warning LAND ROVER DISCOVERY 2002 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 678 of 1672

CLUTCH - V8

ADJUSTMENTS 33-2-11

ADJUST ME NTS

Clutch hydraulic system - bleed

$% 33.15.01

CAUTION: Ensure the fluid in the reservoir is

maintained between the minimum and maximum

levels throughout the bleed procedure using new

brake fluid.

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

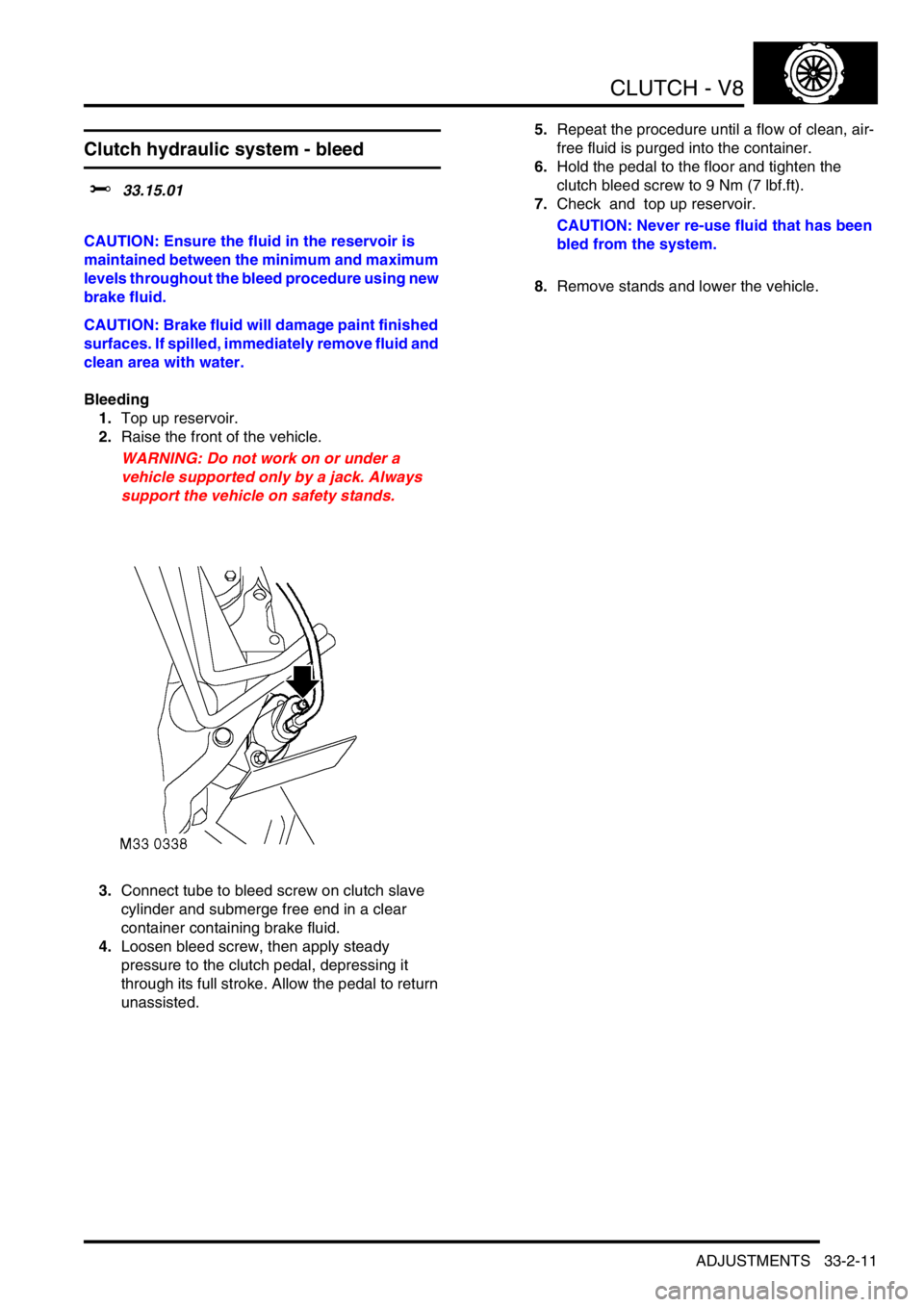

Bleeding

1.Top up reservoir.

2.Raise the front of the vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Connect tube to bleed screw on clutch slave

cylinder and submerge free end in a clear

container containing brake fluid.

