handbrake LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 698 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-15

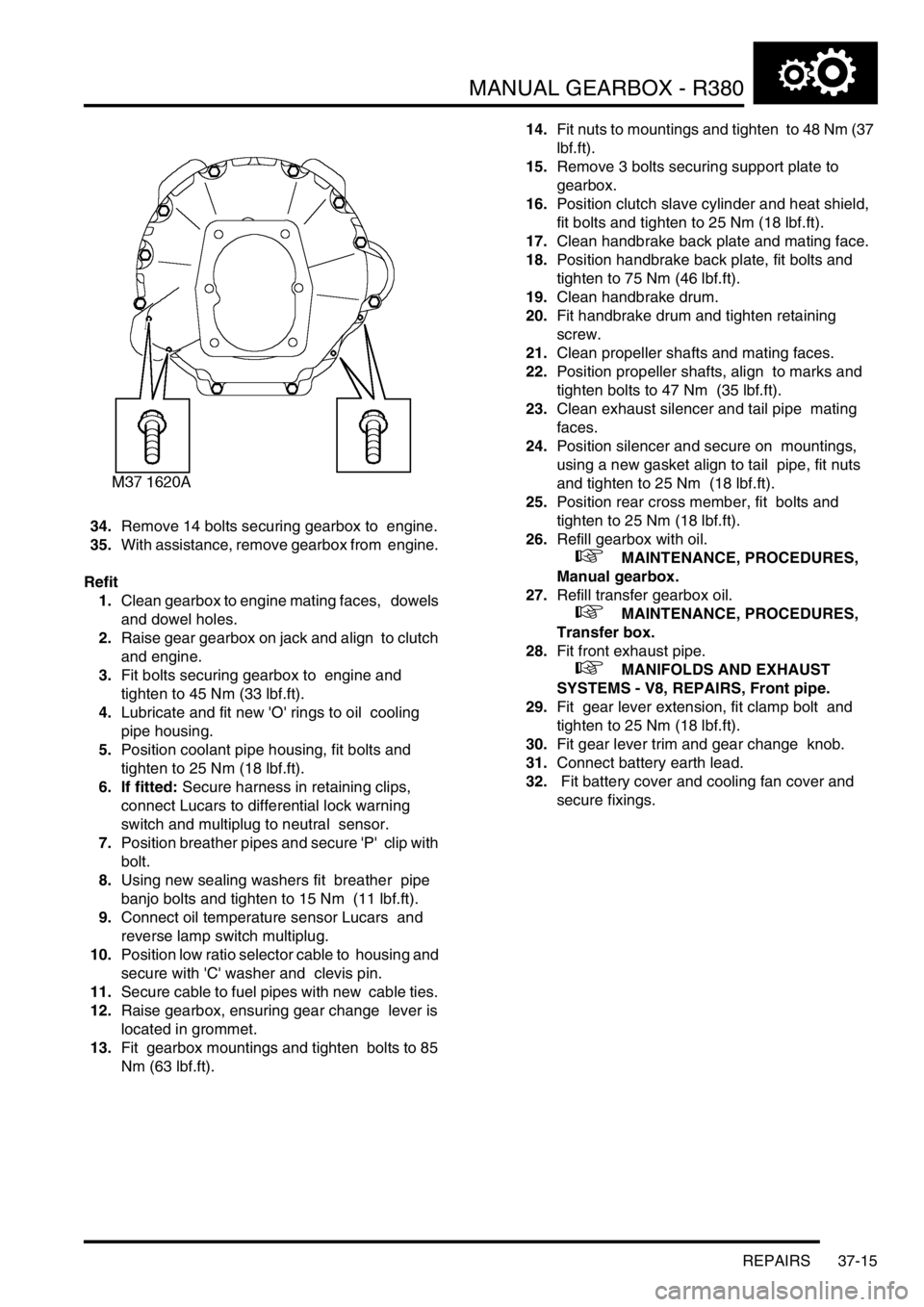

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft). 14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 700 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-17

14.Remove handbrake drum retaining screw and

remove handbrake drum.

15.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

16.Remove 2 bolts securing clutch slave cylinder,

collect heat shield, release slave cylinder and

position aside.

17.Fit support plate LRT-99-007 to gearbox jack.

