Fuel system LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 117 of 1672

MAINTENANCE

10-8 PROCEDURES

Brake fluid

Replace

1.Replace brake fluid.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Fuel filter - diesel engine

Replace

1.Replace filter element.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Element - fuel filter.

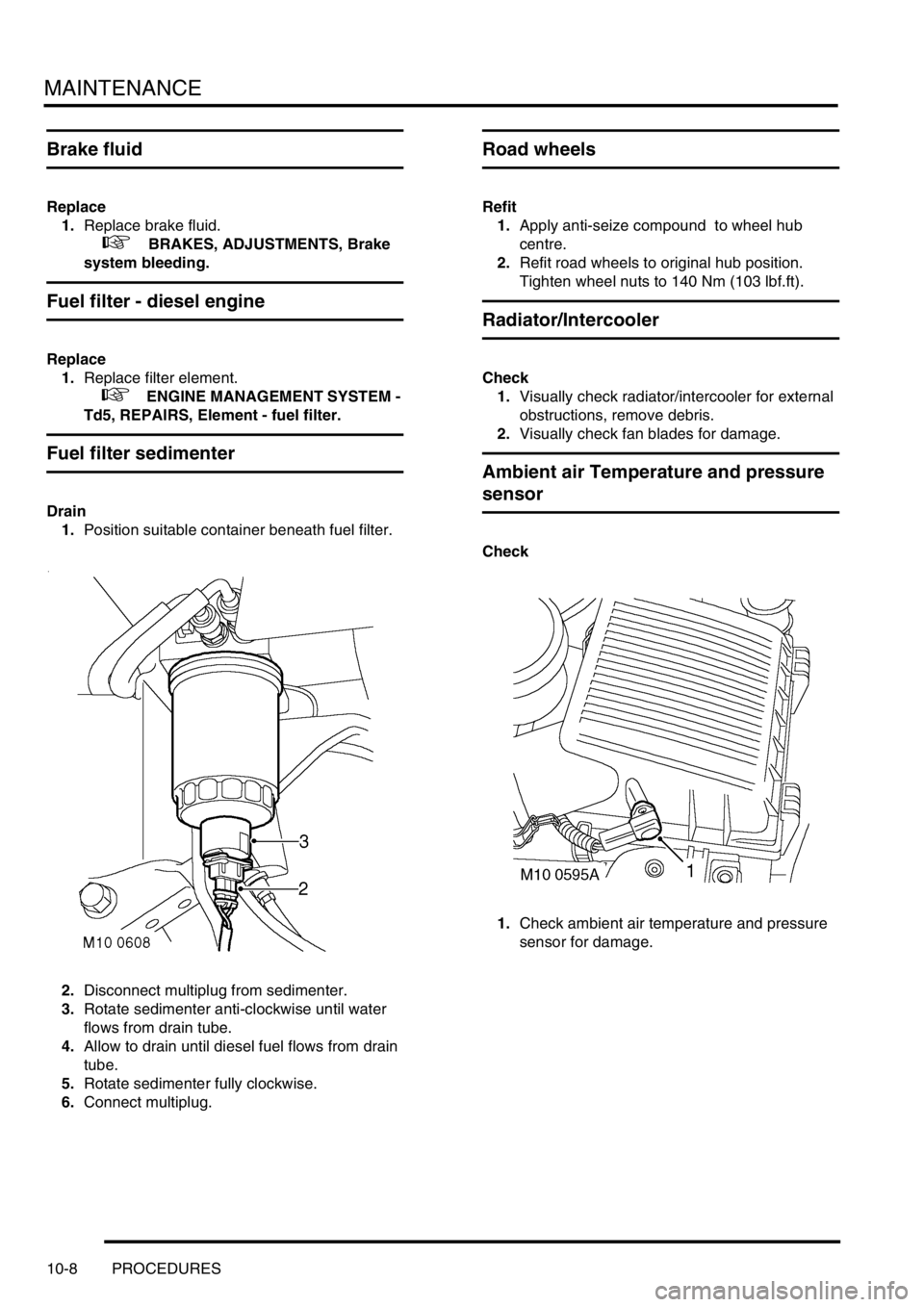

Fuel filter sedimenter

Drain

1.Position suitable container beneath fuel filter.

2.Disconnect multiplug from sedimenter.

3.Rotate sedimenter anti-clockwise until water

flows from drain tube.

4.Allow to drain until diesel fuel flows from drain

tube.

5.Rotate sedimenter fully clockwise.

6.Connect multiplug.

Road wheels

Refit

1.Apply anti-seize compound to wheel hub

centre.

2.Refit road wheels to original hub position.

Tighten wheel nuts to 140 Nm (103 lbf.ft).

Radiator/Intercooler

Check

1.Visually check radiator/intercooler for external

obstructions, remove debris.

2.Visually check fan blades for damage.

Ambient air Temperature and pressure

sensor

Check

1.Check ambient air temperature and pressure

sensor for damage.

