ECU LAND ROVER DISCOVERY 2002 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 232 of 1672

ENGINE - TD5

OVERHAUL 12-1-93

Timing chain and sprockets

$% 12.65.13.01

Disassembly

1.Remove cylinder head gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

CAUTION: If timing chain tensioner is to be

replaced, ensure tensioner is correct for

engine. Tensioner bodies are colour coded

as follows: Engine Serial No. Prefixes 10P to

14P – BLACK with, additionally on later

engines, YELLOW on tensioner hex. head.

Serial No. Prefixes 15P to 19P – body is

colour coded YELLOW. Later tensioners

may be fitted to early engines provided that

the modified adjustable guide is also fitted.

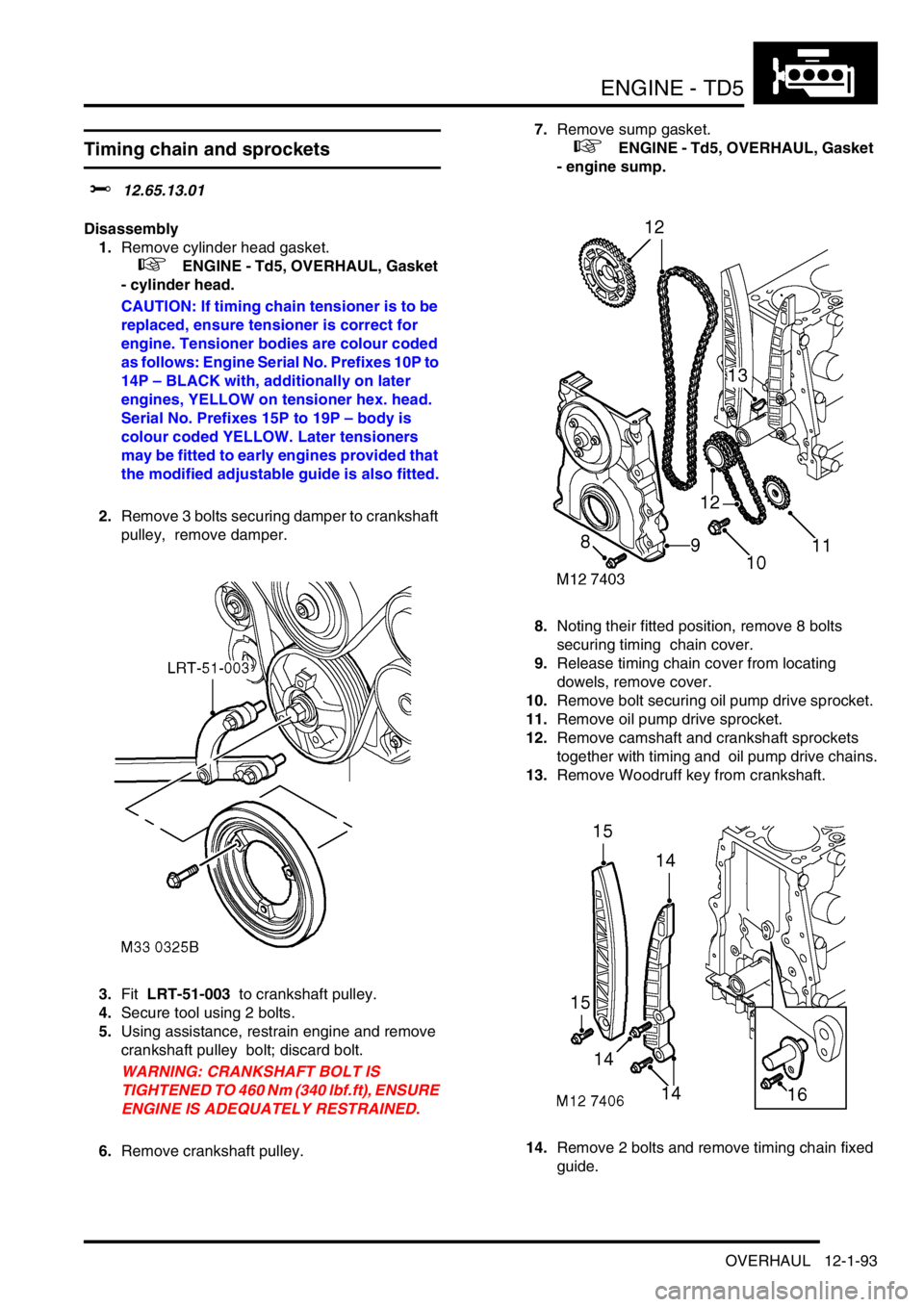

2.Remove 3 bolts securing damper to crankshaft

pulley, remove damper.