18.Position gearbox jack and support plate to

gearbox and secure with 3 bolts. 19.Support the weight of gearbox, remove nuts

securing gearbox mountings to body.

20.Remove 4 bolts securing both mountings to

gearbox, raise gearbox and remove both

mountings.

21.Lower gearbox sufficiently to access top of

gearbox.

22.Ensure gear lever is released from grommet

and no wires or pipes are trapped when

gearbox is lowered.

Page 702 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-19

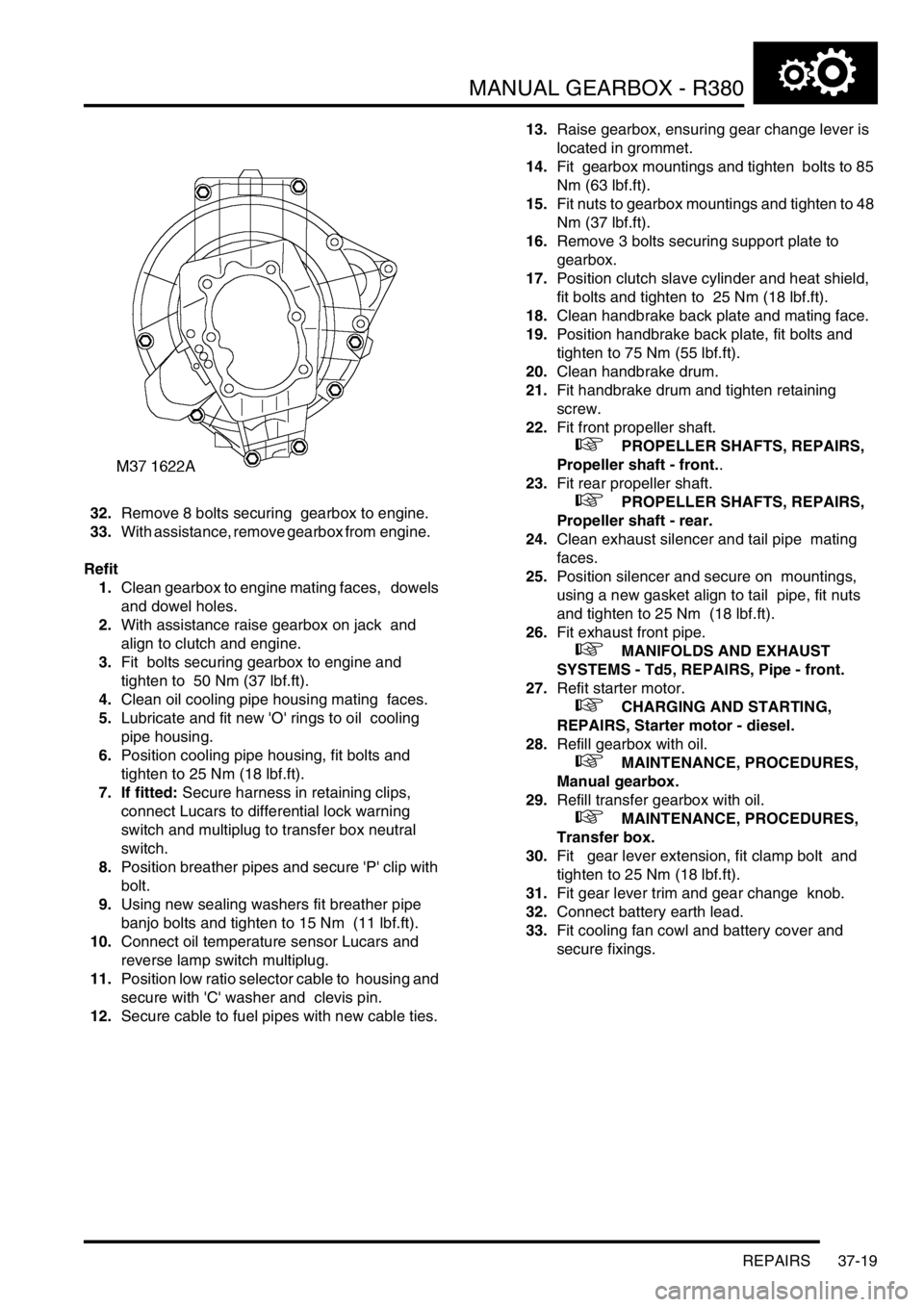

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties. 13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox.

