ECU LAND ROVER DISCOVERY 2002 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 164 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-25

Inlet and exhaust valves

The inlet and exhaust valves are mounted directly above the engine block cylinders.

Each valve is a forged and ground solid one-piece head and stem which is hardened by heat treatment. The stems

are chrome-plated then ground for improved heat transfer, wear resistance and smooth operation. It is not possible

to recut the valve's face angle, but the valves can be lapped to their seats using grinding paste.

The valve springs are made from spring steel and are of the parallel single-coil type. The bottom end of the spring

rests on the flange of a spring seal which has a centre bore that locates on a recess ground into the lower valve stem.

The top end of the spring is held in place by a spring retainer which is held in position at the top end of the valve stem

by split taper collets. The taper collets have grooves on the internal bore that locate to grooves ground into the upper

stems of the valves.

The valve seats and valve guides are sintered and are interference fit into the cylinder head. The valve seats and

guides are non-serviceable.

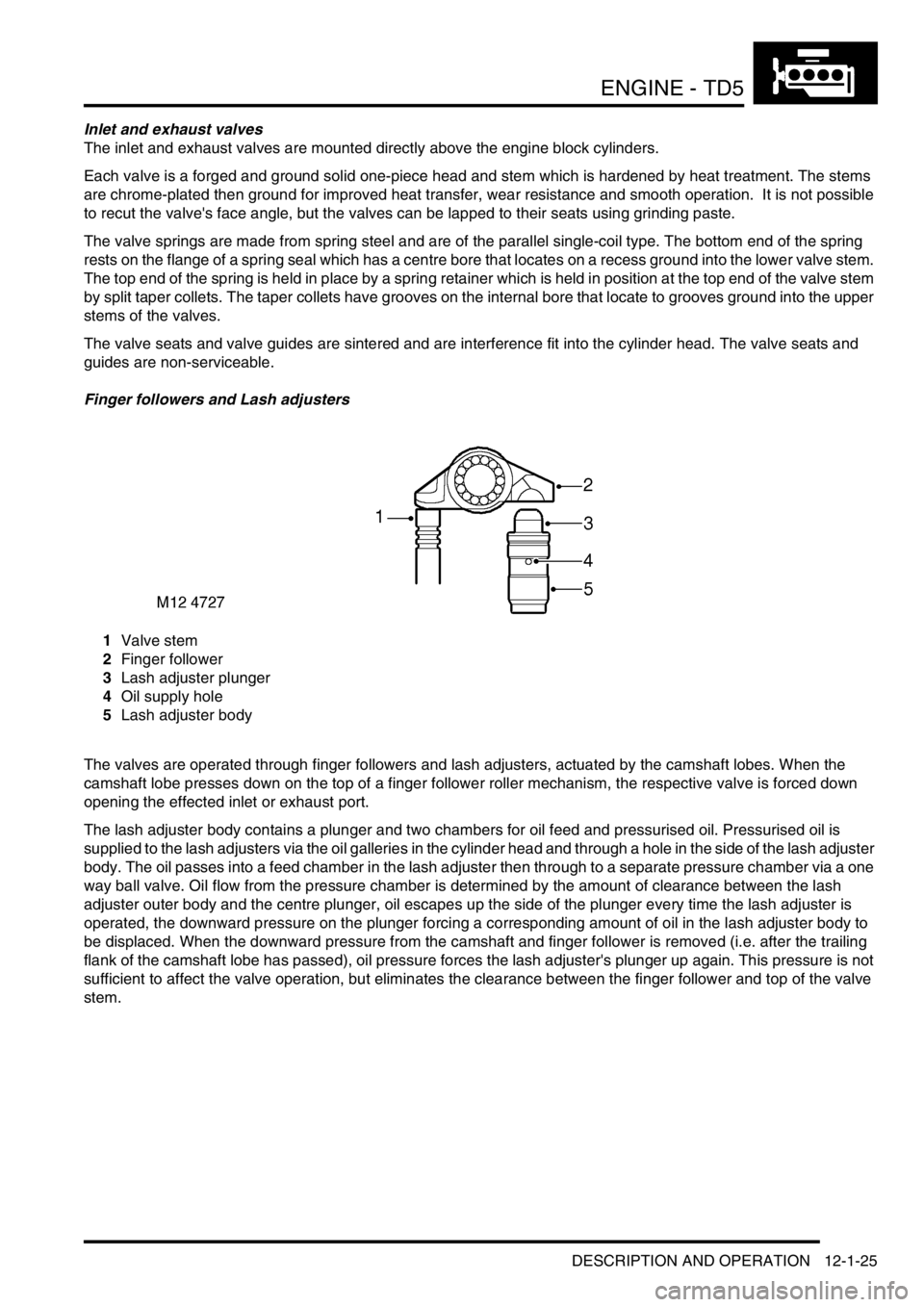

Finger followers and Lash adjusters

1Valve stem

2Finger follower

3Lash adjuster plunger

4Oil supply hole

5Lash adjuster body

The valves are operated through finger followers and lash adjusters, actuated by the camshaft lobes. When the

camshaft lobe presses down on the top of a finger follower roller mechanism, the respective valve is forced down

opening the effected inlet or exhaust port.

The lash adjuster body contains a plunger and two chambers for oil feed and pressurised oil. Pressurised oil is

supplied to the lash adjusters via the oil galleries in the cylinder head and through a hole in the side of the lash adjuster

body. The oil passes into a feed chamber in the lash adjuster then through to a separate pressure chamber via a one

way ball valve. Oil flow from the pressure chamber is determined by the amount of clearance between the lash

adjuster outer body and the centre plunger, oil escapes up the side of the plunger every time the lash adjuster is

operated, the downward pressure on the plunger forcing a corresponding amount of oil in the lash adjuster body to

