LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 491 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-34 DESCRIPTION AND OPERATION

Input/Output

The input value for the relay windings is battery voltage, the input value for the switching contacts comes from fuse

10 in the engine compartment fuse box. The output control of the switching contacts is direct to the fuel pump motor,

and the relay windings are controlled by pin number 18 of connector C0635 of the ECM.

At ignition 'on' (position II) the fuel pump relay contacts remain open until the ECM supplies an earth path for the relay

windings via pin number 18 of connector C0635 of the ECM. At this point, the relay windings are energised, drawing

the relay contacts closed. This allows voltage from fuse 10 in the passenger compartment fuse box to pass directly

to the fuel pump.

The fuel pump relay can fail the following ways or supply incorrect signal:

lRelay drive open circuit.

lShort circuit to vehicle earth.

lShort circuit to vehicle supply.

lComponent failure.

In the event of a fuel pump relay failure any of the following symptoms may be observed:

lEngine stalls or will not start.

lNo fuel pressure at the fuel injectors.

The ECM performs three types of diagnostic test to confirm the fuel pump relay integrity:

lOutput short circuit to earth

lOutput short circuit to battery voltage

lOutput open circuit

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

Evaporative emissions

Refer to Emissions section for description of the evaporative emissions system components.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative emission control system.

Secondary air injection (NAS only)

Refer to Emissions section for description of the secondary air injection system components.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Secondary air injection system.

Fuel tank pressure sensor (NAS only)

Refer to Fuel Delivery section for description of the fuel system components.

+ FUEL DELIVERY SYSTEM - V8, DESCRIPTION AND OPERATION, Description.

Refer to Emissions section for description of the fuel tank pressure sensor.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative emission control system.

P Code J2012 Description Land Rover Description

P1230 Fuel pump relay malfunction Fuel pump relay open circuit - not the fuel pump

P1231 Fuel pump relay circuit low Fuel pump relay short circuit to battery supply - not the

fuel pump

P1232 Fuel pump relay circuit high Fuel pump relay short circuit to earth - not the fuel pump

