ECU LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 292 of 1007

EMISSION CONTROL

ADJUSTMENTS 17-1-1

EMISS ION CONTROL ADJUST ME NTS

Evaporative loss control system

(EVAPS) - leak test - NAS

$% 17.90.02.01

The following procedure allows a fuel leak, indicated

by the Malfunction Indicator Lamp (MIL), to be

accurately located. It must only be carried out once it

has been established that there are no obvious faults

with any of the system components.

Check

1.Check components in fuel and EVAP system

for obvious damage. Ensure all connections

are properly secured.

2.The system must be checked using a EVAPS

Diagnostic Testing Station LRA-19-004.

3.Disconnect vent pipe from purge valve and

connect adapter LRA-19-004/1.

NOTE: The reason for inserting the adapter into

the purge valve is that there is currently no

service port fitted to Freelander.

4.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

5.Release clip and disconnect hose from

charcoal canister.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

6.Block charcoal canister port with bung,

included in LRA-19-004.

7.Connect LRA-19-004 to service port fitted on

purge valve.

8.Carry out procedures given in the operating

instructions, these are supplied with LRA-19-

004.Adjust

1.If a leak has been detected, replace component

as necessary and repeat leak test to validate

repair.

2.Remove bung from charcoal canister.

3.Connect hose to charcoal canister and secure

with clip.

4.Fit rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

5.Disconnect adaptor LRA-19-004/1 from purge

valve.

6.Connect hose to purge valve.

