brake LAND ROVER DISCOVERY 2002 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 670 of 1672

CLUTCH - V8

DESCRIPTION AND OPERATION 33-2-3

1Brake/clutch reservoir

2Connecting hose

3Bolt 2 off

4Master cylinder

5Clutch pedal

6Gearbox housing

7Primary driveshaft

8Bolt 2 off

9Slave cylinder

10Bleed nipple

11Pressure plate

12Drive plate

13Flywheel

14Metal hydraulic pipes

15Ball spigot

16Clutch release bearing sleeve

17Bolt 2 off

18Pivot washer

19Release lever

20Release bearing

21Retaining clip

22Bolt

23Bolt

Page 672 of 1672

CLUTCH - V8

DESCRIPTION AND OPERATION 33-2-5

1Brake/clutch reservoir

2Fluid supply pipe

3Hydraulic feed pipe

4Master cylinder

5Piston

6Clutch pedal

7Primary driveshaft

8Engine crankshaft

9Drive plate

10Flywheel

11Ring gear

12Cover - Pressure plate

13Leaf spring

14Retractor clip

15Diaphragm

16Release bearing

17Ball spigot

18Release bearing sleeve

19Release lever

20Slave cylinder

21Piston

22Bleed nipple

Page 673 of 1672

CLUTCH - V8

33-2-6 DESCRIPTION AND OPERATION

Description

General

The clutch system is a conventional diaphragm type clutch operated by a hydraulic cylinder. The clutch requires no

adjustment to compensate for wear.

Hydraulic clutch

The hydraulic clutch comprises a master cylinder, slave cylinder and a hydraulic reservoir, which is also shared with

the braking system. The master and slave cylinders are connected to each other hydraulically by plastic and metal

pipes. The plastic section of the pipe allows ease of pipe routing and also absorbs engine movements and vibrations.

The master cylinder comprises a body with a central bore. Two ports in the body connect the bore to the hydraulic

feed pipe to the slave cylinder and the brake/clutch fluid reservoir. A piston is fitted in the bore and has an external

rod which is attached to the clutch pedal with a pin. Two coiled springs on the clutch pedal reduce the effort required

to depress the pedal.

The master cylinder is mounted on the bulkhead in the engine compartment and secured with two bolts. The cylinder

is connected to the shared brake/clutch reservoir on the brake servo by a braided connecting hose.

The slave cylinder is located on the left hand side of the gearbox housing and secured with two bolts. A heat shield

protects the underside of the cylinder from heat generated from the exhaust system. The slave cylinder comprises a

cylinder with a piston and a rod. A port in the cylinder body provides the attachment for the hydraulic feed pipe from

the master cylinder. A second port is fitted with a bleed nipple for removing air from the hydraulic system after

servicing. The piston rod locates on a clutch release lever located in the gearbox housing. The rod is positively

retained on the release lever with a clip.

Clutch mechanism

The clutch mechanism comprises a flywheel, drive plate, pressure plate, release lever and a release bearing. The

clutch mechanism is fully enclosed at the rear of the engine by the gearbox housing.

A clutch release bearing sleeve is attached in the gearbox housing with two bolts and located on two dowels. A spigot

with a ball end is formed on the release bearing sleeve and provides a mounting and pivot point for the clutch release

lever. A dished pivot washer is located on the ball of the spigot. When the release lever is located on the ball, the pivot

washer seats against the rear face of the release lever. A spring clip is located on the lever and the pivot washer and

secures the lever on the spigot. A small bolt retains the spring clip in position.

The release lever is forked at its inner end and locates on the clutch release bearing carrier. The outer end of the

release lever has a nylon seat which locates the slave cylinder piston rod. A second nylon seat, positioned centrally

on the release lever, locates on the ball spigot of the release bearing sleeve and allows the release lever to pivot freely

around the ball.

The clutch release bearing locates on the clutch release lever and the release bearing sleeve. The bearing is retained

on a carrier which has two flats to prevent the carrier rotating on the release lever. A clip retains the release lever on

the carrier. The bearing and carrier are not serviceable individually.

