power steering LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 926 of 1672

STEERING

REPAIRS 57-39

Refit

1.Clean seal recess, output shaft, end cover and

mating face.

2.Lubricate new end cover 'O' ring with clean

PAS fluid. Fit 'O' ring to end cover.

3.Position output shaft, fit bolts and tighten to 88

Nm (65 lbf.ft).

4.Tighten rack adjuster one turn, align marks and

secure with Allen screw.

5.Lubricate new output shaft seal with clean PAS

fluid.

6.Fit seal using LRT-57-504.

7.Fit spacer, circlip and seal shield.

8.Clean drop arm and steering box splines.

9.Ensure steering box is in the central position.

Align and fit drop arm to output shaft and

secure with new lock washer and nut. Tighten

nut to 240 Nm (177 lbf.ft).

10.Secure lock washer to drop arm nut.

11.Fit steering box.

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

Pump - power steering - V8

$% 57.20.14

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove cable tie securing harness to air intake

hose.

3.Loosen 3 clips securing air intake hose, release

and remove hose.

Note: Pre 03 MY air intake hose illustrated.

4. Models with ACE: Remove 3 bolts securing

ACE pump, release pump and position aside.

Page 928 of 1672

STEERING

REPAIRS 57-41

Refit

1.Position PAS pump to auxiliary housing and

locate housing to engine. Fit and tighten

auxiliary housing bolts to 40 Nm (30 lbf.ft).

2.Tighten auxiliary housing nut to 10 Nm (7 lbf.ft).

3.Fit bolts securing PAS pump and tighten to 22

Nm (16 lbf.ft).

4.Position PAS pump pipe bracket, fit and tighten

bolt to 22 Nm (16 lbf.ft).

5.Fit and tighten PAS pump pressure pipe.

6.Fit PAS pump inlet hose and secure with clip.

7.Position jockey pulley and tighten bolt to 50 Nm

(37 lbf.ft).

8.Clean PAS pump pulley mating faces.

9.Position PAS pump pulley, fit bolts and tighten

to 22 Nm (16 lbf.ft).

10. Models with ACE: Clean ACE pump dowels

and dowel holes. Position ACE pump, fit bolts

and tighten to 25 Nm (18 lbf.ft).

11. Models with A/C: Clean A/C compressor

dowels and dowel holes. Position A/C

compressor, fit bolts and tighten to 22 Nm (16

lbf.ft).

12.Position air intake hose and secure with clips.

13.Secure harness to air intake hose with new

cable tie.

14.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive..

15.Bleed PAS system.

+ STEERING, ADJUSTMENTS,

Hydraulic system - bleed.

