ECU LAND ROVER DISCOVERY 2002 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 211 of 1672

ENGINE - TD5

12-1-72 OVERHAUL

16.Remove bolt and nut securing front of cylinder

head to timing chain cover.

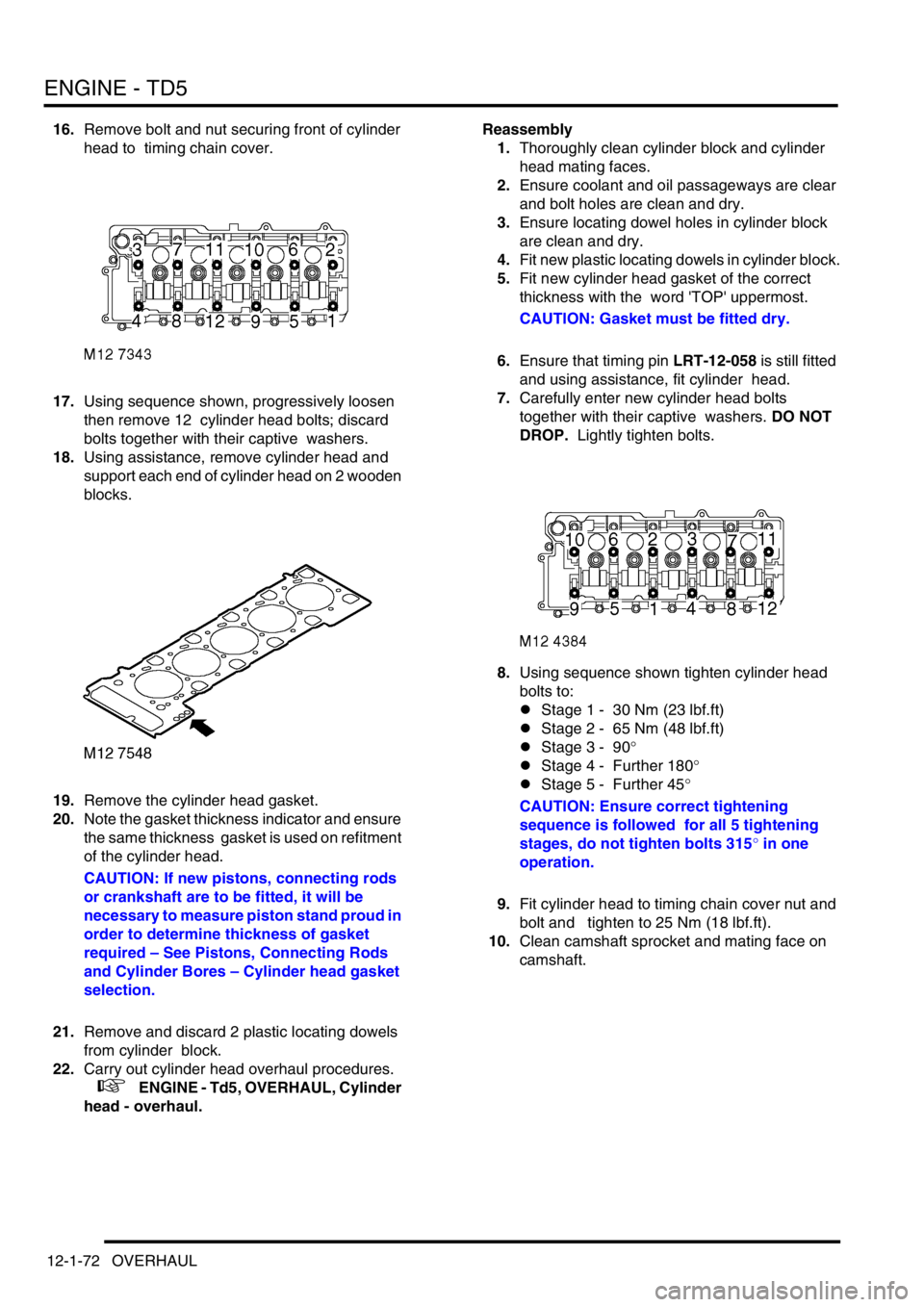

17.Using sequence shown, progressively loosen

then remove 12 cylinder head bolts; discard

bolts together with their captive washers.