Page 294 of 1007

EMISSION CONTROL

REPAIRS 17-1-3

REPAIRS

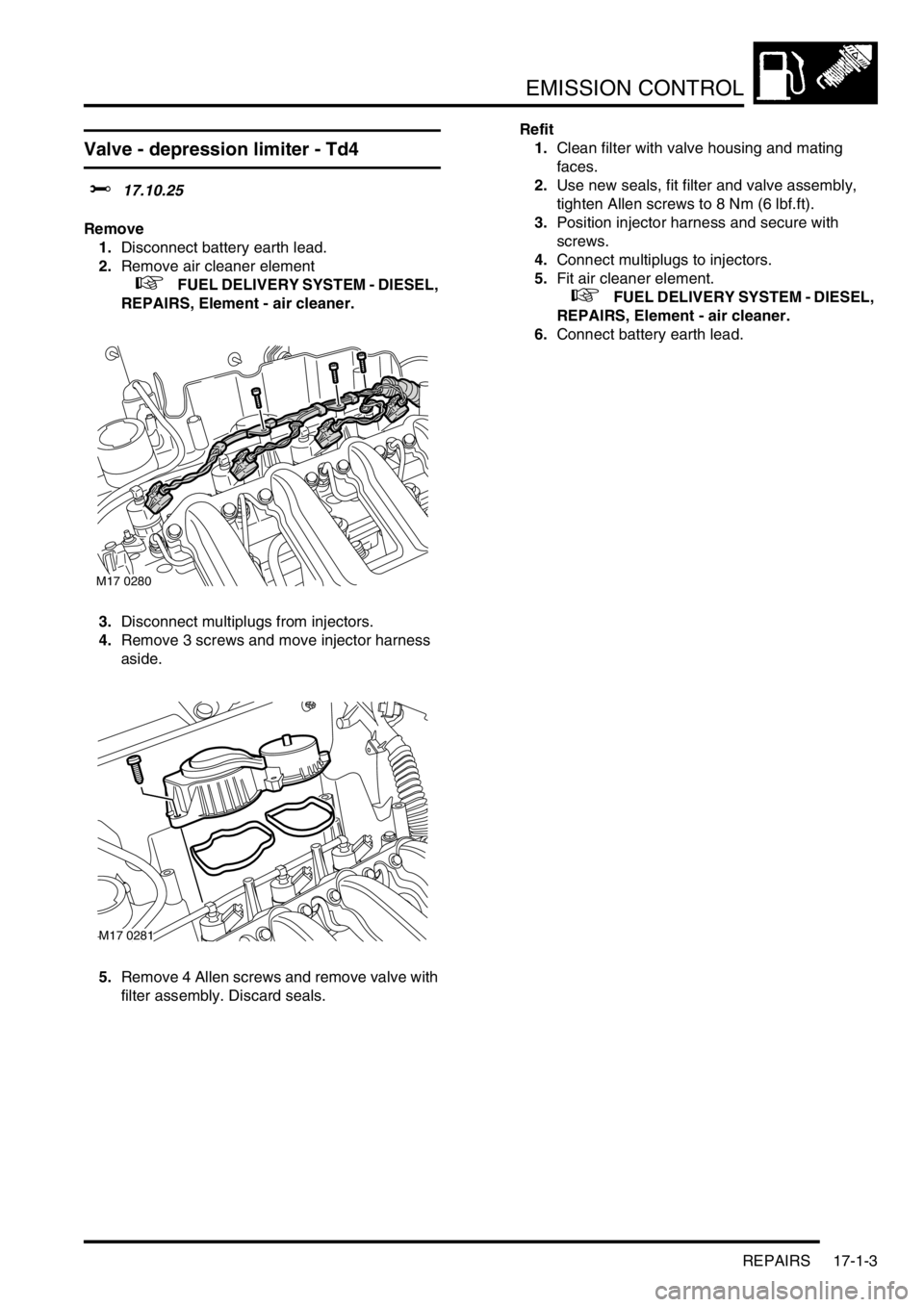

Valve - depression limiter - Td4

$% 17.10.25

Remove

1.Disconnect battery earth lead.

2.Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Disconnect multiplugs from injectors.

4.Remove 3 screws and move injector harness

aside.

5.Remove 4 Allen screws and remove valve with

filter assembly. Discard seals.Refit

1.Clean filter with valve housing and mating

faces.

2.Use new seals, fit filter and valve assembly,

tighten Allen screws to 8 Nm (6 lbf.ft).

3.Position injector harness and secure with

screws.

4.Connect multiplugs to injectors.

5.Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

6.Connect battery earth lead.