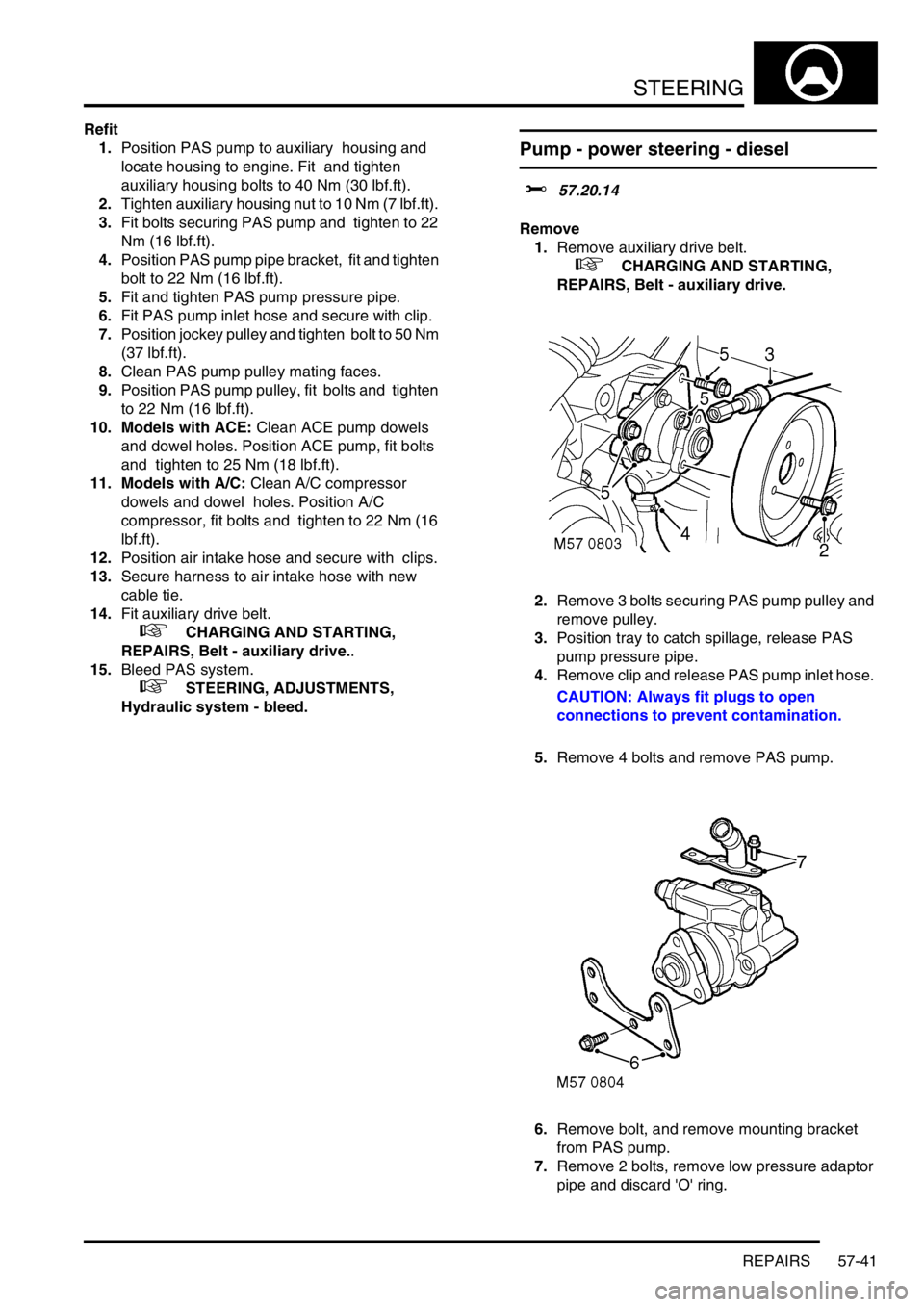

Pump - power steering - diesel

$% 57.20.14

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove 3 bolts securing PAS pump pulley and

remove pulley.

3.Position tray to catch spillage, release PAS

pump pressure pipe.

4.Remove clip and release PAS pump inlet hose.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 4 bolts and remove PAS pump.

6.Remove bolt, and remove mounting bracket

from PAS pump.

7.Remove 2 bolts, remove low pressure adaptor

pipe and discard 'O' ring.

Page 929 of 1672

STEERING

57-42 REPAIRS

Refit

1.Clean PAS pump and adaptor pipe.

2.Fit new 'O' ring to adaptor pipe, fit pipe and

tighten bolts to 10 Nm (7 lbf.ft).

3.Position mounting bracket to PAS pump, fit but

do not tighten bolt.

4.Position PAS pump and align pump drive to

coolant pump. Fit and tighten bolts to 25 Nm

(18 lbf.ft).

5.Tighten mounting plate bolt to 25 Nm (18 lbf.ft).

6.Clean PAS pump and pipe union.

7.Fit and tighten PAS pump pressure pipe to 20

Nm (15 lbf.ft).

8.Fit PAS pump inlet hose and secure with clip.

9.Clean PAS pump and pulley mating faces.

10.Position PAS pump pulley, fit and tighten bolts

to 10 Nm (7 lbf.ft).

11.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

12.Bleed power steering system.

+ STEERING, ADJUSTMENTS,

Hydraulic system - bleed.

Steering column assembly and lock

$% 57.40.01

Remove

1.Remove steering column intermediate shaft.

+ STEERING, REPAIRS, Shaft -

intermediate and universal joint - steering

column.

2.Remove rotary coupler.

+ RESTRAINT SYSTEMS, REPAIRS,

Rotary coupler.

3.Open fascia lower access panel.