Page 678 of 1672

CLUTCH - V8

ADJUSTMENTS 33-2-11

ADJUST ME NTS

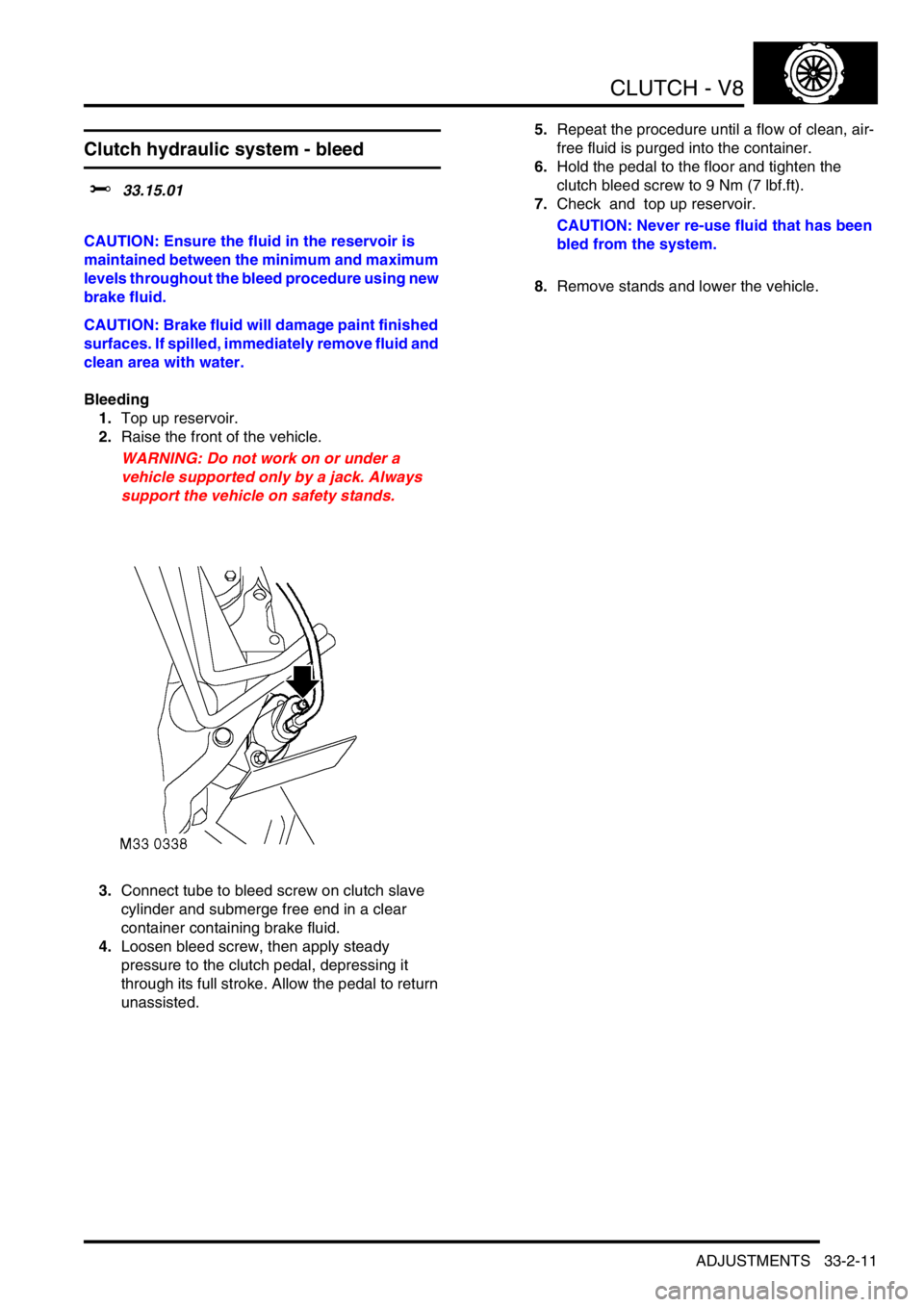

Clutch hydraulic system - bleed

$% 33.15.01

CAUTION: Ensure the fluid in the reservoir is

maintained between the minimum and maximum

levels throughout the bleed procedure using new

brake fluid.

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

Bleeding

1.Top up reservoir.

2.Raise the front of the vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Connect tube to bleed screw on clutch slave

cylinder and submerge free end in a clear

container containing brake fluid.