Page 118 of 1672

MAINTENANCE

PROCEDURES 10-9

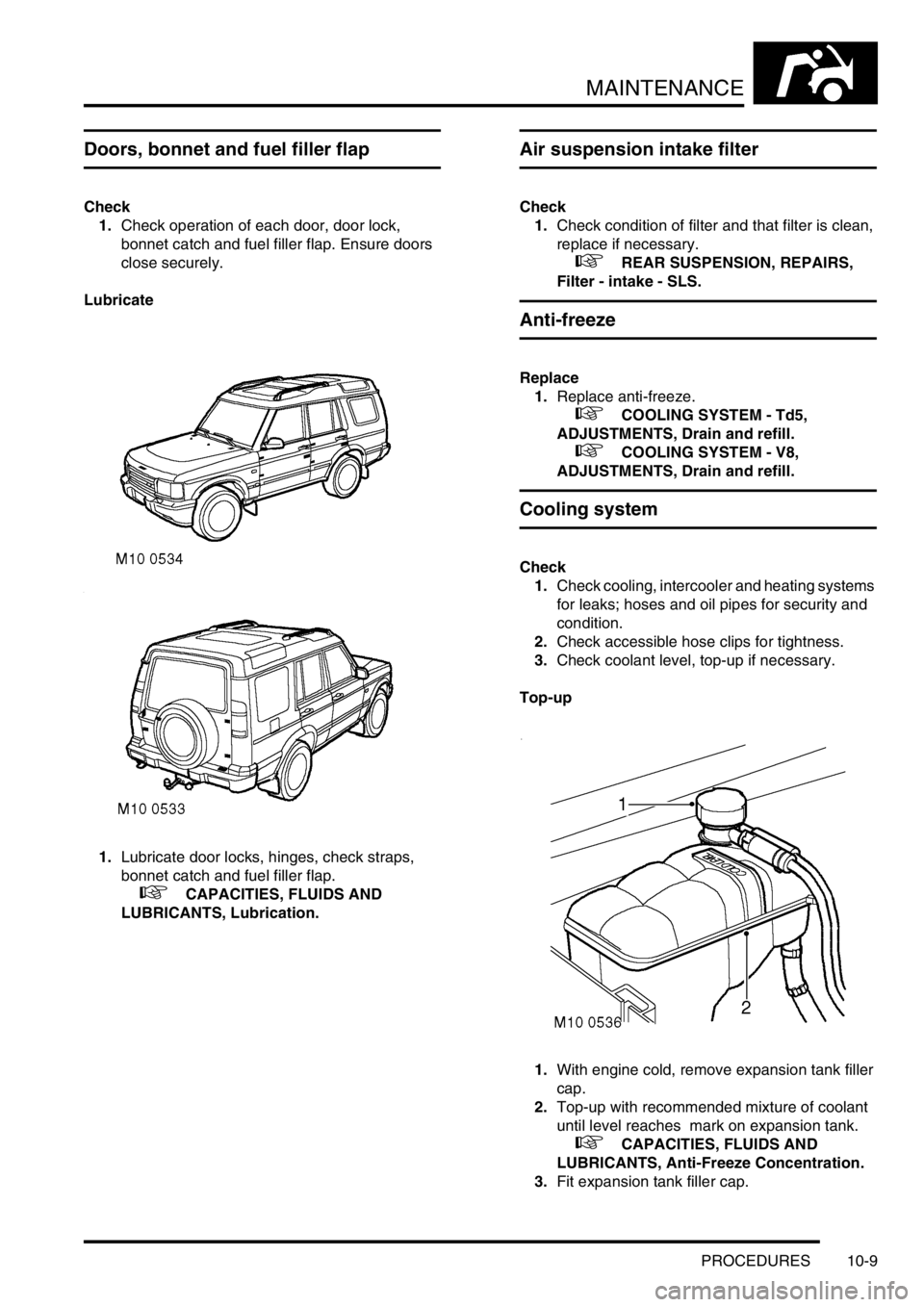

Doors, bonnet and fuel filler flap

Check

1.Check operation of each door, door lock,

bonnet catch and fuel filler flap. Ensure doors

close securely.

Lubricate

1.Lubricate door locks, hinges, check straps,

bonnet catch and fuel filler flap.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

Air suspension intake filter

Check

1.Check condition of filter and that filter is clean,

replace if necessary.

+ REAR SUSPENSION, REPAIRS,

Filter - intake - SLS.

Anti-freeze

Replace

1.Replace anti-freeze.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Cooling system

Check

1.Check cooling, intercooler and heating systems

for leaks; hoses and oil pipes for security and

condition.

2.Check accessible hose clips for tightness.

3.Check coolant level, top-up if necessary.

Top-up

1.With engine cold, remove expansion tank filler

cap.

2.Top-up with recommended mixture of coolant

until level reaches mark on expansion tank.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Anti-Freeze Concentration.

3.Fit expansion tank filler cap.