18.Using assistance, remove cylinder head and

support each end of cylinder head on 2 wooden

blocks.

19.Remove the cylinder head gasket.

20.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of the cylinder head.

CAUTION: If new pistons, connecting rods

or crankshaft are to be fitted, it will be

necessary to measure piston stand proud in

order to determine thickness of gasket

required – See Pistons, Connecting Rods

and Cylinder Bores – Cylinder head gasket

selection.

21.Remove and discard 2 plastic locating dowels

from cylinder block.

22.Carry out cylinder head overhaul procedures.

+ ENGINE - Td5, OVERHAUL, Cylinder

head - overhaul.Reassembly

1.Thoroughly clean cylinder block and cylinder

head mating faces.

2.Ensure coolant and oil passageways are clear

and bolt holes are clean and dry.

3.Ensure locating dowel holes in cylinder block

are clean and dry.

4.Fit new plastic locating dowels in cylinder block.

5.Fit new cylinder head gasket of the correct

thickness with the word 'TOP' uppermost.

CAUTION: Gasket must be fitted dry.

6.Ensure that timing pin LRT-12-058 is still fitted

and using assistance, fit cylinder head.

7.Carefully enter new cylinder head bolts

together with their captive washers. DO NOT

DROP. Lightly tighten bolts.

8.Using sequence shown tighten cylinder head

bolts to:

lStage 1 - 30 Nm (23 lbf.ft)

lStage 2 - 65 Nm (48 lbf.ft)

lStage 3 - 90

°

lStage 4 - Further 180

°

lStage 5 - Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages, do not tighten bolts 315

° in one

operation.

9.Fit cylinder head to timing chain cover nut and

bolt and tighten to 25 Nm (18 lbf.ft).

10.Clean camshaft sprocket and mating face on

camshaft.

