ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 385 of 1672

EMISSION CONTROL - V8

17-2-48 REPAIRS

Sensor - heated oxygen (HO2S) - post-

catalytic converter

$% 19.22.17

Remove

1.Raise vehicle on ramp.

2.Release HO

2S multiplug from support bracket.

3.Disconnect HO

2S multiplug from harness.

4.Using a 22 mm crowsfoot spanner, remove

HO

2S.

CAUTION: HO2 sensors are easily damaged

by dropping, excessive heat or

contamination. Care must be taken not to

damage the sensor housing or tip.Refit

1.Clean sensor and exhaust pipe mating

surfaces.

2.If refitting existing sensor, apply anti-seize

compound to sensor threads.

WARNING: Some types of anti-seize

compound used in service are a health

hazard. Avoid skin contact.

NOTE: A new HO2 sensor is supplied pre-

treated with anti-seize compound.

3.Fit a new sealing washer to HO

2S

4.Fit HO

2S and tighten to 45 Nm (33 lbf.ft).

5. Connect HO

2S multiplug to harness and fit

harness to bracket.

6.Secure harness to clip.

7.Lower vehicle.

Page 386 of 1672

EMISSION CONTROL - V8

REPAIRS 17-2-49

Control Valve - Secondary Air Injection

(SAI)

$% 17.25.02

Remove

1.Release clip and disconnect air hose from

valve.

2.Disconnect vacuum hose from valve.

3.Remove 2 bolts securing valve to air manifold.

4.Remove valve and discard gasket.

Refit

1.Clean SAI control valve and mating face on

manifold.

2.Fit new gasket and fit valve. Tighten bolts to 10

Nm (7 lbf.ft).

3.Connect vacuum hose.

4.Connect air hose and secure with clip.

Reservoir - Vacuum - Secondary Air

Injection (SAI) - up to 03MY

$% 17.25.04

Remove

1.Disconnect 2 vacuum hoses from reservoir.

2.Remove bolt securing reservoir to mounting

bracket and collect reservoir.

Refit

1.Position reservoir to mounting bracket and

tighten bolt to 10 Nm.

2.Connect vacuum hoses to reservoir.

M17 0222

1

2

3

4

M17 0227

2

1

1

Page 387 of 1672

EMISSION CONTROL - V8

17-2-50 REPAIRS

Reservoir - vacuum - Secondary Air

Injection (SAI) - from 03MY

$% 17.25.04

Remove

1.Disconnect 2 vacuum pipes from air reservoir.

2.Remove bolt securing air reservoir to air pump

and remove the reservoir.

Refit

1.Position air reservoir to air pump, fit bolt and

tighten to 10 Nm (7 lbf.ft).

2.Connect vacuum pipes to the air reservoir.

Pump - Air - Secondary Air Injection

(SAI)

$% 17.25.07

Remove

1.Disconnect multiplug from air pump.

2.Release clip and disconnect air hose from air

pump.

3.Remove bolt securing air pump bracket to

body.

4.Remove air pump and bracket assembly.

5.Remove 3 nuts securing bracket to air pump

and collect bracket.

6.Remove 3 mountings from air pump.

Refit

1.Fit mountings to air pump and tighten to 10

Nm.

2.Fit bracket to air pump mountings and tighten

nuts to 10 Nm.

3.Position air pump assembly and tighten bolt to

20 Nm.

4.Connect air hose to SAI pump.

5.Connect multiplug to air pump.

M17 0225

2

1

3

4

M17 0226

5

5

6

Page 388 of 1672

EMISSION CONTROL - V8

REPAIRS 17-2-51

Air Manifold - LH - Secondary Air

Injection (SAI)

$% 17.25.17

Remove

1.Remove SAI control valve.

+ EMISSION CONTROL - V8,

REPAIRS, Control Valve - Secondary Air

Injection (SAI).

2.Loosen 2 union nuts securing air manifold to

cylinder head adaptors.

3.Remove 2 nuts securing air manifold bracket to

inlet manifold.

4.Remove air manifold.

Refit

1.Clean air manifold and cylinder head adaptors.

2.Fit air manifold and start union nuts.

3.Fit nuts securing air manifold to inlet manifold.

4.Tighten air manifold unions to 25 Nm.