M17 0280

M17 0281

Page 295 of 1007

EMISSION CONTROL

17-1-4 REPAIRS

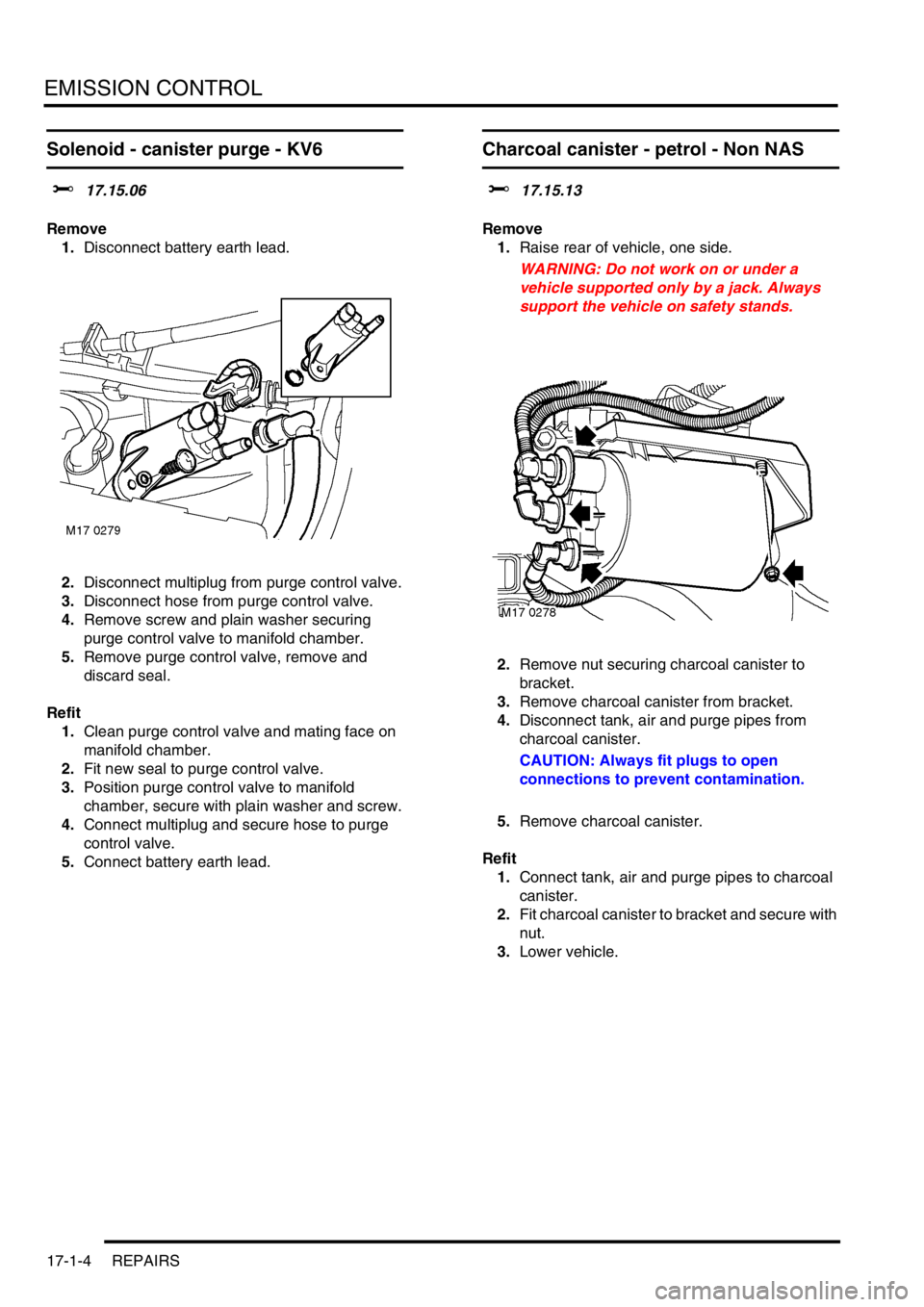

Solenoid - canister purge - KV6

$% 17.15.06

Remove

1.Disconnect battery earth lead.

2.Disconnect multiplug from purge control valve.

3.Disconnect hose from purge control valve.

4.Remove screw and plain washer securing

purge control valve to manifold chamber.

5.Remove purge control valve, remove and

discard seal.

Refit

1.Clean purge control valve and mating face on

manifold chamber.

2.Fit new seal to purge control valve.

3.Position purge control valve to manifold

chamber, secure with plain washer and screw.

4.Connect multiplug and secure hose to purge

control valve.

5.Connect battery earth lead.

Charcoal canister - petrol - Non NAS

$% 17.15.13

Remove

1.Raise rear of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing charcoal canister to

bracket.

3.Remove charcoal canister from bracket.

4.Disconnect tank, air and purge pipes from

charcoal canister.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove charcoal canister.

Refit

1.Connect tank, air and purge pipes to charcoal

canister.

2.Fit charcoal canister to bracket and secure with

nut.

3.Lower vehicle.