Page 492 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-35

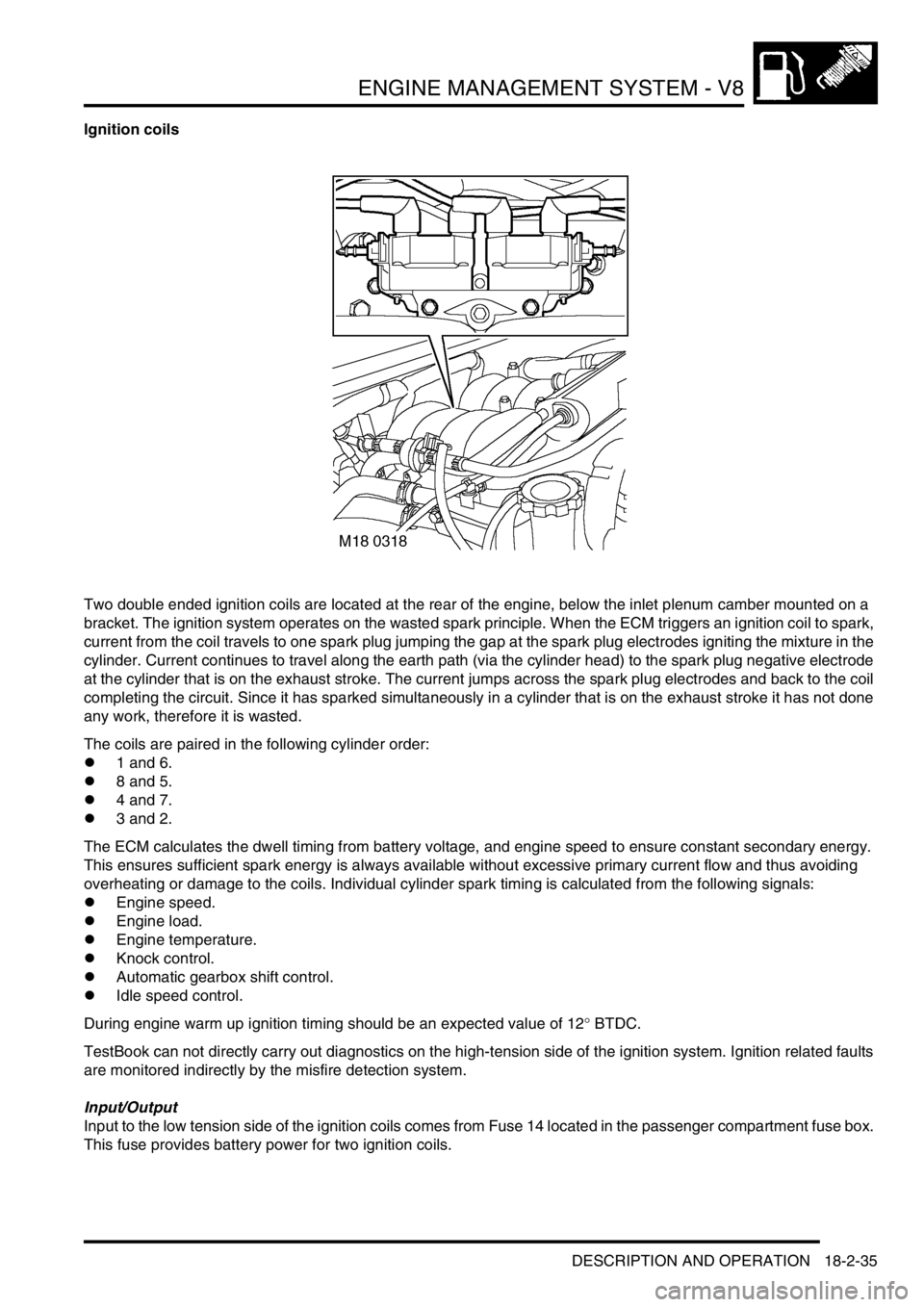

Ignition coils

Two double ended ignition coils are located at the rear of the engine, below the inlet plenum camber mounted on a

bracket. The ignition system operates on the wasted spark principle. When the ECM triggers an ignition coil to spark,

current from the coil travels to one spark plug jumping the gap at the spark plug electrodes igniting the mixture in the

cylinder. Current continues to travel along the earth path (via the cylinder head) to the spark plug negative electrode

at the cylinder that is on the exhaust stroke. The current jumps across the spark plug electrodes and back to the coil

completing the circuit. Since it has sparked simultaneously in a cylinder that is on the exhaust stroke it has not done

any work, therefore it is wasted.

The coils are paired in the following cylinder order:

l1 and 6.

l8 and 5.

l4 and 7.

l3 and 2.

The ECM calculates the dwell timing from battery voltage, and engine speed to ensure constant secondary energy.

This ensures sufficient spark energy is always available without excessive primary current flow and thus avoiding

overheating or damage to the coils. Individual cylinder spark timing is calculated from the following signals:

lEngine speed.

lEngine load.

lEngine temperature.

lKnock control.

lAutomatic gearbox shift control.

lIdle speed control.

During engine warm up ignition timing should be an expected value of 12

° BTDC.

TestBook can not directly carry out diagnostics on the high-tension side of the ignition system. Ignition related faults

are monitored indirectly by the misfire detection system.

Input/Output

Input to the low tension side of the ignition coils comes from Fuse 14 located in the passenger compartment fuse box.

This fuse provides battery power for two ignition coils.

Page 493 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-36 DESCRIPTION AND OPERATION

It is possible to test both primary and secondary coils of the ignition coils for resistance using a multimeter as follows:

lExpected primary coil resistance: 0.5

± 0.05 Ω at 20 °C (68 °F).

lExpected secondary coil resistance: 13.3

± 1.3 kΩ at 20 °C (68 °F).

The ECM provides the earth control for each coil on separate pins as follows:

LH Bank (cylinders 1, 3, 5, 7)

lCylinder 1 - pin 6 of connector C0638 of the ECM multiplug.

lCylinder 3 - pin 2 of connector C0638 of the ECM multiplug.

lCylinder 5 - pin 8 of connector C0638 of the ECM multiplug.

lCylinder 7 - pin 7 of connector C0638 of the ECM multiplug.