4.Loosen bleed screw, then apply steady

pressure to the clutch pedal, depressing it

through its full stroke. Allow the pedal to return

unassisted.5.Repeat the procedure until a flow of clean, air-

free fluid is purged into the container.

6.Hold the pedal to the floor and tighten the

clutch bleed screw to 9 Nm (7 lbf.ft).

7.Check and top up reservoir.

CAUTION: Never re-use fluid that has been

bled from the system.

8.Remove stands and lower the vehicle.

Page 681 of 1672

CLUTCH - V8

33-2-14 REPAIRS

Master cylinder

$% 33.20.01

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Release spring clip securing clutch pedal

clevis pin and remove pin from push rod and

clutch pedal.

3.Position container to catch spillage. Disconnect

hydraulic pipe from clutch master cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.4.Release clip and remove connecting hose from

clutch master cylinder.

5.Remove 2 bolts securing clutch master

cylinder to pedal box and remove clutch master

cylinder.

Refit

1.Clean master cylinder and pedal box mating

faces.

2.Position clutch master cylinder to pedal box, fit

bolts and tighten to 25 Nm (18 lbf.ft).

3.Position clevis pin to push-rod and clutch pedal

and secure with spring clip.

4.Fit connecting hose to brake master cylinder

and tighten clip.

5.Position hydraulic pipe and tighten union to 18

Nm (13 lbf.ft).

6.Bleed clutch.

+ CLUTCH - V8, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 696 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-13