Page 151 of 1672

ENGINE - TD5

12-1-12 DESCRIPTION AND OPERATION

Description

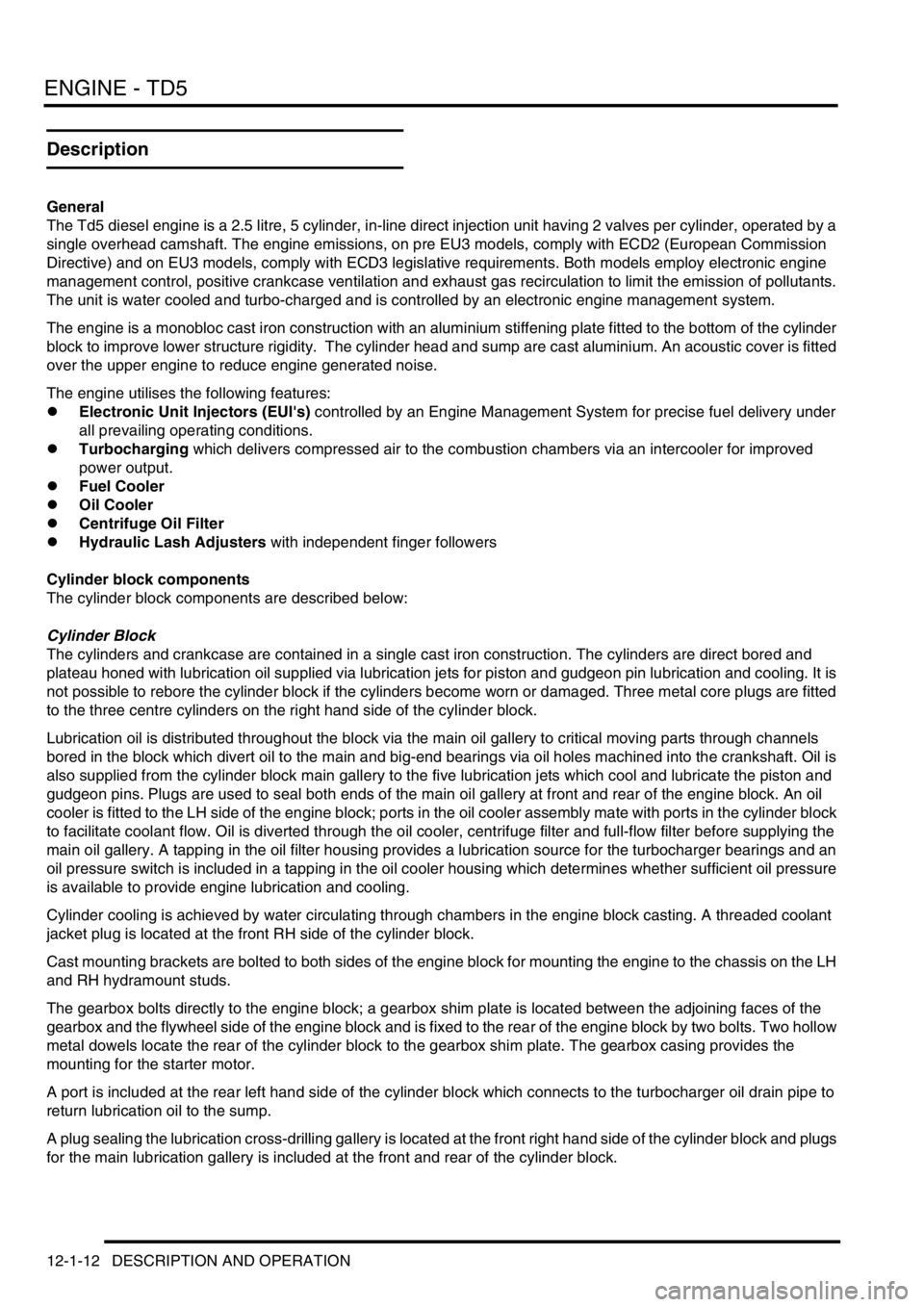

General

The Td5 diesel engine is a 2.5 litre, 5 cylinder, in-line direct injection unit having 2 valves per cylinder, operated by a

single overhead camshaft. The engine emissions, on pre EU3 models, comply with ECD2 (European Commission

Directive) and on EU3 models, comply with ECD3 legislative requirements. Both models employ electronic engine

management control, positive crankcase ventilation and exhaust gas recirculation to limit the emission of pollutants.

The unit is water cooled and turbo-charged and is controlled by an electronic engine management system.

The engine is a monobloc cast iron construction with an aluminium stiffening plate fitted to the bottom of the cylinder

block to improve lower structure rigidity. The cylinder head and sump are cast aluminium. An acoustic cover is fitted

over the upper engine to reduce engine generated noise.

The engine utilises the following features:

lElectronic Unit Injectors (EUI's) controlled by an Engine Management System for precise fuel delivery under

all prevailing operating conditions.

lTurbocharging which delivers compressed air to the combustion chambers via an intercooler for improved

power output.

lFuel Cooler

lOil Cooler

lCentrifuge Oil Filter

lHydraulic Lash Adjusters with independent finger followers

Cylinder block components

The cylinder block components are described below:

Cylinder Block

The cylinders and crankcase are contained in a single cast iron construction. The cylinders are direct bored and

plateau honed with lubrication oil supplied via lubrication jets for piston and gudgeon pin lubrication and cooling. It is

not possible to rebore the cylinder block if the cylinders become worn or damaged. Three metal core plugs are fitted

to the three centre cylinders on the right hand side of the cylinder block.

Lubrication oil is distributed throughout the block via the main oil gallery to critical moving parts through channels

bored in the block which divert oil to the main and big-end bearings via oil holes machined into the crankshaft. Oil is

also supplied from the cylinder block main gallery to the five lubrication jets which cool and lubricate the piston and

gudgeon pins. Plugs are used to seal both ends of the main oil gallery at front and rear of the engine block. An oil

cooler is fitted to the LH side of the engine block; ports in the oil cooler assembly mate with ports in the cylinder block

to facilitate coolant flow. Oil is diverted through the oil cooler, centrifuge filter and full-flow filter before supplying the

main oil gallery. A tapping in the oil filter housing provides a lubrication source for the turbocharger bearings and an

oil pressure switch is included in a tapping in the oil cooler housing which determines whether sufficient oil pressure

is available to provide engine lubrication and cooling.

Cylinder cooling is achieved by water circulating through chambers in the engine block casting. A threaded coolant

jacket plug is located at the front RH side of the cylinder block.

Cast mounting brackets are bolted to both sides of the engine block for mounting the engine to the chassis on the LH

and RH hydramount studs.

The gearbox bolts directly to the engine block; a gearbox shim plate is located between the adjoining faces of the

gearbox and the flywheel side of the engine block and is fixed to the rear of the engine block by two bolts. Two hollow

metal dowels locate the rear of the cylinder block to the gearbox shim plate. The gearbox casing provides the

mounting for the starter motor.

A port is included at the rear left hand side of the cylinder block which connects to the turbocharger oil drain pipe to

return lubrication oil to the sump.

A plug sealing the lubrication cross-drilling gallery is located at the front right hand side of the cylinder block and plugs

for the main lubrication gallery is included at the front and rear of the cylinder block.

