ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 315 of 1672

ENGINE - V8

12-2-72 OVERHAUL

9.Check clearance between connecting rods on

each crankshaft journal.

l Connecting rod clearance = 0.15 to 0.36

mm (0.006 to 0.014 in).

10.Fit oil pick up strainer.

+ ENGINE - V8, OVERHAUL, Strainer

- oil pick-up.

Crankshaft and main bearings

$% 12.21.33.01

Disassembly

1.Remove crankshaft rear oil seal.

+ ENGINE - V8, OVERHAUL, Seal -

crankshaft - rear - automatic models.

2.Remove timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

3.Remove bolt securing camshaft gear.

4.Remove timing chain and gears.

5.Remove connecting rod bearings.

+ ENGINE - V8, OVERHAUL, Bearings

- connecting rods.

Page 316 of 1672

ENGINE - V8

OVERHAUL 12-2-73

6.Reference mark main bearing caps to aid

assembly.

7.Remove 10 side bolts securing main bearing

caps to block.

8.Collect 'Dowty' washers from side bolts. Rear

side bolts have Allen heads.

9.Starting at the centre main bearing cap,

progressively loosen, then remove 2 bolts

securing each main bearing cap.

10.Release and remove main bearing caps.

CAUTION: Keep bearing caps, bearings and

bolts in their fitted order.

11.Remove crankshaft.

12.Remove main bearings from cylinder block and

main bearing caps.

13.Remove key from keyway.

14.Remove rear main sealing washers.

Inspect

1.Clean crankshaft journals and bearing

locations in cylinder block.

2.Inspect main bearings for wear and renew if

necessary. Main bearings are available in two

oversizes. If 2nd oversize bearing is being

fitted, it may be necessary to grind thrust

face of centre main bearing to achieve

correct end-float.

lMain bearing 1st oversize = 0.254 mm (0.01

in).