be displaced. When the downward pressure from the camshaft and finger follower is removed (i.e. after the trailing

flank of the camshaft lobe has passed), oil pressure forces the lash adjuster's plunger up again. This pressure is not

sufficient to affect the valve operation, but eliminates the clearance between the finger follower and top of the valve

stem.

Page 165 of 1672

ENGINE - TD5

12-1-26 DESCRIPTION AND OPERATION

Camshaft cover and engine cover components

The camshaft cover and engine cover components are described below:

Camshaft cover

The camshaft cover is cast from aluminium alloy and is fixed to the camshaft carrier/cylinder head assembly by 13

bolts. The cover has spacers and sealing washers inserted into each of the thirteen bolt holes.

A breather hose is connected to a port at the top of the camshaft cover by means of a hose clip which vents crankcase

gases back to the air intake via a breather valve in the air intake tract, located forward of the turbocharger in the

flexible air intake duct.

A rubber seal is fitted between the camshaft cover.

An oil filler aperture is included in the top of the camshaft cover, which is sealed with a plastic cap with integral rubber

seal.

Camshaft timing chain components

The timing chain cover and timing chain components are described below:

Timing chain cover

The timing chain cover is cast and machined aluminium alloy and is attached to the cylinder head by a bolt at the RH

top of the cover and by a stud and nut at the LH top of the cover. Eight screws are used to attach the timing chain

cover to the front of the engine block. The timing cover is located to the cylinder block front face by two dowels.

A viscous fan is attached to an idler pulley at the front of the engine block. The fan bearing is located on a shaft and

held in place by a circlip and a bearing flange, the inner race of the fan bearing is an interference fit on the shaft. The

fan idler pulley is attached to the bearing hub by three bolts, and the fan itself is secured to the pulley and bearing

shaft by a left hand threaded nut.

+ COOLING SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

The front of the crankshaft passes through a hole in the lower part of the timing cover. An oil seal is pressed into a

recess in the front of the timing cover to seal the interface between the front of the crankshaft and the timing cover.