17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.

Page 757 of 1672

TRANSFER BOX - LT230SE

41-24 REPAIRS

Transfer box - Diesel

$% 41.20.25.99

Remove

1.Remove front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

2.Raise vehicle on ramp.

3.Drain transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

4.Remove 3 nuts securing intermediate silencer

to tail pipe.

5.Release silencer from mounting rubbers.

6.Remove silencer and discard gasket.

7.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

8.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.9.Remove handbrake drum retaining screw and

remove drum.

10.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

11.Remove clevis pin securing high/low ratio

selector cable to selector lever, remove 'C' clip

and release outer cable from abutment bracket.

Page 759 of 1672

TRANSFER BOX - LT230SE

41-26 REPAIRS

Refit

1.Fit new input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

2.Clean transfer box to gearbox mating faces.

3.Raise transfer box on jack and align to guide

studs LRT-41-009.

4.Clean transfer box to gearbox bolt threads.

5.Apply Loctite 290 to bolt and stud threads.

6.Fit and lightly tighten 2 bolts and nut securing

transfer box to gearbox. If new stud is to be

fitted, apply Loctite 290 to stud threads and

tighten to 45 Nm (33 lbf.ft).

7.Remove guide studs, fit and lightly tighten

remaining 3 bolts.

8.Tighten bolts and nut by diagonal selection to

45 Nm (33 lbf.ft).

9.Position gearbox RH mounting and tighten

bolts to 85 Nm (63 lbf.ft).

10.Tighten gearbox RH mounting nut to 48 Nm

(35 lbf.ft).

11.Remove 4 bolts securing support plate to

gearbox jack.

12.Remove 4 bolts securing support plate LRT-99-

010 to transfer box and remove plate.

13.Clean bottom plate bolt threads.

14.Apply Loctite 290 to threads of 4 bottom plate

bolts.

15.Fit 4 bolts securing bottom plate to transfer box

and tighten to 25 Nm (18 lbf.ft).

16.Position breather pipe and secure to bulkhead

clip.

17.Connect multiplug to reverse light switch.

18. If fitted - Connect Lucars to differential lock

switch.

19.Fit multiplug and cable tie to transfer gearbox

bracket. 20.Position high/low ratio selector cable and

secure with clevis pin.

21.Clean handbrake and mating face.

22.Position handbrake back plate and tighten

bolts to 75 Nm (55 lbf.ft).

23.Clean handbrake drum.

24.Fit handbrake drum and tighten retaining

screw.

25.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

26.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

27.Clean exhaust silencer and mating face.

28.Position silencer, fit new gasket , connect

mounting rubbers and tighten nuts to 40 Nm

(30 lbf.ft).

29.Refill transfer box with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

Page 760 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-27

Transfer box - V8

$% 41.20.25.99

Remove

1.Remove front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

2.Drain transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

3.Remove 8 bolts securing rear cross member

and remove cross member.

4.Remove 3 nuts securing intermediate silencer

to tail pipe.

5.Release silencer from mounting rubbers,

remove silencer and discard gasket.

6.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

7.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.8.Remove handbrake drum retaining screw and

remove handbrake drum.

9.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

10.Remove clevis pin and 'C' washer securing

high/low ratio selector cable to selector lever

and release cable from abutment bracket.