lMain bearing 2nd oversize = 0.508 mm

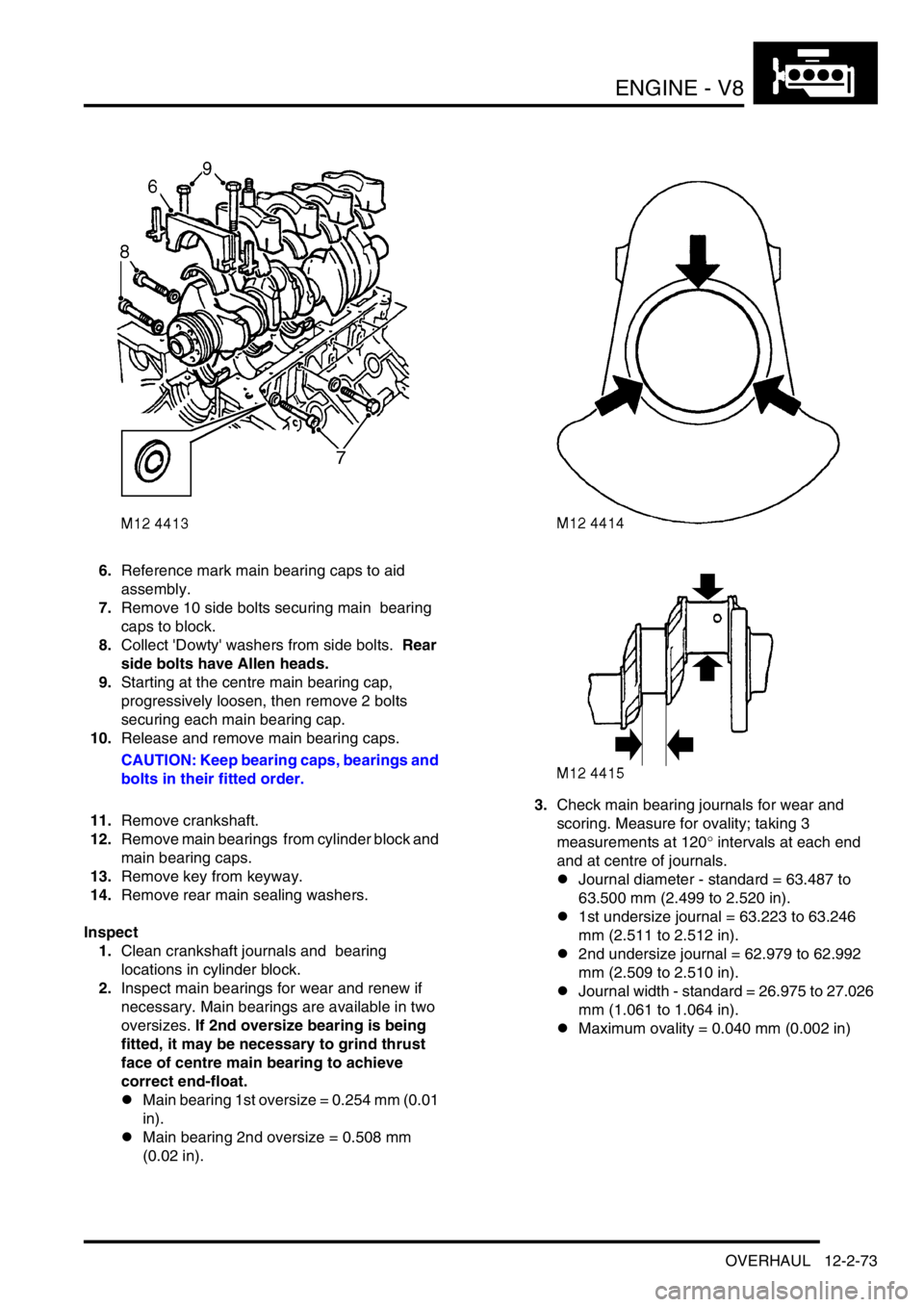

(0.02 in).3.Check main bearing journals for wear and

scoring. Measure for ovality; taking 3

measurements at 120

° intervals at each end

and at centre of journals.

lJournal diameter - standard = 63.487 to

63.500 mm (2.499 to 2.520 in).

l1st undersize journal = 63.223 to 63.246

mm (2.511 to 2.512 in).

l2nd undersize journal = 62.979 to 62.992

mm (2.509 to 2.510 in).

lJournal width - standard = 26.975 to 27.026

mm (1.061 to 1.064 in).

lMaximum ovality = 0.040 mm (0.002 in)

Page 319 of 1672

ENGINE - V8

12-2-76 OVERHAUL

Camshaft

$% 12.13.02.01

Disassembly

1.Remove inlet manifold gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

inlet manifold.

2.Progressively loosen and remove 8 bolts

securing rocker shaft assemblies.

3.Mark each rocker shaft in relation to original

head.

4.Remove rocker shaft assemblies.

5.Remove push rods and store in their fitted

order.

6.Remove tappets.

7.Remove timing chain and gears.