Page 296 of 1007

EMISSION CONTROL

REPAIRS 17-1-5

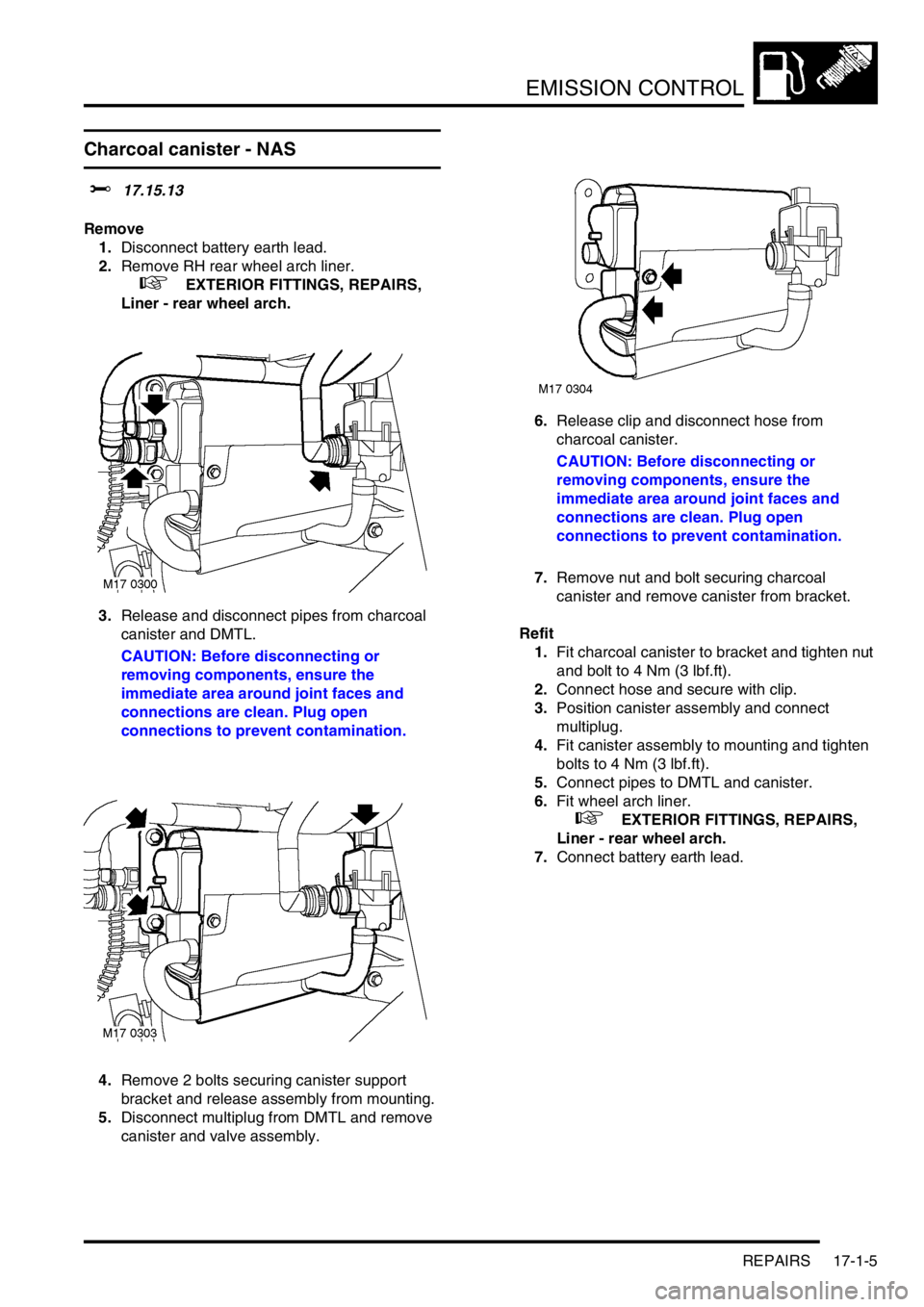

Charcoal canister - NAS

$% 17.15.13

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Release and disconnect pipes from charcoal

canister and DMTL.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

4.Remove 2 bolts securing canister support

bracket and release assembly from mounting.

5.Disconnect multiplug from DMTL and remove

canister and valve assembly.6.Release clip and disconnect hose from

charcoal canister.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

7.Remove nut and bolt securing charcoal

canister and remove canister from bracket.

Refit

1.Fit charcoal canister to bracket and tighten nut

and bolt to 4 Nm (3 lbf.ft).

2.Connect hose and secure with clip.

3.Position canister assembly and connect

multiplug.

4.Fit canister assembly to mounting and tighten

bolts to 4 Nm (3 lbf.ft).

5.Connect pipes to DMTL and canister.

6.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Connect battery earth lead.