4.Loosen bleed screw, then apply steady

pressure to the clutch pedal, depressing it

through its full stroke. Allow the pedal to return

unassisted.5.Repeat the procedure until a flow of clean, air-

free fluid is purged into the container.

6.Hold the pedal to the floor and tighten the

clutch bleed screw to 9 Nm (7 lbf.ft).

7.Check and top up reservoir.

CAUTION: Never re-use fluid that has been

bled from the system.

8.Remove stands and lower the vehicle.

Page 681 of 1672

CLUTCH - V8

33-2-14 REPAIRS

Master cylinder

$% 33.20.01

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Release spring clip securing clutch pedal

clevis pin and remove pin from push rod and

clutch pedal.

3.Position container to catch spillage. Disconnect

hydraulic pipe from clutch master cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.4.Release clip and remove connecting hose from

clutch master cylinder.

5.Remove 2 bolts securing clutch master

cylinder to pedal box and remove clutch master

cylinder.

Refit

1.Clean master cylinder and pedal box mating

faces.

2.Position clutch master cylinder to pedal box, fit

bolts and tighten to 25 Nm (18 lbf.ft).

3.Position clevis pin to push-rod and clutch pedal

and secure with spring clip.

4.Fit connecting hose to brake master cylinder

and tighten clip.

5.Position hydraulic pipe and tighten union to 18

Nm (13 lbf.ft).

6.Bleed clutch.

