earth LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 335 of 1672

EMISSION CONTROL - TD5

17-1-14 REPAIRS

Valve - EGR - Pre EU3 models

$% 17.45.01

On all vehicles up to VIN number 1A736339, the

EGR pipe assembly must be replaced every time the

system is disturbed.

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Remove cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

5.Disconnect vacuum hose(s) from EGR valve.

6.Loosen clip and release air intake from EGR

valve.

7.Remove 4 bolts, release EGR valve from inlet

manifold and discard gasket.

8.Remove 2 bolts and release EGR valve clip

from cylinder head.

9.Remove and discard 2 bolts securing EGR

valve pipe to exhaust manifold. 10.Remove EGR valve assembly.

11.Remove clip and remove pipe from EGR valve.

Refit

1.Clean EGR valve and mating face on pipe.

2.Position pipe to EGR valve and fit retaining clip.

Fit bolt but do not tighten at this stage.

3.Position EGR valve assembly, locate pipe

flange to exhaust manifold, fit new bolts but do

not tighten at this stage.

4.Clean inlet manifold and EGR valve mating

faces.

5.Using new gasket, position EGR valve to inlet

manifold fit bolts and tighten to 10 Nm (7 lbf.ft).

6.Align EGR pipe clip to cylinder head, fit bolts

but do not tighten at this stage.

7.Tighten EGR pipe bolts to correct torque in

following sequence:

lEGR pipe retaining clip bolt 6 Nm (4.5 lbf.ft)

lEGR pipe clip to cylinder head bolts 10 Nm

(7 lbf.ft)

lEGR pipe flange to exhaust manifold bolts

10 Nm (7 lbf.ft)

8.Position air intake hose and tighten clip.

9.Connect vacuum hoses to EGR valve.

10.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

11.Connect battery earth lead.

12.Fit battery cover and secure the fixings.

Page 336 of 1672

EMISSION CONTROL - TD5

REPAIRS 17-1-15

Valve - EGR - EU3 models

$% 17.45.01

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Remove cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

5.Disconnect vacuum hose(s) from EGR valve.

6.Loosen clip screw and disconnect air intake

hose from EGR valve.

7.Remove screw and remove clamp securing

EGR pipe to EGR valve.

8.Remove 4 bolts securing EGR valve, remove

valve and discard gasket.

9.Discard EGR pipe gasket.Refit

1.Clean EGR valve and mating faces.

2.Fit new gasket to EGR pipe.

3.Using new gasket, position EGR valve to inlet

manifold fit bolts and tighten to 10 Nm (7 lbf.ft).

4.Fit EGR pipe clamp and tighten screw to 6 Nm

(4.4 lbf.ft).

5.Connect air intake hose to EGR valve and

tighten clip.

6.Connect vacuum hoses to EGR valve.

7.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

8.Fit engine acoustic cover and tighten bolts to

10 Nm (7 lbf.ft).

9.Connect battery earth lead.

10.Fit battery cover and secure the fixings.

Page 357 of 1672

EMISSION CONTROL - V8

17-2-20 DESCRIPTION AND OPERATION

Purge valve operation is controlled by the engine control module (ECM). The purge valve has a two-pin electrical

connector which links to the ECM via the engine harness. Pin-1 of the connector is the power supply source from fuse

2 in the engine compartment fusebox, and pin-2 of the connector is the switched earth from the ECM (pulse width

modulated (PWM) signal) which is used to control the purge valve operation time. Note that the harness connector

for the purge valve is black, and must not be confused with the connector for the Secondary Air Injection

vacuum solenoid valve which is grey.

When the purge valve is earthed by the ECM, the valve opens to allow hydrocarbons stored in the EVAP canister to

be purged to the engine inlet manifold for combustion.

If the purge valve breaks or becomes stuck in the open or closed position, the EVAP system will cease to function

and there are no default measures available. The ECM will store the fault in memory and illuminate the MIL warning

lamp if the correct monitoring conditions have been achieved (i.e. valve status unchanged for 45 seconds after engine

has been running for 15 minutes). If the purge valve is stuck in the open position, a rich air:fuel mixture is likely to

result at the intake manifold, this could cause the engine to misfire and the fuelling adaptions will change.

The following failure modes are possible:

lSticking valve

lValve blocked

lConnector or harness wiring fault (open or short circuit)

lValve stuck open

If the purge valve malfunctions, the following fault codes may be stored in the ECM diagnostic memory, which can be

retrieved using 'Testbook':

P-code Description

P0440Purge valve not sealing

P0444Purge valve open circuit

P0445Purge valve short circuit to ground

P0443Purge valve short circuit to battery voltage

Page 360 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-23

For systems utilising the vacuum method for determining evaporation leaks, the sensor is used to monitor for a drop

in vacuum pressure. The evaporation system is sealed by the CVS valve and purge valve after a vacuum has been

previously set up from the intake manifold while the purge valve is open and the CVS valve is closed. If any holes or

leaks are present at the evaporation system joints, the vacuum pressure will gradually drop and this change in

pressure will be detected by the fuel tank pressure sensor. This system is capable of determining leaks down to 1 mm

(0.04 in.) in diameter.