5.Fit SAI control valve.

+ EMISSION CONTROL - V8,

REPAIRS, Control Valve - Secondary Air

Injection (SAI).

Air Manifold - RH - Secondary Air

Injection (SAI)

$% 17.25.18

Remove

1.Remove SAI control valve.

+ EMISSION CONTROL - V8,

REPAIRS, Control Valve - Secondary Air

Injection (SAI).

2.Remove heater feed pipe.

+ HEATING AND VENTILATION,

REPAIRS, Pipe - Heater - Feed.

3.Loosen 2 union nuts securing air manifold to

cylinder head adaptors.

4.Remove nut securing air manifold bracket to

inlet manifold.

5.Remove air manifold.

Refit

1.Clean air manifold and cylinder head adaptors.

2.Fit air manifold and start union nuts.

3.Fit nut securing air manifold to inlet manifold.

4.Tighten air manifold unions to 25 Nm.

5.Fit heater feed pipe.

+ HEATING AND VENTILATION,

REPAIRS, Pipe - Heater - Feed.

6.Fit SAI control valve.

+ EMISSION CONTROL - V8,

REPAIRS, Control Valve - Secondary Air

Injection (SAI).

M17 0234

4

3

2

2

M17 0223

43

3

5

Page 389 of 1672

EMISSION CONTROL - V8

17-2-52 REPAIRS

Solenoid - Vacuum - Secondary Air

Injection (SAI)

$% 17.25.47

Remove

1.Release multiplug from solenoid.

2.Disconnect 2 vacuum hoses from solenoid.

3.Release solenoid from mounting bracket and

remove.

Refit

1.Secure solenoid to mounting bracket.

2.Connect vacuum hoses and multiplug to

solenoid.

Pipe - Secondary Air Injection (SAI)

$% 17.25.59

Remove

1.Loosen clip securing RH SAI control valve hose

to air injection pipe.

2.Release hose from air injection pipe.

3.Loosen clip securing SAI pump hose to air

injection pipe.

4.Release hose from air injection pipe.

5.Loosen clip securing LH SAI control valve hose

to air injection pipe.

6.Release hose from air injection pipe.

7.Disconnect multiplug from SAI vacuum

solenoid.