3.Fit LRT-51-003 to crankshaft pulley.

4.Secure tool using 2 bolts.

5.Using assistance, restrain engine and remove

crankshaft pulley bolt; discard bolt.

WARNING: CRANKSHAFT BOLT IS

TIGHTENED TO 460 Nm (340 lbf.ft), ENSURE

ENGINE IS ADEQUATELY RESTRAINED.

6.Remove crankshaft pulley.7.Remove sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

8.Noting their fitted position, remove 8 bolts

securing timing chain cover.

9.Release timing chain cover from locating

dowels, remove cover.

10.Remove bolt securing oil pump drive sprocket.

11.Remove oil pump drive sprocket.

12.Remove camshaft and crankshaft sprockets

together with timing and oil pump drive chains.

13.Remove Woodruff key from crankshaft.

14.Remove 2 bolts and remove timing chain fixed

guide.

Page 235 of 1672

ENGINE - TD5

12-1-96 OVERHAUL

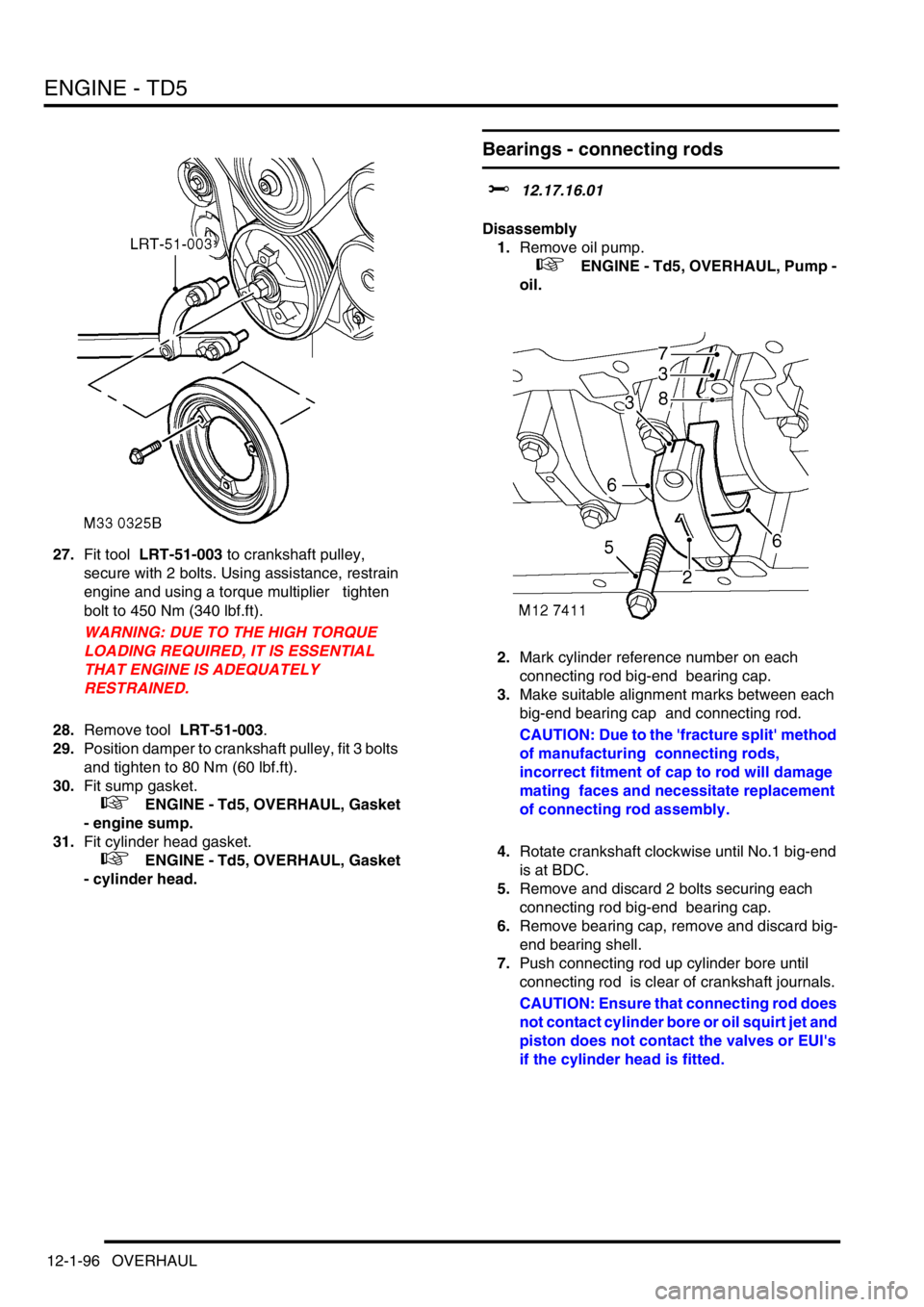

27.Fit tool LRT-51-003 to crankshaft pulley,

secure with 2 bolts. Using assistance, restrain

engine and using a torque multiplier tighten

bolt to 450 Nm (340 lbf.ft).

WARNING: DUE TO THE HIGH TORQUE

LOADING REQUIRED, IT IS ESSENTIAL

THAT ENGINE IS ADEQUATELY

RESTRAINED.

28.Remove tool LRT-51-003.

29.Position damper to crankshaft pulley, fit 3 bolts

and tighten to 80 Nm (60 lbf.ft).

30.Fit sump gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- engine sump.

31.Fit cylinder head gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

Bearings - connecting rods

$% 12.17.16.01

Disassembly

1.Remove oil pump.

+ ENGINE - Td5, OVERHAUL, Pump -

oil.

2.Mark cylinder reference number on each

connecting rod big-end bearing cap.

3.Make suitable alignment marks between each

big-end bearing cap and connecting rod.

CAUTION: Due to the 'fracture split' method

of manufacturing connecting rods,

incorrect fitment of cap to rod will damage