Page 160 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-21

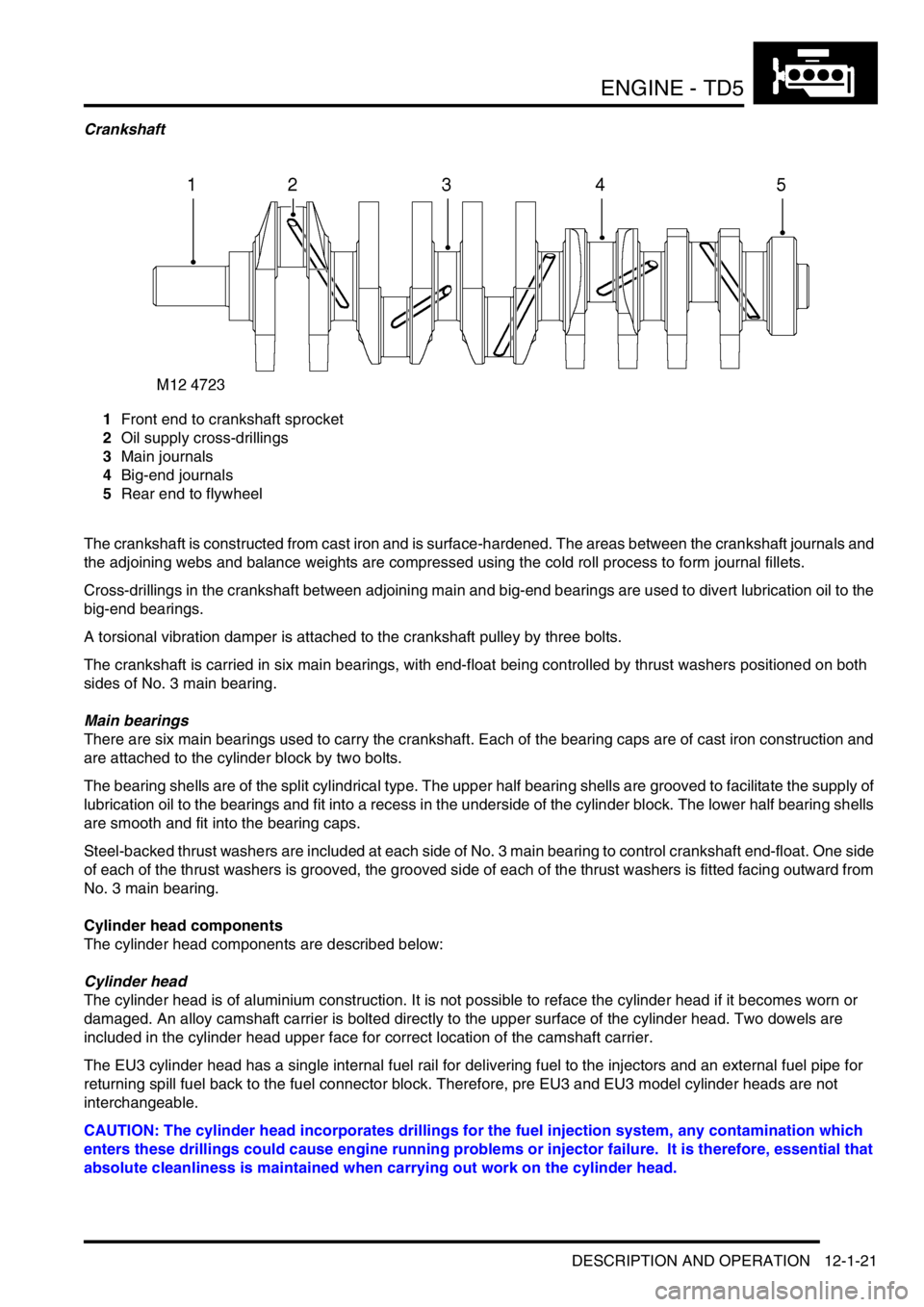

Crankshaft

1Front end to crankshaft sprocket

2Oil supply cross-drillings

3Main journals

4Big-end journals

5Rear end to flywheel

The crankshaft is constructed from cast iron and is surface-hardened. The areas between the crankshaft journals and

the adjoining webs and balance weights are compressed using the cold roll process to form journal fillets.

Cross-drillings in the crankshaft between adjoining main and big-end bearings are used to divert lubrication oil to the

big-end bearings.

A torsional vibration damper is attached to the crankshaft pulley by three bolts.

The crankshaft is carried in six main bearings, with end-float being controlled by thrust washers positioned on both

sides of No. 3 main bearing.

Main bearings

There are six main bearings used to carry the crankshaft. Each of the bearing caps are of cast iron construction and

are attached to the cylinder block by two bolts.

The bearing shells are of the split cylindrical type. The upper half bearing shells are grooved to facilitate the supply of

lubrication oil to the bearings and fit into a recess in the underside of the cylinder block. The lower half bearing shells

are smooth and fit into the bearing caps.

Steel-backed thrust washers are included at each side of No. 3 main bearing to control crankshaft end-float. One side

of each of the thrust washers is grooved, the grooved side of each of the thrust washers is fitted facing outward from

No. 3 main bearing.

Cylinder head components

The cylinder head components are described below:

Cylinder head

The cylinder head is of aluminium construction. It is not possible to reface the cylinder head if it becomes worn or

damaged. An alloy camshaft carrier is bolted directly to the upper surface of the cylinder head. Two dowels are

included in the cylinder head upper face for correct location of the camshaft carrier.

The EU3 cylinder head has a single internal fuel rail for delivering fuel to the injectors and an external fuel pipe for

returning spill fuel back to the fuel connector block. Therefore, pre EU3 and EU3 model cylinder heads are not

interchangeable.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any contamination which

enters these drillings could cause engine running problems or injector failure. It is therefore, essential that

absolute cleanliness is maintained when carrying out work on the cylinder head.

