earth LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 427 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-34 DESCRIPTION AND OPERATION

Turbocharger wastegate modulator

The turbocharger wastegate modulator is located on the ancillary bracket on the engine, and is connected by flexible

pipes to the turbocharger. The modulator controls turbocharger boost pressure by varying the pressure used to open

the turbocharger wastegate. This control is vital to ensure the turbocharger does not over boost the engine.

Input/Output

The turbocharger wastegate modulator receives battery voltage from the main relay. The ECM supplies the earth path

in the form of a pulse width modulated (PWM) signal. The PWM signal from the ECM operates the modulator at a

frequency of less than 50 Hz. This signal allows the turbocharger wastegate modulator to open and close the

wastegate. This permits a proportion of the exhaust gas to bypass the turbocharger through the wastegate, thereby

regulating boost pressure.

Input voltage to the turbocharger wastegate modulator is via the main relay.

The earth path is via a PWM signal generated at pin 21 of the ECM connector C0158.

The turbocharger wastegate modulator can fail as follows:

lOpen circuit.

lShort circuit to voltage supply.

lShort circuit to vehicle earth.

lWiring loom fault.

lConnector water ingress.

lConnector failure due to excess heat.

lComponent failure due to excess heat.

lComponent failure due to excess vibration.

In the event of a turbocharger wastegate modulator failure any of the following symptoms may be observed:

lReduced engine performance.

lIncreased engine performance.

lLack of power.

lExcess smoke.

lReduced fuel economy.

The MIL will not illuminate in the event of a turbocharger wastegate modulator failure.

Page 428 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-35

Cruise control master switch

The cruise control master switch is located on the dashboard. When the driver activates the switch it requests the

cruise control system to be active. The switch acts as a latching switch, on the first operation of the switch the cruise

control system is activated, when the switch is pressed again the cruise control system is de-activated. The cruise

control warning lamp is part of the switch and illuminates when the switch is activated.

Input/Output

Input to the cruise control master switch is 12 volts via the main relay. When the switch is pressed the circuit is

completed by the ECM providing an earth path for the relay via pin 15 of connector C0658 of the ECM.

The cruise control master switch can fail as follows:

lOpen circuit.

lShort circuit to voltage supply.

lShort circuit to vehicle earth.

lWiring loom fault.

In the event of a cruise control master switch failure cruise control does not operate.

Page 429 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-36 DESCRIPTION AND OPERATION

Cruise control set/accelerate (SET+) switch

The cruise control SET+ switch is located on the vehicle steering wheel. The switch is a momentary switch and when

pressed by the driver reacts as follows:

lRequests the cruise control to become active and set at the current road speed if not already set.

lIf the cruise control is already set, pressing the switch increases the road speed at 1 mph (1.6 km/h) intervals.

The cruise control SET+ switch will only become active and operate under the following conditions:

lThe vehicle speed must be above 22 mph (35 km/h).

lThe cruise control master switch must be 'on'.

lThe brake pedal must not be pressed.

lThe automatic transmission must be in 'drive'.

lThe clutch pedal must not be pressed.

lThe suspend switch has not been operated.

Input/Output

Input to the cruise control SET+ switch is 12 volts via the main relay. When the switch is pressed the circuit is

completed by the ECM providing an earth path for the relay via pin 11 of connector C0658 of the ECM.

The cruise control SET+ switch can fail as follows:

lOpen circuit.

lShort circuit to voltage supply.

lShort circuit to vehicle earth.

lWiring loom fault In the event of a cruise control SET+ switch failure cruise control does not operate.

Cruise control resume/suspend (RES) switch

The cruise control RES switch is located on the vehicle steering wheel. The switch is a momentary switch and when

pressed by the driver reacts as follows:

lRequests the cruise control to be suspended if it has already been set.

lRequests that cruise control is resumed at the previously set road speed.

The cruise control RES switch will only become active and operate under the following conditions:

lThe vehicle speed must be above 22 mph (35 km/h).

lThe cruise control master switch must be 'on'.

lThe brake pedal must not be pressed.

lThe automatic transmission must be in 'drive'.

lThe clutch pedal must not be pressed.

Page 430 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-37

Input/Output

Input to the cruise control RES switch is 12 volts via the main relay. When the switch is pressed the circuit is completed

by the ECM providing an earth path for the relay via pin 17 of connector C0658 of the ECM.

The cruise control RES switch can fail as follows:

lOpen circuit.

lShort circuit to voltage supply.

lShort circuit to vehicle earth.

lWiring loom fault.

In the event of a cruise control RES switch failure cruise control resume/ suspend operation does not operate.