Page 762 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-29

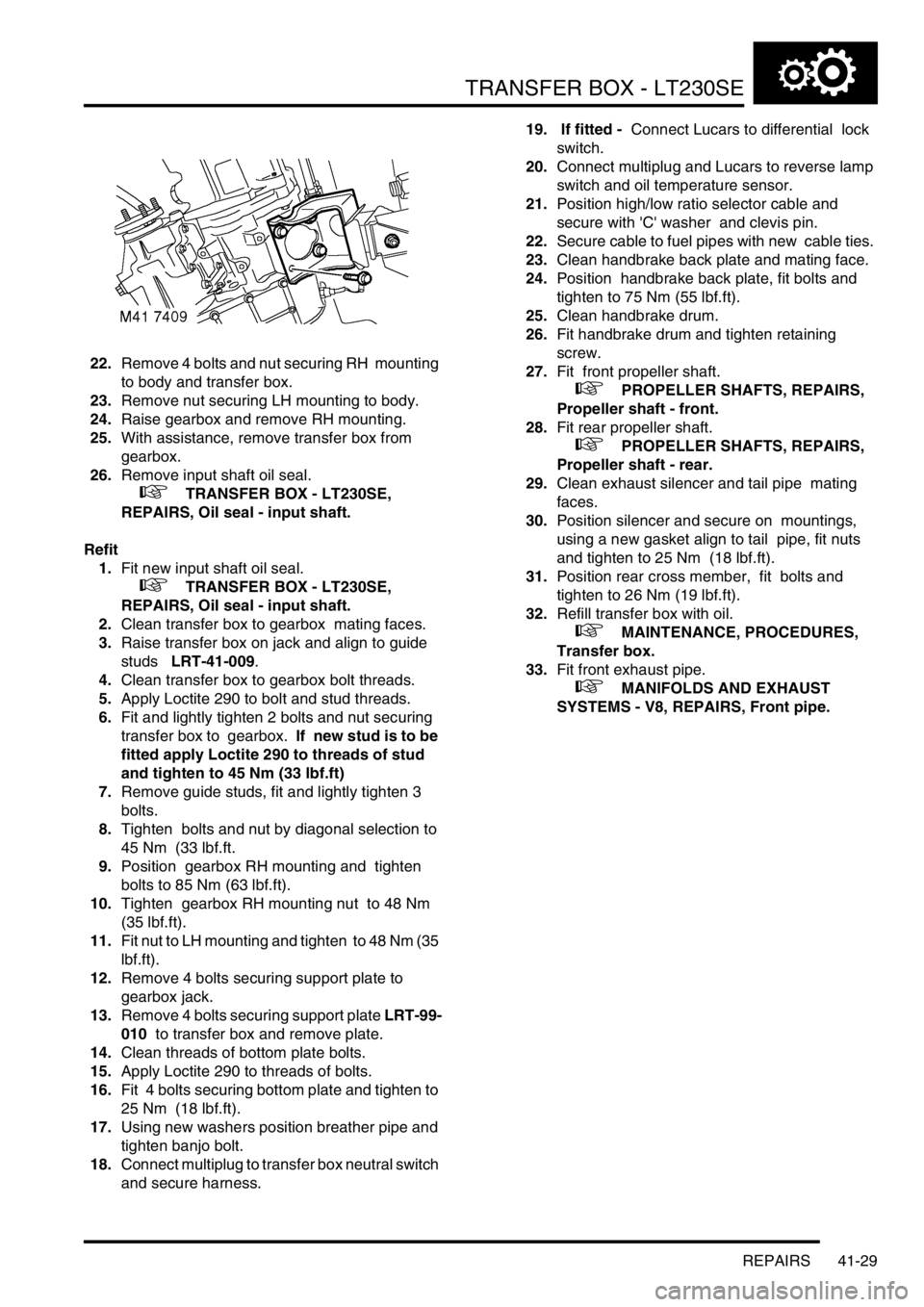

22.Remove 4 bolts and nut securing RH mounting

to body and transfer box.

23.Remove nut securing LH mounting to body.

24.Raise gearbox and remove RH mounting.

25.With assistance, remove transfer box from

gearbox.

26.Remove input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

Refit

1.Fit new input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

2.Clean transfer box to gearbox mating faces.

3.Raise transfer box on jack and align to guide

studs LRT-41-009.

4.Clean transfer box to gearbox bolt threads.

5.Apply Loctite 290 to bolt and stud threads.

6.Fit and lightly tighten 2 bolts and nut securing

transfer box to gearbox. If new stud is to be

fitted apply Loctite 290 to threads of stud

and tighten to 45 Nm (33 lbf.ft)

7.Remove guide studs, fit and lightly tighten 3

bolts.

8.Tighten bolts and nut by diagonal selection to

45 Nm (33 lbf.ft.

9.Position gearbox RH mounting and tighten

bolts to 85 Nm (63 lbf.ft).

10.Tighten gearbox RH mounting nut to 48 Nm

(35 lbf.ft).

11.Fit nut to LH mounting and tighten to 48 Nm (35

lbf.ft).

12.Remove 4 bolts securing support plate to

gearbox jack.