4.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

5.Disconnect multiplug and illumination bulb

from passive coil and remove passive coil.

Page 934 of 1672

STEERING

REPAIRS 57-47

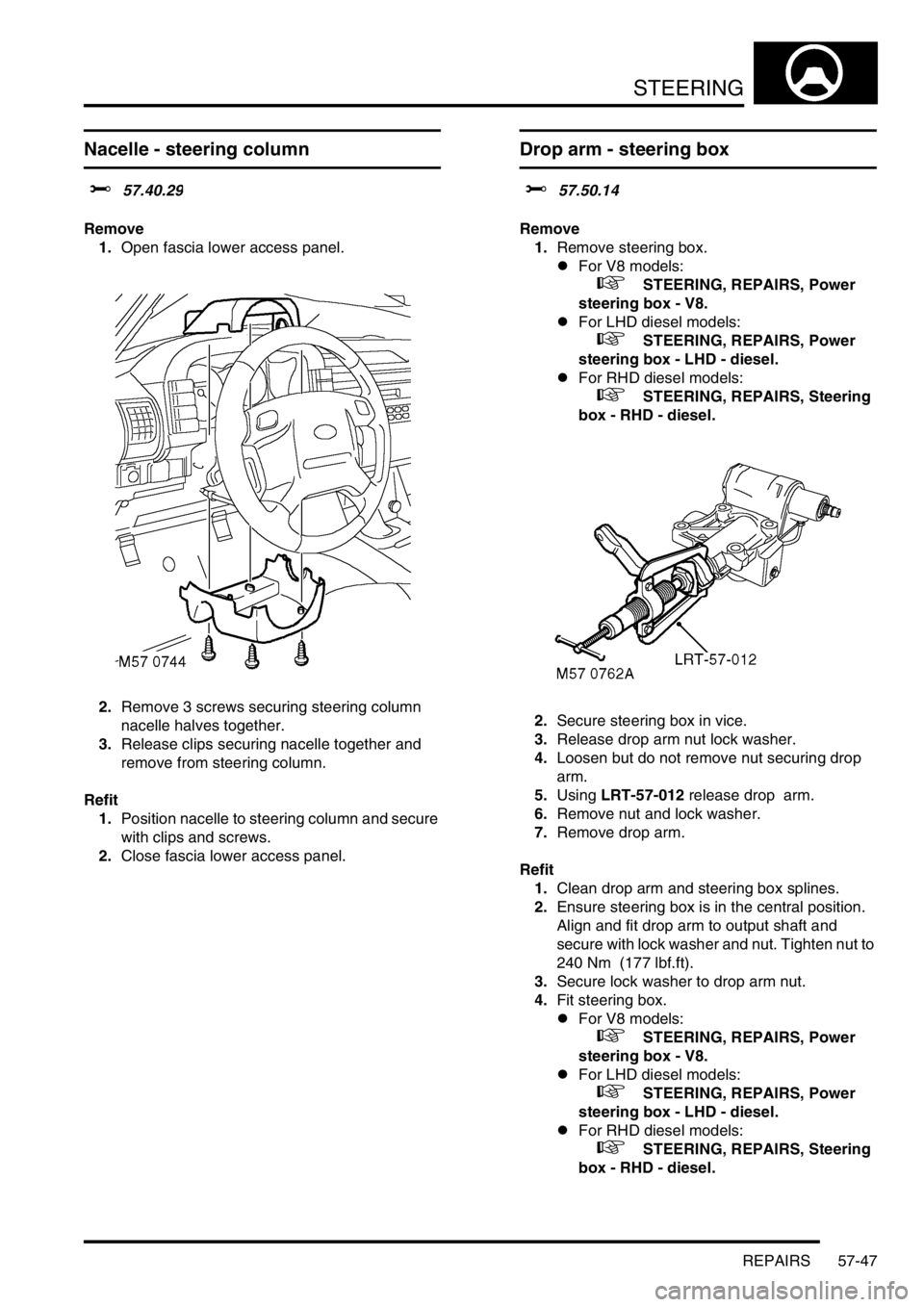

Nacelle - steering column

$% 57.40.29

Remove

1.Open fascia lower access panel.

2.Remove 3 screws securing steering column

nacelle halves together.

