engine coolant LAND ROVER DISCOVERY 2002 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 202 of 1672

ENGINE - TD5

REPAIRS 12-1-63

Refit

1.Clean oil pressure switch threads.

2.Fit oil pressure switch and tighten to 15 Nm (11

lbf.ft).

3.Connect multiplug to oil pressure switch.

4.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolts

to 25 Nm (18 lbf.ft).

5.Fit and secure engine acoustic cover.

6.Top up engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

Cooler - engine oil

$% 12.60.68

Remove

1.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

2.Remove centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

3.Remove clutch housing bolt and release

coolant pipe from rear of engine.

4.Release clip and coolant hose from oil cooler.

5.Disconnect multiplug from oil pressure switch.

6.Remove full-flow oil filter element using a

suitable strap wrench.

7.Remove 3 bolts, remove oil filter adaptor

housing and discard gasket.

8.Remove 7 bolts, remove oil cooler and discard

gasket.

9.Remove oil pressure switch.

Page 203 of 1672

ENGINE - TD5

12-1-64 REPAIRS

Refit

1.Clean oil cooler and mating faces.

2.Fit oil pressure switch and tighten to 9 Nm (7

lbf.ft).

3.Position new gasket and fit oil cooler housing,

tighten bolts to 25 Nm (18 lbf.ft).

4.Position and fit oil filter adaptor housing,

tighten bolts to 25 Nm (18 lbf. ft).

5.Fit oil filter, tighten hand tight then a further half

turn.

6.Position coolant hose to oil cooler and secure

clip.

7.Position coolant pipe bolt and tighten to 50 Nm

(37 lbf.ft) .

8.Connect multiplug to oil pressure switch.