A stub pipe is fitted to the front RH side of the timing cover which is used to attach the oil drain pipe from the vacuum

pump by means of a hose and spring clip.

Timing chains

The timing chain between the camshaft and crankshaft sprockets is a duplex type, each chain having 56 links. The

timing chain is contained between a fixed plastic guide and an hydraulically adjustable plastic tensioner arm which

are attached to the front of the engine block.

To cope with higher injection loads of the EU3 engine, the timing drive between the camshaft and crankshaft has been

upgraded. This requires thicker chain links to be used, therefore, the individual pre EU3 and EU3 components are not

interchangeable.

To distinguish between the two timing chains the links are different colours. A pre EU3 chain has blue links and a EU3

chain has bronze links.

The oil pump timing chain is a single type and traverses the oil pump sprocket and the rear crankshaft sprocket.

The timing chains are oil lubricated, with oil being provided by a chain lubrication jet and from oil flow returning back

to the sump from the cylinder head. An oil hole is included at the front left hand side of the cylinder head which supplies

oil from the cylinder head oil galleries.

Page 176 of 1672

ENGINE - TD5

REPAIRS 12-1-37

REPAIRS

Pulley - crankshaft

$% 12.21.01

Remove

1.Remove fixings and underbelly panel.

2.Remove radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

3.Using a 15 mm ring spanner, release the

auxiliary drive belt tensioner.

4.Remove auxiliary drive belt.

5.Remove 3 bolts and remove crankshaft TV

damper.

6.Position tool LRT-51-003 to crankshaft pulley

and secure with 2 bolts.

7.Remove and discard crankshaft pulley bolt.

Remove crankshaft pulley.

8.Remove 2 bolts and remove tool LRT-51-003

Refit

1.Position new crankshaft pulley to vice.

2.Remove 3 bolts and remove TV damper from

new crankshaft pulley.

3.Using a lint free cloth, thoroughly clean oil seal

recess and the running surface on crankshaft

pulley.

4.Fit crankshaft pulley. 5.Fit tool LRT-51-003 to crankshaft pulley and

secure with 2 bolts.

6.Fit new crankshaft pulley bolt and tighten to

460 Nm (340 lbf.ft), using a torque multiplier.

7.Remove 2 bolts and remove tool LRT-51-003

from crankshaft pulley.

8.Fit TV damper to crankshaft pulley and tighten

– TV damper bolts to 80 Nm (59 lbf.ft) .

9.Fit auxiliary drive belt to pulleys.

10.Fit radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

11.Fit underbelly panel and secure with fixings.

Page 177 of 1672

ENGINE - TD5

12-1-38 REPAIRS

Seal - crankshaft - rear

$% 12.21.20

Remove

1. Automatic models: Remove drive plate

+ ENGINE - Td5, REPAIRS, Plate -

drive - automatic.

2. Manual models: Remove flywheel.

+ ENGINE - Td5, REPAIRS, Flywheel.

3.Remove sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

4.Remove 5 bolts securing crankshaft oil seal

housing to cylinder block.

5.Remove crankshaft oil seal housing.

Refit

1.Clean interface between crankshaft oil seal

housing and cylinder block.

2.Position seal protector, LRT-12-061 over

crankshaft boss. Fit new seal and remove tool

LRT-12-061 .

CAUTION: Oil seal must be fitted dry.3.Fit crankshaft rear oil seal housing bolts and

using sequence shown, tighten to 9 Nm (7

lbf.ft).

4.Fit new sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

5. Automatic models: Fit drive plate

+ ENGINE - Td5, REPAIRS, Plate -

drive - automatic.

6. Manual models: Fit flywheel.

+ ENGINE - Td5, REPAIRS, Flywheel.