Page 162 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-23

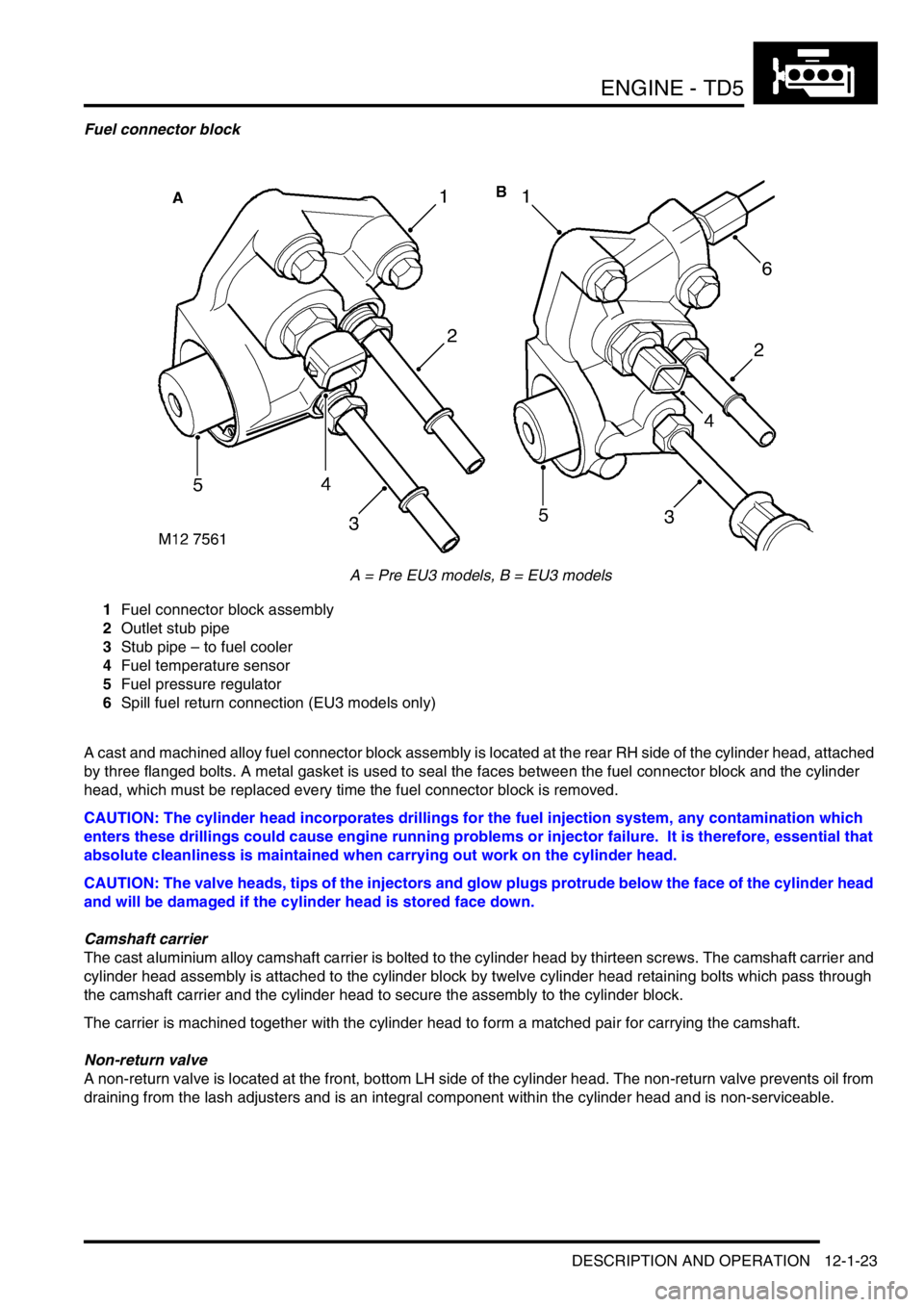

Fuel connector block

A = Pre EU3 models, B = EU3 models

1Fuel connector block assembly

2Outlet stub pipe

3Stub pipe – to fuel cooler

4Fuel temperature sensor

5Fuel pressure regulator

6Spill fuel return connection (EU3 models only)

A cast and machined alloy fuel connector block assembly is located at the rear RH side of the cylinder head, attached

by three flanged bolts. A metal gasket is used to seal the faces between the fuel connector block and the cylinder

head, which must be replaced every time the fuel connector block is removed.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any contamination which

enters these drillings could cause engine running problems or injector failure. It is therefore, essential that

absolute cleanliness is maintained when carrying out work on the cylinder head.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the cylinder head

and will be damaged if the cylinder head is stored face down.

Camshaft carrier

The cast aluminium alloy camshaft carrier is bolted to the cylinder head by thirteen screws. The camshaft carrier and

cylinder head assembly is attached to the cylinder block by twelve cylinder head retaining bolts which pass through

the camshaft carrier and the cylinder head to secure the assembly to the cylinder block.

The carrier is machined together with the cylinder head to form a matched pair for carrying the camshaft.

Non-return valve

A non-return valve is located at the front, bottom LH side of the cylinder head. The non-return valve prevents oil from

draining from the lash adjusters and is an integral component within the cylinder head and is non-serviceable.