+ ENGINE - V8, OVERHAUL, Timing

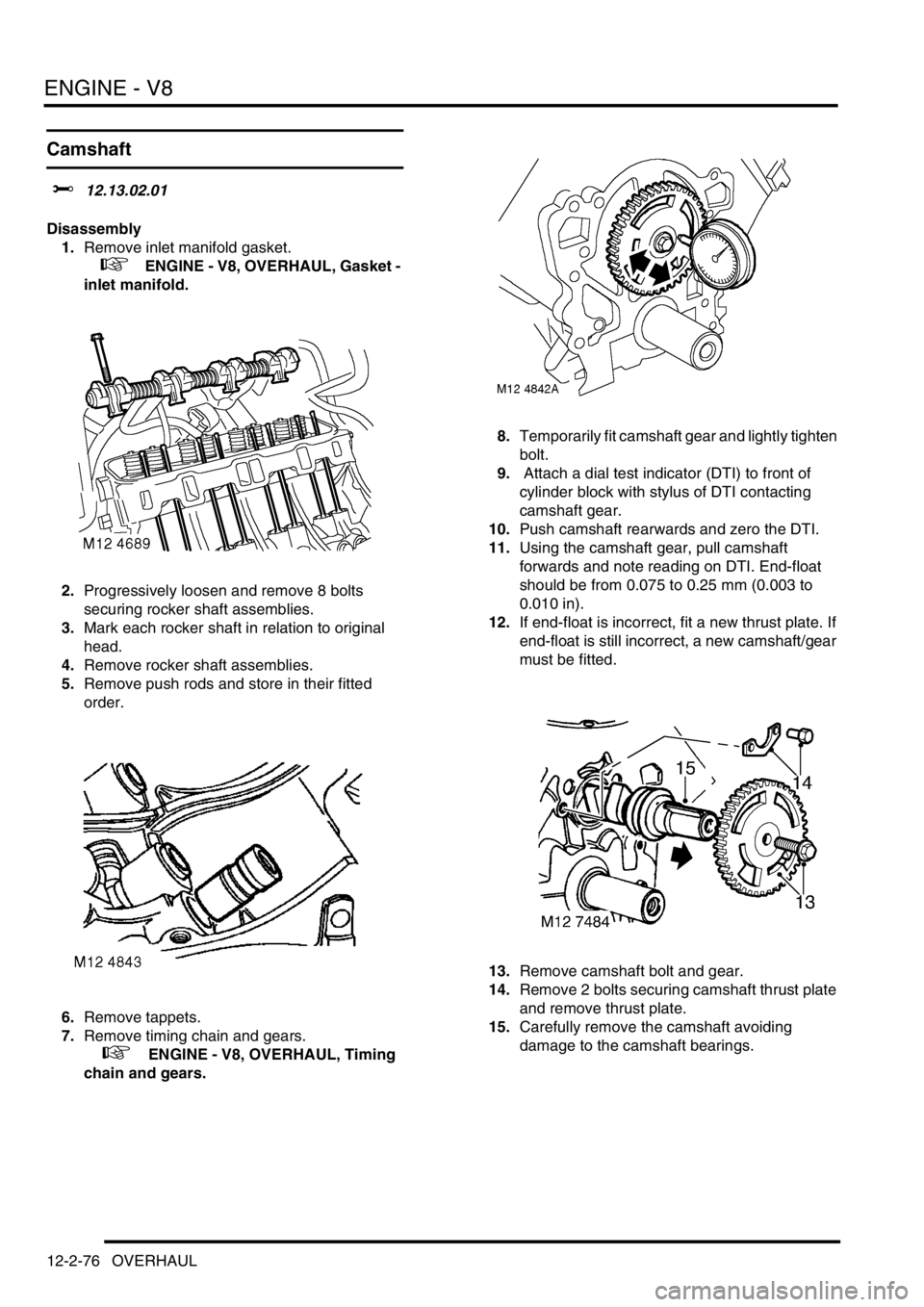

chain and gears.8.Temporarily fit camshaft gear and lightly tighten

bolt.

9. Attach a dial test indicator (DTI) to front of

cylinder block with stylus of DTI contacting

camshaft gear.

10.Push camshaft rearwards and zero the DTI.

11.Using the camshaft gear, pull camshaft

forwards and note reading on DTI. End-float

should be from 0.075 to 0.25 mm (0.003 to

0.010 in).

12.If end-float is incorrect, fit a new thrust plate. If

end-float is still incorrect, a new camshaft/gear

must be fitted.

13.Remove camshaft bolt and gear.

14.Remove 2 bolts securing camshaft thrust plate

and remove thrust plate.

15.Carefully remove the camshaft avoiding

damage to the camshaft bearings.

Page 327 of 1672

EMISSION CONTROL - TD5

17-1-6 DESCRIPTION AND OPERATION

The EGR modulator is located on a plate fixed to the inner wing on the RH side of the engine. The modulator is

attached to the plate by two through-studs, each with two nuts which secure the modulator assembly to a rubber

mounting which helps to reduce noise. The modulator must be mounted in the vertical orientation with the two vacuum

ports uppermost.

The modulator operation is controlled by a signal from the ECM which determines the required amount of EGR

needed in response to inputs relating to air flow and engine operating and ambient conditions. The modulator has a

black two-pin connector at its base to connect it to the ECM through the engine harness.