Page 178 of 1672

ENGINE - TD5

REPAIRS 12-1-39

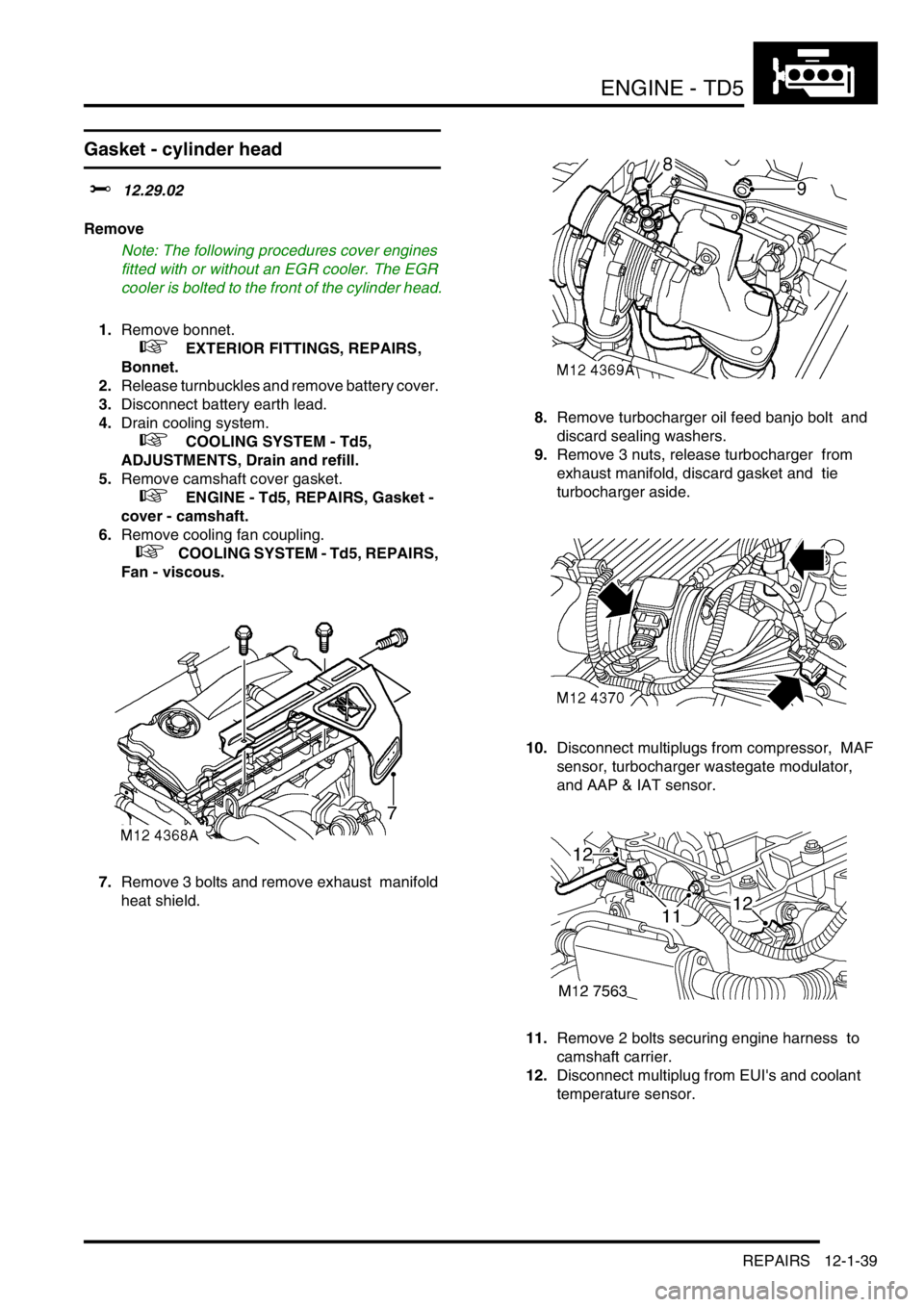

Gasket - cylinder head

$% 12.29.02

Remove

Note: The following procedures cover engines

fitted with or without an EGR cooler. The EGR

cooler is bolted to the front of the cylinder head.