Page 297 of 1007

EMISSION CONTROL

17-1-6 REPAIRS

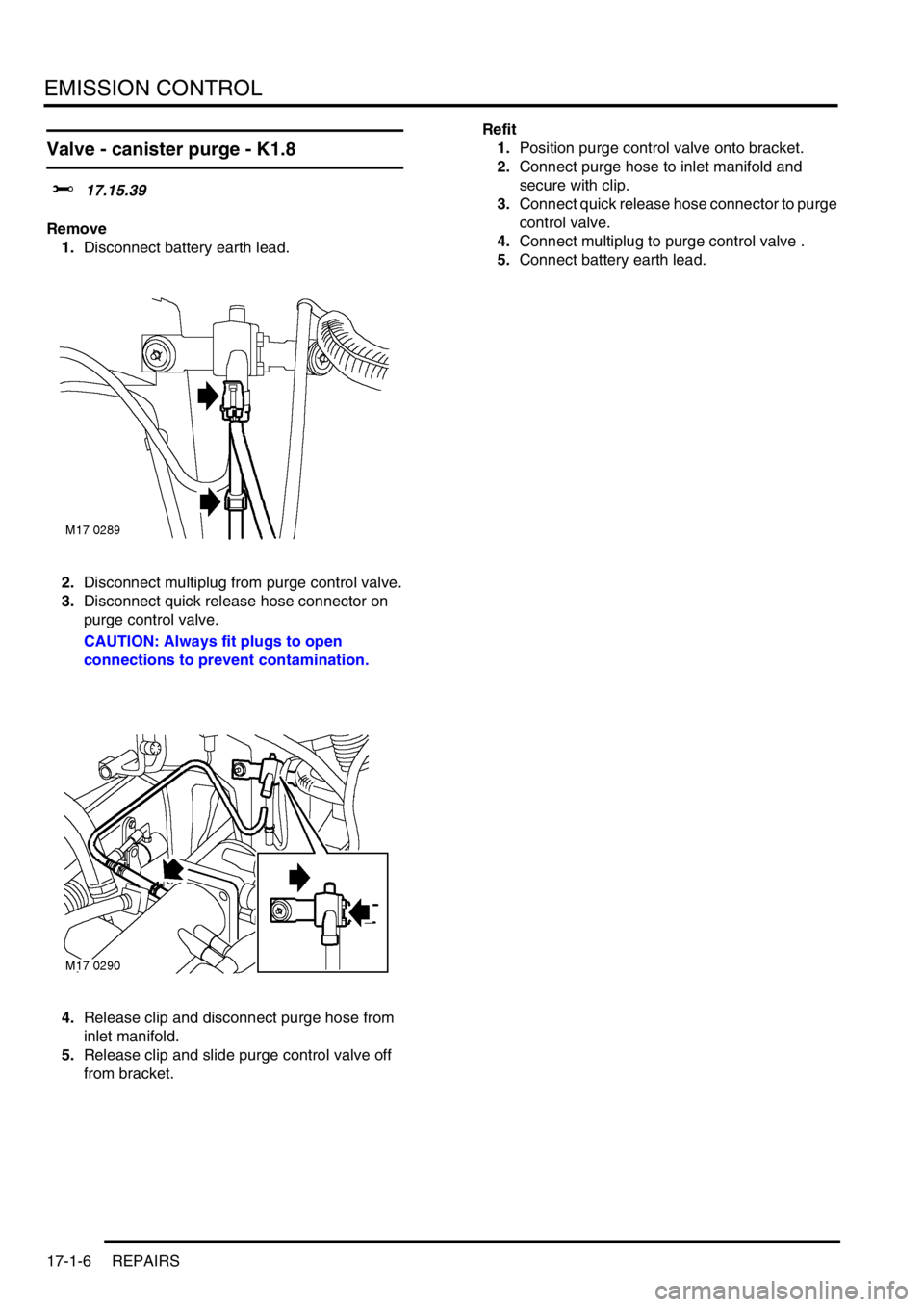

Valve - canister purge - K1.8

$% 17.15.39

Remove

1.Disconnect battery earth lead.

2.Disconnect multiplug from purge control valve.

3.Disconnect quick release hose connector on

purge control valve.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Release clip and disconnect purge hose from

inlet manifold.

5.Release clip and slide purge control valve off

from bracket.Refit

1.Position purge control valve onto bracket.

2.Connect purge hose to inlet manifold and

secure with clip.

3.Connect quick release hose connector to purge

control valve.

4.Connect multiplug to purge control valve .

5.Connect battery earth lead.