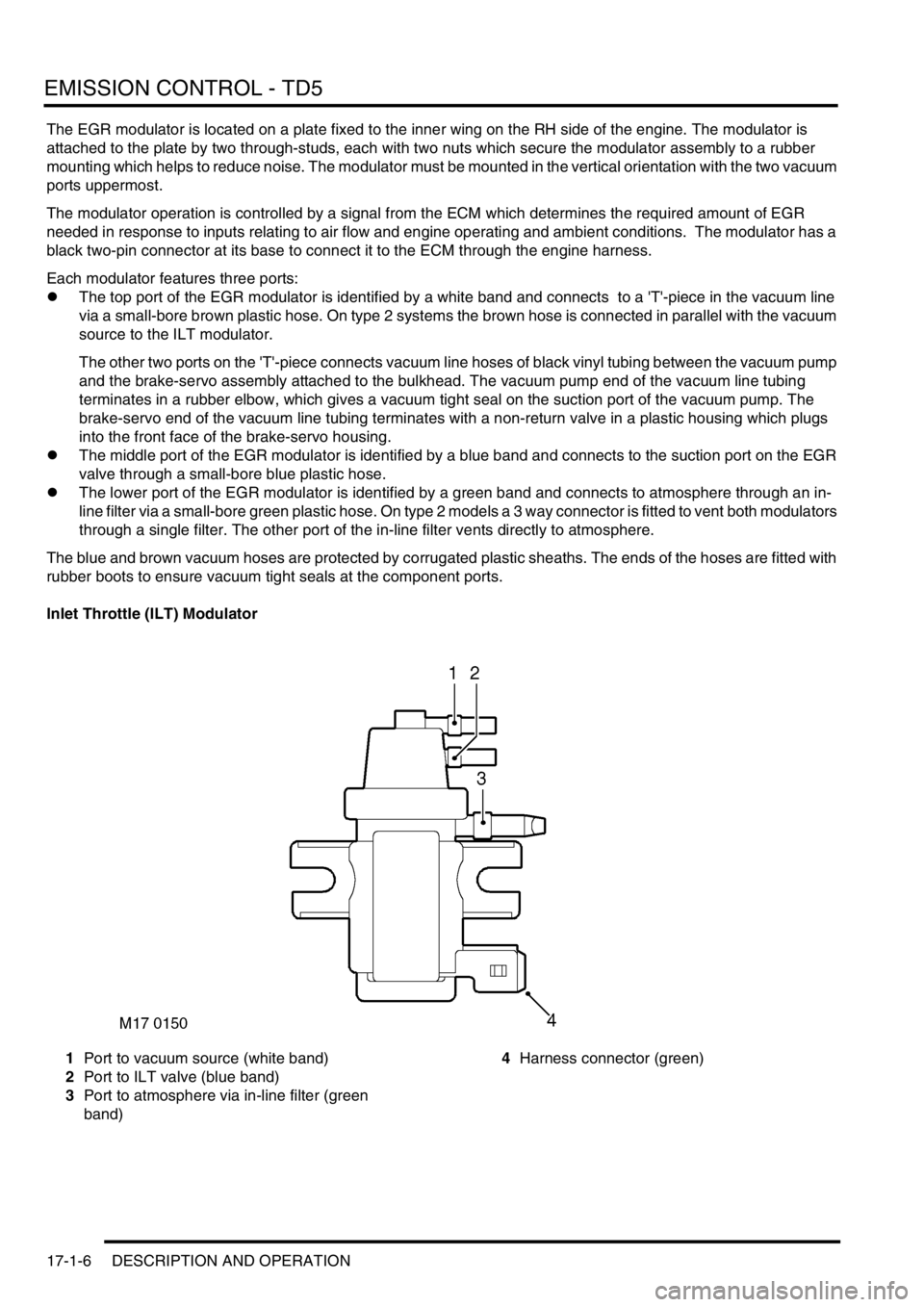

Each modulator features three ports:

lThe top port of the EGR modulator is identified by a white band and connects to a 'T'-piece in the vacuum line

via a small-bore brown plastic hose. On type 2 systems the brown hose is connected in parallel with the vacuum

source to the ILT modulator.

The other two ports on the 'T'-piece connects vacuum line hoses of black vinyl tubing between the vacuum pump

and the brake-servo assembly attached to the bulkhead. The vacuum pump end of the vacuum line tubing

terminates in a rubber elbow, which gives a vacuum tight seal on the suction port of the vacuum pump. The

brake-servo end of the vacuum line tubing terminates with a non-return valve in a plastic housing which plugs

into the front face of the brake-servo housing.

lThe middle port of the EGR modulator is identified by a blue band and connects to the suction port on the EGR

valve through a small-bore blue plastic hose.

lThe lower port of the EGR modulator is identified by a green band and connects to atmosphere through an in-

line filter via a small-bore green plastic hose. On type 2 models a 3 way connector is fitted to vent both modulators

through a single filter. The other port of the in-line filter vents directly to atmosphere.

The blue and brown vacuum hoses are protected by corrugated plastic sheaths. The ends of the hoses are fitted with

rubber boots to ensure vacuum tight seals at the component ports.

Inlet Throttle (ILT) Modulator

1Port to vacuum source (white band)

2Port to ILT valve (blue band)

3Port to atmosphere via in-line filter (green

band)4Harness connector (green)