13.Remove 4 bolts securing support plate LRT-99-

010 to transfer box and remove plate.

14.Clean threads of bottom plate bolts.

15.Apply Loctite 290 to threads of bolts.

16.Fit 4 bolts securing bottom plate and tighten to

25 Nm (18 lbf.ft).

17.Using new washers position breather pipe and

tighten banjo bolt.

18.Connect multiplug to transfer box neutral switch

and secure harness. 19. If fitted - Connect Lucars to differential lock

switch.

20.Connect multiplug and Lucars to reverse lamp

switch and oil temperature sensor.

21.Position high/low ratio selector cable and

secure with 'C' washer and clevis pin.

22.Secure cable to fuel pipes with new cable ties.

23.Clean handbrake back plate and mating face.

24.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

25.Clean handbrake drum.

26.Fit handbrake drum and tighten retaining

screw.

27.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

28.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

29.Clean exhaust silencer and tail pipe mating

faces.

30.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

31.Position rear cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

32.Refill transfer box with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

33.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

Page 767 of 1672

TRANSFER BOX - LT230SE

41-34 REPAIRS

Seal - rear output shaft

$% 41.20.54

Remove

1.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

2.Loosen brake shoe adjuster bolt.

3.Remove screw securing handbrake drum. 4.Remove handbrake drum.

5.Restrain transfer box drive flange using tool

LRT-51-003. Remove and discard drive flange

nut, remove and discard steel and felt washers.

6.Using tool LRT-99-500 if necessary, remove

drive flange from transfer box.

7.Remove seal from transfer box.

Refit

1.Clean seal mating faces.

2.Lubricate seal with gearbox oil.

Page 768 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-35

3.Fit new seal using tool LRT-41-012.

4.Position drive flange, fit new felt and steel

washers.

5.Position tool LRT-51-003 and tighten new

drive flange nut to 148 Nm (109 lbf.ft).

6.Position handbrake drum and tighten screw.

7.Tighten brake shoe adjuster bolt to 25 Nm (18

lbf.ft) then loosen one and a half turns.

8.Check that brake drum is free to rotate.

9.Fit propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

10.Top-up transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Gasket - rear output shaft housing

$% 41.20.55

Remove

1.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

2.Remove rear output shaft seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Seal - rear output shaft.

3.Mark output shaft housing to main casing for

assembly purposes.

4.Note position of shoulder bolt, remove 6 bolts

securing housing to main casing.

Refit

1.Clean output shaft housing, mating face on

main casing and sealant from bolt threads.

2.Apply sealant, Part No. STC 3254 to mating

flange on output shaft housing.

3.Fit output shaft housing to main casing.

4.Apply Loctite 290 to bolt threads.

5.Fit output shaft housing bolts and tighten by

diagonal selection to 45 Nm (33 lbf.ft).

6.Fit rear output shaft seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Seal - rear output shaft.

7.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Page 818 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

ADJUSTMENTS 44-21

ADJUST ME NTS

Cable - selector

$% 44.30.04

Check

1.Position vehicle on ramp.

2.Select position 'P'.

3.Loosen selector cable trunnion nut.

4.Ensure that gearbox selector lever is in 'P'

position, (fully forward) and tighten trunnion

nut.

5.Lower ramp.

Stall test

$% 44.30.13

Testing

1.Chock the wheels and fully apply the

handbrake.

2.Start the engine and run it until it reaches

normal operating temperature.

3.Apply the footbrake and select 'D'.

4.Fully depress the accelerator pedal and note

the tachometer reading. The figures should be

as given below. Do not carry out stall test for

longer than 10 seconds, and DO NOT repeat

until 30 minutes have elapsed.

lV8: 2200 to 2400 rev/min

lDiesel: 2600 to 2800 rev/min

5.A reading below 1300 rev/min indicates a

torque converter fault, ie stator free-wheel.

6.A reading between 1300 and 2200 rev/min (V8)

or between 1300 and 2600 rev/min (Diesel)

indicates reduced engine power.

7.A reading above 2400 rev/min (V8) or above

2800 rev/min (Diesel) indicates clutch slip.

NOTE: The figures quoted above were

measured at sea level with an ambient

temperature of 20

°C (68°F). At higher altitudes

or higher ambient temperatures, these figures

will be reduced.