Page 179 of 1672

ENGINE - TD5

12-1-40 REPAIRS

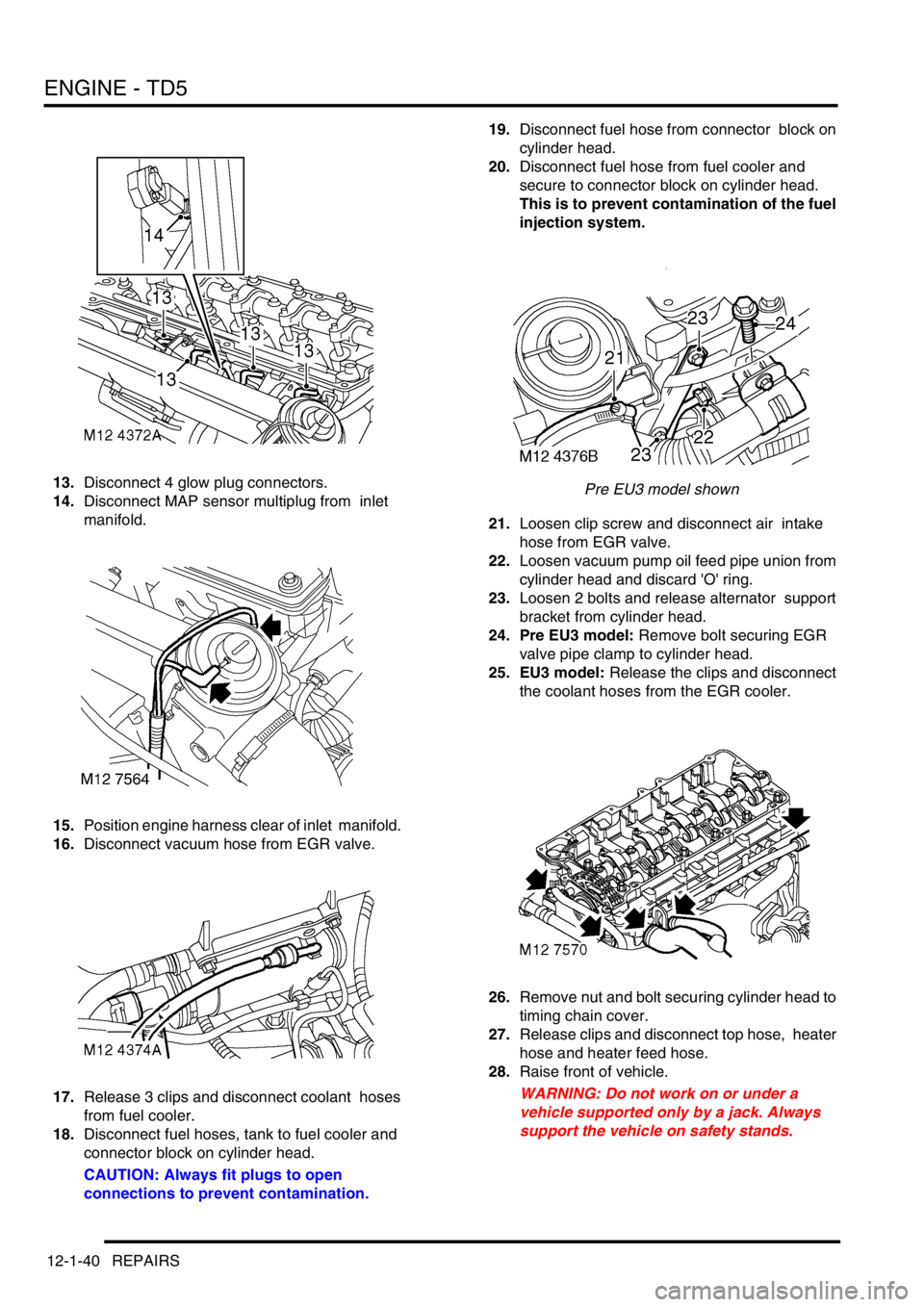

13.Disconnect 4 glow plug connectors.

14.Disconnect MAP sensor multiplug from inlet

manifold.

15.Position engine harness clear of inlet manifold.

16.Disconnect vacuum hose from EGR valve.

17.Release 3 clips and disconnect coolant hoses

from fuel cooler.

18.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Always fit plugs to open

connections to prevent contamination.19.Disconnect fuel hose from connector block on

cylinder head.

20.Disconnect fuel hose from fuel cooler and

secure to connector block on cylinder head.

This is to prevent contamination of the fuel

injection system.

Pre EU3 model shown

21.Loosen clip screw and disconnect air intake

hose from EGR valve.

22.Loosen vacuum pump oil feed pipe union from

cylinder head and discard 'O' ring.

23.Loosen 2 bolts and release alternator support

bracket from cylinder head.

24. Pre EU3 model: Remove bolt securing EGR

valve pipe clamp to cylinder head.

25. EU3 model: Release the clips and disconnect

the coolant hoses from the EGR cooler.

26.Remove nut and bolt securing cylinder head to

timing chain cover.

27.Release clips and disconnect top hose, heater

hose and heater feed hose.

28.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

Page 182 of 1672

ENGINE - TD5

REPAIRS 12-1-43

11.Clean camshaft sprocket and mating face on

camshaft.

12.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

13.Position camshaft sprocket to camshaft; fit and

lightly tighten new bolts, then loosen bolts half

a turn.

14.Clean timing chain fixed guide retaining pin and

apply Loctite 242 to threads.

15.Fit timing chain fixed guide retaining pin and

tighten to 25 Nm (18 lbf.ft) .

16.Clean timing chain tensioner and fit new

sealing washer.

17.Fit timing chain tensioner and tighten to 45 Nm

(22 lbf.ft).

18.Tighten bolts securing camshaft sprocket to

camshaft to 37 Nm (27 lbf.ft).

19.Remove tool LRT-12-058 from camshaft.

20.Remove tool LRT-12-158 from gearbox bell

housing.

21.Fit new camshaft bore blanking plug and 'O'-

ring seal in recess in cylinder head.

22.Clean vacuum pump union.

23.Tighten union securing vacuum pump oil feed

pipe to cylinder head to 10 Nm (7 lbf.ft) .

24.Fit bolts securing alternator support bracket to

cylinder head and tighten to 25 Nm (18 lbf.ft) .

25.Connect top hose and heater hoses and secure

with clips.

26. Pre EU3 model:Fit bolt securing EGR pipe

clamp to cylinder head bolt and tighten to 10

Nm (7 lbf.ft) .

27. EU3 model: Connect coolant hoses to EGR

cooler and secure with the clips.

28.Position air intake hose to EGR valve and

tighten clip screw.

29.Disconnect fuel hose from connector block and

connect to fuel cooler.

30.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

31.Connect coolant hoses to fuel cooler and

secure clips.

32.Connect vacuum hose to EGR valve.

33.Position engine harness and connect multi

plugs and glow plug connectors.

34.Fit and tighten bolts, engine harness to

camshaft carrier.

35.Clean exhaust manifold and turbocharger

interface.

36.Fit new gasket to exhaust manifold, position

turbocharger and tighten – nuts securing

turbocharger to manifold to 30 Nm (22 lbf.ft).

37.Clean turbocharger oil feed hose bolt.

38.Position turbocharger oil feed hose using new

sealing washers. Fit banjo bolt securing

turbocharger oil feed hose and tighten to 25 Nm

(18 lbf.ft) . 39.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolt to

25 Nm (18 lbf.ft).

40.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

41.Fit camshaft cover with new seal.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

42.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

43.Connect battery earth lead.

44.Fit battery cover and secure fixings.