Page 299 of 1007

EMISSION CONTROL

17-1-8 REPAIRS

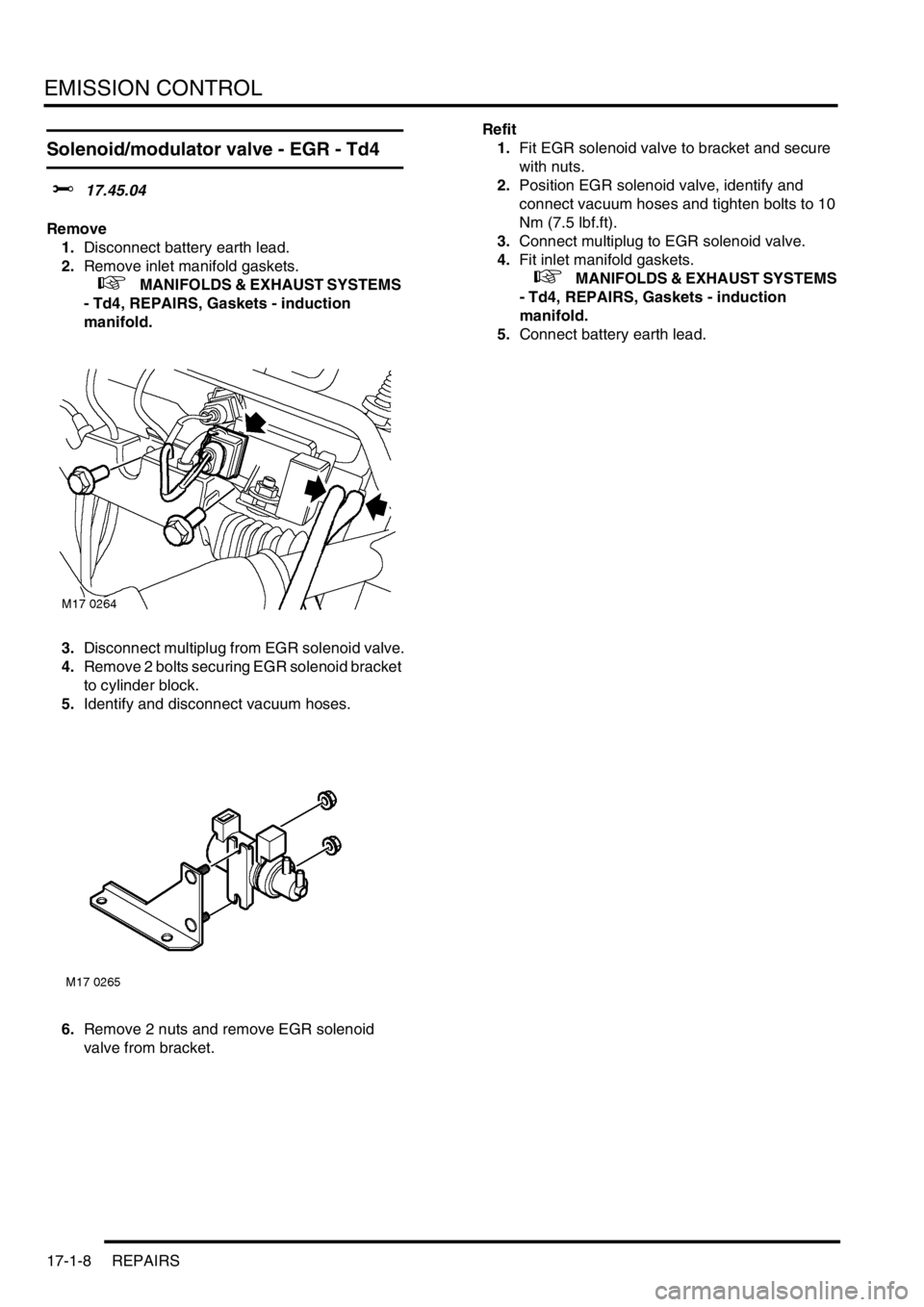

Solenoid/modulator valve - EGR - Td4

$% 17.45.04

Remove

1.Disconnect battery earth lead.

2.Remove inlet manifold gaskets.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Gaskets - induction

manifold.

3.Disconnect multiplug from EGR solenoid valve.

4.Remove 2 bolts securing EGR solenoid bracket

to cylinder block.

5.Identify and disconnect vacuum hoses.

6.Remove 2 nuts and remove EGR solenoid

valve from bracket.Refit

1.Fit EGR solenoid valve to bracket and secure

with nuts.

2.Position EGR solenoid valve, identify and

connect vacuum hoses and tighten bolts to 10

Nm (7.5 lbf.ft).

3.Connect multiplug to EGR solenoid valve.

4.Fit inlet manifold gaskets.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Gaskets - induction

manifold.

5.Connect battery earth lead.