The fuel tank pressure sensor is part of the NAS OBD system, a component failure will not be noticed by the driver,

but if the ECM detects a fault, it will be stored in the diagnostic memory and the MIL light will be illuminated on the

instrument pack. Possible failures are listed below:

lDamaged or blocked sensor

lHarness / connector faulty

lSensor earthing problem

lOpen circuit

lShort circuit to battery voltage

lShort circuit to ground

lECM fault

Possible failure symptoms of the fuel tank pressure sensor are listed below:

lFuel tank pressure sensor poor performance

lFuel tank pressure sensor low range fault

lFuel tank pressure sensor high range fault

If the fuel tank pressure sensor should malfunction, the following fault codes may be stored in the ECM diagnostic

memory, which can be retrieved using 'Testbook':

P-code Description

P0451Fuel tank pressure signal stuck high within range

P0452Fuel tank pressure signal short circuit to battery voltage (out of range - High)

P0453Fuel tank pressure signal short circuit to ground or open circuit (out of range - Low)

Page 361 of 1672

EMISSION CONTROL - V8

17-2-24 DESCRIPTION AND OPERATION

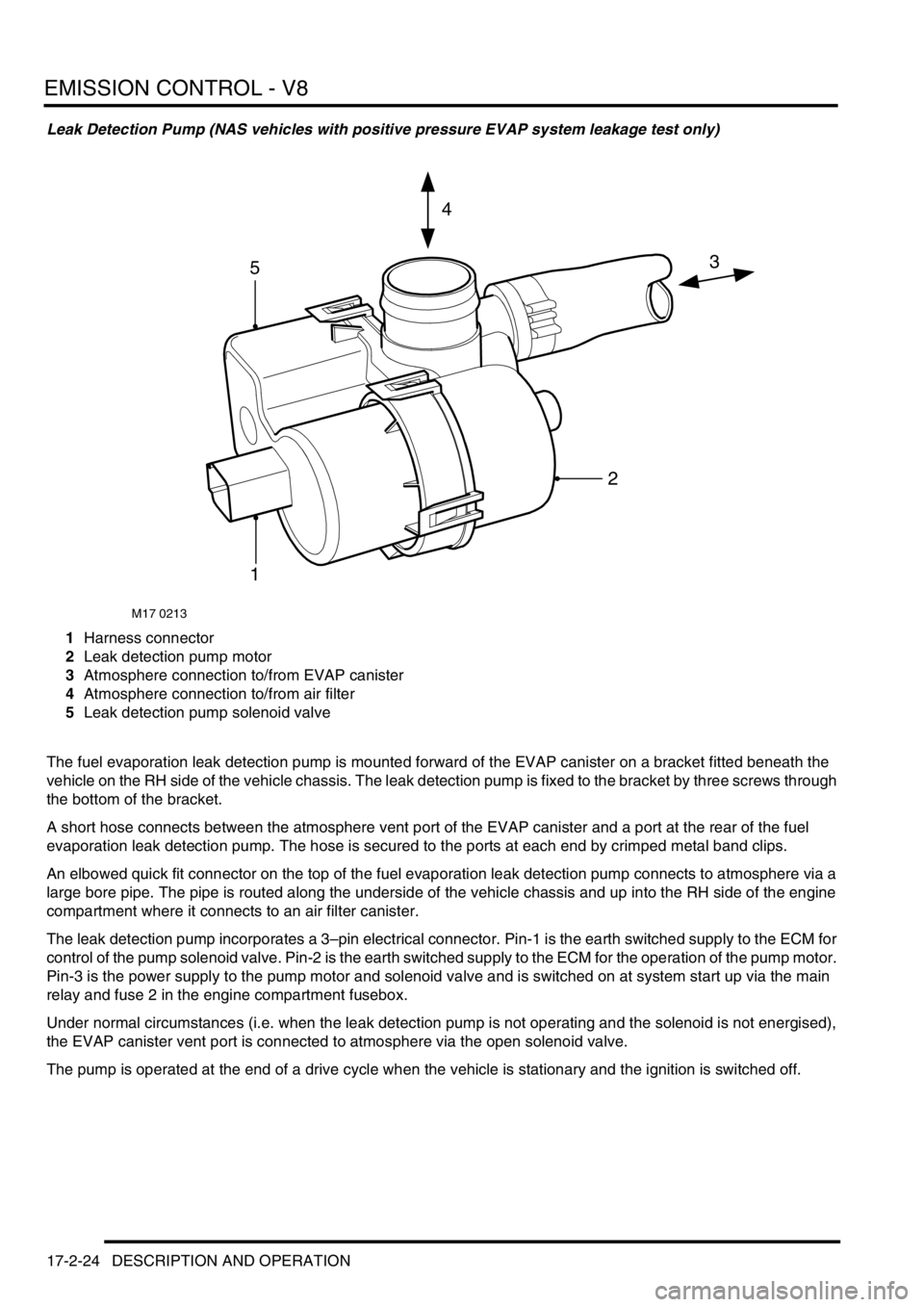

Leak Detection Pump (NAS vehicles with positive pressure EVAP system leakage test only)

1Harness connector

2Leak detection pump motor

3Atmosphere connection to/from EVAP canister

4Atmosphere connection to/from air filter

5Leak detection pump solenoid valve

The fuel evaporation leak detection pump is mounted forward of the EVAP canister on a bracket fitted beneath the

vehicle on the RH side of the vehicle chassis. The leak detection pump is fixed to the bracket by three screws through

the bottom of the bracket.