Page 432 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-39

With the ECM in a 'Secure' state, it will not function unless an alarm system is fitted to the vehicle. A 'Secure' ECM

cannot be configured into a 'No Code' ECM.

With the ECM in a 'No Code' state, it does not require an alarm system to be fitted to allow the engine to operate. If

the ECM senses that an alarm system is fitted it will not start. A 'No Code' ECM can be configured to a 'Secure' ECM

using TestBook. A 'Secure' ECM can not be configured to a 'No Code' state.

Setting up of the ECM immobilisation configurations can only be performed using TestBook.

If a vehicle stalls immediately after starting it is possible that it has been immobilised. This means either:

lThe ECM was configured as 'No Code' but the ECM is receiving a code at its alarm input pin.

lThe ECM received an incorrect code.

lThe ECM was expecting a security code but did not receive one at its alarm input pin.

Fuel delivery/injection control

The fuel delivery/injection control delivers a precise amount of finely atomised fuel to mix with the air in the

combustion chamber to create a controlled explosion.

To precisely control fuel delivery and control fuel injection, the following input conditions must be met:

lCKP information.

lInjection timing map information.

lFT information.

lECT information.

The ECM monitors the conditions required for optimum combustion of fuel in the cylinder from the various sensors

around the engine and then compares it against stored information. From this calculation the ECM can adjust the

quantity and timing of the fuel being delivered to the cylinder.

The ECM uses CKP information as follows:

lTo calculate engine speed.

lTo determine engine crankshaft position.

Engine speed and crankshaft position allows the ECM to determine fuel injection timing.

The ECM also uses ECT information and FT sensor information to allow optimum fuel delivery and injection control

for all engine coolant and fuel temperatures.

Turbocharger control

Turbocharger control is vital to ensure the turbocharger does not over boost the engine. Within the turbocharger is a

wastegate, which when operated by the turbocharger wastegate modulator will open and close a bypass valve

regulating boost pressure.

The turbocharger wastegate modulator, via the ECM, controls boost pressure under the following conditions:

lAcceleration.

lWide open throttle.

lIdle.

lOverrun.

The turbocharger wastegate modulator receives a battery voltage supply from the main relay. The ECM supplies the

earth path in the form of a pulse width modulation (PWM) signal. This signal allows the turbocharger wastegate

modulator to open and close the wastegate. A proportion of the exhaust gas can bypass the turbocharger through

the wastegate, regulating boost pressure.

Page 434 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-41

In the case of a VSS failure on vehicles with automatic transmissions the ECM applies default values derived from

the EAT ECU. There is no default value for manual transmission vehicle.

The VSS can fail in the following ways:

lWiring short circuit to vehicle supply.

lWiring short circuit to vehicle earth.

lWiring open circuit.

In the event of a VSS failure any of the following symptoms may be observed:

lVehicle speed limiting disabled (manual transmission only).

lHill Descent Control (HDC) warning lamp on and audible warning.

Cruise control

All markets have a common cruise control system. The cruise control system, when activated, regulates vehicle

speed. The ECM controls the cruise control system.

Cruise control activation

Cruise control is a passive system, and must be activated by the driver. Cruise control is activated by switching on

the cruise control master switch located on the instrument panel. A LED in the switch illuminates indicating cruise

control is available. The driver must accelerate the vehicle to the desired speed using the accelerator pedal. When

the desired speed is reached, cruise control can be activated by pressing the SET+ switch.

Cruise control will only activate if the following conditions are met:

lVehicle speed is above 22 mph (35 km/h).

lThe brake pedal is not pressed.

lThe clutch pedal is not pressed (manual transmission only).

lThe transmission is not in Park, Reverse or Neutral (automatic transmission only).

The ECM receives the set signal and determines the vehicle speed provided by the SLABS ECU. The ECM then

maintains current road speed.

Cruise control cancellation

Cancelling cruise control enables the driver to regain control of the vehicle speed by using the accelerator pedal.

Cruise control is cancelled if any of the following conditions occur:

lThe brake pedal is pressed.

lThe RES switch is pressed.

lThe clutch pedal is pressed (manual transmission only).

lThe cruise control master switch is switched off.

lThe transmission is placed in Park, Neutral, or Reverse (automatic transmission only).

The ECM cancels cruise control operation and returns it to the control of the accelerator pedal.

The set speed will be stored in the ECM unless:

lThe cruise control master switch is switched off.

lThe ignition is switched off.

If cruise control is deactivated using either of the above methods, the set speed will be erased from the memory of

the ECM.