mating faces and necessitate replacement

of connecting rod assembly.

4.Rotate crankshaft clockwise until No.1 big-end

is at BDC.

5.Remove and discard 2 bolts securing each

connecting rod big-end bearing cap.

6.Remove bearing cap, remove and discard big-

end bearing shell.

7.Push connecting rod up cylinder bore until

connecting rod is clear of crankshaft journals.

CAUTION: Ensure that connecting rod does

not contact cylinder bore or oil squirt jet and

piston does not contact the valves or EUI's

if the cylinder head is fitted.

Page 237 of 1672

ENGINE - TD5

12-1-98 OVERHAUL

Pistons, connecting rods and cylinder

bores

$% 12.17.02.03

Disassembly

1.Remove cylinder head gasket.

+ ENGINE - Td5, OVERHAUL, Gasket

- cylinder head.

2.Remove connecting rod bearings.

+ ENGINE - Td5, OVERHAUL,

Bearings - connecting rods.

3.Remove ridge of carbon from top of cylinder

bore.

4.Suitably identify each piston and connecting

rod assembly to its respective cylinder bore.

5.Carefully push connecting rod to top of cylinder

bore taking care that connecting rod does not

contact oil squirt jet or cylinder wall; remove

each piston and connecting rod in turn.

6.Using a suitable expander, remove and discard

piston rings from pistons.

7.Clean carbon from piston crown and skirt. Do

not use abrasives on graphited area of

piston skirt, do not use a wire brush or

scraper on any part of pistons.

8.Secure connecting rod in a soft jawed vice.

9.Suitably identify each piston to its connecting

rod and fitted position of piston on rod.

10.Using suitable circlip pliers, remove and

discard 2 circlips securing gudgeon pin.

11.Push gudgeon pin out of piston and connecting

rod; remove piston.

12.Suitably identify each gudgeon pin to its

respective piston.

