brake LAND ROVER DISCOVERY 2002 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 749 of 1672

TRANSFER BOX - LT230SE

41-16 DESCRIPTION AND OPERATION

Functionality – Vehicles from 03 model year only

The differential lock must be engaged for 2 wheel rolling road testing. It will also be necessary to disconnect the

propeller shaft from the transfer box output shaft driving the axle whose wheels are NOT on the rolling road. In

addition, the ETC system must be deactivated by either, removing a fuse (10A fuse 28 in the passenger compartment

fusebox, labelled ABS) or disconnecting the ABS modulator pump. This must be done with the ignition switched off.

Note that the SLABS ECU may record a system fault.

The lock can be engaged or disengaged using the selector lever. Vehicles not fitted with a differential lock can be

identified by a high/low range selector lever with no differential lock functionality and the cover and selector shaft

(arrowed), not visible on the front output housing.

WARNING: VEHICLES NOT FITTED WITH A DIFFERENTIAL LOCK MUST NOT BE TESTED ON A ROLLING

ROAD WHERE THE ROLLERS ARE DRIVEN BY THE VEHICLE.

Differential lock warning lamp switch - if fitted - Vehicles up to 03 model year

A differential lock warning lamp switch connected to the SLABS ECU and operated by movement of the selector fork

and shaft is screwed into the top of the output housing. The switch connects to earth when the differential lock is

engaged.

Differential lock warning lamp switches - if fitted - Vehicles from 03 model year

Vehicles from 03 model year are fitted with two differential lock warning lamp switches.

One switch is of a new design and is fitted into the top of the front output housing in the same position as on previous

models. The switch is connected to the SLABS ECU and is operated by movement of the selector fork and shaft.

The second switch is located in a threaded hole on the forward face of the front output housing. The switch is also

connected to the SLABS ECU and is operated by movement of the selector shaft.

Both switches have an aluminium washer which seals the switch to the casing and also sets the switch position,

removing the requirement for a setting procedure.

Both switches are connected in parallel to earth when the differential lock is engaged. This earth is sensed by the

SLABS ECU which illuminates the differential lock warning lamp in the instrument pack.

Differential lock warning lamp - Vehicles up to 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a warning to the driver when the

ignition is switched on that the differential lock is engaged. The warning lamp illuminates in a Red colour.

With the lock engaged, the traction control and electronic brake distribution warning lamps will also be illuminated.

Disengagement of the differential lock should be carried out with the ignition switched off. The warning lamps must

be extinguished when the ignition is switched on again.

Differential lock warning lamp – vehicles from 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a visual warning to the driver, when

the ignition is on, the differential lock is engaged. The warning lamp illuminates in an amber colour.

When the lock is engaged, the warning lamp is illuminated and the instrument pack sounder emits three audible

chimes. When the lock is disengaged, the warning lamp is extinguished and the instrument pack sounder emits three

audible chimes.

Rear output housing

The rear output housing carries the output shaft and flange. A cable operated transmission brake is attached to the

housing, the brake drum being attached to the output flange.

The rear output shaft is supported in the housing by a single bearing and is splined into the differential rear sun gear.

Page 757 of 1672

TRANSFER BOX - LT230SE

41-24 REPAIRS

Transfer box - Diesel

$% 41.20.25.99

Remove

1.Remove front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

2.Raise vehicle on ramp.

3.Drain transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

4.Remove 3 nuts securing intermediate silencer

to tail pipe.

5.Release silencer from mounting rubbers.

6.Remove silencer and discard gasket.

7.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

8.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.9.Remove handbrake drum retaining screw and

remove drum.

10.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

11.Remove clevis pin securing high/low ratio

selector cable to selector lever, remove 'C' clip

and release outer cable from abutment bracket.

Page 759 of 1672

TRANSFER BOX - LT230SE

41-26 REPAIRS

Refit

1.Fit new input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

2.Clean transfer box to gearbox mating faces.

3.Raise transfer box on jack and align to guide

studs LRT-41-009.