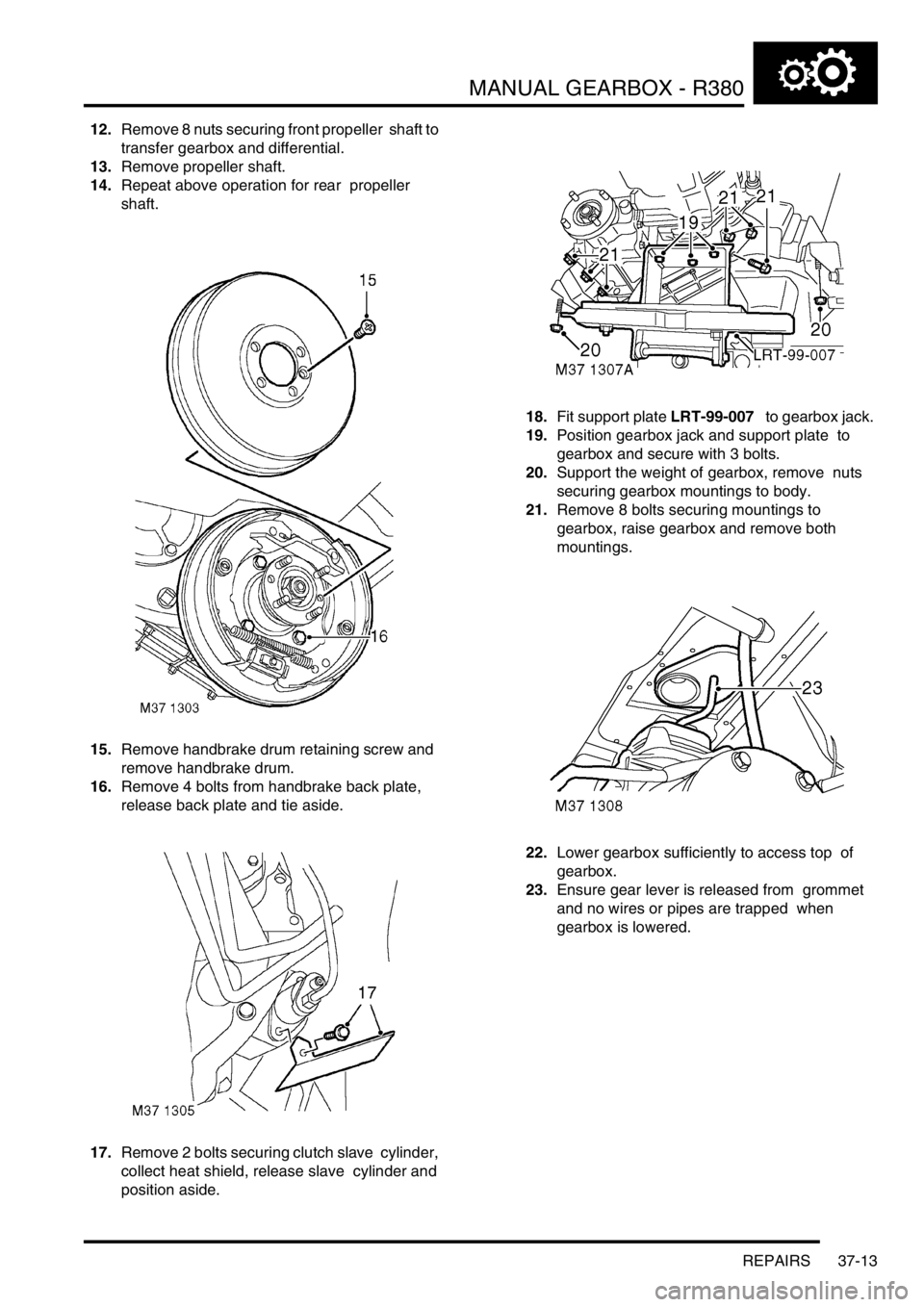

12.Remove 8 nuts securing front propeller shaft to

transfer gearbox and differential.

13.Remove propeller shaft.

14.Repeat above operation for rear propeller

shaft.

15.Remove handbrake drum retaining screw and

remove handbrake drum.

16.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

17.Remove 2 bolts securing clutch slave cylinder,

collect heat shield, release slave cylinder and

position aside. 18.Fit support plate LRT-99-007 to gearbox jack.

19.Position gearbox jack and support plate to

gearbox and secure with 3 bolts.

20.Support the weight of gearbox, remove nuts

securing gearbox mountings to body.

21.Remove 8 bolts securing mountings to

gearbox, raise gearbox and remove both

mountings.

22.Lower gearbox sufficiently to access top of

gearbox.

23.Ensure gear lever is released from grommet

and no wires or pipes are trapped when

gearbox is lowered.