13.Repeat above procedures for remaining

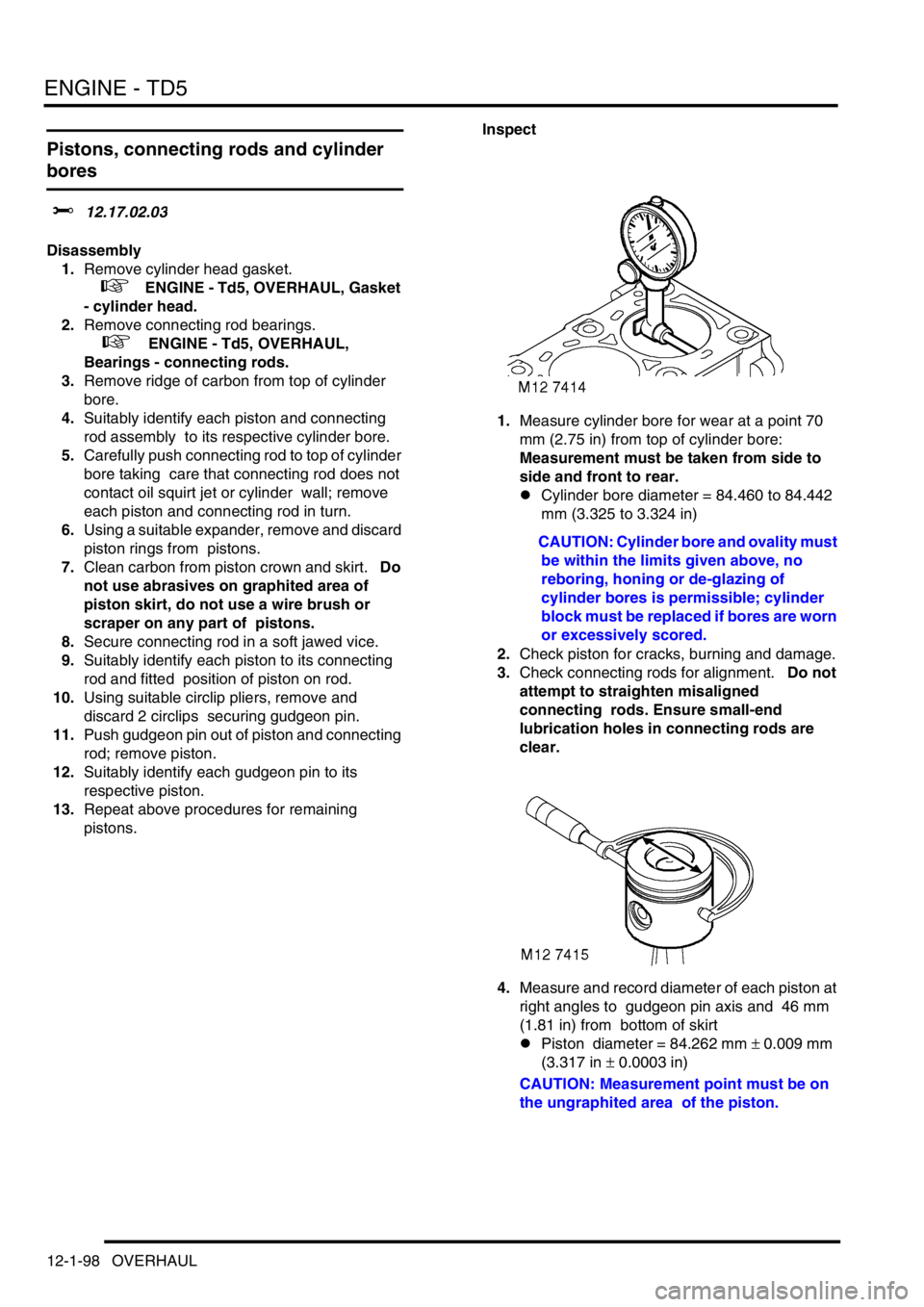

pistons. Inspect

1.Measure cylinder bore for wear at a point 70

mm (2.75 in) from top of cylinder bore:

Measurement must be taken from side to

side and front to rear.

lCylinder bore diameter = 84.460 to 84.442

mm (3.325 to 3.324 in)

CAUTION: Cylinder bore and ovality must

be within the limits given above, no

reboring, honing or de-glazing of

cylinder bores is permissible; cylinder

block must be replaced if bores are worn

or excessively scored.

2.Check piston for cracks, burning and damage.

3.Check connecting rods for alignment. Do not

attempt to straighten misaligned

connecting rods. Ensure small-end

lubrication holes in connecting rods are

clear.

4.Measure and record diameter of each piston at

right angles to gudgeon pin axis and 46 mm

(1.81 in) from bottom of skirt

lPiston diameter = 84.262 mm

± 0.009 mm

(3.317 in

± 0.0003 in)

CAUTION: Measurement point must be on

the ungraphited area of the piston.