RH Bank (cylinders 2, 4, 6, 8)

lCylinder 2 - pin 2 of connector C0638 of the ECM multiplug.

lCylinder 4 - pin 7 of connector C0638 of the ECM multiplug.

lCylinder 6 - pin 6 of connector C0638 of the ECM multiplug.

lCylinder 8 - pin 8 of connector C0638 of the ECM multiplug.

The ignition coil can fail the following ways or supply incorrect signal:

lCoil open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lFaulty component.

In the event of ignition coil failure any of the following symptoms may be observed:

lEngine misfire on specific cylinders.

lEngine will not start.

Knock Sensor (KS)

The ECM uses two knock sensors located between the centre two cylinders of each bank to detect pre-ignition. The

knock sensors consist of piezo ceramic crystals that oscillate to create a voltage signal. During pre-ignition the

frequency of crystal oscillation increases, which alters the signal output to the ECM. The ECM compares the signal

to known signal profiles in its memory. If pre-ignition is detected the ECM retards ignition timing for a number of cycles.

If no more pre-ignition is detected, the timing is gradually advanced to the original setting.

Page 494 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-37

The ignition is calibrated to run on 95 RON premium fuel, but the system will run satisfactorily on 91 RON regular fuel.

If the vehicle is refuelled with a lower grade fuel, some audible detonation will initially be heard. This is non-damaging

and ceases when the system adaption is completed.

Input/Output

Because of the nature of its operation, the knock sensors do not require any electrical input source. The KS output

for LH bank (cylinders 1, 3, 5, 7) is measured via pin 49 of connector C0636 of the ECM. The KS output for RH bank

(cylinders 2, 4, 6, 8) is measured via pin 36 of connector C0636 of the ECM. Both knock sensors have a screened

earth to protect the integrity of the sensor signals. The KS earth for LH bank (cylinders 1, 3, 5, 7) is via pin 48 of

connector C0636 of the ECM. The KS earth for RH bank (cylinders 2, 4, 6, 8) is via pin 35 of connector C0636 of the

ECM.

The connector and sensor terminals are gold plated for corrosion and temperature resistance, care must be exercised

while probing the connector and sensor terminals.

The KS can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lFaulty component.

lIncorrectly tightened sensor.

In the event of a KS signal failure any of the following symptoms may be observed:

lKS disabled, the ECM refers to a 'safe ignition map'.

lRough running.

lEngine performance concern.

The ECM performs the following diagnostic checks to confirm correct knock sensor operation:

lKS signal level is less than the minimum threshold (dependent on engine speed) – the engine must be running,

coolant temperature above 60

°C (140°F), number of camshaft revolutions since start greater than 50 and the KS

signal profile must be less than the threshold value at a given engine speed for a fault condition to be flagged

lKS signal is greater than the maximum threshold (dependent on engine speed) – the engine must be running,

coolant temperature above 60

°C (140°F), number of camshaft revolutions since start greater than 50 and the KS

signal profile must be greater than the threshold value at a given engine speed for a fault condition to be flagged

lError counter for verification of knock internal circuitry exceeded – the engine must be running, coolant

temperature above 60

°C (140°F), number of camshaft revolutions since start greater than 50 and the error

counter greater than the threshold value at a given engine speed for a fault condition to be flagged

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

P Code J2012 Description Land Rover Description

P0327 Knock sensor 1 circuit low input (bank 1 or single

sensor)LH bank signal less than threshold determined from

ECM model above 2200 rev/min

P0328 Knock sensor 1 circuit high input (bank 1 or

single sensor)LH bank signal greater than threshold determined from

ECM model above 2200 rev/min

P0332 Knock sensor 2 circuit low input (bank 2) RH bank signal less than threshold determined from

ECM model above 2200 rev/min

P0333 Knock sensor 2 circuit high input (bank 2) RH bank signal greater than threshold determined from

ECM model above 2200 rev/min

Page 495 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-38 DESCRIPTION AND OPERATION

Spark plugs

The spark plugs are platinum tipped on both centre and earth electrodes. The platinum tips give a long maintenance

free life.

Cleaning or resetting the spark plug gap is not recommended as this could result in damaging the platinum tips and

thereby reducing reliability.