Page 436 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-43

Air Conditioning (A/C)

The ECM controls operation of the A/C compressor and the engine's electric cooling fan in response to requests from

the Automatic Temperature Control (ATC) ECU.

A/C request

When the ATC ECU supplies the ECM with an A/C request, the ECM energises the compressor clutch relay. The

compressor clutch relay is located in the engine compartment fuse box. It is a four pin normally open relay. This means

that the relay must be energised to drive the compressor clutch. During periods of high driver demand such as hard

acceleration or maximum rev/min the ECM will disable the compressor clutch for a short time. This is to reduce the

load on the engine.

The operation of the A/C request is via a switch being connected to earth. Voltage is supplied via pin 9 of connector

C0658 of the ECM, at the point at which the switch is pressed the connection to the earth path is made and the

compressor clutch is engaged.

The ECM provides the earth for the relay windings to allow the compressor clutch relay contacts to close and the

compressor clutch drive to receive battery voltage. The ECM uses a transistor as a switch to generate an open circuit

in the earth path of the relay windings. When the ECM closes down the earth path, the return spring in the relay will

pull the contacts apart to shut down the compressor clutch drive. Fuse 6, located in the engine compartment fuse box,

provides voltage to the compressor clutch relay switching contacts. The relay windings are supplied with battery

voltage from the main relay, also located in the engine compartment fuse box. The earth path for the relay windings

is via pin 29 of the ECM connector C0658. When the relay is energised the output from the switching contacts is

directly to the compressor clutch.

Cooling fan request

The A/C fan request is an input to the ECM from the ATC ECU to request that the engine's electric cooling fan is

activated to provide additional cooling for the A/C condenser.

The cooling fan relay is located in the engine compartment fuse box and is also controlled by the ECM. It is a four pin

normally open relay. This means that the relay must be energised to drive the cooling fan. The cooling fan is used

especially when the engine is operating at excessively high temperatures. It is also used as a part of the ECM backup

strategy if the ECT sensor fails.

The operation of the cooling fan request is via a switch being connected to earth. Voltage is supplied via pin 23 of

connector C0658 of the ECM, at the point at when the switch is pressed the connection to the earth path is made and

the cooling fan is engaged.

The ECM provides the earth for the cooling fan relay windings to allow the relay contacts to close and the cooling fan

motor to receive battery voltage. The ECM uses a transistor as a switch to generate an open circuit in the earth path

of the relay windings. When the ECM closes down the earth path, the return spring in the relay will pull the contacts

apart to shut down the cooling fan motor drive. Input to the A/C cooling fan relay switching contacts is via fuse 4

located in the engine compartment fuse box. The relay windings are supplied with battery voltage from the main relay,

also located in the engine compartment fuse box. The earth path for the relay windings is via pin 4 of the ECM

connector C0658. When the relay is energised the output from the switching contacts is directly to the cooling fan

motor.