9.Fit centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

10.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

11.Top up engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

Gasket - centrifuge oil drain pipe

$% 12.60.90

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

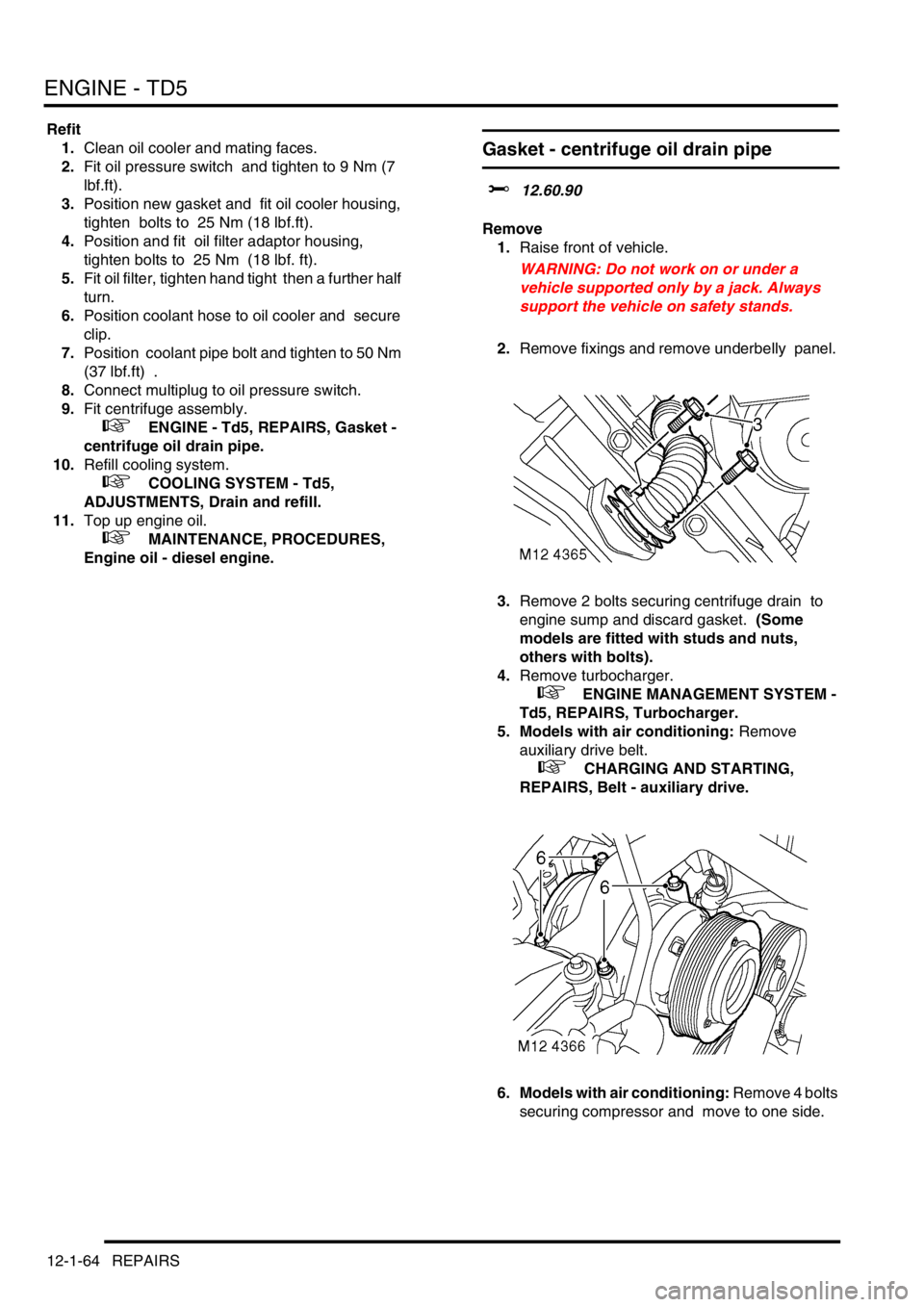

2.Remove fixings and remove underbelly panel.

3.Remove 2 bolts securing centrifuge drain to

engine sump and discard gasket. (Some

models are fitted with studs and nuts,

others with bolts).

4.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

5. Models with air conditioning: Remove

auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

6. Models with air conditioning: Remove 4 bolts

securing compressor and move to one side.