Page 239 of 1672

ENGINE - TD5

12-1-100 OVERHAUL

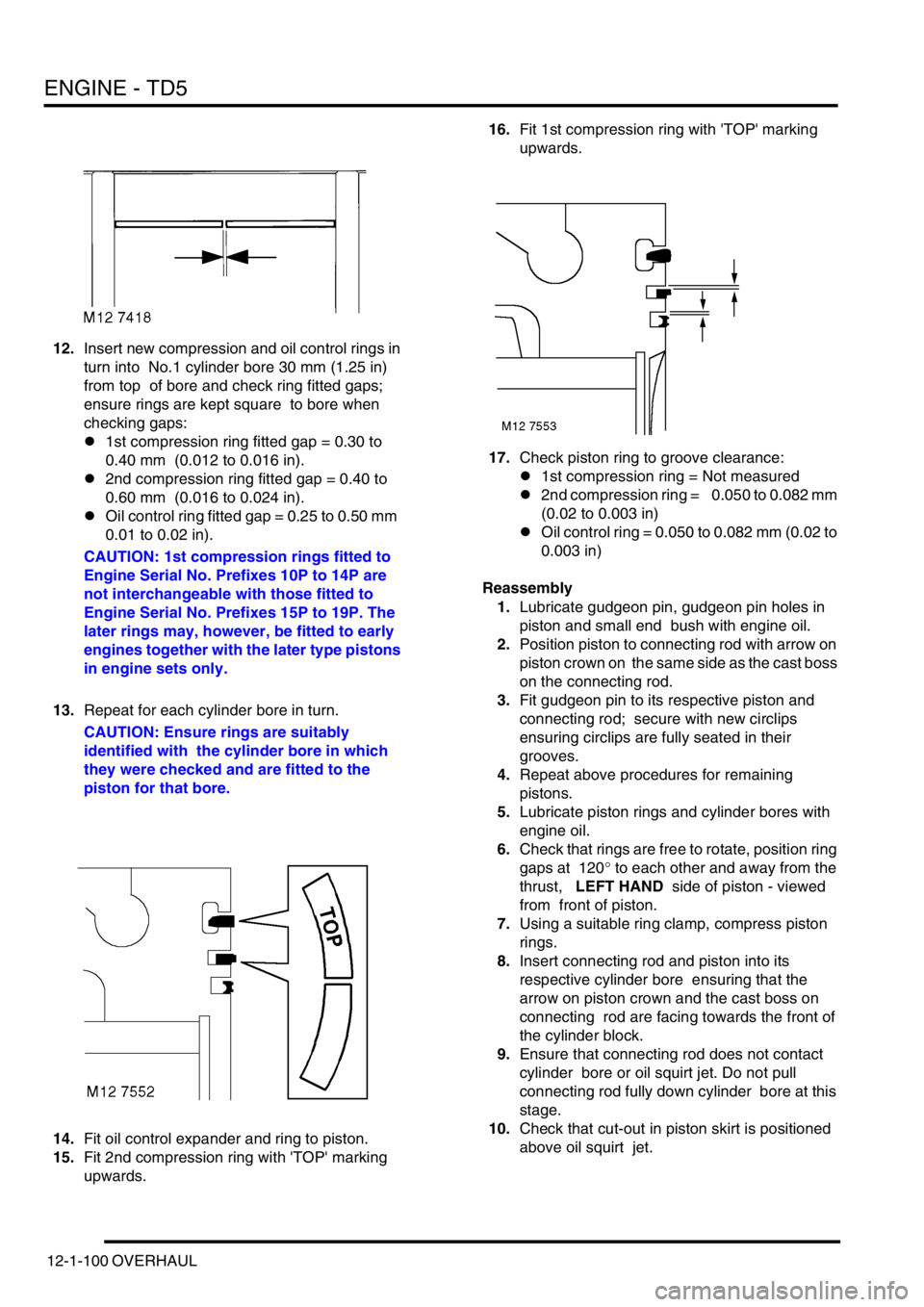

12.Insert new compression and oil control rings in

turn into No.1 cylinder bore 30 mm (1.25 in)

from top of bore and check ring fitted gaps;

ensure rings are kept square to bore when

checking gaps:

l1st compression ring fitted gap = 0.30 to

0.40 mm (0.012 to 0.016 in).

l2nd compression ring fitted gap = 0.40 to

0.60 mm (0.016 to 0.024 in).

lOil control ring fitted gap = 0.25 to 0.50 mm

0.01 to 0.02 in).

