX - LT230SE

41-58 OVERHAUL

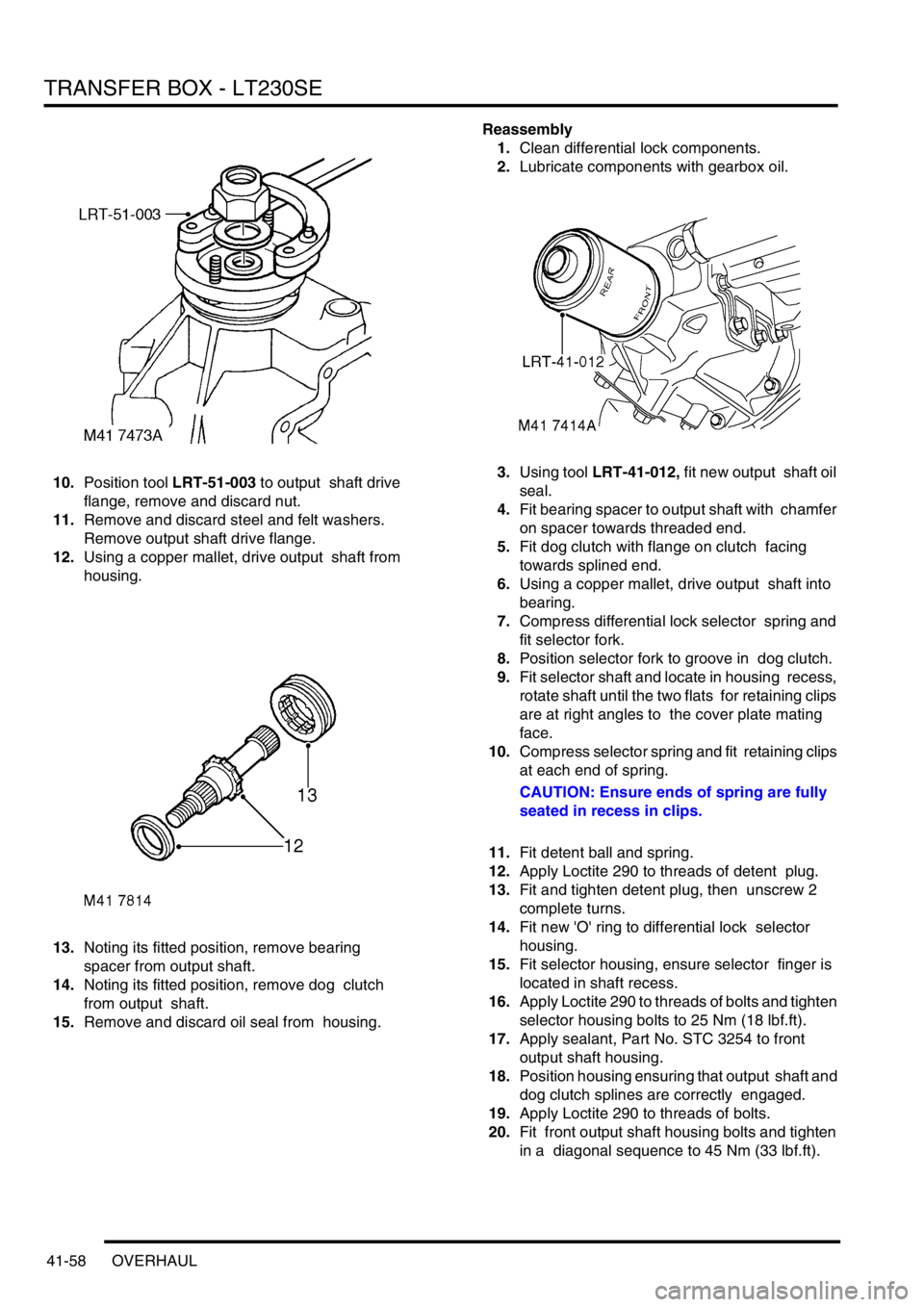

10.Position tool LRT-51-003 to output shaft drive

flange, remove and discard nut.

11.Remove and discard steel and felt washers.

Remove output shaft drive flange.

12.Using a copper mallet, drive output shaft from

housing.

13.Noting its fitted position, remove bearing

spacer from output shaft.

14.Noting its fitted position, remove dog clutch

from output shaft.

15.Remove and discard oil seal from housing. Reassembly

1.Clean differential lock components.

2.Lubricate components with gearbox oil.

3.Using tool LRT-41-012, fit new output shaft oil

seal.

4.Fit bearing spacer to output shaft with chamfer

on spacer towards threaded end.

5.Fit dog clutch with flange on clutch facing

towards splined end.

6.Using a copper mallet, drive output shaft into

bearing.

7.Compress differential lock selector spring and

fit selector fork.

8.Position selector fork to groove in dog clutch.

9.Fit selector shaft and locate in housing recess,

rotate shaft until the two flats for retaining clips

are at right angles to the cover plate mating

face.