A short hose connects between the atmosphere vent port of the EVAP canister and a port at the rear of the fuel

evaporation leak detection pump. The hose is secured to the ports at each end by crimped metal band clips.

An elbowed quick fit connector on the top of the fuel evaporation leak detection pump connects to atmosphere via a

large bore pipe. The pipe is routed along the underside of the vehicle chassis and up into the RH side of the engine

compartment where it connects to an air filter canister.

The leak detection pump incorporates a 3–pin electrical connector. Pin-1 is the earth switched supply to the ECM for

control of the pump solenoid valve. Pin-2 is the earth switched supply to the ECM for the operation of the pump motor.

Pin-3 is the power supply to the pump motor and solenoid valve and is switched on at system start up via the main

relay and fuse 2 in the engine compartment fusebox.

Under normal circumstances (i.e. when the leak detection pump is not operating and the solenoid is not energised),

the EVAP canister vent port is connected to atmosphere via the open solenoid valve.

The pump is operated at the end of a drive cycle when the vehicle is stationary and the ignition is switched off.

M17 0213

3

4

5

1

2

Page 367 of 1672

EMISSION CONTROL - V8

17-2-30 DESCRIPTION AND OPERATION

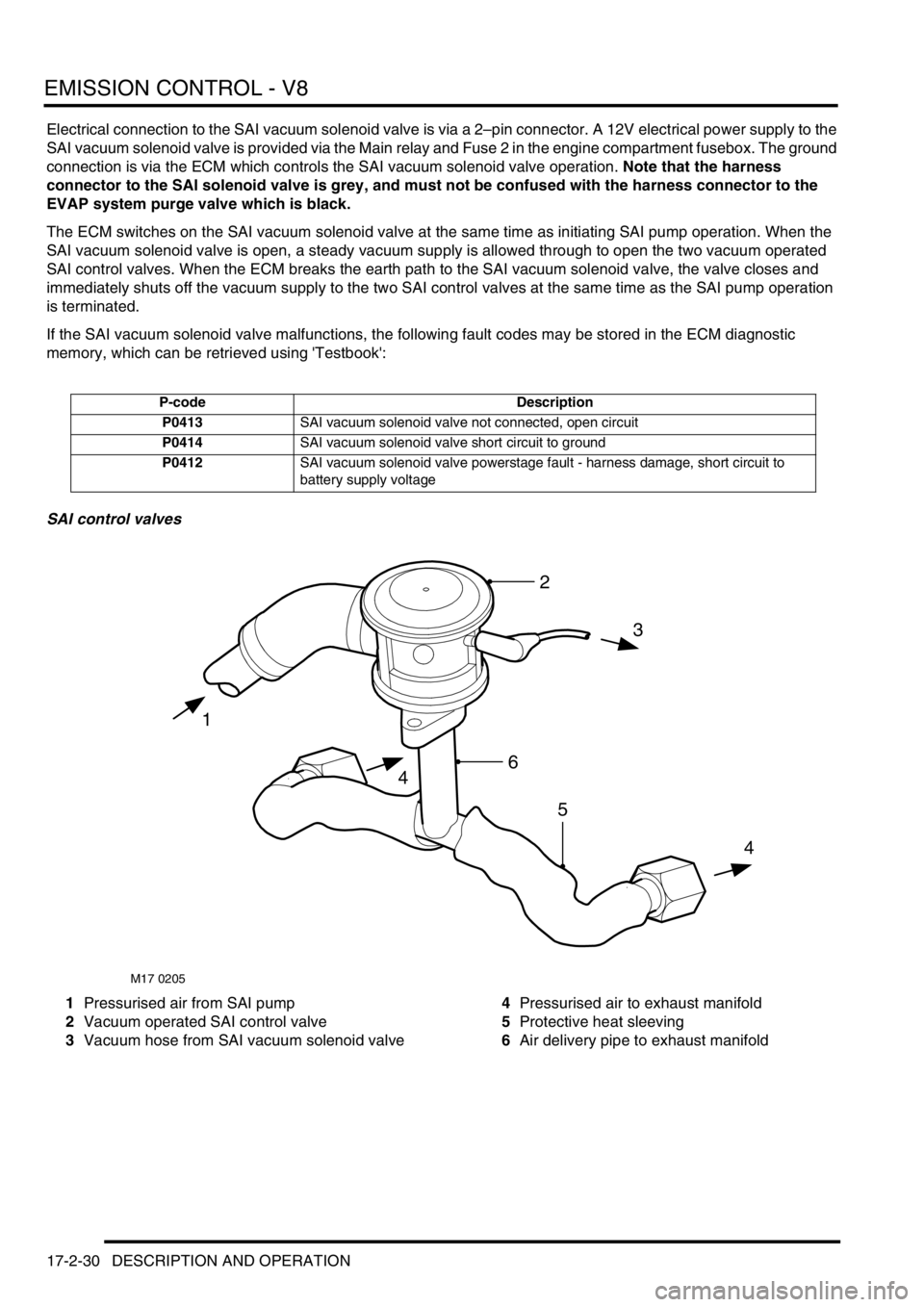

Electrical connection to the SAI vacuum solenoid valve is via a 2–pin connector. A 12V electrical power supply to the

SAI vacuum solenoid valve is provided via the Main relay and Fuse 2 in the engine compartment fusebox. The ground

connection is via the ECM which controls the SAI vacuum solenoid valve operation. Note that the harness

connector to the SAI solenoid valve is grey, and must not be confused with the harness connector to the

EVAP system purge valve which is black.

The ECM switches on the SAI vacuum solenoid valve at the same time as initiating SAI pump operation. When the

SAI vacuum solenoid valve is open, a steady vacuum supply is allowed through to open the two vacuum operated

SAI control valves. When the ECM breaks the earth path to the SAI vacuum solenoid valve, the valve closes and

immediately shuts off the vacuum supply to the two SAI control valves at the same time as the SAI pump operation

is terminated.

If the SAI vacuum solenoid valve malfunctions, the following fault codes may be stored in the ECM diagnostic

memory, which can be retrieved using 'Testbook':

SAI control valves

1Pressurised air from SAI pump

2Vacuum operated SAI control valve

3Vacuum hose from SAI vacuum solenoid valve4Pressurised air to exhaust manifold

5Protective heat sleeving

6Air delivery pipe to exhaust manifold

P-code Description

P0413SAI vacuum solenoid valve not connected, open circuit

P0414SAI vacuum solenoid valve short circuit to ground

P0412SAI vacuum solenoid valve powerstage fault - harness damage, short circuit to

battery supply voltage

M17 0205

1

3

4

4

2

6

5

Page 378 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-41