M17 0236

1

2

2

3

M17 0230

Page 390 of 1672

EMISSION CONTROL - V8

REPAIRS 17-2-53

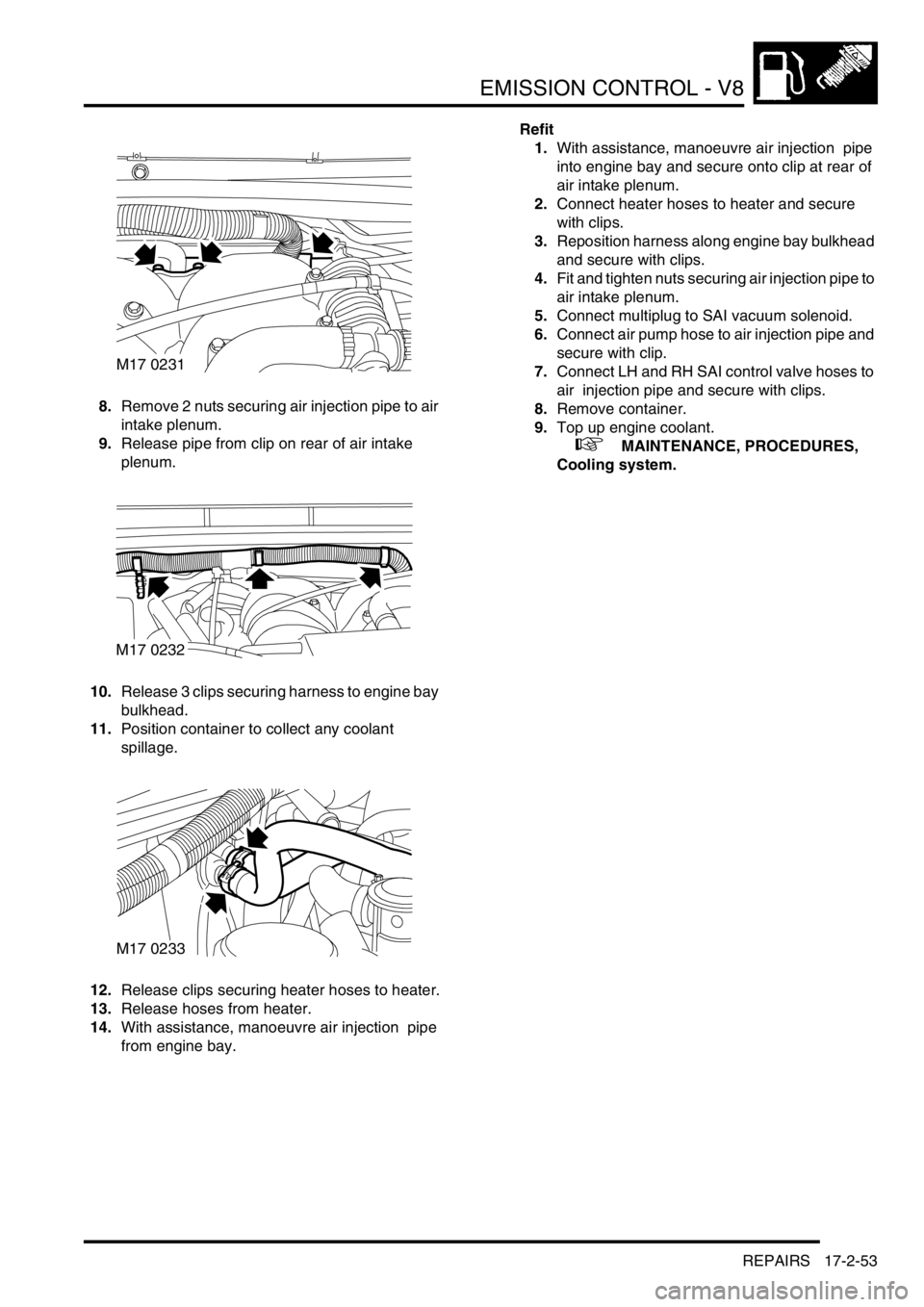

8.Remove 2 nuts securing air injection pipe to air

intake plenum.

9.Release pipe from clip on rear of air intake

plenum.

10.Release 3 clips securing harness to engine bay

bulkhead.

11.Position container to collect any coolant

spillage.

12.Release clips securing heater hoses to heater.

13.Release hoses from heater.

14.With assistance, manoeuvre air injection pipe

from engine bay.Refit

1.With assistance, manoeuvre air injection pipe

into engine bay and secure onto clip at rear of

air intake plenum.

2.Connect heater hoses to heater and secure

with clips.

3.Reposition harness along engine bay bulkhead

and secure with clips.

4.Fit and tighten nuts securing air injection pipe to

air intake plenum.

5.Connect multiplug to SAI vacuum solenoid.

6.Connect air pump hose to air injection pipe and

secure with clip.

7.Connect LH and RH SAI control valve hoses to

air injection pipe and secure with clips.

8.Remove container.

9.Top up engine coolant.

+ MAINTENANCE, PROCEDURES,

Cooling system.

M17 0231

M17 0232

M17 0233

Page 391 of 1672

EMISSION CONTROL - V8

17-2-54 REPAIRS

Pump - Fuel Leak Detection - up to 03MY

$% 17.45.41

Remove

1.Raise the vehicle on lift.

2.Disconnect multiplug from fuel leak detection

pump.

3.Release leak detection air filter hose from top of

pump.

4.Remove 3 Torx screws securing pump to

mounting bracket.

5.Remove clip securing EVAP canister hose to

pump.

6.Release EVAP canister hose from pump.

7.Remove pump.

Refit

1.Connect EVAP canister hose to pump and

secure with clip.

2.Position pump to mounting bracket and secure

with Torx screws.

3.Connect leak detection air filter hose to top of

leak detection pump.

4.Connect multiplug to pump.

5.Lower vehicle.

Pump - fuel leak detection - from 03MY

$% 17.45.41

Remove

1.Raise the vehicle on lift.

2.Disconnect multiplug from the fuel leak

detection pump.

3.Remove 3 screws securing the fuel leak

detection pump to the chassis mounting

bracket.