4.Clean transfer box to gearbox bolt threads.

5.Apply Loctite 290 to bolt and stud threads.

6.Fit and lightly tighten 2 bolts and nut securing

transfer box to gearbox. If new stud is to be

fitted, apply Loctite 290 to stud threads and

tighten to 45 Nm (33 lbf.ft).

7.Remove guide studs, fit and lightly tighten

remaining 3 bolts.

8.Tighten bolts and nut by diagonal selection to

45 Nm (33 lbf.ft).

9.Position gearbox RH mounting and tighten

bolts to 85 Nm (63 lbf.ft).

10.Tighten gearbox RH mounting nut to 48 Nm

(35 lbf.ft).

11.Remove 4 bolts securing support plate to

gearbox jack.

12.Remove 4 bolts securing support plate LRT-99-

010 to transfer box and remove plate.

13.Clean bottom plate bolt threads.

14.Apply Loctite 290 to threads of 4 bottom plate

bolts.

15.Fit 4 bolts securing bottom plate to transfer box

and tighten to 25 Nm (18 lbf.ft).

16.Position breather pipe and secure to bulkhead

clip.

17.Connect multiplug to reverse light switch.

18. If fitted - Connect Lucars to differential lock

switch.

19.Fit multiplug and cable tie to transfer gearbox

bracket. 20.Position high/low ratio selector cable and

secure with clevis pin.

21.Clean handbrake and mating face.

22.Position handbrake back plate and tighten

bolts to 75 Nm (55 lbf.ft).

23.Clean handbrake drum.

24.Fit handbrake drum and tighten retaining

screw.

25.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

26.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

27.Clean exhaust silencer and mating face.

28.Position silencer, fit new gasket , connect

mounting rubbers and tighten nuts to 40 Nm

(30 lbf.ft).

29.Refill transfer box with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

Page 760 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-27

Transfer box - V8

$% 41.20.25.99

Remove

1.Remove front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

2.Drain transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

3.Remove 8 bolts securing rear cross member

and remove cross member.

4.Remove 3 nuts securing intermediate silencer

to tail pipe.

5.Release silencer from mounting rubbers,

remove silencer and discard gasket.

6.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

7.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.8.Remove handbrake drum retaining screw and

remove handbrake drum.

9.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

10.Remove clevis pin and 'C' washer securing

high/low ratio selector cable to selector lever

and release cable from abutment bracket.

Page 762 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-29

22.Remove 4 bolts and nut securing RH mounting

to body and transfer box.

23.Remove nut securing LH mounting to body.

24.Raise gearbox and remove RH mounting.

25.With assistance, remove transfer box from

gearbox.

26.Remove input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

Refit

1.Fit new input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

2.Clean transfer box to gearbox mating faces.

3.Raise transfer box on jack and align to guide

studs LRT-41-009.

4.Clean transfer box to gearbox bolt threads.

5.Apply Loctite 290 to bolt and stud threads.

6.Fit and lightly tighten 2 bolts and nut securing

transfer box to gearbox. If new stud is to be

fitted apply Loctite 290 to threads of stud

and tighten to 45 Nm (33 lbf.ft)

7.Remove guide studs, fit and lightly tighten 3

bolts.

8.Tighten bolts and nut by diagonal selection to

45 Nm (33 lbf.ft.

9.Position gearbox RH mounting and tighten

bolts to 85 Nm (63 lbf.ft).

10.Tighten gearbox RH mounting nut to 48 Nm

(35 lbf.ft).

11.Fit nut to LH mounting and tighten to 48 Nm (35

lbf.ft).

12.Remove 4 bolts securing support plate to

gearbox jack.

13.Remove 4 bolts securing support plate LRT-99-

010 to transfer box and remove plate.

14.Clean threads of bottom plate bolts.

15.Apply Loctite 290 to threads of bolts.

16.Fit 4 bolts securing bottom plate and tighten to

25 Nm (18 lbf.ft).

17.Using new washers position breather pipe and

tighten banjo bolt.