Page 300 of 1007

EMISSION CONTROL

REPAIRS 17-1-9

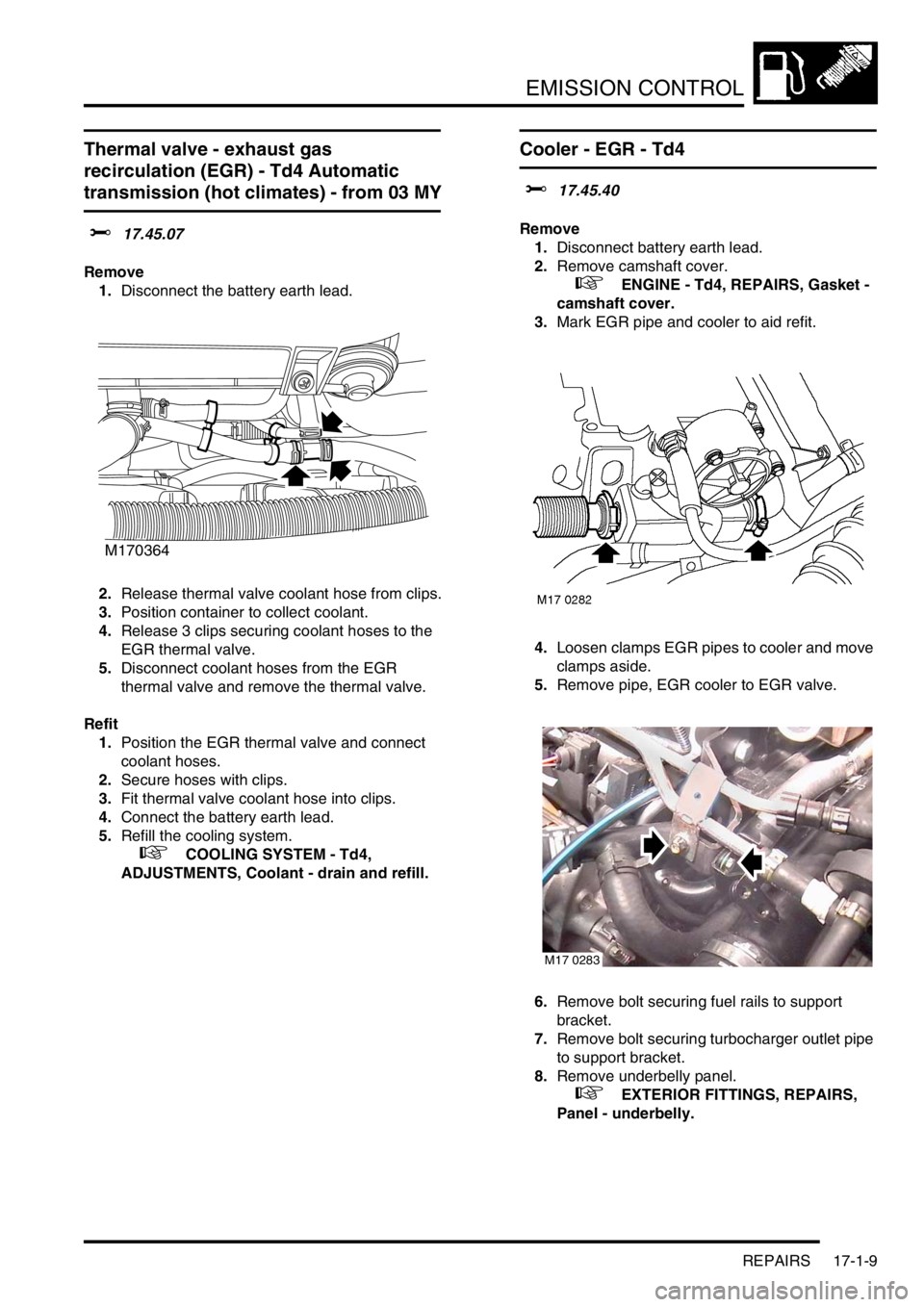

Thermal valve - exhaust gas

recirculation (EGR) - Td4 Automatic

transmission (hot climates) - from 03 MY

$% 17.45.07

Remove

1.Disconnect the battery earth lead.

2.Release thermal valve coolant hose from clips.

3.Position container to collect coolant.

4.Release 3 clips securing coolant hoses to the

EGR thermal valve.

5.Disconnect coolant hoses from the EGR

thermal valve and remove the thermal valve.

Refit

1.Position the EGR thermal valve and connect

coolant hoses.

2.Secure hoses with clips.

3.Fit thermal valve coolant hose into clips.

4.Connect the battery earth lead.

5.Refill the cooling system.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

Cooler - EGR - Td4

$% 17.45.40

Remove

1.Disconnect battery earth lead.

2.Remove camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

3.Mark EGR pipe and cooler to aid refit.

4.Loosen clamps EGR pipes to cooler and move

clamps aside.

5.Remove pipe, EGR cooler to EGR valve.

6.Remove bolt securing fuel rails to support

bracket.

7.Remove bolt securing turbocharger outlet pipe

to support bracket.