+ CLUTCH - V8, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 682 of 1672

CLUTCH - V8

REPAIRS 33-2-15

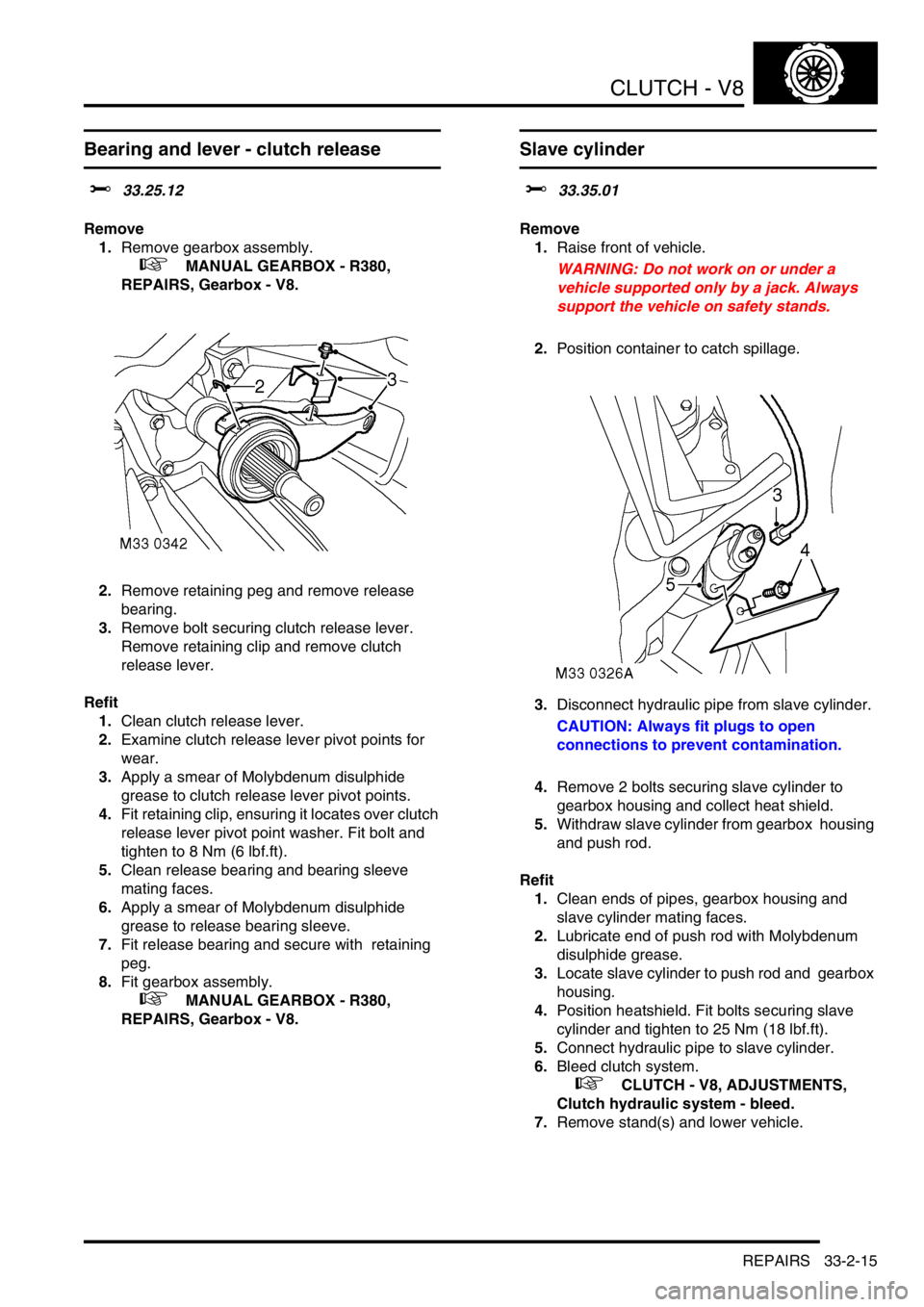

Bearing and lever - clutch release

$% 33.25.12

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release lever.

Remove retaining clip and remove clutch

release lever.

Refit

1.Clean clutch release lever.

2.Examine clutch release lever pivot points for

wear.

3.Apply a smear of Molybdenum disulphide

grease to clutch release lever pivot points.

4.Fit retaining clip, ensuring it locates over clutch

release lever pivot point washer. Fit bolt and

tighten to 8 Nm (6 lbf.ft).

5.Clean release bearing and bearing sleeve

mating faces.

6.Apply a smear of Molybdenum disulphide

grease to release bearing sleeve.

7.Fit release bearing and secure with retaining

peg.

8.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Slave cylinder

$% 33.35.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Position container to catch spillage.

3.Disconnect hydraulic pipe from slave cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove 2 bolts securing slave cylinder to

gearbox housing and collect heat shield.

5.Withdraw slave cylinder from gearbox housing

and push rod.

Refit

1.Clean ends of pipes, gearbox housing and

slave cylinder mating faces.

2.Lubricate end of push rod with Molybdenum

disulphide grease.

3.Locate slave cylinder to push rod and gearbox

housing.

4.Position heatshield. Fit bolts securing slave

cylinder and tighten to 25 Nm (18 lbf.ft).

5.Connect hydraulic pipe to slave cylinder.

6.Bleed clutch system.

+ CLUTCH - V8, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 698 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-15