Page 211 of 1672

ENGINE - TD5

12-1-72 OVERHAUL

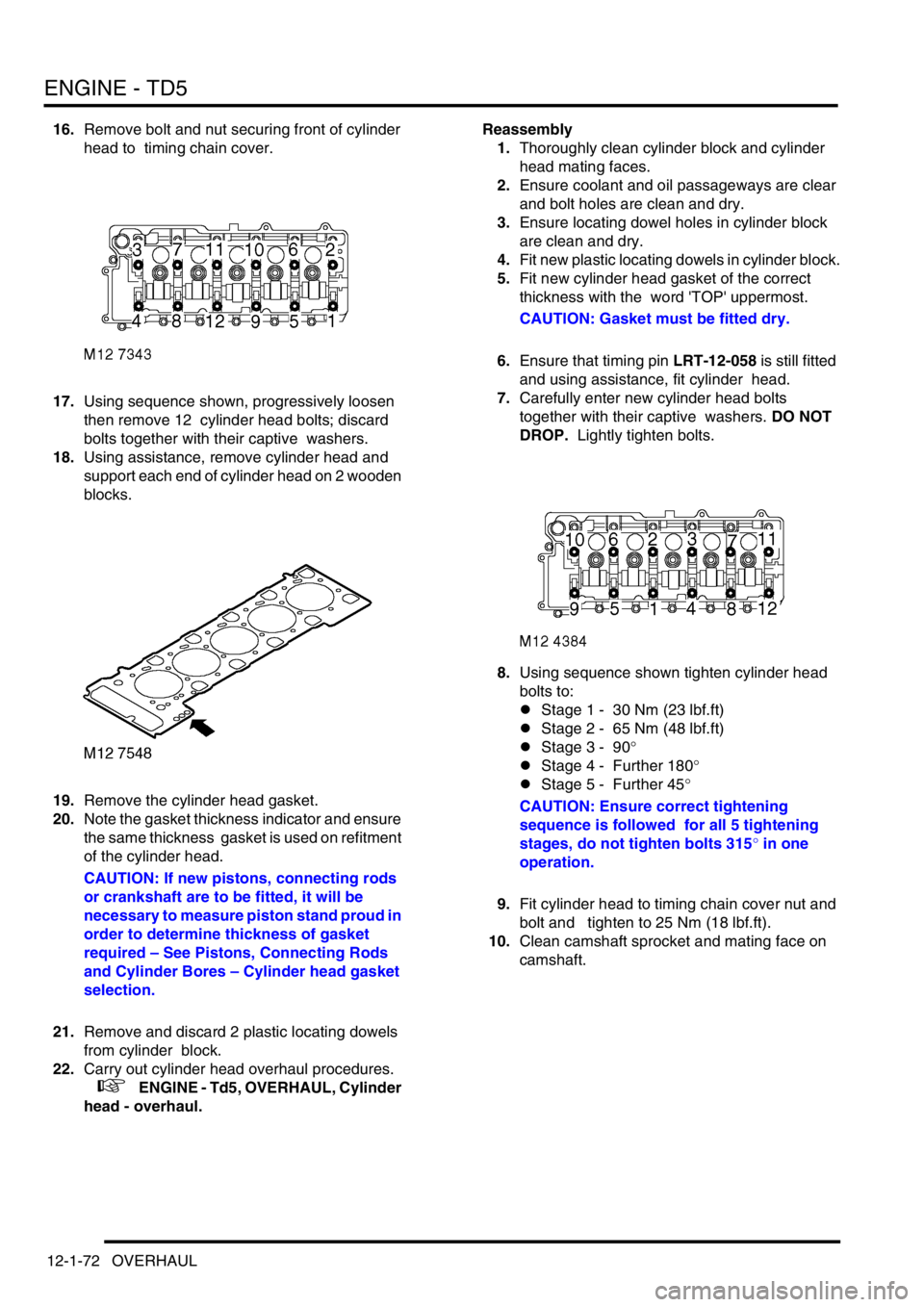

16.Remove bolt and nut securing front of cylinder

head to timing chain cover.

17.Using sequence shown, progressively loosen

then remove 12 cylinder head bolts; discard

bolts together with their captive washers.

18.Using assistance, remove cylinder head and

support each end of cylinder head on 2 wooden

blocks.

19.Remove the cylinder head gasket.

20.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of the cylinder head.

CAUTION: If new pistons, connecting rods

or crankshaft are to be fitted, it will be

necessary to measure piston stand proud in

order to determine thickness of gasket

required – See Pistons, Connecting Rods

and Cylinder Bores – Cylinder head gasket

selection.

21.Remove and discard 2 plastic locating dowels

from cylinder block.

22.Carry out cylinder head overhaul procedures.

+ ENGINE - Td5, OVERHAUL, Cylinder

head - overhaul.Reassembly

1.Thoroughly clean cylinder block and cylinder

head mating faces.

2.Ensure coolant and oil passageways are clear

and bolt holes are clean and dry.

3.Ensure locating dowel holes in cylinder block

are clean and dry.

4.Fit new plastic locating dowels in cylinder block.

5.Fit new cylinder head gasket of the correct

thickness with the word 'TOP' uppermost.

CAUTION: Gasket must be fitted dry.

6.Ensure that timing pin LRT-12-058 is still fitted

and using assistance, fit cylinder head.

7.Carefully enter new cylinder head bolts

together with their captive washers. DO NOT

DROP. Lightly tighten bolts.

8.Using sequence shown tighten cylinder head

bolts to:

lStage 1 - 30 Nm (23 lbf.ft)

lStage 2 - 65 Nm (48 lbf.ft)

lStage 3 - 90

°

lStage 4 - Further 180

°

lStage 5 - Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages, do not tighten bolts 315

° in one

operation.

9.Fit cylinder head to timing chain cover nut and

bolt and tighten to 25 Nm (18 lbf.ft).

10.Clean camshaft sprocket and mating face on

camshaft.