Page 212 of 1672

ENGINE - TD5

OVERHAUL 12-1-73

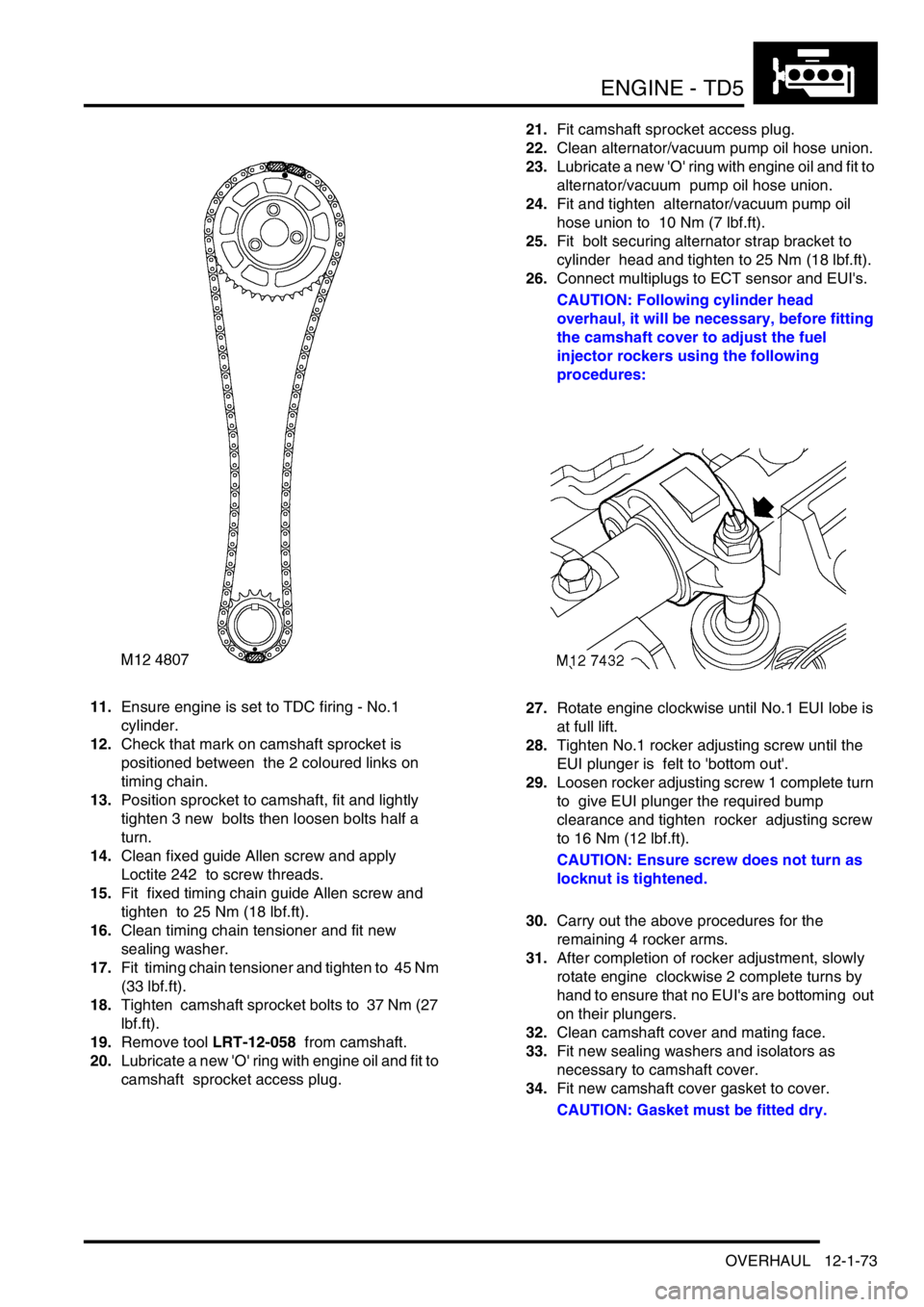

11.Ensure engine is set to TDC firing - No.1

cylinder.

12.Check that mark on camshaft sprocket is

positioned between the 2 coloured links on

timing chain.

13.Position sprocket to camshaft, fit and lightly

tighten 3 new bolts then loosen bolts half a

turn.

14.Clean fixed guide Allen screw and apply

Loctite 242 to screw threads.

15.Fit fixed timing chain guide Allen screw and

tighten to 25 Nm (18 lbf.ft).

16.Clean timing chain tensioner and fit new

sealing washer.

17.Fit timing chain tensioner and tighten to 45 Nm

(33 lbf.ft).

18.Tighten camshaft sprocket bolts to 37 Nm (27

lbf.ft).

19.Remove tool LRT-12-058 from camshaft.

20.Lubricate a new 'O' ring with engine oil and fit to

camshaft sprocket access plug.21.Fit camshaft sprocket access plug.

22.Clean alternator/vacuum pump oil hose union.

23.Lubricate a new 'O' ring with engine oil and fit to

alternator/vacuum pump oil hose union.

24.Fit and tighten alternator/vacuum pump oil

hose union to 10 Nm (7 lbf.ft).

25.Fit bolt securing alternator strap bracket to

cylinder head and tighten to 25 Nm (18 lbf.ft).

26.Connect multiplugs to ECT sensor and EUI's.

CAUTION: Following cylinder head

overhaul, it will be necessary, before fitting

the camshaft cover to adjust the fuel

injector rockers using the following

procedures:

27.Rotate engine clockwise until No.1 EUI lobe is

at full lift.

28.Tighten No.1 rocker adjusting screw until the

EUI plunger is felt to 'bottom out'.