Page 328 of 1672

EMISSION CONTROL - TD5

DESCRIPTION AND OPERATION 17-1-7

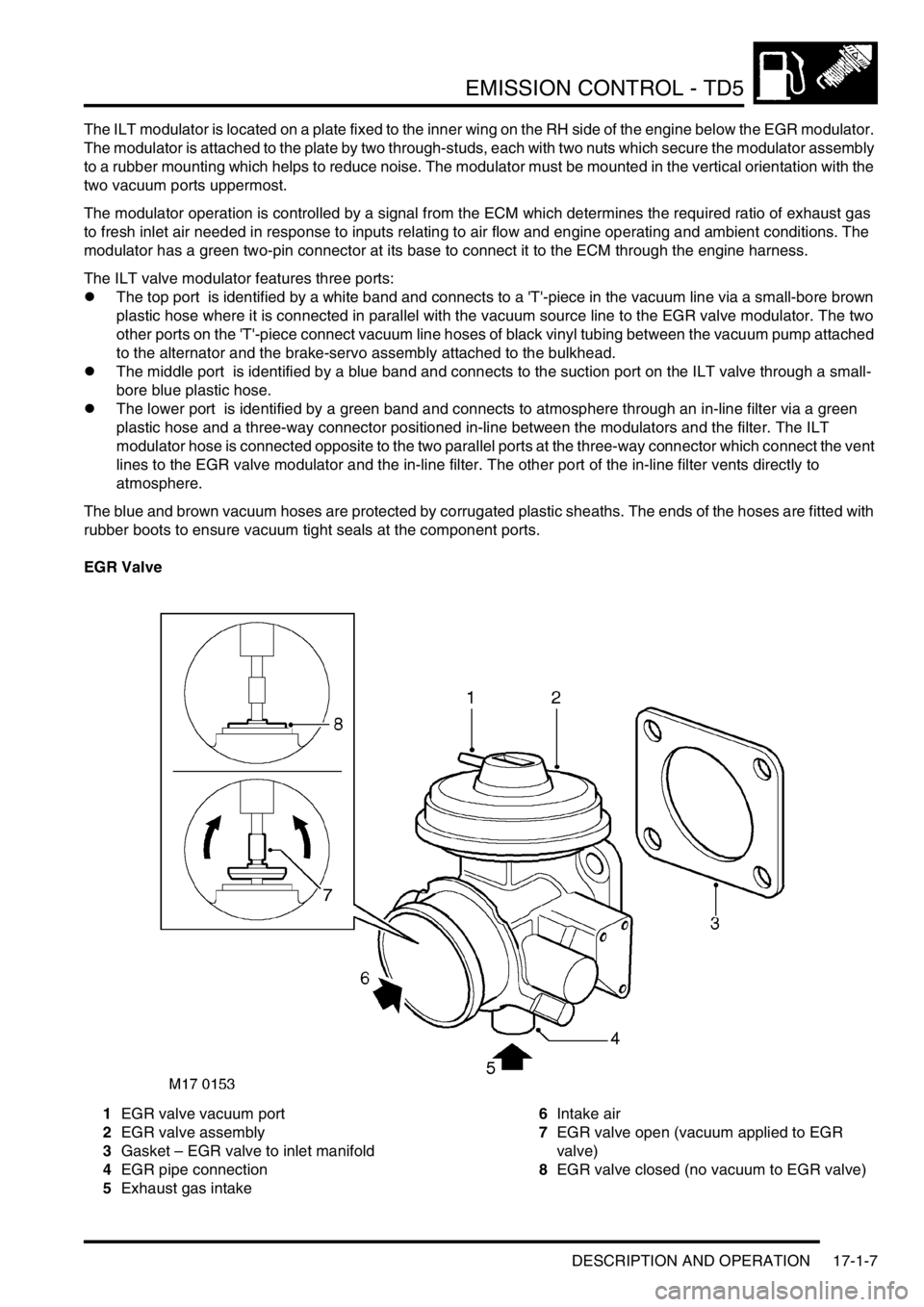

The ILT modulator is located on a plate fixed to the inner wing on the RH side of the engine below the EGR modulator.

The modulator is attached to the plate by two through-studs, each with two nuts which secure the modulator assembly

to a rubber mounting which helps to reduce noise. The modulator must be mounted in the vertical orientation with the

two vacuum ports uppermost.

The modulator operation is controlled by a signal from the ECM which determines the required ratio of exhaust gas

to fresh inlet air needed in response to inputs relating to air flow and engine operating and ambient conditions. The

modulator has a green two-pin connector at its base to connect it to the ECM through the engine harness.

The ILT valve modulator features three ports:

lThe top port is identified by a white band and connects to a 'T'-piece in the vacuum line via a small-bore brown

plastic hose where it is connected in parallel with the vacuum source line to the EGR valve modulator. The two

other ports on the 'T'-piece connect vacuum line hoses of black vinyl tubing between the vacuum pump attached

to the alternator and the brake-servo assembly attached to the bulkhead.

lThe middle port is identified by a blue band and connects to the suction port on the ILT valve through a small-

bore blue plastic hose.

lThe lower port is identified by a green band and connects to atmosphere through an in-line filter via a green

plastic hose and a three-way connector positioned in-line between the modulators and the filter. The ILT

modulator hose is connected opposite to the two parallel ports at the three-way connector which connect the vent

lines to the EGR valve modulator and the in-line filter. The other port of the in-line filter vents directly to

atmosphere.

The blue and brown vacuum hoses are protected by corrugated plastic sheaths. The ends of the hoses are fitted with

rubber boots to ensure vacuum tight seals at the component ports.