CAUTION: 1st compression rings fitted to

Engine Serial No. Prefixes 10P to 14P are

not interchangeable with those fitted to

Engine Serial No. Prefixes 15P to 19P. The

later rings may, however, be fitted to early

engines together with the later type pistons

in engine sets only.

13.Repeat for each cylinder bore in turn.

CAUTION: Ensure rings are suitably

identified with the cylinder bore in which

they were checked and are fitted to the

piston for that bore.

14.Fit oil control expander and ring to piston.

15.Fit 2nd compression ring with 'TOP' marking

upwards. 16.Fit 1st compression ring with 'TOP' marking

upwards.

17.Check piston ring to groove clearance:

l1st compression ring = Not measured

l2nd compression ring = 0.050 to 0.082 mm

(0.02 to 0.003 in)

lOil control ring = 0.050 to 0.082 mm (0.02 to

0.003 in)

Reassembly

1.Lubricate gudgeon pin, gudgeon pin holes in

piston and small end bush with engine oil.

2.Position piston to connecting rod with arrow on

piston crown on the same side as the cast boss

on the connecting rod.

3.Fit gudgeon pin to its respective piston and

connecting rod; secure with new circlips

ensuring circlips are fully seated in their

grooves.

4.Repeat above procedures for remaining

pistons.

5.Lubricate piston rings and cylinder bores with

engine oil.

6.Check that rings are free to rotate, position ring

gaps at 120

° to each other and away from the

thrust, LEFT HAND side of piston - viewed

from front of piston.

7.Using a suitable ring clamp, compress piston

rings.

8.Insert connecting rod and piston into its

respective cylinder bore ensuring that the

arrow on piston crown and the cast boss on

connecting rod are facing towards the front of

the cylinder block.

9.Ensure that connecting rod does not contact

cylinder bore or oil squirt jet. Do not pull

connecting rod fully down cylinder bore at this

stage.

10.Check that cut-out in piston skirt is positioned

above oil squirt jet.

Page 241 of 1672

ENGINE - TD5

12-1-102 OVERHAUL

Crankshaft

$% 12.21.33.01

Disassembly

1.Remove timing chain and sprockets.

+ ENGINE - Td5, OVERHAUL, Timing

chain and sprockets.

2.Remove crankshaft rear oil seal.

+ ENGINE - Td5, OVERHAUL, Seal -

crankshaft - rear - manual models.

3.Remove connecting rod bearings.

+ ENGINE - Td5, OVERHAUL,

Bearings - connecting rods.

4.Check that cylinder reference number is on

each main bearing cap and make alignment

marks between each main bearing cap and

cylinder block.

5.Starting at No.3 main bearing cap and working

outwards, progressively loosen, then remove 2

bolts securing each cap. Discard main bearing

cap bolts. 6.Fit 2 slave bolts into main bearing cap in turn

and ease bearing caps from cylinder block.

7.Remove and discard plain bearing shells from

each main bearing cap.

8.Using assistance, remove crankshaft.

9.Remove and discard grooved main bearing

shells and 2 thrust washers from cylinder

block.

10.Remove Torx screw securing each oil squirt jet

to cylinder block, remove squirt jets.

11.Clean main bearing shell and thrust washer

locations in cylinder block, ensure bolt holes

are clean and dry.

12.Clean main bearing caps.

13.Clean crankshaft bearing journals, check

oilways are clear.

14.Ensure drillings in oil squirt jets are clear.

Page 242 of 1672

ENGINE - TD5

OVERHAUL 12-1-103

15.Check core plugs in cylinder block for corrosion

or signs of leakage, seal replacement plugs

with Loctite 243.

Crankshaft - Inspection

1.Check crankshaft main and big-end bearings

for scoring, wear and ovality, make 3 checks at

120

° intervals in centre of journals.

lMain bearings = 62.0 mm

± 0.013 mm

(2.441 in

± 0.001 in).

lBig-end bearings = 54.000 mm

± 0.01 mm

(2.125 in

± 0.0004 in).

2. Crankshafts may not be reground, only one

size of main and big-end bearing shell is

available and if journals are found to be

scored, oval or worn, crankshaft must be

replaced. Main and big-end bearing shells

and thrust washers must be replaced

whenever they are removed.