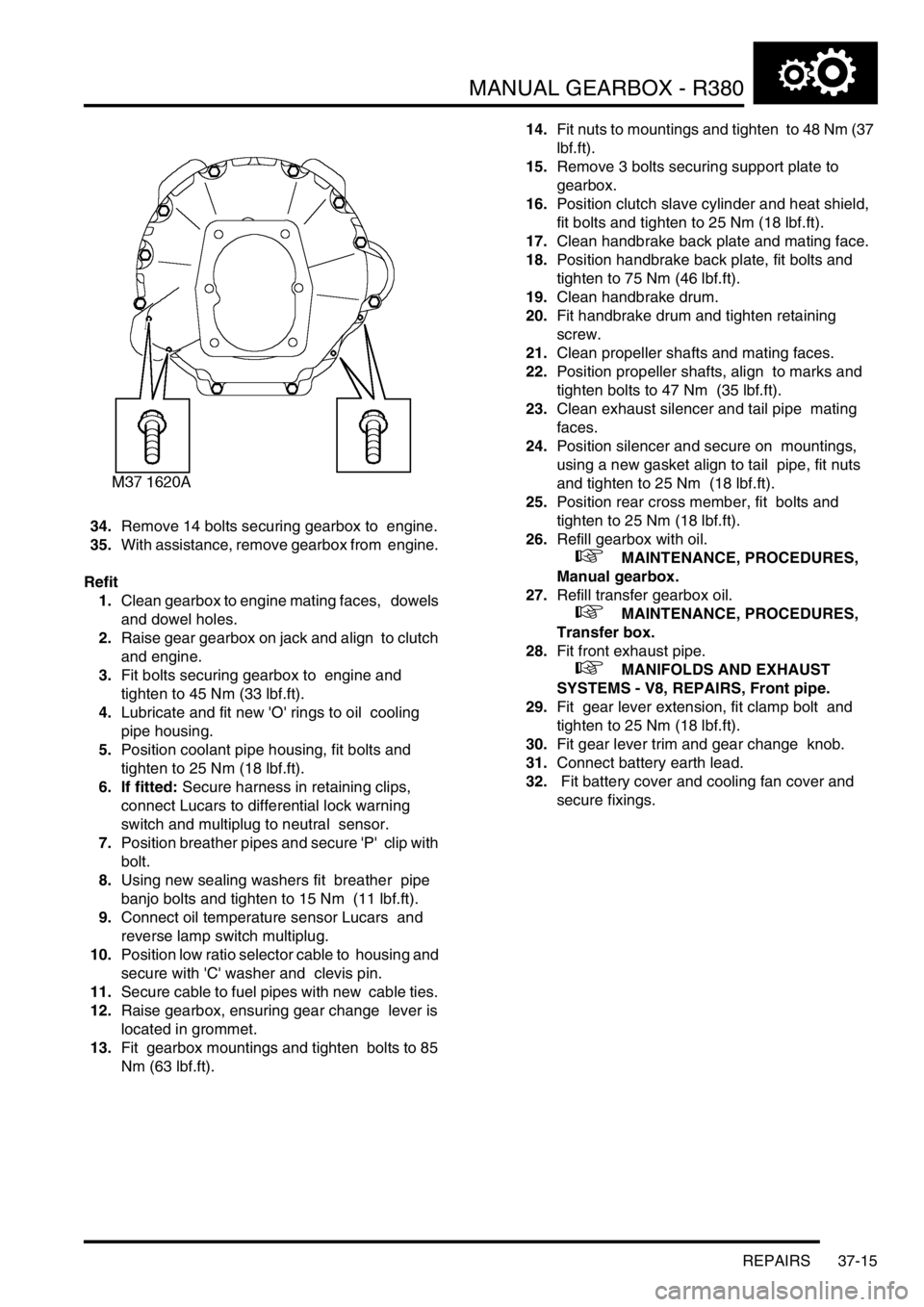

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft). 14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 702 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-19