Page 440 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-47

REPAIRS

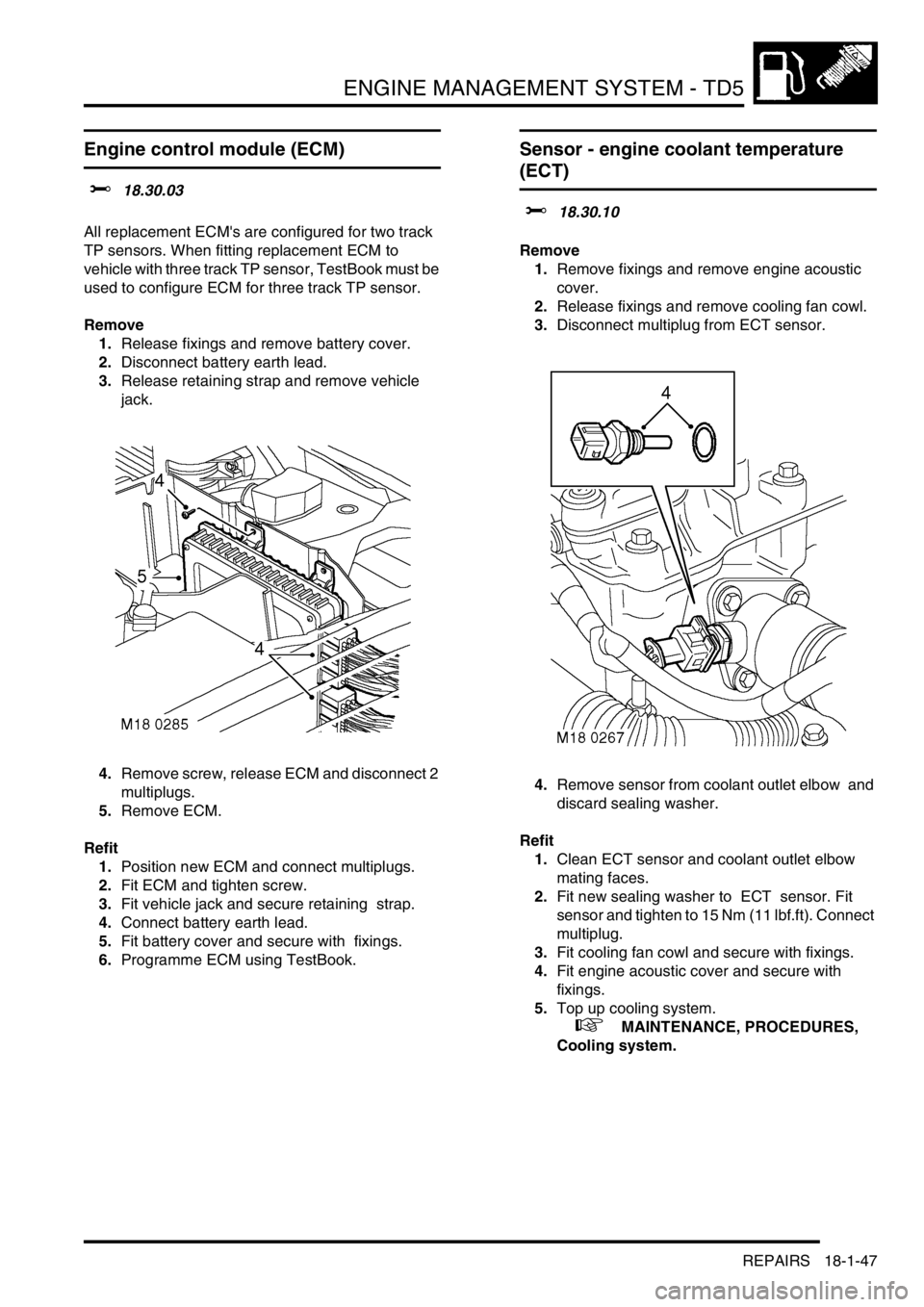

Engine control module (ECM)

$% 18.30.03

All replacement ECM's are configured for two track

TP sensors. When fitting replacement ECM to

vehicle with three track TP sensor, TestBook must be

used to configure ECM for three track TP sensor.

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Release retaining strap and remove vehicle

jack.

4.Remove screw, release ECM and disconnect 2

multiplugs.

5.Remove ECM.

Refit

1.Position new ECM and connect multiplugs.

2.Fit ECM and tighten screw.

3.Fit vehicle jack and secure retaining strap.

4.Connect battery earth lead.

5.Fit battery cover and secure with fixings.

6.Programme ECM using TestBook.

Sensor - engine coolant temperature

(ECT)

$% 18.30.10

Remove

1.Remove fixings and remove engine acoustic

cover.

2.Release fixings and remove cooling fan cowl.

3.Disconnect multiplug from ECT sensor.

4.Remove sensor from coolant outlet elbow and

discard sealing washer.

Refit

1.Clean ECT sensor and coolant outlet elbow

mating faces.

2.Fit new sealing washer to ECT sensor. Fit

sensor and tighten to 15 Nm (11 lbf.ft). Connect

multiplug.

3.Fit cooling fan cowl and secure with fixings.

4.Fit engine acoustic cover and secure with

fixings.

5.Top up cooling system.

+ MAINTENANCE, PROCEDURES,

Cooling system.