29.Loosen rocker adjusting screw 1 complete turn

to give EUI plunger the required bump

clearance and tighten rocker adjusting screw

to 16 Nm (12 lbf.ft).

CAUTION: Ensure screw does not turn as

locknut is tightened.

30.Carry out the above procedures for the

remaining 4 rocker arms.

31.After completion of rocker adjustment, slowly

rotate engine clockwise 2 complete turns by

hand to ensure that no EUI's are bottoming out

on their plungers.

32.Clean camshaft cover and mating face.

33.Fit new sealing washers and isolators as

necessary to camshaft cover.

34.Fit new camshaft cover gasket to cover.

CAUTION: Gasket must be fitted dry.

Page 214 of 1672

ENGINE - TD5

OVERHAUL 12-1-75

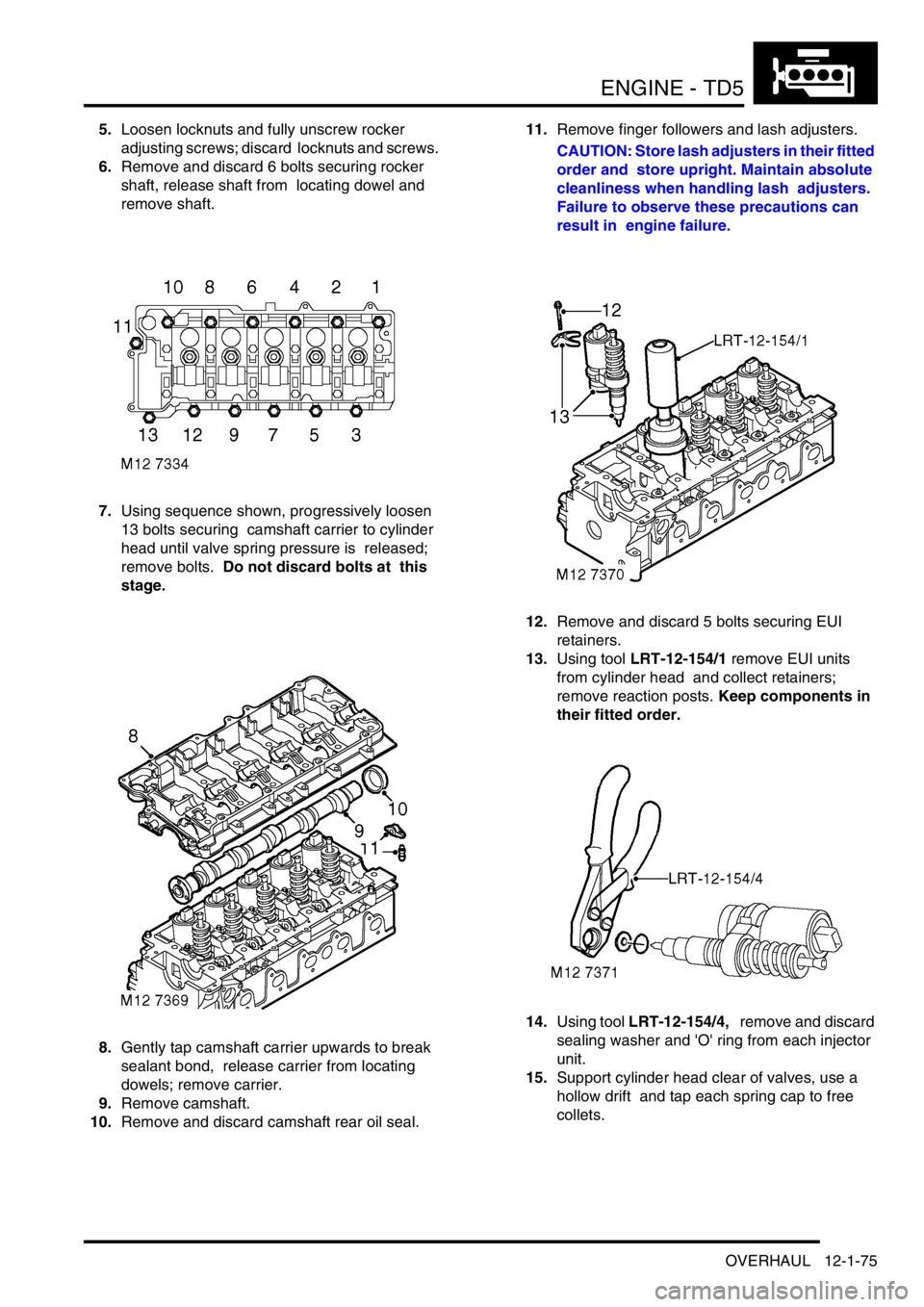

5.Loosen locknuts and fully unscrew rocker

adjusting screws; discard locknuts and screws.

6.Remove and discard 6 bolts securing rocker

shaft, release shaft from locating dowel and

remove shaft.

7.Using sequence shown, progressively loosen

13 bolts securing camshaft carrier to cylinder

head until valve spring pressure is released;

remove bolts. Do not discard bolts at this

stage.

8.Gently tap camshaft carrier upwards to break

sealant bond, release carrier from locating

dowels; remove carrier.

9.Remove camshaft.

10.Remove and discard camshaft rear oil seal.11.Remove finger followers and lash adjusters.

CAUTION: Store lash adjusters in their fitted

order and store upright. Maintain absolute

cleanliness when handling lash adjusters.

Failure to observe these precautions can