10.Compress selector spring and fit retaining clips

at each end of spring.

CAUTION: Ensure ends of spring are fully

seated in recess in clips.

11.Fit detent ball and spring.

12.Apply Loctite 290 to threads of detent plug.

13.Fit and tighten detent plug, then unscrew 2

complete turns.

14.Fit new 'O' ring to differential lock selector

housing.

15.Fit selector housing, ensure selector finger is

located in shaft recess.

16.Apply Loctite 290 to threads of bolts and tighten

selector housing bolts to 25 Nm (18 lbf.ft).

17.Apply sealant, Part No. STC 3254 to front

output shaft housing.

18.Position housing ensuring that output shaft and

dog clutch splines are correctly engaged.

19.Apply Loctite 290 to threads of bolts.

20.Fit front output shaft housing bolts and tighten

in a diagonal sequence to 45 Nm (33 lbf.ft).

Page 796 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-63

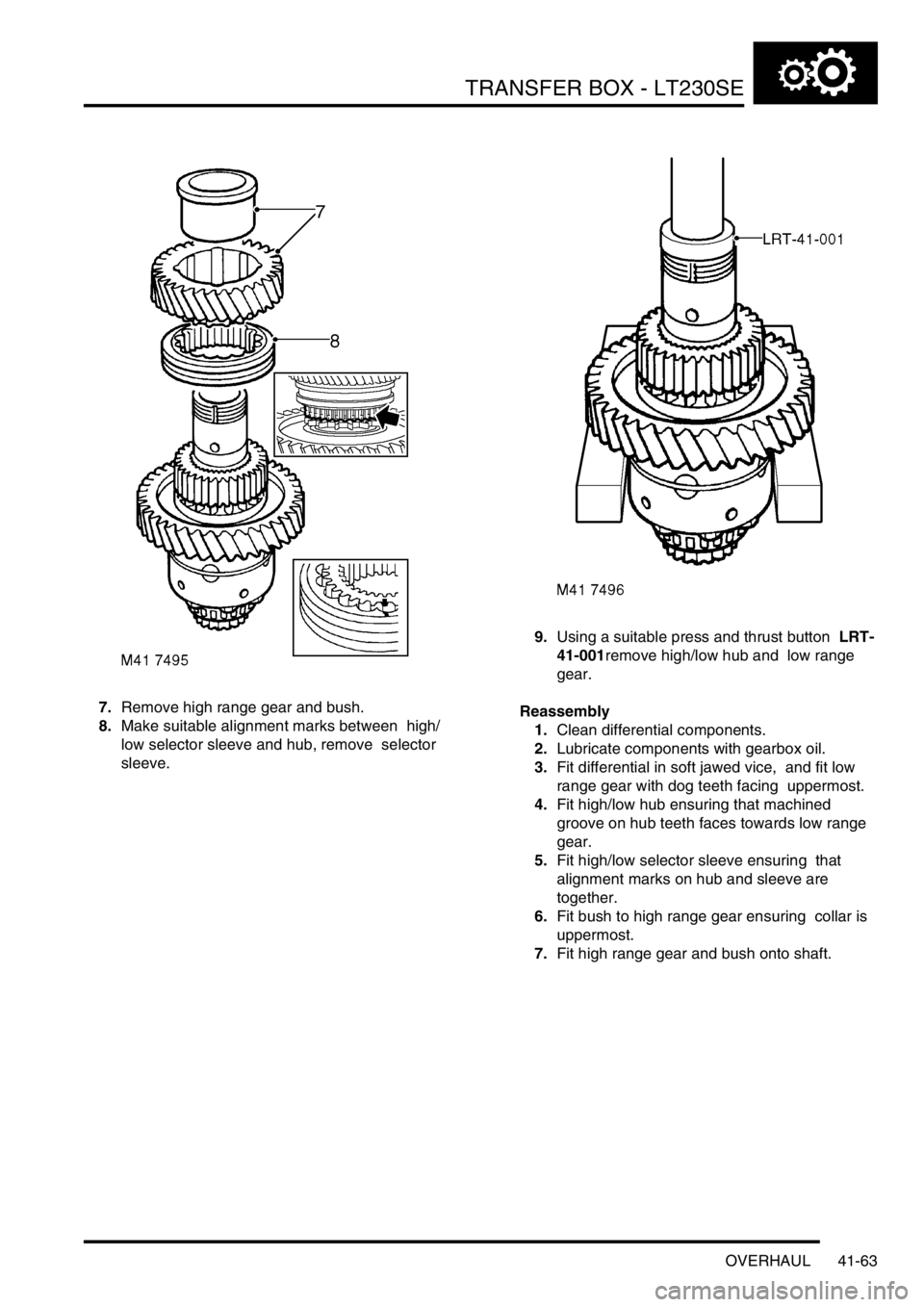

7.Remove high range gear and bush.