3.Release clips securing nacelle together and

remove from steering column.

Refit

1.Position nacelle to steering column and secure

with clips and screws.

2.Close fascia lower access panel.

Drop arm - steering box

$% 57.50.14

Remove

1.Remove steering box.

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

2.Secure steering box in vice.

3.Release drop arm nut lock washer.

4.Loosen but do not remove nut securing drop

arm.

5.Using LRT-57-012 release drop arm.

6.Remove nut and lock washer.

7.Remove drop arm.

Refit

1.Clean drop arm and steering box splines.

2.Ensure steering box is in the central position.

Align and fit drop arm to output shaft and

secure with lock washer and nut. Tighten nut to

240 Nm (177 lbf.ft).

3.Secure lock washer to drop arm nut.

4.Fit steering box.

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

Page 1065 of 1672

BRAKES

70-20 DESCRIPTION AND OPERATION

Operation

Refer to illustration.

+ BRAKES, DESCRIPTION AND OPERATION, Brake system control diagram.

When the ignition is switched on, the SLABS ECU performs a check of the brake related warning lamps as part of the

power up procedure. The warning lamps are illuminated for approximately 3 seconds and then extinguished. If a fault

warning lamp remains illuminated after the lamp check, a fault has been detected and repair action is required.

ABS

The ABS function prevents the road wheels locking during brake application, thus maintaining vehicle stability even

under emergency conditions.

WARNING: ABS is an aid to retaining steering control and stability while braking:

lABS cannot defy the natural laws of physics acting on the vehicle.

lABS will not prevent accidents resulting from excessive cornering speeds, following another vehicle too

closely, aquaplaning, etc.

lThe additional control provided by ABS must never be exploited in a dangerous or reckless manner

which could jeopardise the safety of driver or other road users.

lThe fitting of ABS does not imply that the vehicle will always stop in a shorter distance.

NOTE: During normal braking the feel of the brake pedal on vehicles equipped with ABS will be the same as that on

non ABS vehicles. During anti-lock braking operation the driver will experience feedback in the form of a pulsating

brake pedal and solenoid/pump motor noise from the ABS modulator.

The anti-lock braking function is automatically enabled whenever the ABS modulator is in the normal braking mode.

While the anti-lock braking function is enabled, if the SLABS ECU detects a wheel decelerating faster than the

average and at the calibrated wheel slip limit for ABS operation, it operates the ABS modulator in the ABS braking

mode for the affected wheel.

EBD

The EBD function optimises the distribution of hydraulic pressure between the front and rear axles, under all vehicle

load configurations and road conditions, to maintain vehicle stability during braking. EBD operates in forward and

reverse and is automatically enabled whenever the ABS modulator is in the normal braking mode at vehicle

deceleration rates of 0.3 g and above (i.e. medium to high brake pedal loads). EBD operation is similar to that of ABS,

but is calibrated to intervene at lower wheel slip limits and operates the brakes in axle pairs instead of individually.

During braking, if the SLABS ECU detects the wheels of one axle going slower than those of the other axle, i.e. a

potential wheel slip situation, it signals the ABS modulator to close the inlet solenoid valve for the brakes of the slower

wheels. This prevents any further increase in hydraulic pressure to those brakes, while allowing the hydraulic pressure

to the brakes on the other axle to increase and so maximise the overall braking effort. If the wheel speeds of the axle

being subjected to EBD control return within the calibrated wheel slip limits, the SLABS ECU signals a stepped

opening of the inlet solenoid valves, which allows a progressive increase of hydraulic pressure to the related brakes.

Operation of EBD is detectable from a stiffening of brake pedal movement as the inlet solenoid valves close and a

slight pulsing of the brake pedal as the inlet solenoid valves open. EBD operation ceases immediately the brake pedal

is released.

The wheel slip limit for EBD operation varies with vehicle speed. During normal operation, the inlet solenoid valves

always operate in axle pairs, with only one axle pair closed at any one time. Since the most lightly loaded wheel during

a braking manoeuvre will usually be the first to reach the slip limit, under most vehicle load configurations and road

conditions EBD control occurs on the trailing axle. However, EBD control can occur on the leading axle or switch

between axles during the braking manoeuvre.