result in engine failure.

12.Remove and discard 5 bolts securing EUI

retainers.

13.Using tool LRT-12-154/1 remove EUI units

from cylinder head and collect retainers;

remove reaction posts. Keep components in

their fitted order.

14.Using tool LRT-12-154/4, remove and discard

sealing washer and 'O' ring from each injector

unit.

15.Support cylinder head clear of valves, use a

hollow drift and tap each spring cap to free

collets.

Page 218 of 1672

ENGINE - TD5

OVERHAUL 12-1-79

24.Compare figures obtained with camshaft

bearing clearance:

lCamshaft bearing clearance = 0.04 to 0.10

mm (0.002 to 0.004 in)

25.If any bearing clearance is found to exceed

figures given, repeat the above procedures

using a new camshaft. If, after repeating the

clearance check using a new camshaft the

clearances are still excessive, a new cylinder

head and camshaft carrier assembly must be

fitted.

26.Remove all traces of Plastigage using an oily

cloth, do not use a scraper.

27.On completion, discard camshaft carrier bolts.

28.Check free length of valve springs:

lFree length = 46.75 to 47.25 mm (1.84 to

1.86 in)

29. Replace valve springs as a set, if springs

are to be refitted, keep them in their fitted

order.

30.Clean carbon from valves, check valves for

burning, pitting or cracking; replace as

necessary.

31.Clean carbon from valve seat inserts, remove

all loose particles on completion.

32.Check valve seat inserts for pitting and burning.

It is not permissible to recut or replace valve

seat inserts.