Following the test, the system returns to normal purge operation after the canister vent solenoid opens. Possible

reasons for an EVAP system leak test failure are listed below:

lFuel filler not tightened or cap missing.

lSensor or actuator open circuit.

lShort circuit to vehicle supply or ground.

lEither purge or CVS valve stuck open.

lEither purge or CVS valve stuck shut or blocked pipe.

lPiping broken or not connected.

lLoose or leaking connection.

If the piping is broken forward of the purge valve or is not connected, the engine may run rough and fuelling adaptions

will drift. The fault will not be detected by the leak detection diagnostic, but it will be determined by the engine

management ECM through the fuelling adaption diagnostics.

The evaluation of leakage is dependent on the differential pressure between the fuel tank and ambient atmospheric

pressure, the diagnostic is disabled above altitudes of 9500 ft. (2800 m) to avoid false detection of fuel leaks due to

the change in atmospheric pressure at altitude.

Fuel leak detection system (positive pressure leak detection type) – NAS only

The EVAP system with positive pressure leak detection capability used on NAS vehicles is similar to the standard

system, but also includes a fuel evaporation leak detection pump with integral solenoid valve. It is capable of detecting

holes in the EVAP system down to 0.5 mm (0.02 in.). The test is carried out at the end of a drive cycle, when the

vehicle is stationary and the ignition switch has been turned off. The ECM maintains an earth supply to the Main relay

to hold it on, so that power can be supplied to the leak detection pump.

First a reference measurement is established by passing the pressurised air through a by-pass circuit containing a

fixed sized restriction. The restriction assimilates a 0.5 mm (0.02 in) hole and the current drawn by the pump motor

during this procedure is recorded for comparison against the value to be obtained in the system test. The purge valve

is held closed, and the reversing valve in the leak detection pump module is not energised while the leak detection

pump is switched on. The pressurised air from the leak detection pump is forced through an orifice while the current

drawn by the pump motor is monitored.

Next the EVAP system diagnostic is performed; the solenoid valve is energised so that it closes off the EVAP system's

vent line to atmosphere, and opens a path for the pressurised air from the leak detection pump to be applied to the

closed EVAP system.

The current drawn by the leak detection pump is monitored and checked against that obtained during the reference

measurement. If the current is less than the reference value, this infers there is a hole in the EVAP system greater

than 0.5 mm (0.02 in) which is allowing the positive air pressure to leak out. If the current drawn by the pump motor

is greater than the value obtained during the reference check, the system is sealed and free from leaks. If an EVAP

system leak is detected, the ECM stores the fault in diagnostic memory and the MIL light on the instrument pack is

illuminated.