8.Make suitable alignment marks between high/

low selector sleeve and hub, remove selector

sleeve. 9.Using a suitable press and thrust button LRT-

41-001remove high/low hub and low range

gear.

Reassembly

1.Clean differential components.

2.Lubricate components with gearbox oil.

3.Fit differential in soft jawed vice, and fit low

range gear with dog teeth facing uppermost.

4.Fit high/low hub ensuring that machined

groove on hub teeth faces towards low range

gear.

5.Fit high/low selector sleeve ensuring that

alignment marks on hub and sleeve are

together.

6.Fit bush to high range gear ensuring collar is

uppermost.

7.Fit high range gear and bush onto shaft.

Page 798 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-1

AUTOMATIC GE ARBOX - ZF4HP22 - 24 DESCRIPTION AND OPERAT ION

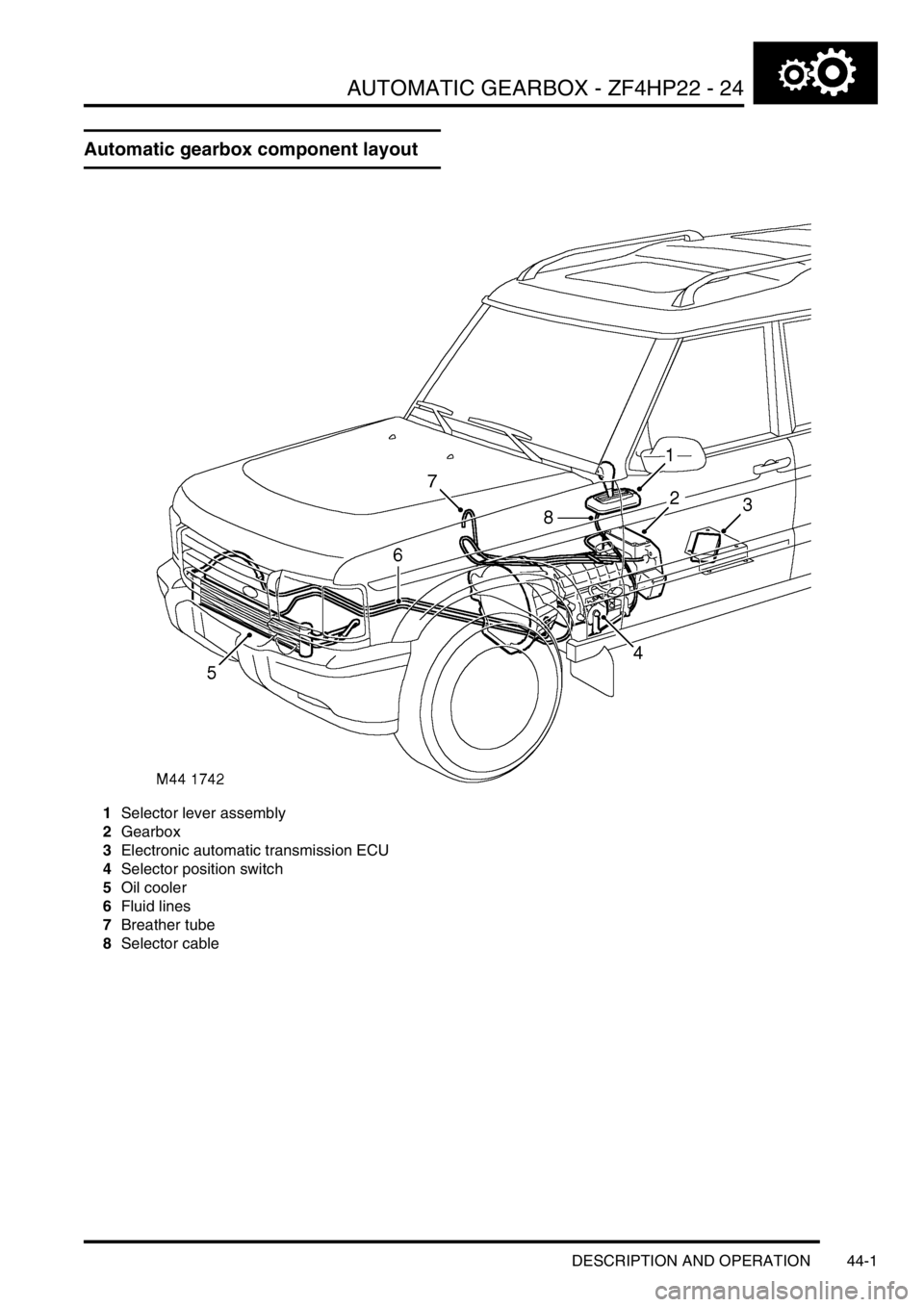

Automatic gearbox component layout

1Selector lever assembly

2Gearbox

3Electronic automatic transmission ECU

4Selector position switch

5Oil cooler

6Fluid lines

7Breather tube

8Selector cable

Page 799 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-2 DESCRIPTION AND OPERATION

Control schematic