4.Position absorbent cloth around fuel hoses to

collect any fuel spillage.

5.Disconnect the fuel leak detection filter pipe

from the fuel leak detection pump.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove and discard clip securing EVAP pipe

to the fuel leak detection pump and disconnect

the pipe.

7.Remove the fuel leak detection pump.

Refit

1.Connect the EVAP pipe to the fuel leak

detection pump and secure with a new clip.

2.Connect the fuel leak detection filter pipe to the

fuel leak detection pump.

3.Remove absorbent cloth.

4.Fit and tighten 3 screws securing the fuel leak

detection pump to the chassis mounting

bracket.

5.Connect multiplug to the fuel leak detection

pump.

6.Lower the vehicle lift.

M17 0235

2

3

4

57

Page 392 of 1672

EMISSION CONTROL - V8

REPAIRS 17-2-55

Filter - fuel leak detection pump - up to

03MY

$% 17.45.42

Remove

1.Remove bolt securing air filter to mounting

bracket and collect nut.

2.Remove clip securing hose to air filter.

3.Release hose from air filter.

4.Remove air filter.

Refit

1.Connect hose to air filter and secure with clip.

2.Position air filter to mounting bracket and

secure with nut and bolt.

Filter - fuel leak detection pump - from

03MY

$% 17.45.42

Remove

1.Remove Allen bolt securing fuel leak detection

pump filter to the mounting bracket.

2.Remove and discard clip securing fuel pipe to

the fuel leak detection pump filter and

disconnect the pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

3.Remove the fuel leak detection pump filter.

Refit

1.Connect fuel pipe to the fuel leak detection

pump and secure with a new clip.

2.Position fuel leak detection pump filter to

mounting bracket, fit Allen bolt and tighten to 3

Nm (2.2 lbf.ft).