On NAS vehicles, the ECM works on a 2 trip cycle before illuminating the MIL. On EU-3 vehicles, the ECM works on

a 3 trip cycle before illuminating the MIL.

Following the test, the solenoid valve is opened to normalise the EVAP system pressure and the system returns to

normal purge operation at the start of the next drive cycle. Possible reasons for an EVAP system leak test failure are

listed below:

lFuel filler not tightened or cap missing.

lSensor or actuator open circuit.

lShort circuit to vehicle supply or ground.

lEither purge or solenoid valve stuck open.

lEither purge or solenoid valve stuck shut.

lBlocked pipe or air filter.

lPiping broken or not connected.

lLoose or leaking connection.

If the piping is broken forward of the purge valve or is not connected, the engine may run rough and fuelling adaptions

will drift. The fault will not be detected by the leak detection test, but will be determined by the engine management

ECM through the fuelling adaption diagnostics. This test can be run from TestBook.

Page 379 of 1672

EMISSION CONTROL - V8

17-2-42 DESCRIPTION AND OPERATION

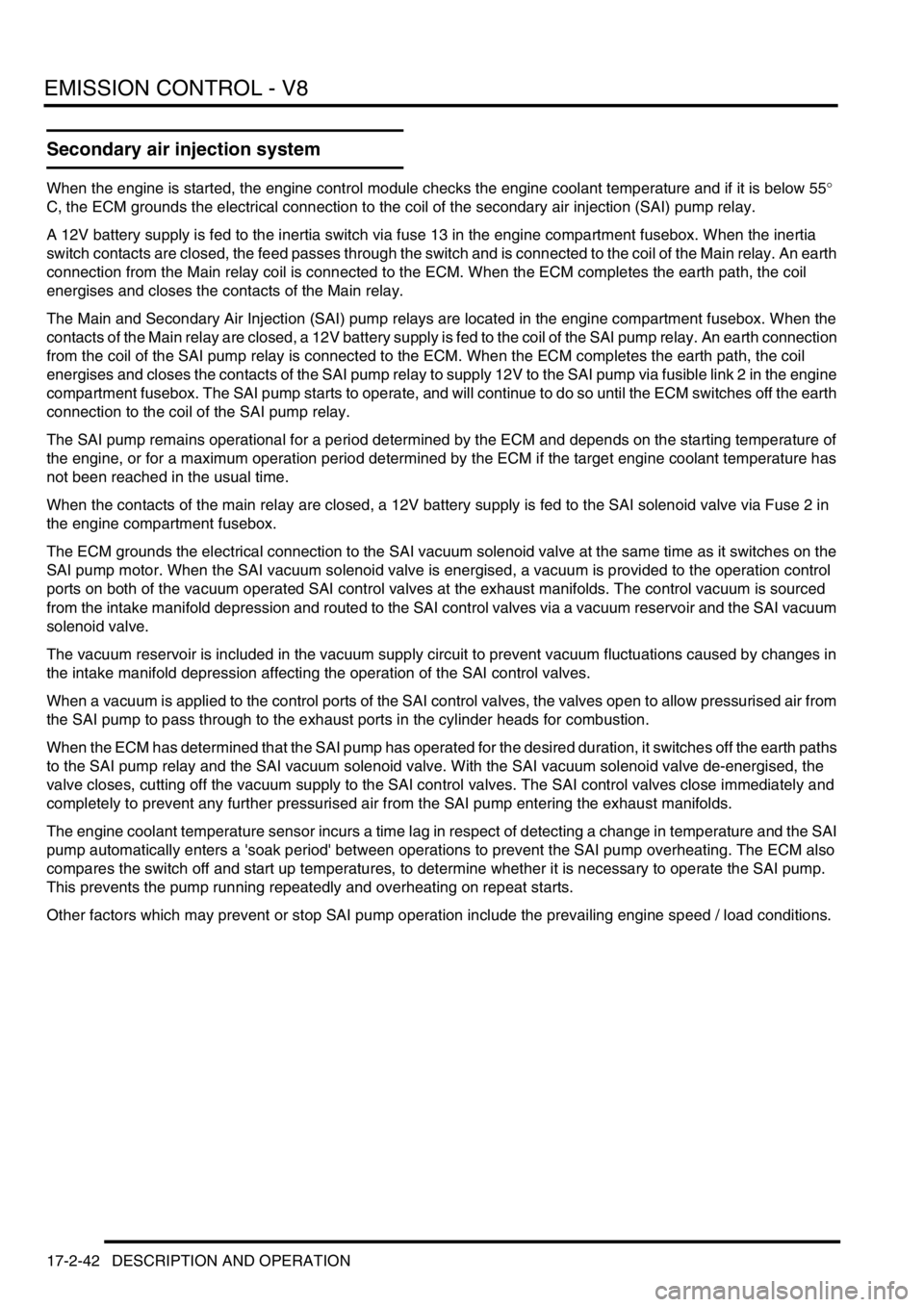

Secondary air injection system

When the engine is started, the engine control module checks the engine coolant temperature and if it is below 55°

C, the ECM grounds the electrical connection to the coil of the secondary air injection (SAI) pump relay.