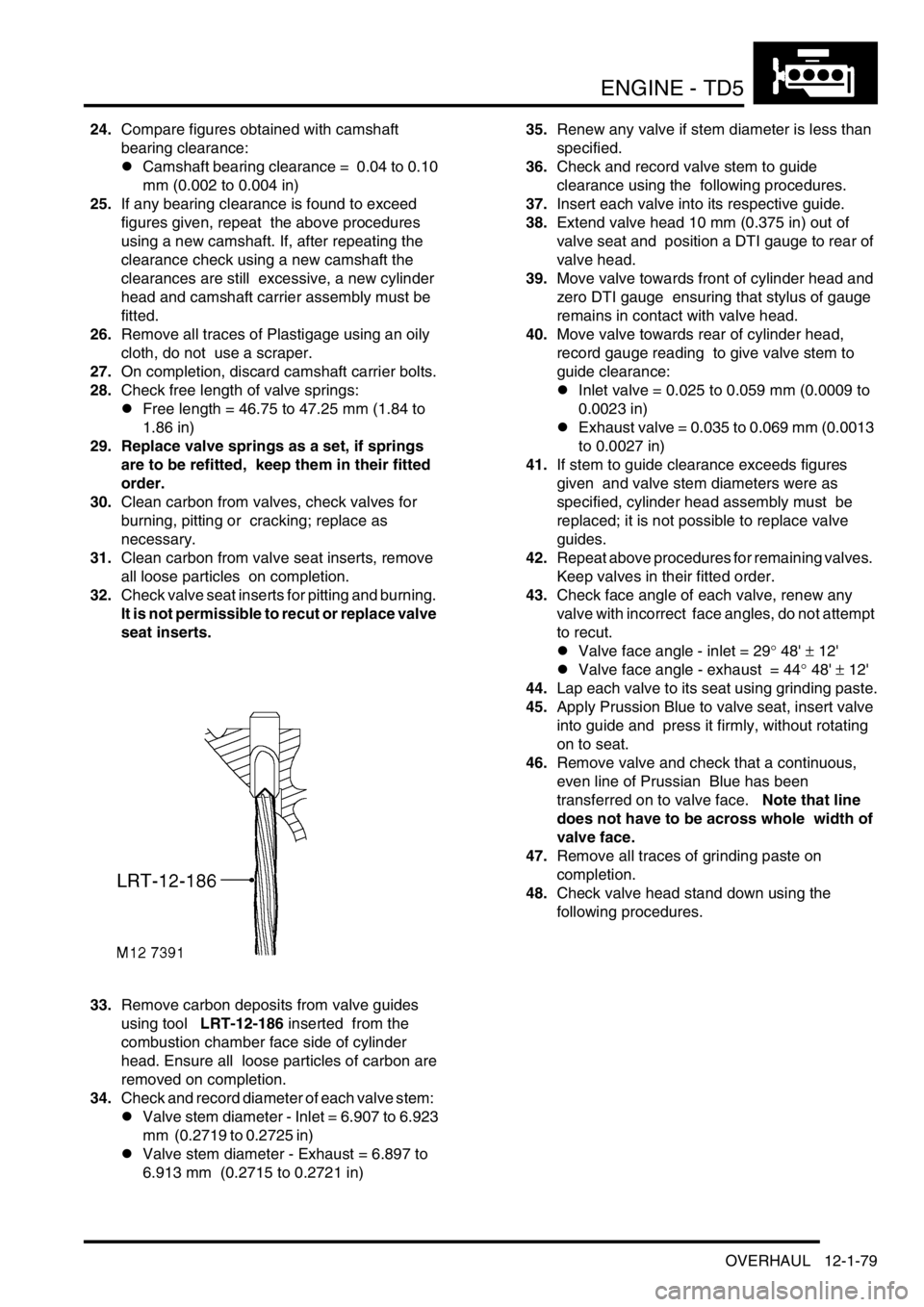

33.Remove carbon deposits from valve guides

using tool LRT-12-186 inserted from the

combustion chamber face side of cylinder

head. Ensure all loose particles of carbon are

removed on completion.

34.Check and record diameter of each valve stem:

lValve stem diameter - Inlet = 6.907 to 6.923

mm (0.2719 to 0.2725 in)

lValve stem diameter - Exhaust = 6.897 to

6.913 mm (0.2715 to 0.2721 in)35.Renew any valve if stem diameter is less than

specified.

36.Check and record valve stem to guide

clearance using the following procedures.

37.Insert each valve into its respective guide.

38.Extend valve head 10 mm (0.375 in) out of

valve seat and position a DTI gauge to rear of

valve head.

39.Move valve towards front of cylinder head and

zero DTI gauge ensuring that stylus of gauge

remains in contact with valve head.