The misfire detection system will malfunction and store erroneous codes if the incorrect spark plugs are used.

Input/Output

The ignition coils provide a voltage to the spark plugs via the ht leads. The cylinder head via the individual thread of

each spark plug provides the earth path.

The spark plugs can fail in the following ways:

lFaulty component.

lConnector or wiring fault.

lBreakdown of high tension lead causing tracking to chassis earth.

lIncorrect spark plugs fitted.

In the event of a spark plug failure, misfire on specific cylinder may be observed:

High tension (ht) leads

The ht leads are located on top of the engine, below the plenum chamber. Their function is to transfer the ht voltage

generated by the ignition coils to the spark plugs in the engine.

Input/Output

The input to the ht lead is ht voltage from the ignition coil pack. The ht lead then supplies this voltage to the spark

plug. Output ht voltage is used by the spark plugs to ignite the air/fuel mixture in the combustion chamber.

The ht leads can fail in the following ways:

lConnector/ Wiring fault.

lFaulty component causing spark tracking to chassis earth.

lDamage to ht leads during component removal.

In the event of a ht lead failure the following symptom may be observed:

lMisfire on specific cylinder.

All ignition system related faults are diagnosed by the misfire detection system and its fault codes.

Page 496 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-39

Hill Decent Control (HDC)

Refer to Brakes for description of the hill descent control.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

High/Low ratio switch

Refer to Transfer Box for description of the high/ low ratio switch transfer box components.

+ TRANSFER BOX - LT230SE, DESCRIPTION AND OPERATION, Description.

Malfunction Indicator Lamp (MIL)/ service engine soon warning lamp

The MIL/ service engine soon warning lamp is located in the instrument cluster. It illuminates to alert the driver to

system malfunctions. Service engine soon warning lamp is the name for this warning lamp in NAS only, it is called

MIL in all other markets.

During ignition a self-test function of the lamp is carried out. The lamp will illuminate for 3 seconds then it will

extinguish if no faults exist.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Input/Output

The MIL is supplied with battery voltage from the instrument cluster. When the ECM detects a fault, it provides an

earth path to illuminate the MIL. Output to the MIL is via pin 20 of connector C0637 of the ECM.

Page 497 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-40 DESCRIPTION AND OPERATION

Air Temperature Control (ATC) request

The ATC request comes via the ATC switch located in the facia panel. When the driver operates the switch it acts as

a request from the ATC ECU to engage the ATC clutch to drive the system.

During periods of high driver demand such as hard acceleration or maximum rev/min the ATC clutch will be disabled

for a short time. This is to reduce the load on the engine.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

Input/Output

The operation of the ATC request is via a switch being connected to earth. Voltage is supplied via pin 38 of connector

C0637 of the ECM, at the point at when the switch is pressed the connection is made and the ATC clutch is engaged.

The ATC request can fail as follows:

lOpen circuit.

lShort circuit to voltage supply.

lShort circuit to vehicle earth.

lWiring loom fault.

In the event of an ATC request failure, the ATC system does not work.

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

ATC compressor clutch relay

The ATC compressor clutch relay is located in the engine compartment fuse box. It is a four pin normally open relay.

The relay must be energised to drive the ATC compressor clutch.

P Code J2012 Description Land Rover Description

P1535 Air conditioning compressor request

malfunctionATC requested when not in standby mode

Page 498 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-41

Input/Output

The ECM provides the earth for the relay coil to allow the relay contacts to close and the ATC clutch drive to receive

battery voltage. The ECM uses a transistor as a switch to generate an open circuit in the earth path of the relay coil.

When the ECM opens the earth path, the return spring in the relay will pull the contacts apart to shut down the ATC

clutch drive.

Input to the ATC clutch relay switching contacts is via fuse 6 located in the engine compartment fuse box. The relay

coils are supplied with battery voltage from the main relay, also located in the engine compartment fuse box. The earth

path for the relay coil is via pin 29 of the ECM C0657 connector. When the relay is energised the output from the

switching contacts goes directly to the ATC compressor clutch.

The ATC clutch relay can fail in the following ways:

lRelay open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lBroken return spring.