A 12V battery supply is fed to the inertia switch via fuse 13 in the engine compartment fusebox. When the inertia

switch contacts are closed, the feed passes through the switch and is connected to the coil of the Main relay. An earth

connection from the Main relay coil is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the Main relay.

The Main and Secondary Air Injection (SAI) pump relays are located in the engine compartment fusebox. When the

contacts of the Main relay are closed, a 12V battery supply is fed to the coil of the SAI pump relay. An earth connection

from the coil of the SAI pump relay is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the SAI pump relay to supply 12V to the SAI pump via fusible link 2 in the engine

compartment fusebox. The SAI pump starts to operate, and will continue to do so until the ECM switches off the earth

connection to the coil of the SAI pump relay.

The SAI pump remains operational for a period determined by the ECM and depends on the starting temperature of

the engine, or for a maximum operation period determined by the ECM if the target engine coolant temperature has

not been reached in the usual time.

When the contacts of the main relay are closed, a 12V battery supply is fed to the SAI solenoid valve via Fuse 2 in

the engine compartment fusebox.

The ECM grounds the electrical connection to the SAI vacuum solenoid valve at the same time as it switches on the

SAI pump motor. When the SAI vacuum solenoid valve is energised, a vacuum is provided to the operation control

ports on both of the vacuum operated SAI control valves at the exhaust manifolds. The control vacuum is sourced

from the intake manifold depression and routed to the SAI control valves via a vacuum reservoir and the SAI vacuum

solenoid valve.

The vacuum reservoir is included in the vacuum supply circuit to prevent vacuum fluctuations caused by changes in

the intake manifold depression affecting the operation of the SAI control valves.

When a vacuum is applied to the control ports of the SAI control valves, the valves open to allow pressurised air from

the SAI pump to pass through to the exhaust ports in the cylinder heads for combustion.

When the ECM has determined that the SAI pump has operated for the desired duration, it switches off the earth paths

to the SAI pump relay and the SAI vacuum solenoid valve. With the SAI vacuum solenoid valve de-energised, the

valve closes, cutting off the vacuum supply to the SAI control valves. The SAI control valves close immediately and

completely to prevent any further pressurised air from the SAI pump entering the exhaust manifolds.

The engine coolant temperature sensor incurs a time lag in respect of detecting a change in temperature and the SAI

pump automatically enters a 'soak period' between operations to prevent the SAI pump overheating. The ECM also

compares the switch off and start up temperatures, to determine whether it is necessary to operate the SAI pump.

This prevents the pump running repeatedly and overheating on repeat starts.

Other factors which may prevent or stop SAI pump operation include the prevailing engine speed / load conditions.

Page 401 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-8 DESCRIPTION AND OPERATION