EGR Valve

1EGR valve vacuum port

2EGR valve assembly

3Gasket – EGR valve to inlet manifold

4EGR pipe connection

5Exhaust gas intake6Intake air

7EGR valve open (vacuum applied to EGR

valve)

8EGR valve closed (no vacuum to EGR valve)

Page 331 of 1672

EMISSION CONTROL - TD5

17-1-10 DESCRIPTION AND OPERATION

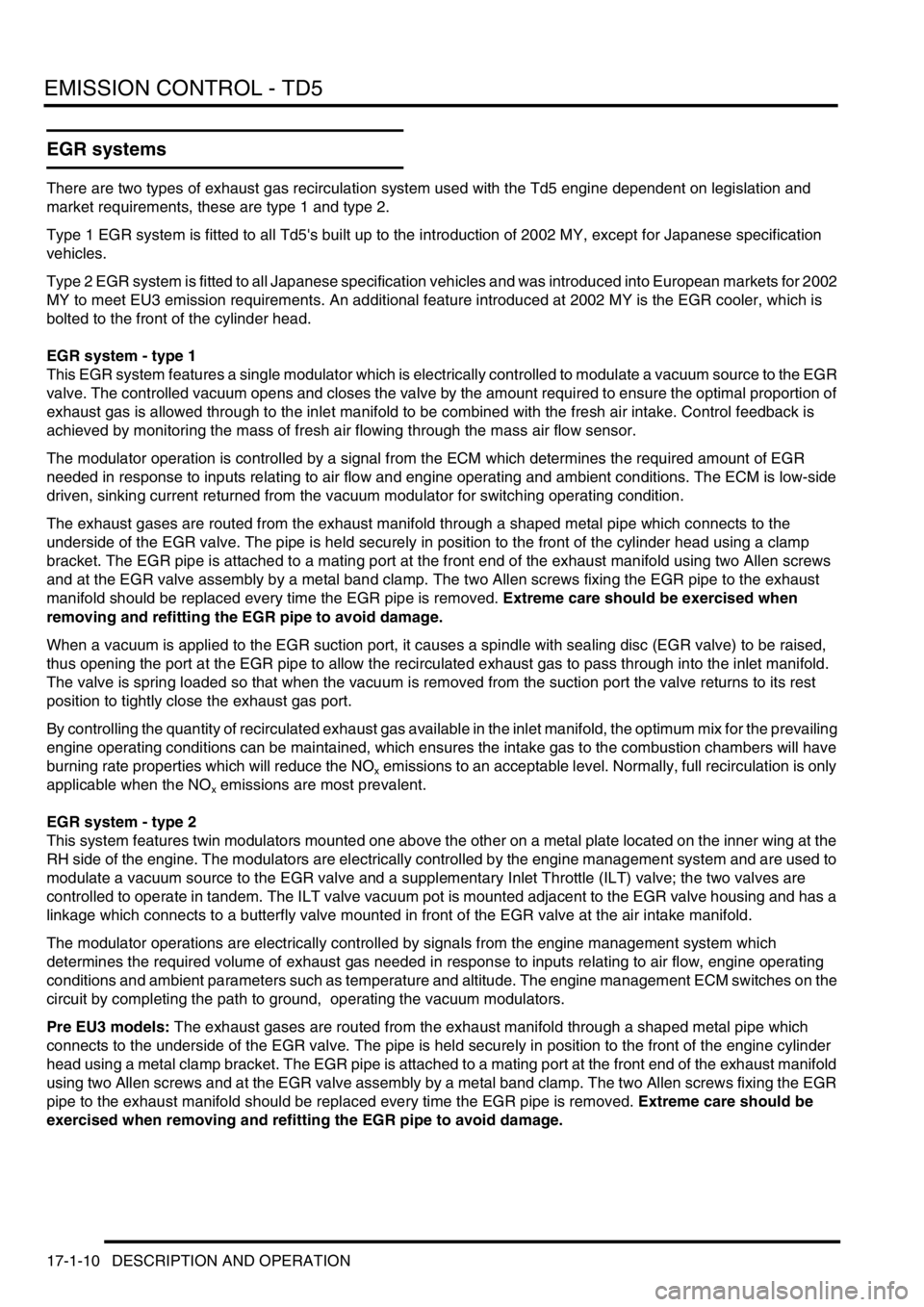

EGR systems

There are two types of exhaust gas recirculation system used with the Td5 engine dependent on legislation and

market requirements, these are type 1 and type 2.

Type 1 EGR system is fitted to all Td5's built up to the introduction of 2002 MY, except for Japanese specification

vehicles.

Type 2 EGR system is fitted to all Japanese specification vehicles and was introduced into European markets for 2002

MY to meet EU3 emission requirements. An additional feature introduced at 2002 MY is the EGR cooler, which is

bolted to the front of the cylinder head.