1.Remove bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

2.Release turnbuckles and remove battery cover.

3.Disconnect battery earth lead.

4.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

5.Remove camshaft cover gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

6.Remove cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

7.Remove 3 bolts and remove exhaust manifold

heat shield. 8.Remove turbocharger oil feed banjo bolt and

discard sealing washers.

9.Remove 3 nuts, release turbocharger from

exhaust manifold, discard gasket and tie

turbocharger aside.

10.Disconnect multiplugs from compressor, MAF

sensor, turbocharger wastegate modulator,

and AAP & IAT sensor.

11.Remove 2 bolts securing engine harness to

camshaft carrier.

12.Disconnect multiplug from EUI's and coolant

temperature sensor.

Page 179 of 1672

ENGINE - TD5

12-1-40 REPAIRS

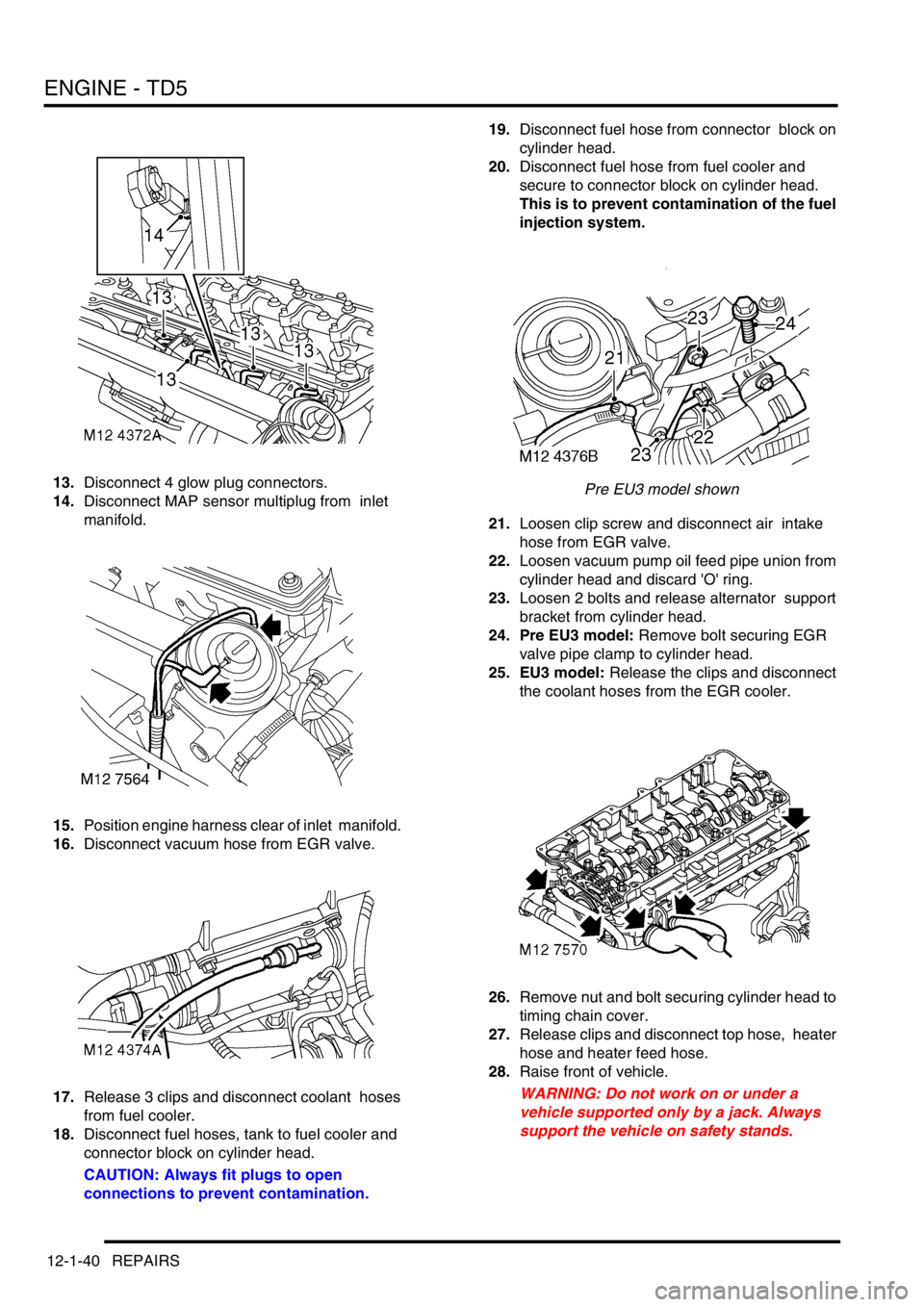

13.Disconnect 4 glow plug connectors.

14.Disconnect MAP sensor multiplug from inlet

manifold.

15.Position engine harness clear of inlet manifold.

16.Disconnect vacuum hose from EGR valve.

17.Release 3 clips and disconnect coolant hoses

from fuel cooler.

18.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Always fit plugs to open

connections to prevent contamination.19.Disconnect fuel hose from connector block on

cylinder head.

20.Disconnect fuel hose from fuel cooler and

secure to connector block on cylinder head.

This is to prevent contamination of the fuel

injection system.

Pre EU3 model shown

21.Loosen clip screw and disconnect air intake

hose from EGR valve.

22.Loosen vacuum pump oil feed pipe union from

cylinder head and discard 'O' ring.

23.Loosen 2 bolts and release alternator support

bracket from cylinder head.

24. Pre EU3 model: Remove bolt securing EGR

valve pipe clamp to cylinder head.

25. EU3 model: Release the clips and disconnect

the coolant hoses from the EGR cooler.

26.Remove nut and bolt securing cylinder head to

timing chain cover.

27.Release clips and disconnect top hose, heater