Page 1429 of 1672

WIPERS AND WASHERS

84-8 DESCRIPTION AND OPERATION

Description

General

All markets have a common wiper system with headlamp powerwash as an option.

The wipers system comprises two front wipers and one rear wiper which are powered by electric motors. A washer

reservoir is located in the front left hand wheel arch and is fitted with two electric pumps. Each pump supplies washer

fluid to either the front or rear screens. On certain models, a third pump can be fitted to operate a headlamp power

wash function. Operation of the front and rear wipers and washers is controlled by the driver using switches located

on a steering column stalk and push button switches on the fascia.

Control of the wipers and washers is achieved by the following components:

lBCU.

lIDM.

lFront wiper relay.

lFront wash/ wipe switch.

lVariable delay switch.

lFront wiper motor assembly.

lFront washer pump motor.

lRear wiper relay.

lRear wiper switch.

lRear washer switch.

lRear wiper motor.

lRear washer pump motor.

Both the Body Control Unit (BCU) and the Intelligent Driver Module (IDM) control the wiper system. The BCU controls

the time delay function of the wiper system and is located below and behind the passenger glovebox. During engine

cranking the BCU prevents wiper functions. Two relays are located in the passenger compartment fusebox. The

relays control the delay operation of the front and rear wipers. The relays are an integral part of the fusebox and

cannot be renewed separately.

Power for the wiper system is supplied by the IDM, which is integral with the passenger fusebox and cannot be

renewed as a component. A serial communication link allows communication between the IDM and the BCU.

The system has diagnostic capabilities through TestBook.

Front wipers

The two front windscreen wipers are operated by a linkage assembly and an electric motor located under the plenum

grill below the windscreen. The linkage and motor assembly is handed for left and right hand drive vehicles. The motor

is an integral part of the linkage and cannot be replaced separately.

The linkage comprises a pressed steel mounting plate which provides for the attachment of a wheel box at each end.

The mounting plate is secured to the bulkhead with flanged nuts which attach to a stud plate located behind the

bulkhead. A link arm is attached to each wheel box by a short link and secured with circlips. The link arm has an

attachment hole centrally located along its length for the electric motor drive link.

The electric motor is mounted in a recess in the bulkhead below a sealed cover plate. The drive spindle of the motor

protrudes through the cover plate and is fitted with a link. The link is attached to a tapered spline on the motor spindle

and is secured with a lock washer and nut. The opposite end of the link is attached to the central attachment point on

the link arm and secured with a circlip.

Each wheel box has a taper splined shaft which allows for the attachment of the wiper arm which is secured with a

washer and nut. The shaft of each wheel box is passed through a rubber sealed aperture in the plenum. The wiper

arm attachment to the splined shaft has a pivot to which the remainder of the arm is attached. The two parts of the

arm are connected by a spring which controls the pressure of the blade on the screen to a predetermined amount.

Page 1433 of 1672

WIPERS AND WASHERS

84-12 DESCRIPTION AND OPERATION

Rear wiper motor

The DC motor contains two permanent magnets and a park switch. An earth braid attached between the motor casing

and the brush pack is utilised to minimise radio interference during wiper functions.

The rear wiper switch provides an earth signal to the BCU, which determines the delay interval, if appropriate. The

BCU then signals the IDM to activate the rear wiper motor relay, which provides power to the rear wiper motor.

To allow the rear wiper to park when the rear wiper is switched off, power flows through the park switch until a cam

in the wiper motor assembly breaks the contact of the park switch. Triggering the park switch grounds the positive

side of the wiper motor causing it to stop abruptly

Washers

The washer system comprises a reservoir, washer pumps, hoses and washer jets. The front washers are controlled

from a stalk switch on the steering column and the rear washers are operated by a non-latching pushbutton switch on

the fascia adjacent to the instrument pack.

Reservoir

The reservoir is located behind the front bumper in the inner wheel arch and has a capacity of 6.0 litres (12.5 US pints).

A filler neck tube is connected to the reservoir with a seal and extends into the engine compartment on the front left

hand side. The filler neck tube contains a removable filter to prevent particle contamination and a yellow float to show

reservoir contents. The washer filler neck tube is sealed with a cap which is coloured blue for identification.