18.Connect multiplug to transfer box neutral switch

and secure harness. 19. If fitted - Connect Lucars to differential lock

switch.

20.Connect multiplug and Lucars to reverse lamp

switch and oil temperature sensor.

21.Position high/low ratio selector cable and

secure with 'C' washer and clevis pin.

22.Secure cable to fuel pipes with new cable ties.

23.Clean handbrake back plate and mating face.

24.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

25.Clean handbrake drum.

26.Fit handbrake drum and tighten retaining

screw.

27.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

28.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

29.Clean exhaust silencer and tail pipe mating

faces.

30.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

31.Position rear cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

32.Refill transfer box with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

33.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

Page 767 of 1672

TRANSFER BOX - LT230SE

41-34 REPAIRS

Seal - rear output shaft

$% 41.20.54

Remove

1.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

2.Loosen brake shoe adjuster bolt.

3.Remove screw securing handbrake drum. 4.Remove handbrake drum.

5.Restrain transfer box drive flange using tool

LRT-51-003. Remove and discard drive flange

nut, remove and discard steel and felt washers.

6.Using tool LRT-99-500 if necessary, remove

drive flange from transfer box.

7.Remove seal from transfer box.

Refit

1.Clean seal mating faces.

2.Lubricate seal with gearbox oil.

Page 768 of 1672

TRANSFER BOX - LT230SE

REPAIRS 41-35

3.Fit new seal using tool LRT-41-012.

4.Position drive flange, fit new felt and steel

washers.

5.Position tool LRT-51-003 and tighten new

drive flange nut to 148 Nm (109 lbf.ft).

6.Position handbrake drum and tighten screw.

7.Tighten brake shoe adjuster bolt to 25 Nm (18

lbf.ft) then loosen one and a half turns.

8.Check that brake drum is free to rotate.

9.Fit propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

10.Top-up transfer box oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Gasket - rear output shaft housing

$% 41.20.55

Remove

1.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

2.Remove rear output shaft seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Seal - rear output shaft.

3.Mark output shaft housing to main casing for

assembly purposes.

4.Note position of shoulder bolt, remove 6 bolts

securing housing to main casing.

Refit

1.Clean output shaft housing, mating face on

main casing and sealant from bolt threads.

2.Apply sealant, Part No. STC 3254 to mating

flange on output shaft housing.

3.Fit output shaft housing to main casing.

4.Apply Loctite 290 to bolt threads.

5.Fit output shaft housing bolts and tighten by

diagonal selection to 45 Nm (33 lbf.ft).

6.Fit rear output shaft seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Seal - rear output shaft.

7.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

Page 783 of 1672

TRANSFER BOX - LT230SE

41-50 OVERHAUL

2.Secure rear half of differential carrier in a soft

jawed vice.

3.Fit each planet gear to its respective cross

shaft, fit new dished thrust washer to each

gear.

4.Fit cross shafts, planet gears and dished thrust

washers in rear half of carrier.Ensure that

cross shafts are fitted correctly. Do not fit

the sun gear into the rear half carrier at this

stage.

5.Fit retaining ring.

6.Fit a 1.05 mm (0.04 in) thrust washer to sun

gear from front half of carrier. Position gear in

front half of carrier.

7.Ensuring that assembly marks are aligned, fit

both halves of carrier together.

8.Fit the differential carrier bolts and, working in a

diagonal sequence, tighten the bolts to 60 Nm,

(44 lbf.ft).9.Insert the front output shaft into the front half of

the carrier and check that the gears rotate

freely.

10.Fit output flange on to the splines of the output

shaft, but do not fit flange nut at this stage.

11.Fit transmission brake drum to output flange

and secure the drum using 2 nuts.

12.Secure a length of cord around the drum and

attach one end of the cord to a spring balance.

13.Pull on the spring balance and note the load at

which the brake drum starts to turn. Used

gears should rotate smoothly, while new

gears will have a 'notchy' feel as they rotate.