hose and heater feed hose.

28.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

Page 181 of 1672

ENGINE - TD5

12-1-42 REPAIRS

37.Using suitable lifting chains and tool LRT-12-

138 carefully remove cylinder head and place

on wooden blocks or stands.

CAUTION: Support both ends of cylinder

head on blocks of wood. With the camshaft

carrier bolted down, the injector nozzles

and some of the valves will protrude from

the face of the cylinder head.

38.Remove cylinder head gasket.

39.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of cylinder head.

40.Remove and discard plastic dowels from

cylinder block.Refit

1.Clean mating faces of cylinder head and

cylinder block.

2.Check cylinder head for warping, across centre

and from corner to corner: – Maximum warp =

0.10 mm (0.0004 in)

CAUTION: Cylinder heads may not be

refaced, replace cylinder head if warping

exceeds figure given.

3.Ensure coolant and oil passages are clean.

4.Clean dowel holes and fit new plastic dowels.

5.Lightly lubricate threads and beneath heads of

cylinder head bolts with clean engine oil.

6.Fit new cylinder head gasket of the correct

thickness with the word 'TOP' uppermost.

7.Using assistance, fit cylinder head and locate

onto dowels.

8.Carefully enter cylinder head bolts, DO NOT

DROP. Lightly tighten bolts.

9.Using the sequence shown, progressively

tighten cylinder head bolts to 30 Nm (22 lbf.ft),

then to 65 Nm (48 lbf.ft), then a further 90

°, then

a further 180

° and finally a further 45°.

CAUTION: Ensure correct sequence is

followed for all 5 tightening stages. Do not

tighten bolts 315 degrees in one operation.

10.Fit nut and bolt securing cylinder head to timing

chain cover and tighten to 25 Nm (18 lbf.ft).

Page 182 of 1672

ENGINE - TD5

REPAIRS 12-1-43

11.Clean camshaft sprocket and mating face on

camshaft.

12.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

13.Position camshaft sprocket to camshaft; fit and

lightly tighten new bolts, then loosen bolts half

a turn.