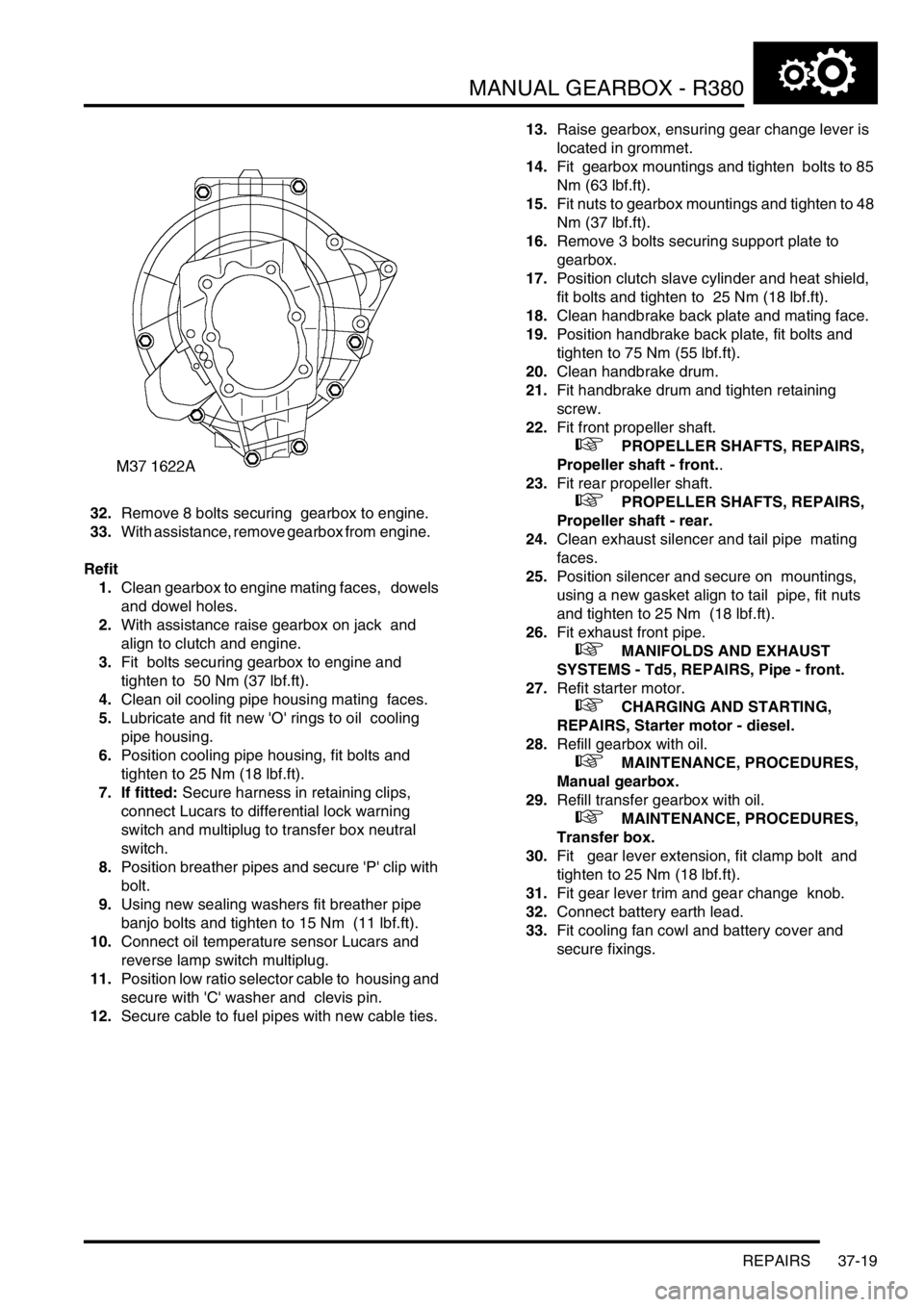

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties. 13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox.

17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.