17M 0224

Page 398 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-5

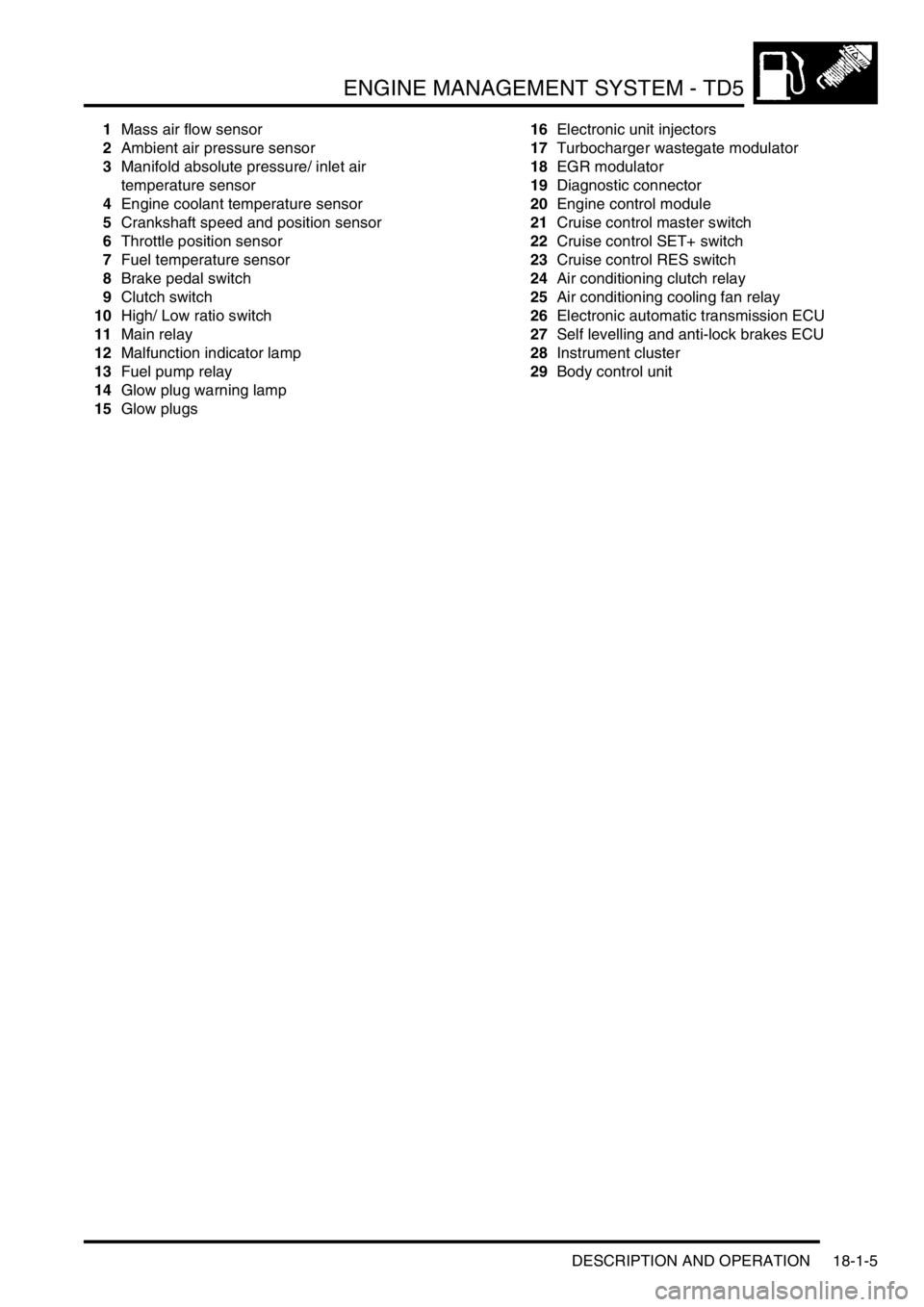

1Mass air flow sensor

2Ambient air pressure sensor

3Manifold absolute pressure/ inlet air

temperature sensor

4Engine coolant temperature sensor

5Crankshaft speed and position sensor

6Throttle position sensor

7Fuel temperature sensor

8Brake pedal switch

9Clutch switch

10High/ Low ratio switch

11Main relay

12Malfunction indicator lamp

13Fuel pump relay

14Glow plug warning lamp

15Glow plugs16Electronic unit injectors

17Turbocharger wastegate modulator

18EGR modulator

19Diagnostic connector

20Engine control module

21Cruise control master switch

22Cruise control SET+ switch

23Cruise control RES switch

24Air conditioning clutch relay

25Air conditioning cooling fan relay

26Electronic automatic transmission ECU

27Self levelling and anti-lock brakes ECU

28Instrument cluster

29Body control unit

Page 402 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-9

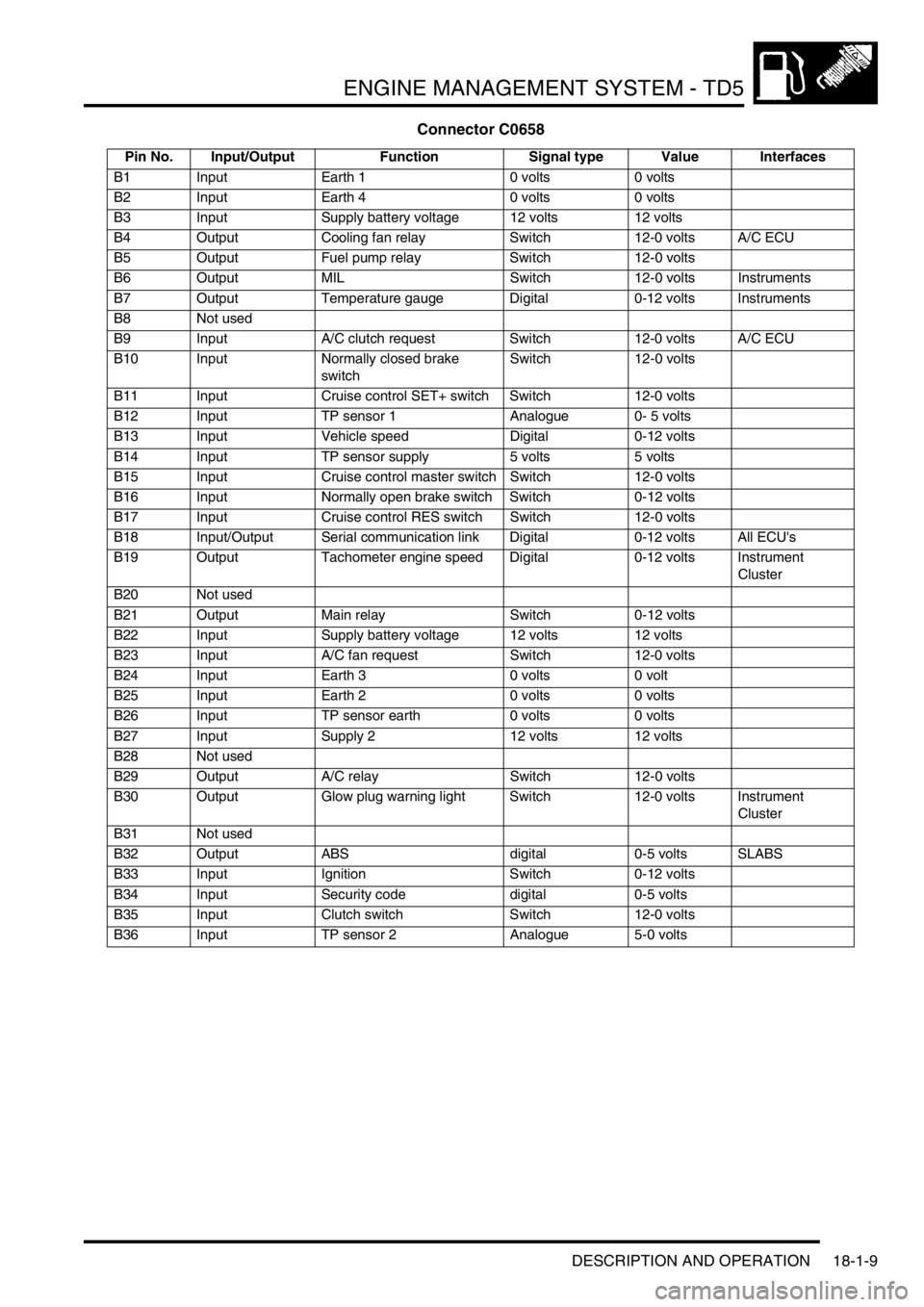

Connector C0658

Pin No. Input/Output Function Signal type Value Interfaces

B1 Input Earth 1 0 volts 0 volts

B2 Input Earth 4 0 volts 0 volts

B3 Input Supply battery voltage 12 volts 12 volts

B4 Output Cooling fan relay Switch 12-0 volts A/C ECU

B5 Output Fuel pump relay Switch 12-0 volts