EGR system - type 1

This EGR system features a single modulator which is electrically controlled to modulate a vacuum source to the EGR

valve. The controlled vacuum opens and closes the valve by the amount required to ensure the optimal proportion of

exhaust gas is allowed through to the inlet manifold to be combined with the fresh air intake. Control feedback is

achieved by monitoring the mass of fresh air flowing through the mass air flow sensor.

The modulator operation is controlled by a signal from the ECM which determines the required amount of EGR

needed in response to inputs relating to air flow and engine operating and ambient conditions. The ECM is low-side

driven, sinking current returned from the vacuum modulator for switching operating condition.

The exhaust gases are routed from the exhaust manifold through a shaped metal pipe which connects to the

underside of the EGR valve. The pipe is held securely in position to the front of the cylinder head using a clamp

bracket. The EGR pipe is attached to a mating port at the front end of the exhaust manifold using two Allen screws

and at the EGR valve assembly by a metal band clamp. The two Allen screws fixing the EGR pipe to the exhaust

manifold should be replaced every time the EGR pipe is removed. Extreme care should be exercised when

removing and refitting the EGR pipe to avoid damage.

When a vacuum is applied to the EGR suction port, it causes a spindle with sealing disc (EGR valve) to be raised,

thus opening the port at the EGR pipe to allow the recirculated exhaust gas to pass through into the inlet manifold.

The valve is spring loaded so that when the vacuum is removed from the suction port the valve returns to its rest

position to tightly close the exhaust gas port.

By controlling the quantity of recirculated exhaust gas available in the inlet manifold, the optimum mix for the prevailing

engine operating conditions can be maintained, which ensures the intake gas to the combustion chambers will have

burning rate properties which will reduce the NO

x emissions to an acceptable level. Normally, full recirculation is only

applicable when the NO

x emissions are most prevalent.

EGR system - type 2

This system features twin modulators mounted one above the other on a metal plate located on the inner wing at the

RH side of the engine. The modulators are electrically controlled by the engine management system and are used to

modulate a vacuum source to the EGR valve and a supplementary Inlet Throttle (ILT) valve; the two valves are

controlled to operate in tandem. The ILT valve vacuum pot is mounted adjacent to the EGR valve housing and has a

linkage which connects to a butterfly valve mounted in front of the EGR valve at the air intake manifold.

The modulator operations are electrically controlled by signals from the engine management system which

determines the required volume of exhaust gas needed in response to inputs relating to air flow, engine operating

conditions and ambient parameters such as temperature and altitude. The engine management ECM switches on the

circuit by completing the path to ground, operating the vacuum modulators.

Pre EU3 models: The exhaust gases are routed from the exhaust manifold through a shaped metal pipe which

connects to the underside of the EGR valve. The pipe is held securely in position to the front of the engine cylinder

head using a metal clamp bracket. The EGR pipe is attached to a mating port at the front end of the exhaust manifold

using two Allen screws and at the EGR valve assembly by a metal band clamp. The two Allen screws fixing the EGR

pipe to the exhaust manifold should be replaced every time the EGR pipe is removed. Extreme care should be

exercised when removing and refitting the EGR pipe to avoid damage.

Page 332 of 1672

EMISSION CONTROL - TD5

DESCRIPTION AND OPERATION 17-1-11

EU3 models: The exhaust gases are routed from the exhaust manifold through the EGR cooler to the underside of

the EGR valve. The EGR cooler is bolted to the front of the engine cylinder head. An EGR pipe connects the EGR

cooler to the exhaust manifold and is secured by two Allen screws. The two Allen screws fixing the EGR pipe to the

exhaust manifold should be replaced every time the EGR pipe is removed. A second pipe connects the EGR cooler

to the EGR valve; this pipe is secured to the EGR valve by a clip, and to the cooler by two Allen screws.Extreme care

should be exercised when removing and refitting the EGR pipe to avoid damage. When refitting the EGR

cooler, always tighten the pipe connections BEFORE tightening the bolts securing the cooler to the cylinder

head.

When a vacuum is applied to the EGR suction port, it causes a spindle with sealing disc (EGR valve) to be raised,

opening the port at the EGR pipe to allow the recirculated exhaust gas to pass through into the inlet manifold. The

valve is spring loaded so that when the vacuum is removed from the suction port, the valve returns to its rest position

to tightly close the exhaust gas port.

A vacuum is simultaneously applied to the inlet throttle (ILT) valve suction port which causes the butterfly valve in the

inlet manifold to close by means of a spindle and lever mechanism. Closing the butterfly valve limits the supply of

fresh intercooled air entering the inlet manifold and causes a depression within the inlet manifold to create a greater

suction at the open port to the EGR delivery pipe. In this condition a greater mass of recirculated exhaust gas is drawn

into the inlet manifold for use in the combustion process. When the vacuum is released from the ILT valve suction port

a spring returns the butterfly valve to its fully open position.