Two electric washer pumps are located on the rear face of the reservoir and supply washer fluid to the front

windscreen and the tail door window. Each pump is sealed to the reservoir with a rubber sealing grommet.

On vehicles with headlamp powerwash fitted, a third pump is fitted with a sealing grommet to the front face of the

reservoir.

The reservoir and filler neck tube are manufactured from moulded opaque nylon. The reservoir has moulded lugs for

attachment to the vehicle body. A bracket is attached to the top of the filler neck tube and locates in a hole in the body

to secure the top of the tube.

Page 1470 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-1

BODY CONTROL UNIT DESCRIPTION AND OPERAT ION

Description

General

The Body Control Unit (BCU) is located behind the passenger glovebox and is connected to the main harness by four

connectors on its bottom edge and an additional connector located on the side of the BCU casing. Mounting the BCU

behind the fascia makes it reasonably inaccessible for intruders to disable the anti-theft system.

The BCU uses solid-state microprocessor control to perform logical operations and timing functions for a variety of

the vehicle's electrically operated systems, these include:

lDoor locking.

lAnti-theft alarm and immobilisation system.

lExterior lighting including direction indicators and hazard warning lamps.

lCourtesy lighting.

lWipers and washers.

lElectric windows and sunroof.

lHeated windows.

The BCU also communicates with several other electronically controlled systems such as the EAT ECU and SLABS

ECU and also has a datalink between the Intelligent Driver Module (IDM) and the instrument pack. The datalink is a

low speed bus capable of transmitting and receiving messages at a data rate of 10,400 bits per second. Additional

inputs and outputs to peripheral devices are included which are necessary for determining vehicle status for particular

logical operations e.g. crank, ignition key inserted, fuel flap enable etc.

The BCU receives its power supply from the engine compartment fuse box, and is protected by a 10 A fuse.

The BCU communicates with the IDM to provide the control signals to perform power switching operations in

conjunction with dedicated relays.

IDM

The IDM is integrated into the passenger compartment fuse box, which is mounted behind the fascia below the

steering column. There are no harnesses between the fuse box and the IDM. The IDM performs the power switching

operations for several of the vehicle's electrical systems.

The IDM communicates with the BCU and the instrument pack via a serial interface. If the BCU or the IDM is replaced,

the communications link between the two units has to be re-established. This can be done either by switching on the

ignition and leaving it on for five minutes, or by using TestBook. The vehicle immobilisation will remain active until the

communications link between the BCU and IDM has been re-established.

Transit mode

To prevent excessive battery drain during transit to overseas markets, the vehicle is placed in a transit mode. The

following functions are disabled when the vehicle is in transit mode:

lVolumetric sensors.

lPassive immobilisation.

lImmobilisation of the vehicle by use of door lock.

lIgnition key interlock.

lElectric seat enable time-out with driver's door open.

Page 1483 of 1672

BODY CONTROL UNIT

86-3-14 DESCRIPTION AND OPERATION

Alarm system

The alarm system comprises the following components:

lRF receiver.

lRF transmitter.

lBCU.

lIDM.

lDoor switches, door lock switches and bonnet switch.

lBattery backed-up sounder (BBUS).

lStatus LED.

On non NAS vehicles, power supply for the alarm sounder and the battery BBUS is provided through two relays in the

passenger compartment fuse box. Each of the coils of the alarm relays are directly connected to the IDM which

controls their operation under the direction of BCU signals received via the serial data bus.

On NAS vehicles, an audible warning is provided through operation of the vehicle horns. The BCU provides an earth

path for the coil of the horn relay to initiate vehicle horn operation.

+ ALARM SYSTEM AND HORN, DESCRIPTION AND OPERATION, Description.

Central Door Locking (CDL)

The BCU carries out the logic control operation for CDL. A CDL switch is mounted on the fascia panel and has two

inputs to the BCU, one for lock and one for unlock.

Door locking and unlocking can be performed using the remote transmitter in the keys and the receiver unit located

above the vehicle's headlining, behind the rear sunroof aperture. The receiver detects the signals sent from the

remote transmitter and sends a decoded signal to the BCU for processing.