In the event of an ATC clutch relay failure, the ATC does not work.

Should a malfunction of the component occur, the following fault codes may be evident and can be retrieved by

TestBook.

P Code J2012 Description Land Rover Description

P1536 Air conditioning compressor request range/

performanceATC compressor clutch relay open circuit

P1537 Air conditioning compressor request low input ATC compressor clutch relay short to earth

P1538 Air conditioning compressor request high input ATC compressor clutch relay short to battery supply

Page 499 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-42 DESCRIPTION AND OPERATION

Cooling fan relay

The cooling fan relay is located in the engine compartment fuse box. It is a four pin normally open relay. The relay

must be energised to drive the cooling fan.

The cooling fan is used to cool both the condenser in which the ATC refrigerant is held and the radiator. This fan is

used especially when the engine is operating at excessively high temperatures. It is also used as a part of the ECM

backup strategy if the ECT fails.

Input/Output

The ECM provides the earth for the relay coils to allow the relay contacts to close and the cooling fan motor to receive

battery voltage. The ECM uses a transistor as a switch to generate an open circuit in the earth path of the relay

windings. When the ECM opens the earth path, the return spring in the relay will pull the contacts apart to shut down

the cooling fan motor drive.

Input to the cooling fan relay switching contacts is via fuse 5 located in the engine compartment fuse box. The relay

coils are supplied with battery voltage from the main relay, also located in the engine compartment fuse box. The earth

path for the relay coils is via pin 31 of the ECM connector C0636. When the relay is energised the output from the

switching contacts is directly to the cooling fan motor.

The cooling fan relay can fail in the following ways:

lRelay open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lBroken return spring.

In the event of a cooling fan relay failure, the cooling fan does not work.

Page 500 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-43

Operation - engine management

Fuel quantity

The ECM controls engine fuel quantity by providing sequential injection to the cylinders. Sequential injection allows

each injector to deliver fuel to the cylinders in the required firing order.

To achieve optimum fuel quantity under all driving conditions, the ECM provides an adaptive fuel strategy.

Conditions

Adaptive fuel strategy must be maintained under all throttle positions except:

lCold starting.

lHot starting.

lWide open throttle.

lAcceleration.

All of the throttle positions mentioned above are deemed to be 'open loop'. Open loop fuelling does not rely on

information from the HO

2 sensors, but the air/ fuel ratio is set directly by the ECM. During cold start conditions the

ECM uses ECT information to allow more fuel to be injected into the cylinders to facilitate cold starting. This strategy

is maintained until the HO

2 sensors are at working temperature and can pass exhaust gas information to the ECM.

Because of the specific nature of the other functions e.g. hot starting, idle, wide open throttle, and acceleration they

also require an 'open loop' strategy. For NAS vehicles with secondary air injection for cold start conditions, refer to

the Emissions section.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Secondary air injection system.

Adaptive fuel strategy also allows for wear in the engine and components, as well as slight differences in component

signals, as no two components will give exactly the same readings.

Function

To be able to calculate the amount of fuel to be injected into each cylinder, the ECM needs to determine the amount

of air mass drawn into each cylinder. To perform this calculation, the ECM processes information from the following

sensors:

lMass air flow (MAF) sensor.

lCrank speed and position (CKP) sensor.

lEngine coolant temperature (ECT) sensor.

lThrottle position (TP) sensor.

During one engine revolution, 4 of the 8 cylinders draw in air. The ECM uses CKP sensor information to determine

that one engine revolution has taken place, and the MAF sensor information to determine how much air has been

drawn into engine. The amount of air drawn into each cylinder is therefore 1/4 of the total amount measured by the

ECM via the MAF sensor.

The ECM refers the measured air mass against a fuel quantity map in its memory and then supplies an earth path to

the relevant fuel injector for a period corresponding to the exact amount of fuel to be injected into the lower inlet

manifold. This fuel quantity is in direct relation to the air mass drawn into each cylinder to provide the optimum ratio.

During adaptive fuelling conditions, information from the heated oxygen sensors (HO

2S) is used by the ECM to correct

the fuel quantity to keep the air/ fuel ratio as close to the stoichiometric ideal as possible.