Page 216 of 1672

ENGINE - TD5

OVERHAUL 12-1-77

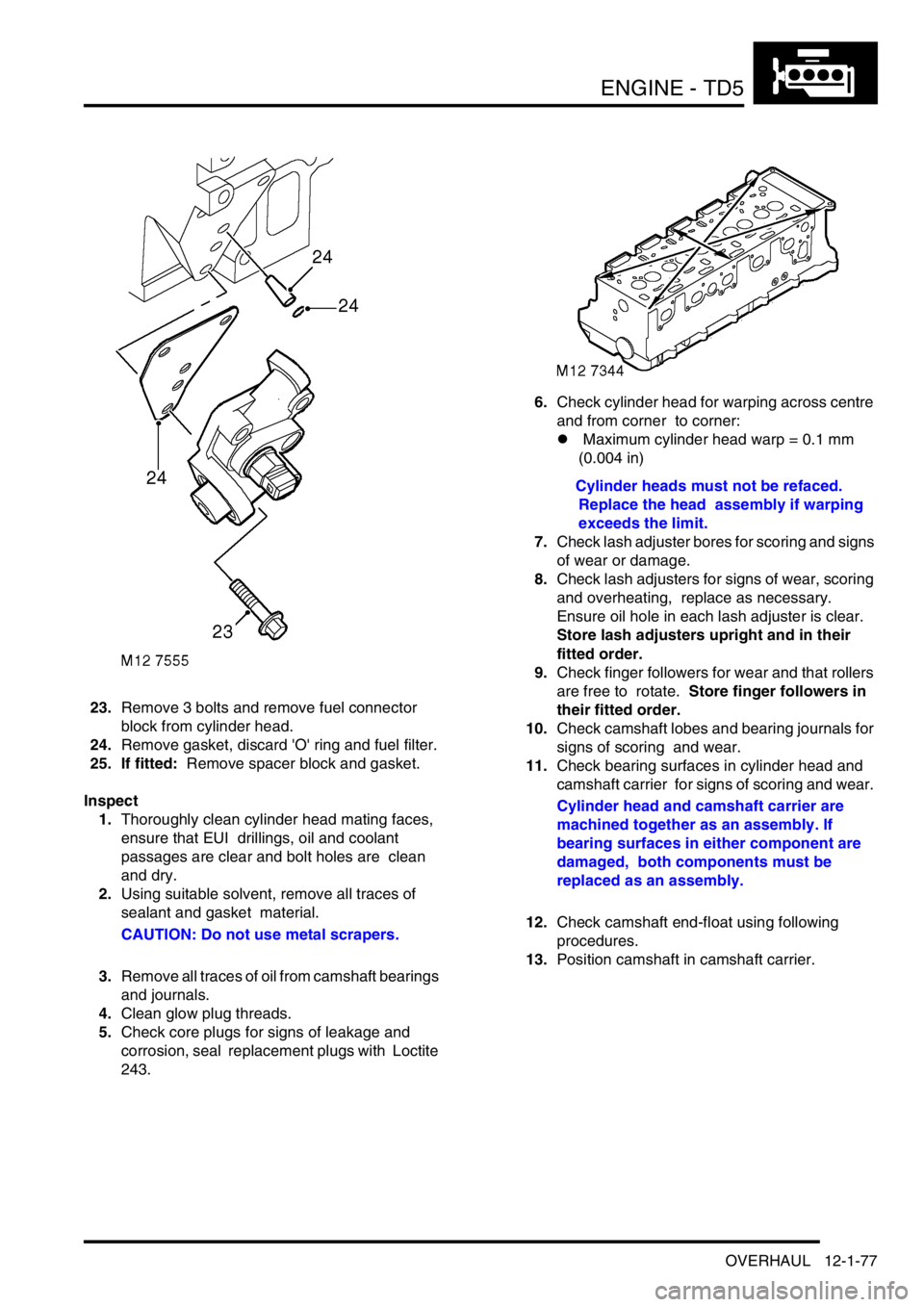

23.Remove 3 bolts and remove fuel connector

block from cylinder head.

24.Remove gasket, discard 'O' ring and fuel filter.

25. If fitted: Remove spacer block and gasket.

Inspect

1.Thoroughly clean cylinder head mating faces,

ensure that EUI drillings, oil and coolant

passages are clear and bolt holes are clean

and dry.

2.Using suitable solvent, remove all traces of

sealant and gasket material.

CAUTION: Do not use metal scrapers.

3.Remove all traces of oil from camshaft bearings

and journals.

4.Clean glow plug threads.

5.Check core plugs for signs of leakage and

corrosion, seal replacement plugs with Loctite

243.6.Check cylinder head for warping across centre

and from corner to corner:

l Maximum cylinder head warp = 0.1 mm

(0.004 in)

Cylinder heads must not be refaced.