14.Compare the figure obtained with the following.

lUsed gears = 0.45 kg (1.0 lb)

lNew gears = 1.72 kg (3.8 lb)

15.If the load to turn figure is below the specified

limits, proceed as follows.

16.Remove the front output shaft and brake drum.

17.Remove the 8 bolts securing the two halves of

the differential carrier

18.Separate the differential carrier and remove the

sun gear and thrust washer from the front half.

19.Select a thicker thrust washer from the range

available. 5 different thrust washers are

available, rising in increments of 0.10 mm

(0.004 in) from 1.05 mm to 1.45 mm (0.04 to

0.06 in).

20.Repeat steps 7 to 19 as necessary until the

load to turn figure is as specified

21.When specified load to turn is obtained,

proceed as follows.

22.Remove the front output shaft and brake drum.

23.Remove the 8 bolts securing the two halves of

the differential carrier

24.Separate the differential carrier and remove the

sun gear and thrust washer from the front

half.Retain the selected thrust washer with

its sun gear.

Page 784 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-51

25.Remove retaining ring, then remove the planet

gears and cross shafts.

26.Fit a 1.05 mm (0.04 in) thrust washer to sun

gear from rear half of carrier. Position gear in

rear half of carrier.

27.Fit planet gears, cross shafts and dished thrust

washers to rear half of carrier. Ensure that

cross shafts are fitted correctly. Do not fit

the sun gear into the rear half carrier at this

stage.

28.Fit retaining ring.

29.Ensuring that assembly marks are aligned, fit

both halves of carrier together.

30.Fit the differential carrier bolts and, working in a

diagonal sequence, tighten the bolts to 60 Nm,

(44 lbf.ft).31.Invert the assembly in the vice, insert the rear

output shaft into the rear half of the carrier and

check that the gears rotate freely.

32.Fit output flange on to the splines of the output

shaft, but do not fit flange nut at this stage.

33.Fit transmission brake drum to output flange

and secure the drum using 2 nuts.

34.Carry out the load to turn check, using the same

method as for the front half carrier. Record the

shim thickness when the load to turn is correct.

35.Fit the sun gear and selected thickness shim to

the front half carrier.

36.Ensuring that assembly marks are aligned, fit

both halves of carrier together.

37.Fit the differential carrier bolts and, working in a

diagonal sequence, tighten the bolts to 60 Nm,

(44 lbf.ft).

38.With differential assembled, fit rear output shaft

and brake drum, then check overall load to turn.

This should be approximately the same as the

combined load to turn figure of both front and

rear half carriers.

lUsed gears = 0.90 kg (2.0 lb)

lNew gears = 3.44 kg (7.6 lb)