Page 737 of 1672

TRANSFER BOX - LT230SE

41-4 DESCRIPTION AND OPERATION

Main casing components – Vehicles up

to 03 model year

1Retaining plate

2Stake nut - intermediate shaft

3Bolt - retaining plate

4'O' rings - intermediate shaft

5Bearings and outer tracks - mainshaft input

gear

6Mainshaft input gear bearing housing

7Cover plate

8Bolt - cover plate

9Selective shim

10Mainshaft input gear

11Oil filler/level plug

12Oil temperature switch - if fitted

13Bearings and outer tracks - intermediate gears

14Circlips

15Intermediate gears

16Bottom cover plate

17Bolt - bottom cover plate

18Selective spacer

19Mainshaft oil seal20Oil drain plug

21Main casing

22Intermediate shaft

23Locating dowel

24Detent ball - high/low selector

25Detent spring - high/low selector

26Detent plug - high/low selector

27Neutral warning switch - Automatic gearbox

only - North America and Japan

28Bolt - interlock solenoid cover - Automatic

gearbox only - North America and Japan

29Cover - interlock solenoid - Automatic gearbox

only - North America and Japan

30Belleville washer - Automatic gearbox only -

North America and Japan

31Interlock solenoid - Automatic gearbox only -

North America and Japan

Page 738 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-5

Main casing components – Vehicles

from 03 model year

1Retaining plate

2Stake nut - intermediate shaft

3Bolt - retaining plate

4'O' rings - intermediate shaft

5Bearings and outer tracks - mainshaft input

gear

6Mainshaft input gear bearing housing

7Cover plate

8Bolt - cover plate

9Selective shim

10Mainshaft input gear

11Oil filler/level plug

12Oil temperature switch - if fitted

13Bearings and outer tracks - intermediate gears14Intermediate gears

15Bottom cover plate

16Bolt - bottom cover plate

17Selective spacer

18Mainshaft oil seal

19Oil drain plug

20Main casing

21Intermediate shaft

22Locating dowel

23Detent ball - high/low selector

24Detent spring - high/low selector

25Detent plug - high/low selector

26Neutral warning switch - Automatic gearbox

only - North America and Japan

Page 742 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-9

1Breather pipe, banjo bolt and sealing washers

2Bolt - high/low cross shaft housing and

abutment bracket

3Selector cable abutment bracket

4Multiplug bracket

5Hollow plug

6High/low cross shaft housing

7'O' ring

8High/low cross shaft and lever

9Front output shaft - Differential lock - If fitted

10Dog clutch - Differential lock - If fitted

11Warning lamp switch - Differential lock - If fitted

12Detent plug - Differential lock - If fitted

13Detent spring - Differential lock - If fitted

14Selector shaft - Differential lock - If fitted

15Detent ball - Differential lock - If fitted

16Threaded spacer - Differential lock - If fitted

17Front output housing

18Spring and clips - Differential lock - If fitted

19Bolt - cover plate

20Cover plate21Selector fork - Differential lock - If fitted

22Bolt - front output housing

23Hollow plug

24Circlip

25Front output flange

26Steel washer

27Self-locking nut

28Felt washer

29Oil seal

30Output shaft bearing

31Bearing spacer

32High/low detect switch

33Selector finger and shaft - Differential lock - If

fitted

34'O' rings - Differential lock - If fitted

35Bolt - selector housing - Differential lock - If

fitted

36Selector housing - Differential lock - If fitted

37High/low selector finger

38Front output shaft - Vehicles not fitted with

differential lock

Page 744 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-11

1Breather pipe, banjo bolt and sealing washers

2Bolt - high/low cross shaft housing and

abutment bracket

3Selector cable abutment bracket

4Multiplug bracket

5Hollow plug

6High/low cross shaft housing

7'O' ring

8High/low cross shaft and lever

9Front output shaft - Differential lock - If fitted

10Dog clutch - Differential lock - If fitted

11Warning lamp switch - Differential lock - If fitted

12Detent plug - Differential lock - If fitted

13Detent spring - Differential lock - If fitted

14Selector shaft - Differential lock - If fitted

15Detent ball - Differential lock - If fitted

16Threaded spacer - Differential lock - If fitted

17Front output housing

18Spring and clips - Differential lock - If fitted

19Bolt - cover plate

20Cover plate

21Selector fork - Differential lock - If fitted

22Bolt - front output housing23Aluminium washer

24Warning lamp switch - Differential lock - If fitted

25Circlip

26Front output flange

27Steel washer

28Self-locking nut

29Felt washer

30Oil seal

31Output shaft bearing

32Bearing spacer

33High/low detect switch

34Selector finger and shaft - Differential lock - If

fitted

35'O' rings - Differential lock - If fitted

36Bolt - selector housing - Differential lock - If

fitted

37Selector housing - Differential lock - If fitted

38High/low selector finger

39Front output shaft - Vehicles not fitted with

differential lock

40Washer

41Nut

Page 746 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-13

Description

General

The LT 230SE transfer box is mounted at the rear of the gearbox and transmits drive via high or low reduction ratios

to the front and rear axles via the propeller shafts. The high/low ratios are 1.211:1 and 3.32:1 respectively.

Transfer boxes fitted to this model have the prefixes 41D and 42D to the unit serial number. Prefix 41D denotes that

the unit is not fitted with interlock whilst 42D denotes that interlock is fitted.

Vehicles up to 03 model year – Whilst similar to LT230Q transfer boxes fitted to other models, the LT230SE transfer

box has certain engineering modifications incorporated which are as follows:

lUprated torque capacity

lModified front and rear output and cross shaft housings

lIntermediate gear bearing pre-load now controlled by a selective, non-collapsible spacer

lSpeedometer drive and driven gears not fitted for this application

lModified high/low sleeve

lModified front output flange and mud shield

lDifferential lock fitted to certain vehicles, but no longer driver operated

lFixed setting of differential lock warning lamp switch on vehicles fitted with differential lock

Vehicles from 03 model year – The LT230SE transfer box is as described above for vehicles up to 03 model year

with the following modifications:

The following items are introduced on vehicles from 03 model year

lRibs added to main casing to reduce operating noise

lBearing retaining nut on the differential carrier has patchlock added to the threads

lInterlock solenoid moved from main casing to selector lever assembly

lIntermediate gears modified with machined internal shoulder and bearing circlips deleted

The following items are introduced later in the 03 model year build programme and therefore may not appear on all

03 model year vehicles

lDriver operated differential lock (if fitted)

lHigh/Low selector shaft fitted with spring assist

lExisting differential lock switch replaced by new design switch.

lNew secondary differential lock switch installed in the front output housing

Construction

The transfer box comprises three main assemblies; the main casing, the front output housing and the rear output

housing. Both output housings and all cover plates are sealed to the main casing by sealant; mud and water ingress

being prevented by mud shields located on the output flanges.

Main casing

The main casing carries the mainshaft input gear, the intermediate gears and the differential, together with the high/

low range gears, selector shaft and fork. The front and rear output housings are bolted to either side of the main

casing.

Transmission neutral sensor

A transmission neutral sensor is fitted on automatic gearbox vehicles for North America and Japan. The sensor is

connected to the BCU and is normally in the open position. The sensor provides an earth path for the BCU which then

interprets the signal and activates an audible warning generated by the IDM if neutral is selected on the transfer box

when the ignition is on.