40.Move valve towards rear of cylinder head,

record gauge reading to give valve stem to

guide clearance:

lInlet valve = 0.025 to 0.059 mm (0.0009 to

0.0023 in)

lExhaust valve = 0.035 to 0.069 mm (0.0013

to 0.0027 in)

41.If stem to guide clearance exceeds figures

given and valve stem diameters were as

specified, cylinder head assembly must be

replaced; it is not possible to replace valve

guides.

42.Repeat above procedures for remaining valves.

Keep valves in their fitted order.

43.Check face angle of each valve, renew any

valve with incorrect face angles, do not attempt

to recut.

lValve face angle - inlet = 29

° 48' ± 12'

lValve face angle - exhaust = 44

° 48' ± 12'

44.Lap each valve to its seat using grinding paste.

45.Apply Prussion Blue to valve seat, insert valve

into guide and press it firmly, without rotating

on to seat.

46.Remove valve and check that a continuous,

even line of Prussian Blue has been

transferred on to valve face. Note that line

does not have to be across whole width of

valve face.

47.Remove all traces of grinding paste on

completion.

48.Check valve head stand down using the

following procedures.

Page 223 of 1672

ENGINE - TD5

12-1-84 OVERHAUL

30.Fit new fuel filter, 'O' ring, and gasket.

CAUTION: Gasket must be fitted dry.

31. If fitted: Fit fuel connector spacer block and

gasket.

32.Fit fuel connector block, fit bolts and tighten to

25 Nm (18 lbf.ft).

33.Clean glow plugs.

34.Fit glow plugs to cylinder head and tighten to

16 Nm (12 lbf.ft).

35.Fit new cylinder head gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

36. Engine Serial No. Prefixes 15P to

19P:Lubricate new 'O' rings with engine oil and

fit to spill return pipe, fit pipe and tighten

connectors to 20 Nm (15 lbf.ft).

37.Before fitting the camshaft cover, the fuel

injector rockers must be adjusted following the

procedures given in Cylinder head gasket -

Refit.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

Gasket - engine sump

$% 12.60.38.01

Disassembly

1.Remove 2 bolts securing centrifuge oil drain

pipe to sump, remove and discard gasket.

2.Using sequence shown and noting their fitted

positions, remove 20 bolts securing sump to

cylinder block.

3.Release sump from locating dowels, remove

sump; remove and discard gasket.

Reassembly

1.Clean sump and mating faces, ensure bolt

holes in cylinder block are clean and dry.

2.Using suitable solvent, remove all traces of

sealant from joint faces of timing chain cover

and crankshaft rear oil seal housing.

3.Clean centrifuge oil drain pipe and mating

faces.

Page 225 of 1672

ENGINE - TD5

12-1-86 OVERHAUL

Seal - crankshaft - rear - manual models

$% 12.21.20.01

Disassembly

1.Remove flywheel.

+ ENGINE - Td5, OVERHAUL,

Flywheel.

2.Remove sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

3.Remove 5 bolts securing crankshaft rear oil

seal housing to cylinder block.

4.Release crankshaft rear oil seal housing from

locating dowels, discard rear oil seal and

housing.

Reassembly

1.Clean crankshaft oil seal housing mating face

on cylinder block, ensure bolt and dowel holes

are clean and dry. Remove all traces of oil from

oil seal running surface on crankshaft.

2.Position seal protector LRT-12-061 over

crankshaft boss. Fit new oil seal and housing

and remove tool LRT-12-061.

CAUTION: Oil seal must be fitted dry.3.Fit oil seal housing bolts and using sequence

shown, tighten to 9 Nm (7 lbf.ft).

4.Fit sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

5.Fit flywheel.

+ ENGINE - Td5, OVERHAUL,

Flywheel.

Page 226 of 1672

ENGINE - TD5

OVERHAUL 12-1-87

Seal - crankshaft - rear - automatic

models

$% 12.21.20.01

Disassembly

1.Remove sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

2.Remove drive plate.