B6 Output MIL Switch 12-0 volts Instruments

B7 Output Temperature gauge Digital 0-12 volts Instruments

B8 Not used

B9 Input A/C clutch request Switch 12-0 volts A/C ECU

B10 Input Normally closed brake

switchSwitch 12-0 volts

B11 Input Cruise control SET+ switch Switch 12-0 volts

B12 Input TP sensor 1 Analogue 0- 5 volts

B13 Input Vehicle speed Digital 0-12 volts

B14 Input TP sensor supply 5 volts 5 volts

B15 Input Cruise control master switch Switch 12-0 volts

B16 Input Normally open brake switch Switch 0-12 volts

B17 Input Cruise control RES switch Switch 12-0 volts

B18 Input/Output Serial communication link Digital 0-12 volts All ECU's

B19 Output Tachometer engine speed Digital 0-12 volts Instrument

Cluster

B20 Not used

B21 Output Main relay Switch 0-12 volts

B22 Input Supply battery voltage 12 volts 12 volts

B23 Input A/C fan request Switch 12-0 volts

B24 Input Earth 3 0 volts 0 volt

B25 Input Earth 2 0 volts 0 volts

B26 Input TP sensor earth 0 volts 0 volts

B27 Input Supply 2 12 volts 12 volts

B28 Not used

B29 Output A/C relay Switch 12-0 volts

B30 Output Glow plug warning light Switch 12-0 volts Instrument

Cluster

B31 Not used

B32 Output ABS digital 0-5 volts SLABS

B33 Input Ignition Switch 0-12 volts

B34 Input Security code digital 0-5 volts

B35 Input Clutch switch Switch 12-0 volts

B36 Input TP sensor 2 Analogue 5-0 volts