Page 802 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-5

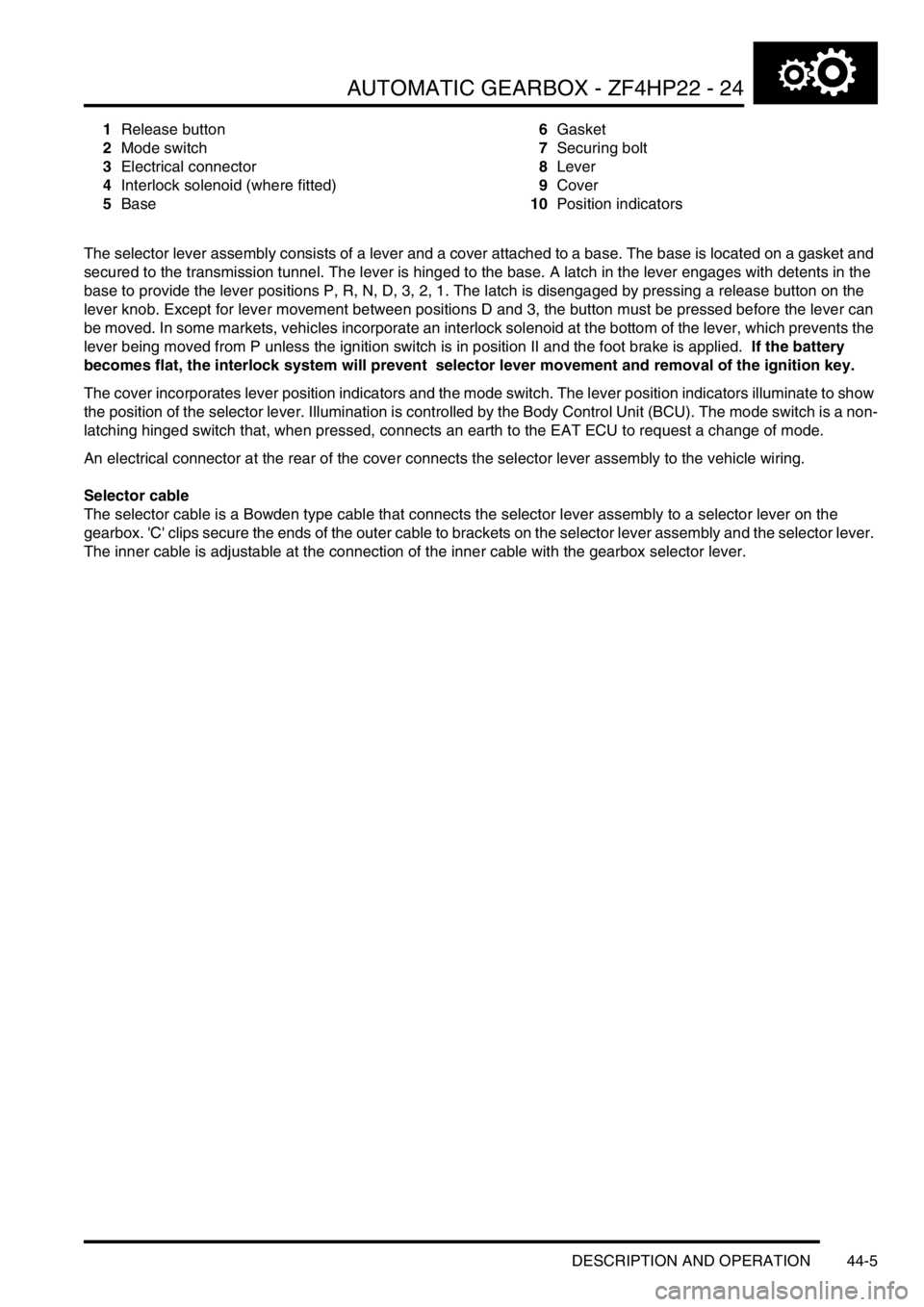

1Release button

2Mode switch

3Electrical connector

4Interlock solenoid (where fitted)

5Base6Gasket

7Securing bolt

8Lever

9Cover

10Position indicators

The selector lever assembly consists of a lever and a cover attached to a base. The base is located on a gasket and

secured to the transmission tunnel. The lever is hinged to the base. A latch in the lever engages with detents in the

base to provide the lever positions P, R, N, D, 3, 2, 1. The latch is disengaged by pressing a release button on the

lever knob. Except for lever movement between positions D and 3, the button must be pressed before the lever can

be moved. In some markets, vehicles incorporate an interlock solenoid at the bottom of the lever, which prevents the

lever being moved from P unless the ignition switch is in position II and the foot brake is applied. If the battery

becomes flat, the interlock system will prevent selector lever movement and removal of the ignition key.

The cover incorporates lever position indicators and the mode switch. The lever position indicators illuminate to show

the position of the selector lever. Illumination is controlled by the Body Control Unit (BCU). The mode switch is a non-

latching hinged switch that, when pressed, connects an earth to the EAT ECU to request a change of mode.

An electrical connector at the rear of the cover connects the selector lever assembly to the vehicle wiring.

Selector cable

The selector cable is a Bowden type cable that connects the selector lever assembly to a selector lever on the

gearbox. 'C' clips secure the ends of the outer cable to brackets on the selector lever assembly and the selector lever.

The inner cable is adjustable at the connection of the inner cable with the gearbox selector lever.