14.Clean timing chain fixed guide retaining pin and

apply Loctite 242 to threads.

15.Fit timing chain fixed guide retaining pin and

tighten to 25 Nm (18 lbf.ft) .

16.Clean timing chain tensioner and fit new

sealing washer.

17.Fit timing chain tensioner and tighten to 45 Nm

(22 lbf.ft).

18.Tighten bolts securing camshaft sprocket to

camshaft to 37 Nm (27 lbf.ft).

19.Remove tool LRT-12-058 from camshaft.

20.Remove tool LRT-12-158 from gearbox bell

housing.

21.Fit new camshaft bore blanking plug and 'O'-

ring seal in recess in cylinder head.

22.Clean vacuum pump union.

23.Tighten union securing vacuum pump oil feed

pipe to cylinder head to 10 Nm (7 lbf.ft) .

24.Fit bolts securing alternator support bracket to

cylinder head and tighten to 25 Nm (18 lbf.ft) .

25.Connect top hose and heater hoses and secure

with clips.

26. Pre EU3 model:Fit bolt securing EGR pipe

clamp to cylinder head bolt and tighten to 10

Nm (7 lbf.ft) .

27. EU3 model: Connect coolant hoses to EGR

cooler and secure with the clips.

28.Position air intake hose to EGR valve and

tighten clip screw.

29.Disconnect fuel hose from connector block and

connect to fuel cooler.

30.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

31.Connect coolant hoses to fuel cooler and

secure clips.

32.Connect vacuum hose to EGR valve.

33.Position engine harness and connect multi

plugs and glow plug connectors.

34.Fit and tighten bolts, engine harness to

camshaft carrier.

35.Clean exhaust manifold and turbocharger

interface.

36.Fit new gasket to exhaust manifold, position

turbocharger and tighten – nuts securing

turbocharger to manifold to 30 Nm (22 lbf.ft).

37.Clean turbocharger oil feed hose bolt.

38.Position turbocharger oil feed hose using new

sealing washers. Fit banjo bolt securing

turbocharger oil feed hose and tighten to 25 Nm

(18 lbf.ft) . 39.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolt to

25 Nm (18 lbf.ft).

40.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

41.Fit camshaft cover with new seal.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

42.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

43.Connect battery earth lead.

44.Fit battery cover and secure fixings.

45.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 183 of 1672

ENGINE - TD5

12-1-44 REPAIRS

Rocker shaft assembly

$% 12.29.29

Remove

1.Remove cooling fan.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

2.Remove camshaft cover gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

3.Loosen lock nuts and fully retract rocker

adjusting screws to prevent damage on

reassembly. 4.Rotate engine clockwise, until camshaft

sprocket and timing chain marks are aligned

and fit tool LRT-12-058 through camshaft

carrier to lock camshaft.

5.Progressively loosen then remove and discard

6 bolts securing rocker shaft assembly.

6.Remove and discard lock nuts and rocker

adjusting screws.

Page 185 of 1672

ENGINE - TD5

12-1-46 REPAIRS

Gasket - cover - camshaft

$% 12.29.40

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Release clip and disconnect breather hose

from camshaft cover.

3.Remove 13 bolts securing camshaft cover.

4.Collect sealing washers and spacers.

5.Remove camshaft cover and gasket.

Refit

1.Clean camshaft cover and mating face.

2.Renew sealing washers and spacers as

necessary. 3. Not EU3 model:- Apply two 3 mm diameter

beads of sealant, STC 5433, to areas 'A' shown

on illustration.

Excessive use of sealant could result in

blockage of oil drain hole, arrowed 'B' on

illustration.

4.Fit new gasket, fit camshaft cover to camshaft

carrier and tighten – camshaft cover bolts to 9

Nm (7 lbf.ft).

5.Position breather hose to camshaft cover and

secure with clip.

6.Fit engine acoustic cover and secure with

fixings.

M12 7538

A

B

A