By controlling the quantities of recirculated exhaust gas and fresh intake air available in the inlet manifold, the

optimum mix for the prevailing engine operating conditions can be maintained which ensures the intake gas to the

combustion chambers will have burning rate properties which will reduce the NO

x emissions to an acceptable level.

Normally, full recirculation is only applicable when the NO

x emissions are most prevalent.

Page 334 of 1672

EMISSION CONTROL - TD5

REPAIRS 17-1-13

REPAIRS

Modulator - EGR

$% 17.45.04

There are two types of modulator fitted. System type

1 has a single modulator, and type 2 has a second

modulator (ILT modulator) bolted to the same

mounting plate.

Remove

1.Disconnect vacuum pipe(s) and multiplug(s)

from EGR modulator.

2.Remove 2 nuts and remove EGR modulator.

Refit

1.Position EGR modulator and tighten securing

nuts.

2.Connect vacuum hose(s) and multiplug(s).

Inlet Throttle (ILT) Modulator

$% 17.45.03

Remove

1.Identify the fitted positions of the 3 vacuum

pipes, then disconnect from the ILT modulator

valve.

2.Disconnect multiplug from ILT modulator.

3.Remove 2 nuts securing modulator and remove

ILT modulator from its mountings.

Refit

1.Fit ILT modulator to its mountings, fit the nuts

and tighten to 10 Nm (7 lbf.ft).

2.Connect vacuum pipes to the positions

identified during removal.

3.Connect multiplug to ILT modulator.

Page 335 of 1672

EMISSION CONTROL - TD5

17-1-14 REPAIRS

Valve - EGR - Pre EU3 models

$% 17.45.01

On all vehicles up to VIN number 1A736339, the

EGR pipe assembly must be replaced every time the

system is disturbed.

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Remove cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

5.Disconnect vacuum hose(s) from EGR valve.

6.Loosen clip and release air intake from EGR

valve.

7.Remove 4 bolts, release EGR valve from inlet

manifold and discard gasket.

8.Remove 2 bolts and release EGR valve clip

from cylinder head.

9.Remove and discard 2 bolts securing EGR

valve pipe to exhaust manifold. 10.Remove EGR valve assembly.

11.Remove clip and remove pipe from EGR valve.

Refit

1.Clean EGR valve and mating face on pipe.

2.Position pipe to EGR valve and fit retaining clip.

Fit bolt but do not tighten at this stage.

3.Position EGR valve assembly, locate pipe

flange to exhaust manifold, fit new bolts but do

not tighten at this stage.

4.Clean inlet manifold and EGR valve mating

faces.

5.Using new gasket, position EGR valve to inlet

manifold fit bolts and tighten to 10 Nm (7 lbf.ft).

6.Align EGR pipe clip to cylinder head, fit bolts

but do not tighten at this stage.

7.Tighten EGR pipe bolts to correct torque in

following sequence:

lEGR pipe retaining clip bolt 6 Nm (4.5 lbf.ft)

lEGR pipe clip to cylinder head bolts 10 Nm

(7 lbf.ft)

lEGR pipe flange to exhaust manifold bolts

10 Nm (7 lbf.ft)

8.Position air intake hose and tighten clip.

9.Connect vacuum hoses to EGR valve.

10.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

11.Connect battery earth lead.

12.Fit battery cover and secure the fixings.

Page 336 of 1672

EMISSION CONTROL - TD5

REPAIRS 17-1-15

Valve - EGR - EU3 models

$% 17.45.01

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Remove cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

5.Disconnect vacuum hose(s) from EGR valve.

6.Loosen clip screw and disconnect air intake

hose from EGR valve.

7.Remove screw and remove clamp securing

EGR pipe to EGR valve.

8.Remove 4 bolts securing EGR valve, remove

valve and discard gasket.

9.Discard EGR pipe gasket.Refit

1.Clean EGR valve and mating faces.

2.Fit new gasket to EGR pipe.

3.Using new gasket, position EGR valve to inlet

manifold fit bolts and tighten to 10 Nm (7 lbf.ft).

4.Fit EGR pipe clamp and tighten screw to 6 Nm

(4.4 lbf.ft).

5.Connect air intake hose to EGR valve and

tighten clip.

6.Connect vacuum hoses to EGR valve.

7.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

8.Fit engine acoustic cover and tighten bolts to

10 Nm (7 lbf.ft).

9.Connect battery earth lead.

10.Fit battery cover and secure the fixings.