+ ENGINE - Td5, OVERHAUL, Drive

plate.

3.Remove 5 bolts securing crankshaft rear oil

seal housing to cylinder block.

4.Release crankshaft rear oil seal housing from

locating dowels, discard rear oil seal and

housing.

Reassembly

1.Clean crankshaft oil seal housing mating face

on cylinder block, ensure bolt and dowel holes

are clean and dry. Remove all traces of oil from

oil seal running surface on crankshaft.2.Position seal protector LRT-12-061 over

crankshaft boss. Fit new oil seal and housing

and remove tool LRT-12-061.

CAUTION: Oil seal must be fitted dry.

3.Fit oil seal housing bolts and using sequence

shown, tighten to 9 Nm (7 lbf.ft).

4.Fit sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

5.Fit drive plate.

+ ENGINE - Td5, OVERHAUL, Drive

plate.

Page 227 of 1672

ENGINE - TD5

12-1-88 OVERHAUL

Flywheel

$% 12.53.07.01

Disassembly

1.Remove 3 bolts securing damper to crankshaft

pulley, fit LRT-51-003 to crankshaft pulley,

secure with 2 bolts.

2.Restrain crankshaft using LRT-51-003,

remove and discard 8 bolts securing flywheel

to crankshaft. Release flywheel from locating

dowels; remove flywheel.

Reassembly

1.Clean flywheel and crankshaft mating faces.

2.Position flywheel on crankshaft.

3.Fit new bolts to retain flywheel and tighten by

diagonal selection to:

lStage 1 - 40 Nm (30 lbf.ft)

lStage 2 - Further 90

°

CAUTION: Do not carry out stages 1 and 2 in

one operation.

4.Remove tool LRT-51-003, fit damper and

tighten bolts to 80 Nm (59 lbf.ft).

Drive plate

$% 12.53.13.01

Disassembly

1.Remove 3 bolts securing damper to crankshaft

pulley, fit LRT-51-003 to crankshaft pulley,

secure with 2 bolts.

2.Restrain crankshaft using LRT-51-003,

remove and discard 8 bolts securing drive

plate, spacer and starter ring gear to

crankshaft, release starter ring gear from

locating dowels and remove.

Page 229 of 1672

ENGINE - TD5

12-1-90 OVERHAUL

Pump - oil

$% 12.60.26.02

Disassembly

1.Remove sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

2.Remove bolt securing oil pump drive sprocket.

3.Release drive sprocket from chain, remove

sprocket.

4.Remove 3 Torx screws securing oil pick-up

strainer, remove strainer.

5.Remove and discard 'O' ring.6.Using sequence shown, remove and discard 22

bolts securing oil pump and stiffener plate

assembly to cylinder block.

7.Release stiffener plate from locating dowels,

remove oil pump and stiffener plate assembly.

8.Remove and discard 'O' ring from oil pump

housing outlet.

Inspection

1. Inspection/overhaul procedures for the oil

pump are limited to carrying out

dimensional checks. In the event of wear or

damage being found, a replacement pump

and stiffener plate assembly must be fitted.

Page 230 of 1672

ENGINE - TD5

OVERHAUL 12-1-91

2.Remove and discard 5 screws securing cover

to oil pump, remove cover.

3.Using a felt tipped pen, make suitable

alignment marks between inner and outer

rotors and oil pump body.

4.Remove inner and outer rotors.

5.Check rotors and pump body for signs of

scoring and wear.

6.Fit rotors ensuring that marks are aligned and

identification mark on inner rotor is facing

outwards.7.Using feeler gauges, check pump outer rotor to

body clearance:

lOuter rotor to body clearance = 0.295 to

0.375 mm (0.012 to 0.015 in)

8.Using feeler gauges, check clearance of inner

to outer rotor in 2 positions; both clearances

must be within limit given:

lInner to outer rotor clearance = 0.13 mm

(0.05 in)