45.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 186 of 1672

ENGINE - TD5

REPAIRS 12-1-47

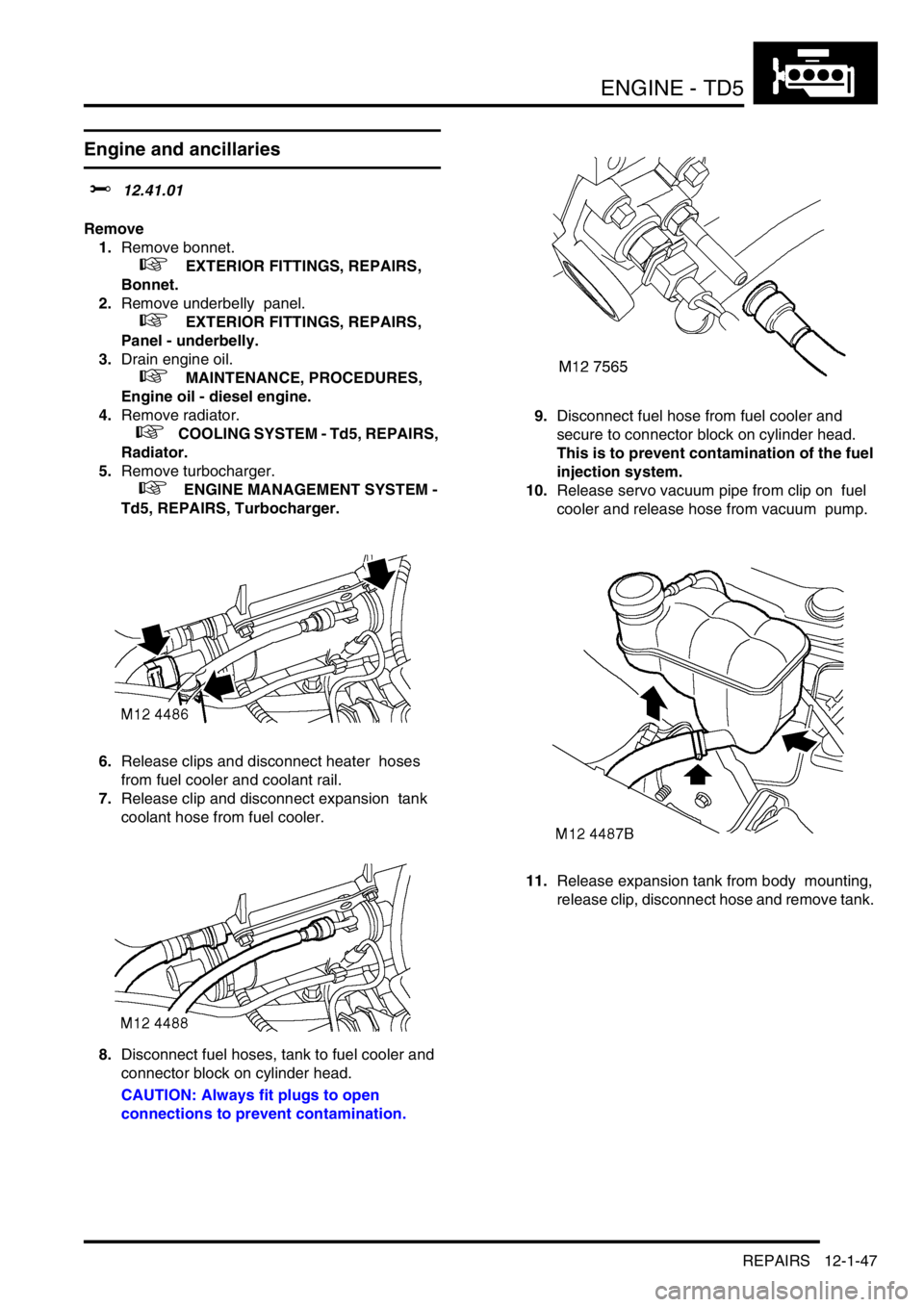

Engine and ancillaries

$% 12.41.01

Remove

1.Remove bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

4.Remove radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

5.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

6.Release clips and disconnect heater hoses

from fuel cooler and coolant rail.

7.Release clip and disconnect expansion tank

coolant hose from fuel cooler.

8.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Always fit plugs to open

connections to prevent contamination.9.Disconnect fuel hose from fuel cooler and

secure to connector block on cylinder head.

This is to prevent contamination of the fuel

injection system.

10.Release servo vacuum pipe from clip on fuel

cooler and release hose from vacuum pump.

11.Release expansion tank from body mounting,

release clip, disconnect hose and remove tank.

Page 191 of 1672

ENGINE - TD5

12-1-52 REPAIRS

5.Fit 2 upper bolts securing engine oil cooler pipe

and gearbox housing to engine and tighten to

50 Nm (37 lbf.ft) .

6.Lower engine onto mountings, and tighten nuts

to 85 Nm (63 lbf.ft) .

7.Remove tool LRT-12-138 from engine.

8.Fit and tighten bolt securing engine closing

panel to gearbox.

9.Raise vehicle on ramp.

10.Fit nuts and bolts securing engine LH and RH

mountings to chassis and tighten to 85 Nm (63

lbf.ft).

11.Fit remaining bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

12.Rotate crankshaft and align drive plate to

torque converter.

13.Using a magnetic socket, fit and tighten new

torque converter drive plate bolts to 50 Nm (37

lbf.ft) .

14.Fit front cross member and tighten bolts to 26

Nm (19 lbf.ft).

15.Align gearbox oil cooler pipes.

16.Fit oil cooler pipe clip and tighten bolts to 9 Nm

(7 lbf.ft).

17.Position gearbox oil cooler pipe clamps and

tighten nuts.

18.Position coolant rail and secure support bracket

in engine LH and RH mounting brackets.

19.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

20.Lower ramp.

21.Position coolant rail to front chassis member, fit

and tighten bolt to 10 Nm (7 lbf.ft).

22.Connect heater hose to coolant rail and secure

with clip.

23.Connect hose to coolant pump and secure with

clip.

24.Position PAS pump and tighten bolts to 25 Nm

(18 lbf.ft).

25.Position PAS pump pulley and lightly tighten

bolts.

26.Position ACE pump, fit bolts and tighten to 25

Nm (18 lbf.ft).

27.Position A/C compressor, fit bolts and tighten

to 25 Nm (18 lbf.ft).

28.Position ancillary drive belt, rotate tensioner

anti-clockwise and locate belt to pulleys.

29.Tighten PAS pump pulley bolts to 10 Nm (7

lbf.ft).

30.Position air intake hose to air cleaner and

secure clips.

31.Position engine harness and connect

multiplugs to compressor, MAF sensor,

turbocharger boost solenoid, AAP & IAT

sensor.

32.Position air inlet hose to turbocharger and

tighten clip. 33.Connect hoses to turbocharger boost solenoid

and secure clips.

34.Clean CKP sensor and mating face.

CAUTION: If originally fitted: Fit spacer to

CKP sensor.