Replace the head assembly if warping

exceeds the limit.

7.Check lash adjuster bores for scoring and signs

of wear or damage.

8.Check lash adjusters for signs of wear, scoring

and overheating, replace as necessary.

Ensure oil hole in each lash adjuster is clear.

Store lash adjusters upright and in their

fitted order.

9.Check finger followers for wear and that rollers

are free to rotate. Store finger followers in

their fitted order.

10.Check camshaft lobes and bearing journals for

signs of scoring and wear.

11.Check bearing surfaces in cylinder head and

camshaft carrier for signs of scoring and wear.

Cylinder head and camshaft carrier are

machined together as an assembly. If

bearing surfaces in either component are

damaged, both components must be

replaced as an assembly.

12.Check camshaft end-float using following

procedures.

13.Position camshaft in camshaft carrier.

Page 263 of 1672

ENGINE - V8

12-2-20 REPAIRS

8. Models with air conditioning: Position fan

cowl and secure clips.

9.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

Gasket - rocker cover - RH

$% 12.29.41

Remove

1.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2.Remove upper inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

3. Models with SAI: Disconnect 2 air manifold

unions from adapters in cylinder head and

remove manifold.

4.Remove 2 bolts securing coolant rails to inlet

manifold.

Page 264 of 1672

ENGINE - V8

REPAIRS 12-2-21

5.Release coolant rail from inlet manifold and

discard 'O' ring.

6.Remove nuts securing alternator cables and

release cables from alternator.

7.Disconnect multiplugs from RH bank of

injectors and release harness from fuel rail.

8.Release ht leads from clips on rocker cover.

9.Remove 4 bolts securing rocker cover.

10.Remove rocker cover and collect gasket. Refit

1.Clean mating faces of rocker cover and

cylinder head.

2.Using a new gasket, fitted dry, position rocker

cover ensuring gasket is correctly located.

3.Fit rocker cover bolts and working in diagonal

sequence, tighten to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

4.Ensure that outer rim of gasket is correctly

positioned around periphery of rocker cover.

5.Secure ht leads in rocker cover clips.

6.Secure injector harness to fuel rail and connect

multiplugs to injectors.

7.Position alternator cables, and tighten terminal

B+ nut to 18 Nm (13 lbf.ft) and terminal D+ nut

to 5 Nm (3 lbf.ft).

8.Clean coolant rail 'O' ring recess.

9.Lubricate and fit new 'O' ring to coolant rail,

position coolant rails, fit bolts and tighten to 22

Nm (16 lbf.ft).

10. Models with SAI: Clean air manifold unions,

position manifold and tighten unions nuts to 25

Nm (18 lbf.ft).