3.Check crankshaft spigot bush for wear, replace

if necessary using the following procedures:

4.Secure crankshaft in a suitably padded vice.

5.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

6.Fit impulse extractor to spigot bush.

7.Remove spigot bush.

8.Clean spigot bush recess in crankshaft.

9.Fit new spigot bush to crankshaft using a

suitable mandrel. Reassembly

1.Fit oil squirt jets, fit Torx screws and tighten to

8 Nm (6 lbf.ft).

2.Lubricate new, grooved, main bearing shells

with engine oil and fit to cylinder block.

3.Lubricate new thrust washers with engine oil

and fit, grooved side facing outward, to recess

in each side of No.3 main bearing in cylinder

block.

4.Lubricate crankshaft journals with engine oil

and using assistance, position crankshaft in

cylinder block.

5.Lubricate new, plain, main bearing shells with

engine oil and fit to main bearing caps.

6.Fit main bearing caps in their original fitted

positions ensuring reference marks are

aligned.

7.Fit and lightly tighten new main bearing cap

bolts. Do not lubricate bolt threads.

8.Starting with No.3 main bearing cap and

working outwards, tighten main bearing cap

bolts to:

lStage 1 - 33 Nm (24 lbf.ft)

lStage 2 - Further 90

°

CAUTION: Do not carry out stages 1 and

2 in one operation.

9.Check that crankshaft rotates smoothly.

10. Attach a magnetic base DTI to front of cylinder

block with stylus of gauge on end of crankshaft.

Page 250 of 1672

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-7

Oil sump

The oil sump is bolted to the bottom of the cylinder block and the timing cover and is sealed to both components with

a one piece gasket. A removable baffle to prevent oil surge is fitted in the sump. The oil pick-up pipe and strainer

assembly is positioned within the sump and is attached at the pick-up end to a stud screwed into number four main

bearing cap and at the delivery end to the oil pump. The oil drain plug is located in the bottom of the sump and is

sealed with a washer.

Pistons and connecting rods

Each of the aluminium alloy pistons has two compression rings and an oil control ring. The pistons are secured to the

connecting rods by semi-floating gudgeon pins. Each gudgeon pin is offset by 0.5 mm (0.02 in). The top of each piston

is recessed, the depth of recess determining the compression ratio of the engine. Plain, big-end bearing shells are

fitted to each connecting rod and cap.

Page 257 of 1672

ENGINE - V8

12-2-14 REPAIRS

Gasket - cylinder head - LH

$% 12.29.02

Remove

1.Remove inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

2.Noting their fitted order, disconnect ht leads

from spark plugs.

3.Remove bolt securing engine harness to rear

of cylinder head.

4. LH drive models: Remove brake servo heat

shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

5.Remove 8 bolts securing exhaust manifold to

cylinder head, release manifold and collect 2

gaskets.6.Progressively remove 4 bolts securing the

rocker shaft and remove rocker shaft.

7.Remove push rods. Store push rods in their

fitted order.

8. Models with SAI: Remove 2 air injection

adapters from cylinder head and discard.

9.In the sequence shown, remove 10 bolts

securing the cylinder head to block. Discard the

bolts.

Page 259 of 1672

ENGINE - V8

12-2-16 REPAIRS

17. LH drive models: Fit brake servo heat shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

18.Fit engine harness bolt and tighten to 22 Nm

(16 lbf.ft).

19.Connect ht leads to spark plugs in their correct

fitted order.

20.Fit inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

Gasket - cylinder head - RH

$% 12.29.03

Remove

1.Remove inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

2.Remove bolt securing auxiliary drive belt

tensioner and remove tensioner.

3.Remove 4 bolts securing alternator mounting

bracket and remove bracket.

4.Noting their fitted order, disconnect ht leads

from spark plugs.

5.Remove bolt securing engine earth lead.

Page 260 of 1672

ENGINE - V8

REPAIRS 12-2-17

6. RH drive models: Remove brake servo heat

shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

7.Remove 8 bolts securing exhaust manifold to

cylinder head, release manifold and collect 2

gaskets.

8.Progressively remove 4 bolts securing the

rocker shaft and remove rocker shaft.

9.Remove push rods. Store push rods in their

fitted order. 10. Models with SAI: Remove 2 air injection

adapters and discard.

11.In the sequence shown, remove 10 bolts

securing the cylinder head to block. Discard the

bolts.

12.Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

13.Remove cylinder head gasket.