35.Using new 'O' ring, fit CKP sensor, tighten CKP

sensor bolt to 9 Nm (7 lbf.ft) and connect

multiplug.

36.Connect multiplug to EGR modulator.

37.Connect engine earth lead to battery earth lead

and tighten bolt.

38.Connect engine harness multiplug to ECM and

main harness.

39.Connect engine harness multiplugs to fuse

box.

40.Position glow plug lead to fusebox and secure

with bolt.

41.Position battery and alternator leads to fusebox

and secure with bolts.

42.Fit engine compartment fuse box cover.

43.Connect vacuum hose to EGR valve.

44.Connect hose to vacuum pump and secure

vacuum pipe to fuel cooler.

45.Disconnect fuel hose from connector block and

connect to fuel cooler.

46.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

47.Position expansion tank, connect hose and

secure with clip. Secure tank to body mounting.

48.Connect coolant hoses to fuel cooler and

coolant rail and secure clips.

49.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

50. Fit radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

51.Fill engine with oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

52.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

53.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 213 of 1672

ENGINE - TD5

12-1-74 OVERHAUL

35.Fit camshaft cover to camshaft carrier, fit bolts

and working from the centre outwards tighten

bolts to 10 Nm (7 lbf.ft).

36.Fit inlet manifold gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- inlet manifold.

37.Fit exhaust manifold gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- exhaust manifold.

38. EGR cooler fitted: Position EGR pipe to

cooler, fit new Allen screws and tighten to 10

Nm (7 lbf.ft)

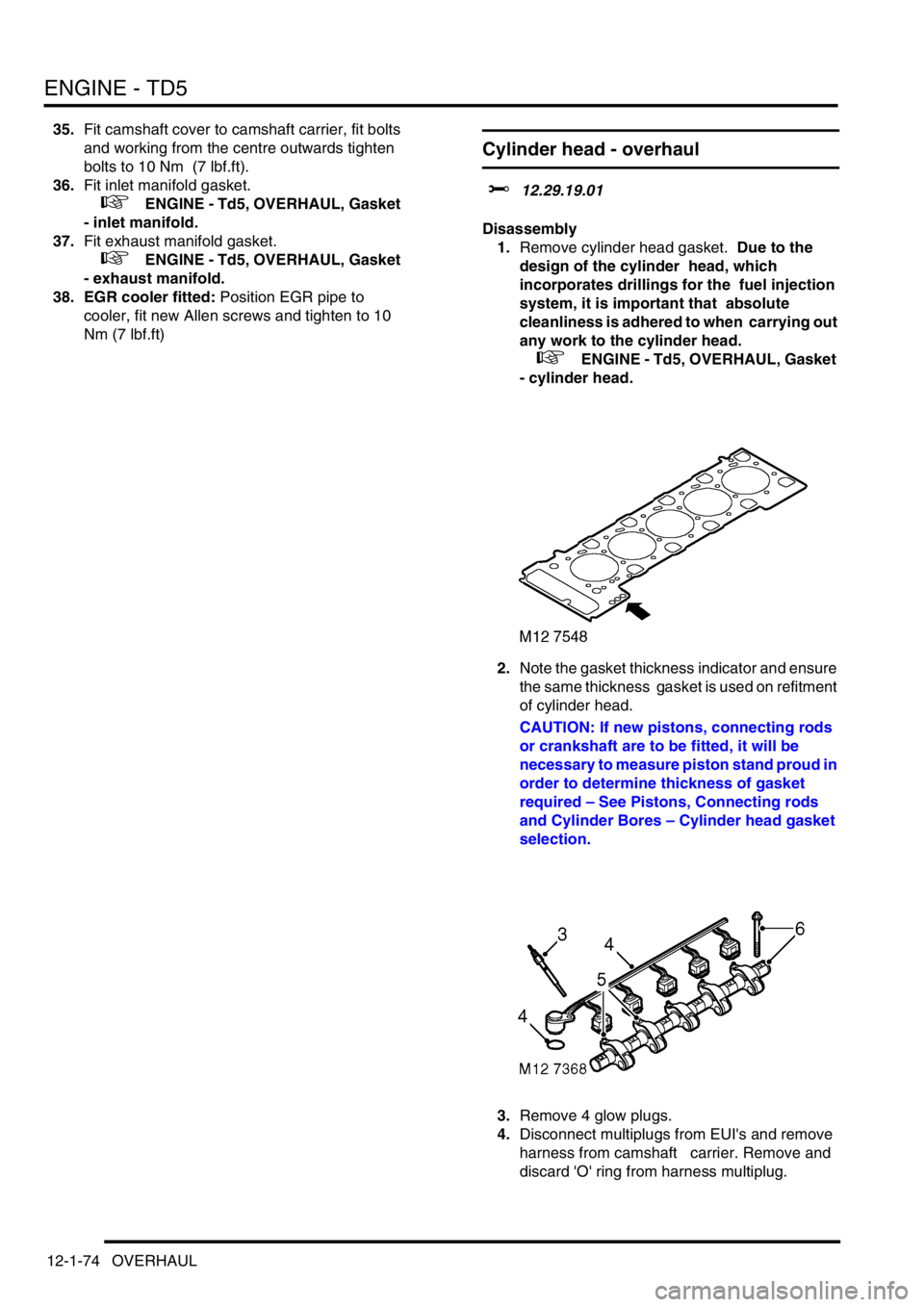

Cylinder head - overhaul

$% 12.29.19.01

Disassembly

1.Remove cylinder head gasket. Due to the

design of the cylinder head, which

incorporates drillings for the fuel injection

system, it is important that absolute

cleanliness is adhered to when carrying out

any work to the cylinder head.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

2.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of cylinder head.

CAUTION: If new pistons, connecting rods

or crankshaft are to be fitted, it will be

necessary to measure piston stand proud in

order to determine thickness of gasket

required – See Pistons, Connecting rods

and Cylinder Bores – Cylinder head gasket

selection.

3.Remove 4 glow plugs.

4.Disconnect multiplugs from EUI's and remove

harness from camshaft carrier. Remove and

discard 'O' ring from harness multiplug.