11.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

12.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 270 of 1672

ENGINE - V8

REPAIRS 12-2-27

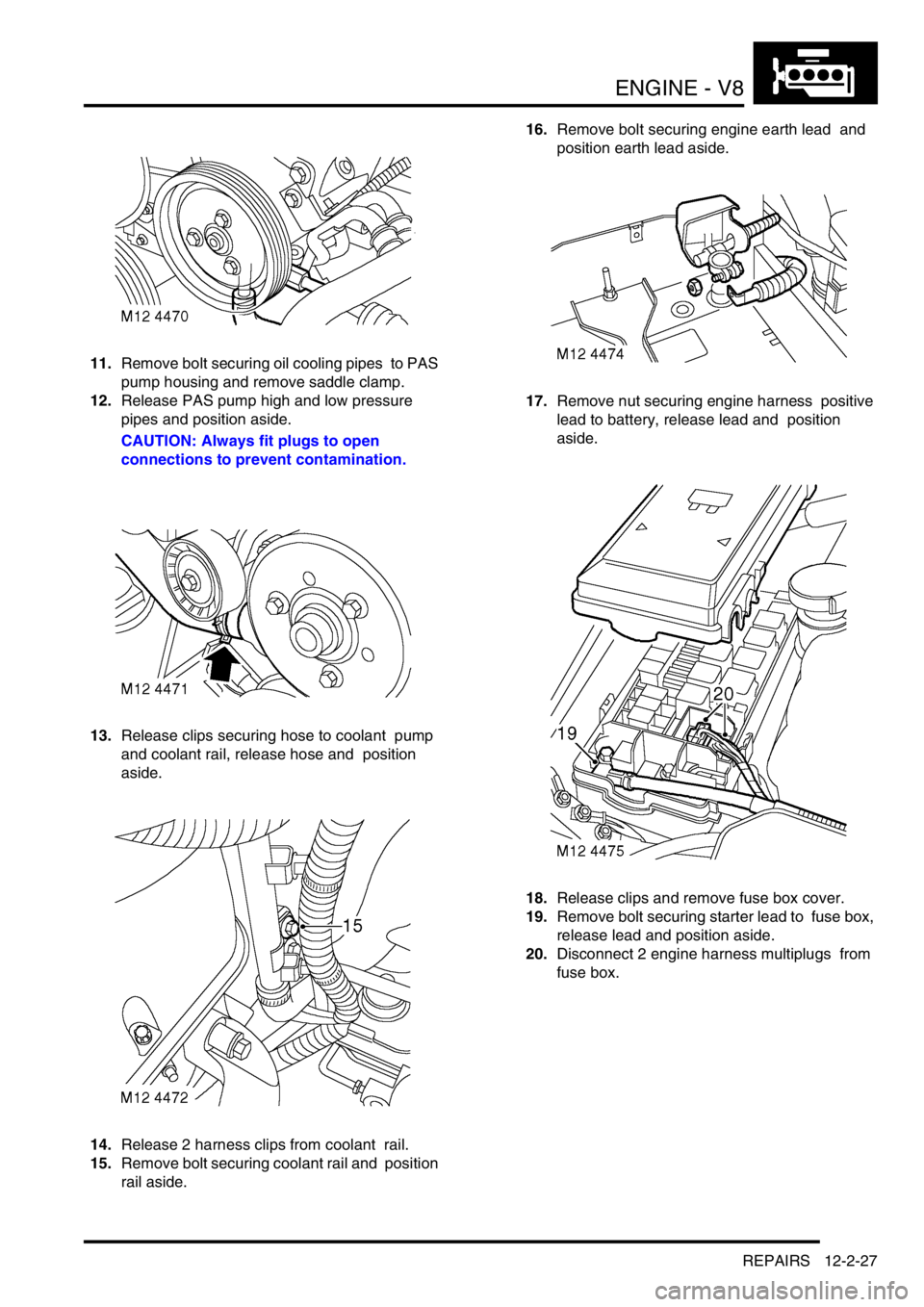

11.Remove bolt securing oil cooling pipes to PAS

pump housing and remove saddle clamp.

12.Release PAS pump high and low pressure

pipes and position aside.

CAUTION: Always fit plugs to open

connections to prevent contamination.

13.Release clips securing hose to coolant pump

and coolant rail, release hose and position

aside.

14.Release 2 harness clips from coolant rail.

15.Remove bolt securing coolant rail and position

rail aside. 16.Remove bolt securing engine earth lead and

position earth lead aside.

17.Remove nut securing engine harness positive

lead to battery, release lead and position

aside.

18.Release clips and remove fuse box cover.

19.Remove bolt securing starter lead to fuse box,

release lead and position aside.

20.Disconnect 2 engine harness multiplugs from

fuse box.

Page 273 of 1672

ENGINE - V8

12-2-30 REPAIRS

Refit

1.Clean mating faces of engine and gearbox,

dowel and dowel holes.

2.Lubricate splines and bearing surface on first

motion shaft with grease.

3.With assistance position engine in engine bay,

align to gearbox and locate on dowels.

4.Position support brackets, fit bell housing bolts

and tighten to 50 Nm (37 lbf.ft).

5.Position engine mountings, fit nuts and tighten

to 85 Nm (63 lbf.ft).

6.Lower lifting equipment and remove from

engine.

7. Models with automatic gearbox: Align torque

converter to drive plate, fit bolts and tighten to

50 Nm (37 lbf.ft). Fit access plug.

8.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

9.Position oil cooling pipe saddle clamps and

tighten bolts.

10.Position engine harness into foot well.

11.Connect 5 multiplugs to ECM.

12.Fit toe board and secure with trim fixings.

13.Connect engine harness earth to body and

secure with nut.

14.Connect engine harness to main harness

multiplug.