Page 698 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-15

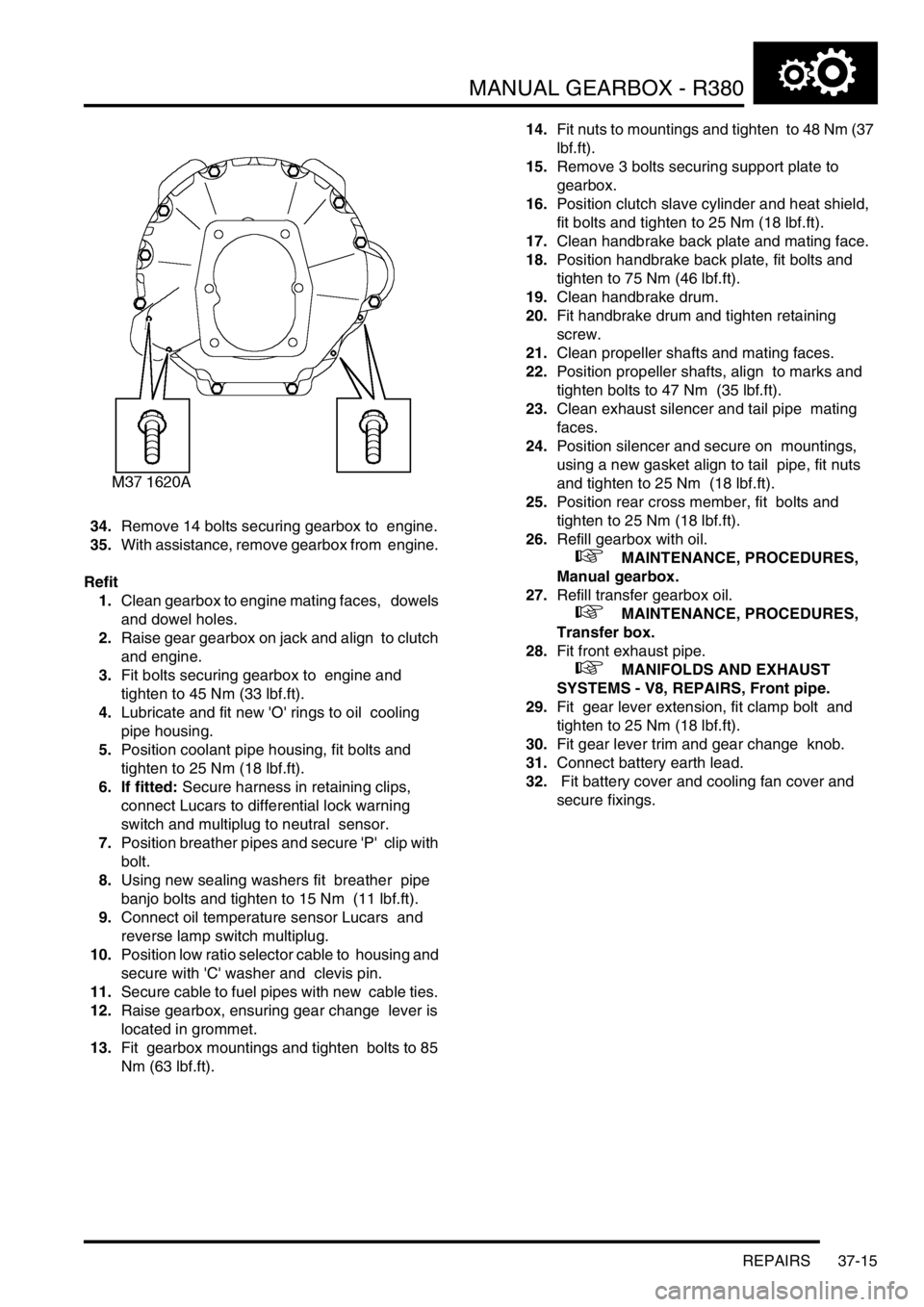

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft). 14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 700 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-17

14.Remove handbrake drum retaining screw and

remove handbrake drum.

15.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

16.Remove 2 bolts securing clutch slave cylinder,

collect heat shield, release slave cylinder and

position aside.

17.Fit support plate LRT-99-007 to gearbox jack.

18.Position gearbox jack and support plate to

gearbox and secure with 3 bolts. 19.Support the weight of gearbox, remove nuts

securing gearbox mountings to body.

20.Remove 4 bolts securing both mountings to

gearbox, raise gearbox and remove both

mountings.

21.Lower gearbox sufficiently to access top of

gearbox.

22.Ensure gear lever is released from grommet

and no wires or pipes are trapped when

gearbox is lowered.

Page 702 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-19

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties. 13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox.

17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.

Page 748 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-15

High/low detect switch

A high/low detect switch is fitted in the front output housing and connects to earth when low is selected. The switch is

connected to the engine ECM, the SLABS ECU and the EAT ECU. The purpose of the switch is to enable selection

of the hill descent feature and to modify the engine fuelling and automatic gearbox gearshift maps stored within the

respective ECM's and ECU's.

Differential lock - Fitted to certain vehicles only

The differential lock selector housing is bolted to the top of the front output housing, the selector finger passes through

the housing, locating in a slot in the differential lock selector shaft. The differential lock selector shaft passes through

the selector fork which is located beneath a plate bolted to the side of the output housing. The selector fork engages

the dog clutch sleeve with the differential rear shaft when the splines of the sleeve and differential rear shaft are

aligned. A spring loaded detent ball fitted in the output housing locates in grooves in the shaft.

Functionality – Vehicles up to 03 model year only

The function of the differential lock used in previous applications is performed on this vehicle by the Electronic Traction

Control System. However, for the purposes of 2 wheel rolling road testing , the differential lock components are

retained. For all driving conditions however, the differential lock must be set in the unlocked position.

Up to 03 model year specification shown

The differential lock must only be engaged for 2 wheel rolling road testing as engagement of the lock disables the

traction control feature and inhibits correct operation of the electronic brake distribution and hill descent features. It

will also be necessary to disconnect the propeller shaft from the transfer box output shaft driving the axle whose

wheels are NOT on the rolling road. The lock may be engaged/disengaged by using a 10 mm open ended spanner

on the flats (arrowed) machined on the differential lock selector shaft.

Vehicles not fitted with a differential lock may be identified by there being no cover or selector shaft (arrowed) on the

front output housing.

WARNING: VEHICLES NOT FITTED WITH A DIFFERENTIAL LOCK MUST NOT BE TESTED ON A ROLLING

ROAD WHERE THE ROLLERS ARE DRIVEN BY THE VEHICLE.