Four methods of door locking are available:

lRemote handset locking.

lVehicle key locking.

lCDL switch locking.

lSpeed related locking.

Two security levels of door locking are available, CDL and Superlocking. The anti-theft alarm system works in

conjunction with the CDL system.

Electric windows and sunroof

The BCU controls the logical operations and the timing periods for the electric front windows. The rear windows are

hard-wired and the two electric sunroofs are controlled by a dedicated ECU which is enabled by the BCU.

The front windows are electrically operated using two rocker switches located in the centre console. Electric motors

are located in each of the front doors.

The rear windows are enabled by the IDM controlling the operation of the rear window relay located in the passenger

compartment fuse box.

Wipers and washers

The wiper and washer functions are controlled by the BCU and the IDM.

The front wipers and washers are operated from the switch stalk located on the right hand side of the steering column

and only operate when the ignition switch is in position I or II. The front wipers are operated by a motor located below

the windscreen plenum.

+ WIPERS AND WASHERS, DESCRIPTION AND OPERATION, Description.

Page 1484 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-15

The BCU controls the wiper motor frequency of operation via the IDM when intermittent wipe or wash is selected. The

front intermittent wipe option features five different intermittent delay periods. The shortest delay period is 3 seconds

and this is increased by 2 second increments up to a maximum delay of 11 seconds. The desired delay period for the

front wipers is set by the position of the rotary switch located on the wiper column stalk.

The rear wiper switch is located on the instrument pack cowl and is latched when pressed. The rear wiper electric

motor is located in the tail door. The rear wiper operation is controlled according to a programmed strategy via the

BCU and the IDM. The BCU also checks for a signal from either the reverse lamp switch located in the vehicle gearbox

(manual gearbox models) or the gear position switch (automatic gearbox models) for operating the rear wipers when

the vehicle is in reverse. The rear wiper and washer only operate when the ignition switch is in position II.

The front and rear washer pumps and the headlamp powerwash (where fitted) are also controlled through the BCU.

The washers are operated from electric pumps attached to the washer reservoir located in the left hand wheel arch.

The front wash switch is located on the wiper column stalk and is pulled towards the steering wheel to select the

washer function. When the front washers are operated, the wipers are also activated for three full cycles. The rear

wash switch is located on the instrument pack cowl. The BCU programme can be configured in one of two modes of

operation:

lNo wiper operation when the wash switch is pressed.

lWiper action after an initial delay of 400 ms.

Headlamp wash is activated by the BCU via the IDM and operates when the headlamps are on and the front washers

function is selected.

Electric seats

The BCU controls the logical operation of the electrically operated front seats. Two modes of operation are available:

+ SEATS, DESCRIPTION AND OPERATION, Description - electric seats.

lElectric seat adjustment is enabled if the ignition is on or the driver's door is opened for a short time period.

lElectric seat adjustment is enabled if the ignition is on and the driver's door is closed.

The seats are operated by four electric motors which control the seat cushion rear up/ down, the seat cushion front

up/ down, seat cushion forward/ rearward and seat squab recline. The electrically powered lumbar adjustment in each

seat is operated by a single motorised air pump and a solenoid located on the seat squab frame. The air pump inflates

a cushion in the seat squab and the solenoid operates a valve to deflate the cushion. The seat squab and cushion

may also contain heater elements to provide heated seat operation.

The switches for electrically operated seats are located either side of the centre console.

Direction indicators and hazard warning lamps

The direction indicator lamps are operated from a three position direction indicator switch on the left hand, steering

column stalk. The BCU only allows the lamps to work as direction indicators when the ignition switch is in position II.

The BCU also controls the lamps to operate as hazard warning lamps and as a visual warning for the anti-theft system,

in which cases all lamps flash simultaneously irrespective of the ignition switch position.

System control of the direction indicators and hazard warning lamps is provided by the BCU operating with the IDM

and two electronic relays located in the passenger compartment fuse box. The IDM and relays are integral parts of

the passenger compartment fuse box and cannot be serviced individually. The serial data bus is used for

communication of status and operation requests between the BCU, IDM and instrument pack.

The hazard warning lamps are operated from a latching pushbutton switch located on the fascia.

All direction indicator/ hazard warning lamp bulbs are rated at 5 Watts.