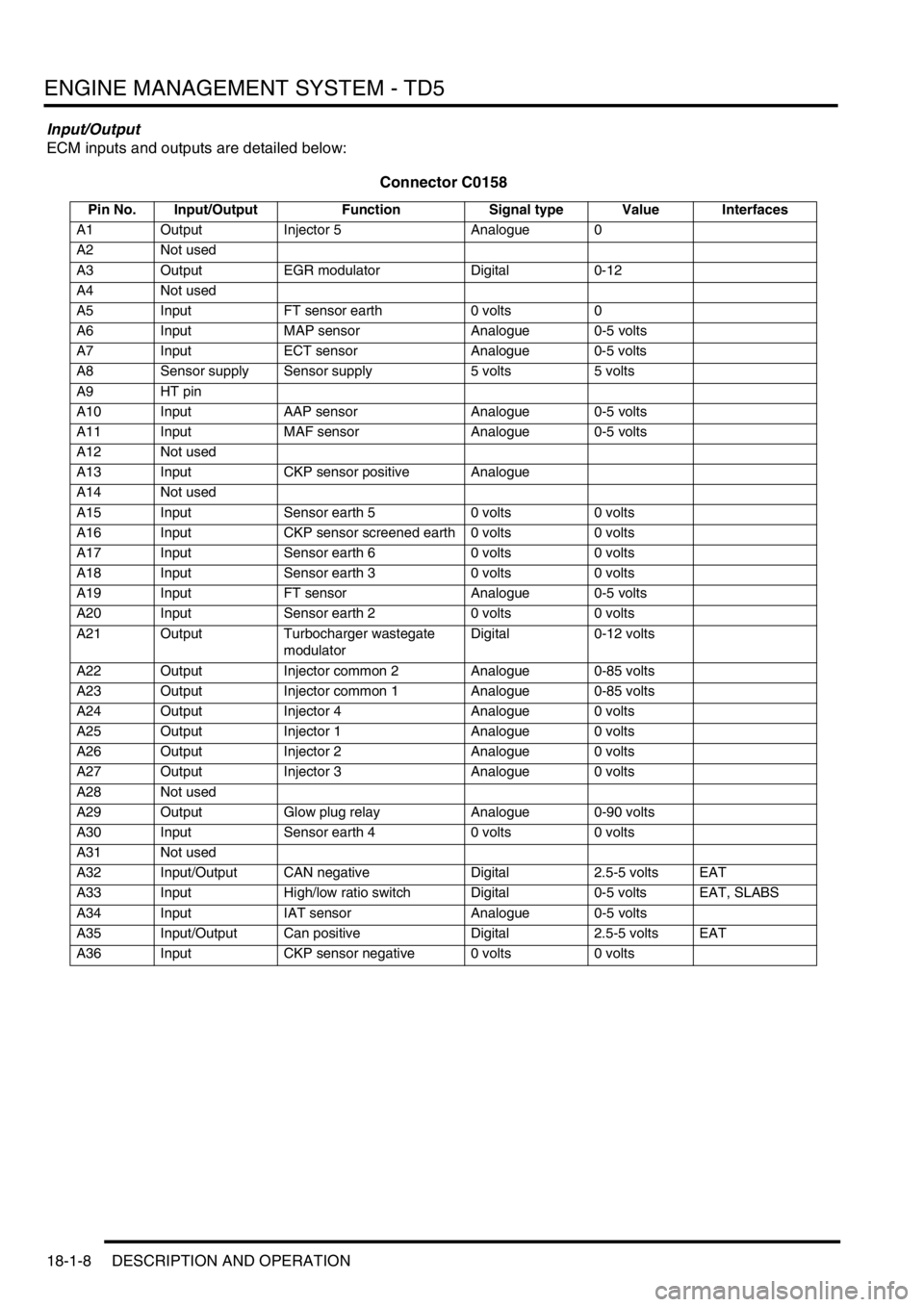

Input/Output

ECM inputs and outputs are detailed below:

Connector C0158

Pin No. Input/Output Function Signal type Value Interfaces

A1 Output Injector 5 Analogue 0

A2 Not used

A3 Output EGR modulator Digital 0-12

A4 Not used

A5 Input FT sensor earth 0 volts 0

A6 Input MAP sensor Analogue 0-5 volts

A7 Input ECT sensor Analogue 0-5 volts

A8 Sensor supply Sensor supply 5 volts 5 volts

A9 HT pin

A10 Input AAP sensor Analogue 0-5 volts

A11 Input MAF sensor Analogue 0-5 volts

A12 Not used

A13 Input CKP sensor positive Analogue

A14 Not used

A15 Input Sensor earth 5 0 volts 0 volts

A16 Input CKP sensor screened earth 0 volts 0 volts

A17 Input Sensor earth 6 0 volts 0 volts

A18 Input Sensor earth 3 0 volts 0 volts

A19 Input FT sensor Analogue 0-5 volts

A20 Input Sensor earth 2 0 volts 0 volts

A21 Output Turbocharger wastegate

modulatorDigital 0-12 volts

A22 Output Injector common 2 Analogue 0-85 volts

A23 Output Injector common 1 Analogue 0-85 volts

A24 Output Injector 4 Analogue 0 volts

A25 Output Injector 1 Analogue 0 volts

A26 Output Injector 2 Analogue 0 volts

A27 Output Injector 3 Analogue 0 volts

A28 Not used

A29 Output Glow plug relay Analogue 0-90 volts

A30 Input Sensor earth 4 0 volts 0 volts

A31 Not used

A32 Input/Output CAN negative Digital 2.5-5 volts EAT

A33 Input High/low ratio switch Digital 0-5 volts EAT, SLABS

A34 Input IAT sensor Analogue 0-5 volts

A35 Input/Output Can positive Digital 2.5-5 volts EAT

A36 Input CKP sensor negative 0 volts 0 volts

Page 402 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-9

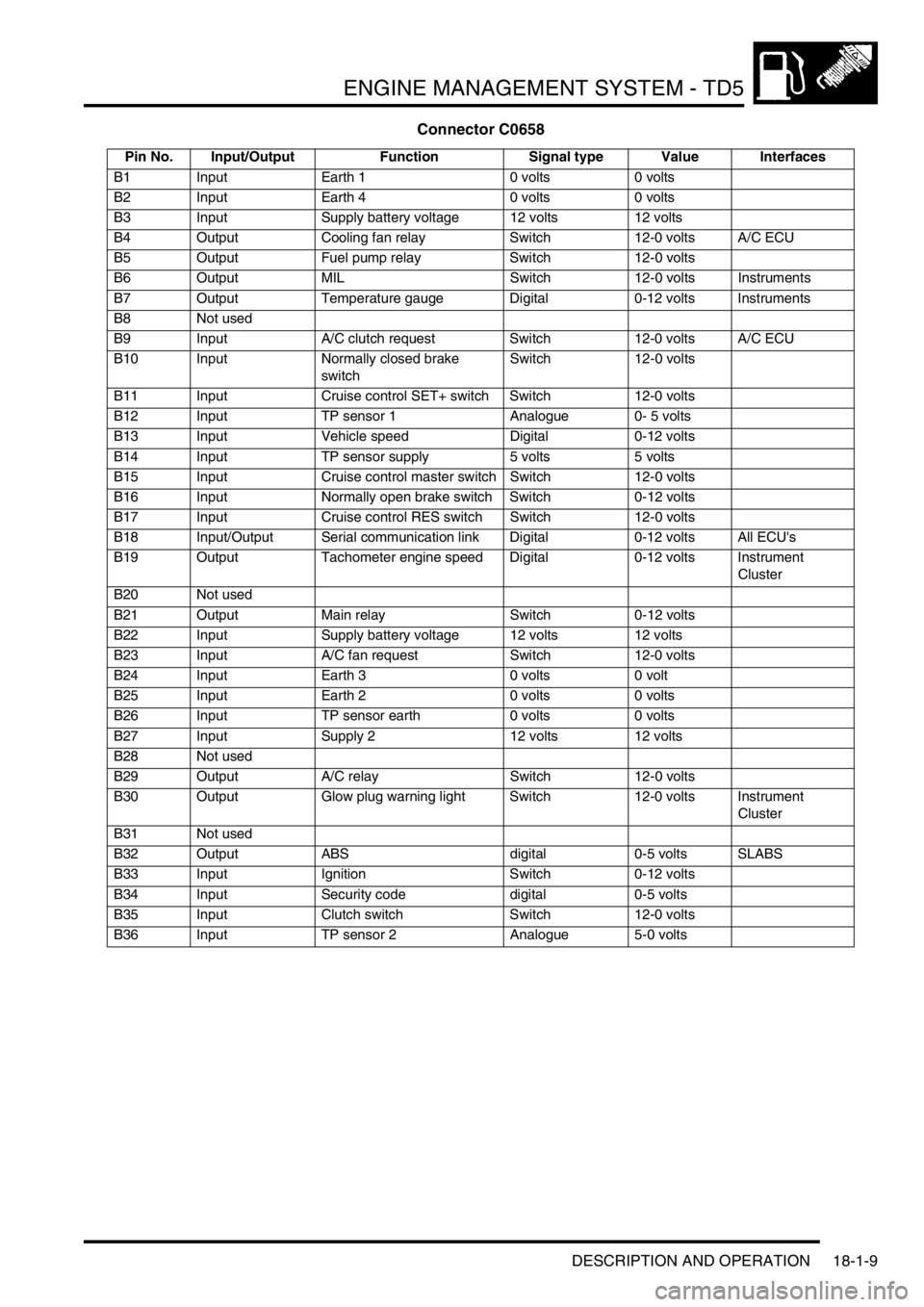

Connector C0658

Pin No. Input/Output Function Signal type Value Interfaces

B1 Input Earth 1 0 volts 0 volts

B2 Input Earth 4 0 volts 0 volts

B3 Input Supply battery voltage 12 volts 12 volts

B4 Output Cooling fan relay Switch 12-0 volts A/C ECU

B5 Output Fuel pump relay Switch 12-0 volts

B6 Output MIL Switch 12-0 volts Instruments

B7 Output Temperature gauge Digital 0-12 volts Instruments

B8 Not used

B9 Input A/C clutch request Switch 12-0 volts A/C ECU

B10 Input Normally closed brake

switchSwitch 12-0 volts

B11 Input Cruise control SET+ switch Switch 12-0 volts

B12 Input TP sensor 1 Analogue 0- 5 volts

B13 Input Vehicle speed Digital 0-12 volts

B14 Input TP sensor supply 5 volts 5 volts

B15 Input Cruise control master switch Switch 12-0 volts

B16 Input Normally open brake switch Switch 0-12 volts

B17 Input Cruise control RES switch Switch 12-0 volts

B18 Input/Output Serial communication link Digital 0-12 volts All ECU's

B19 Output Tachometer engine speed Digital 0-12 volts Instrument

Cluster

B20 Not used

B21 Output Main relay Switch 0-12 volts

B22 Input Supply battery voltage 12 volts 12 volts

B23 Input A/C fan request Switch 12-0 volts

B24 Input Earth 3 0 volts 0 volt

B25 Input Earth 2 0 volts 0 volts

B26 Input TP sensor earth 0 volts 0 volts

B27 Input Supply 2 12 volts 12 volts

B28 Not used

B29 Output A/C relay Switch 12-0 volts

B30 Output Glow plug warning light Switch 12-0 volts Instrument

Cluster

B31 Not used

B32 Output ABS digital 0-5 volts SLABS

B33 Input Ignition Switch 0-12 volts

B34 Input Security code digital 0-5 volts

B35 Input Clutch switch Switch 12-0 volts

B36 Input TP sensor 2 Analogue 5-0 volts