15.Connect multiplug to EVAP purge valve.

16.Connect engine harness multiplugs to fuse

box.

17.Connect starter lead to fuse box and secure

with nut.

18.Connect engine harness positive lead to

battery and tighten nut.

19.Fit fuse box cover.

20.Position engine earth lead and secure with

bolt.

21.Position coolant rail and secure with bolt.

22.Connect harness clips to coolant rail.

23.Connect hose to coolant rail and coolant pump

and secure with clips.

24.Connect PAS pump high and low pressure

pipes and secure with clips.

25.Position oil cooling pipe saddle clamp to PAS

pump housing and secure with bolt.

26.Clean A/C compressor and housing mating

faces, dowels and dowel holes. 27.Position A/C compressor, fit bolts and tighten

to 22 Nm (16 lbf.ft).

28.Connect multiplug to A/C compressor.

29.Clean ACE pump and housing mating faces,

dowels and dowel holes.

30.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

31.Clean all pulley 'V's, fit auxiliary drive belt,

using a 15mm spanner, release belt tensioner

secure belt and re-tension drive belt .

32.Ensure auxiliary drive belt is correctly located

on all pulleys.

33.Fit radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

34.Fit top hose and secure with clips.

35.Connect fuel pipe to fuel rail.

36.Position ignition coils and connect ht leads.

37.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

38.Fit new oil filter and refill engine with oil.

+ ENGINE - V8, REPAIRS, Filter - oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

39.Top up gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 278 of 1672

ENGINE - V8

REPAIRS 12-2-35

Strainer - oil pick-up

$% 12.60.20

Remove

1.Remove sump gasket.

+ ENGINE - V8, REPAIRS, Gasket -

sump.

2.Remove 2 bolts and one nut securing oil pick-

up strainer.

3.Remove oil pick-up strainer.

4.Collect spacer from stud.

5.Remove and discard 'O'ring.

Refit

1.Clean oil pick up strainer and 'O' ring recess.

2.Lubricate and fit new 'O' ring.

3.Locate spacer on stud.

4.Position oil pick-up strainer, fit bolts and tighten

to 10 Nm (8 lbf.ft). Fit nut and tighten to 22 Nm

(16 lbf.ft).

5.Fit new sump gasket.

+ ENGINE - V8, REPAIRS, Gasket -

sump.

Pump - oil

$% 12.60.26

Remove

1.Remove timing gear cover gasket.

+ ENGINE - V8, REPAIRS, Gasket -

timing gear cover.

2.Remove bolt securing CMP sensor, remove

clamp and sensor.

3.Remove 6 bolts securing coolant pump,

remove pump and discard gasket.

4.Remove oil pressure switch and discard

sealing washer.

5.Remove 4 bolts securing oil filter head, remove

filter head and discard 2 'O' rings.

6.Remove filter head adaptor.

Refit

1.Ensure filter head adaptor is clean and apply

Loctite 577 sealant to thread.

2.Fit filter head adaptor and tighten bolts to 13

Nm (9 lbf.ft).

3.Clean filter head and mating face.

4.Fit new 'O' rings to filter head and filter head

adaptor.

5.Fit filter head and tighten bolts to 8 Nm (6 lbf.ft).

6.Ensure oil pressure switch and mating face is

clean.

7.Fit new sealing washer and tighten switch to 15

Nm (11 lbf.ft).

Page 279 of 1672

ENGINE - V8

12-2-36 REPAIRS

8.Clean coolant pump and mating face.

9.Use a new gasket and fit coolant pump.

Tighten bolts securing coolant pump to 25 Nm

(19 lbf.ft).

10.Ensure CMP sensor is clean and fit sensor to

cover.

11.Fit clamp to CMP sensor and tighten bolt to 8

Nm (6 lbf.ft).

12.Fit timing gear cover gasket.

+ ENGINE - V8, REPAIRS, Gasket -

timing gear cover.

Gasket - sump

$% 12.60.38

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove dipstick.

4.Raise the vehicle on a ramp.

5.Drain engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

6.Remove 8 bolts securing cross member and

remove cross member.

7.Raise front of vehicle under body to increase

clearance between engine and front axle.

8.Disconnect and release gearbox oil cooler pipe

and discard 'O' ring.