Page 441 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-48 REPAIRS

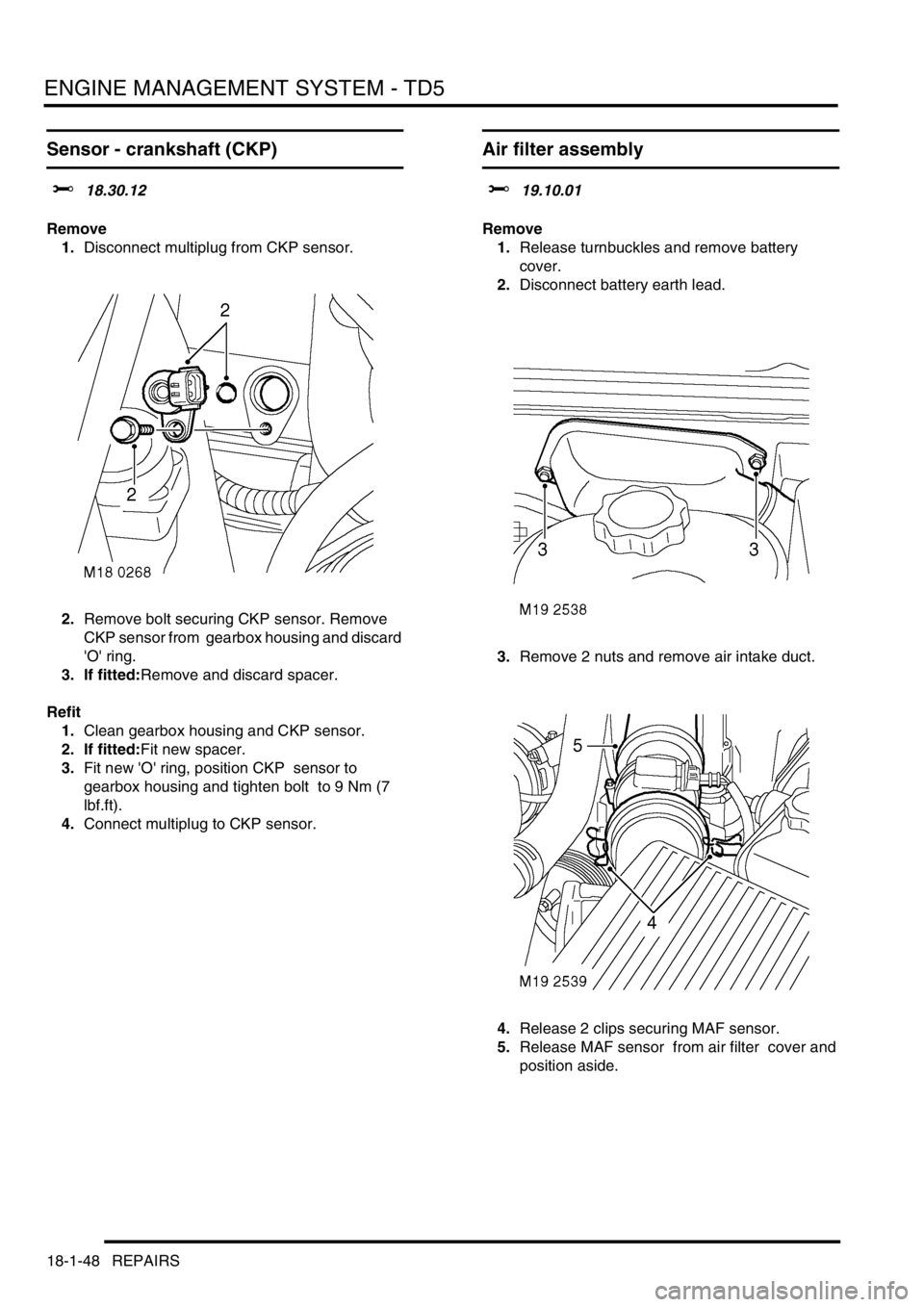

Sensor - crankshaft (CKP)

$% 18.30.12

Remove

1.Disconnect multiplug from CKP sensor.

2.Remove bolt securing CKP sensor. Remove

CKP sensor from gearbox housing and discard

'O' ring.

3. If fitted:Remove and discard spacer.

Refit

1.Clean gearbox housing and CKP sensor.

2. If fitted:Fit new spacer.

3.Fit new 'O' ring, position CKP sensor to

gearbox housing and tighten bolt to 9 Nm (7

lbf.ft).

4.Connect multiplug to CKP sensor.

Air filter assembly

$% 19.10.01

Remove

1.Release turnbuckles and remove battery

cover.

2.Disconnect battery earth lead.

3.Remove 2 nuts and remove air intake duct.

4.Release 2 clips securing MAF sensor.

5.Release MAF sensor from air filter cover and

position aside.

Page 442 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-49

6.Release air filter from 3 grommets, remove

assembly and discard 'O' ring.

7.Remove 2 screws, remove AAP sensor and

discard 'O' ring.

Refit

1.Clean MAF sensor and air filter mating faces.

2.Fit new 'O' ring to air filter.

3.Clean AAP sensor.

4.Using new 'O' ring, fit AAP sensor and tighten

screws.

5.Position air filter assembly and secure in

grommets.

6.Position MAF sensor and secure clips.

7.Position intake duct to air filter and tighten nuts.

8.Connect battery earth lead.

9.Fit battery cover and secure with fixings.

Element - air filter

$% 19.10.10

Remove

1.Release 2 clips and disconnect MAF sensor

from air filter cover.