8.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M170364

M17 0283

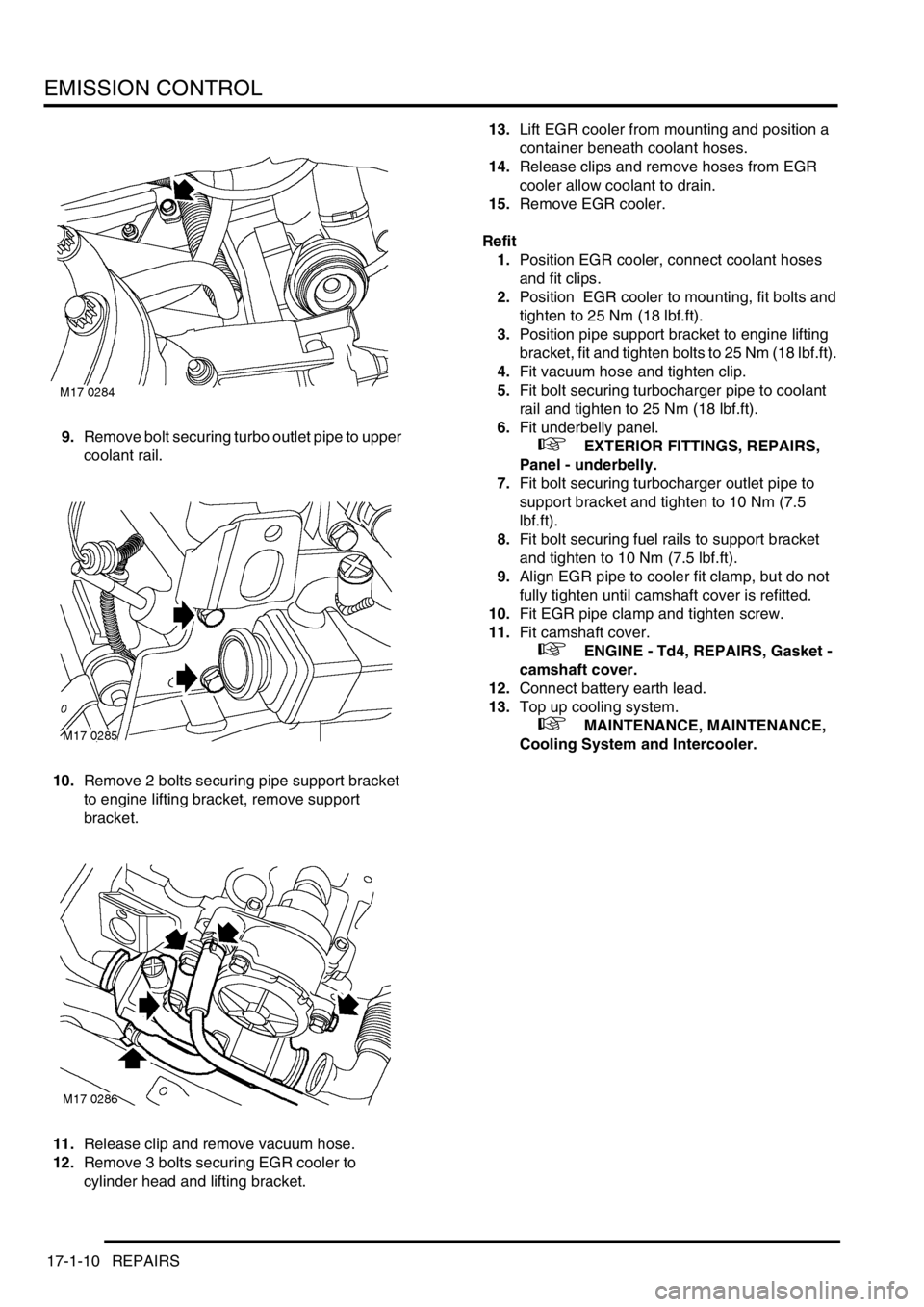

Page 301 of 1007

EMISSION CONTROL

17-1-10 REPAIRS

9.Remove bolt securing turbo outlet pipe to upper

coolant rail.

10.Remove 2 bolts securing pipe support bracket

to engine lifting bracket, remove support

bracket.

11.Release clip and remove vacuum hose.

12.Remove 3 bolts securing EGR cooler to

cylinder head and lifting bracket.13.Lift EGR cooler from mounting and position a

container beneath coolant hoses.

14.Release clips and remove hoses from EGR

cooler allow coolant to drain.

15.Remove EGR cooler.

Refit

1.Position EGR cooler, connect coolant hoses

and fit clips.

2.Position EGR cooler to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

3.Position pipe support bracket to engine lifting

bracket, fit and tighten bolts to 25 Nm (18 lbf.ft).

4.Fit vacuum hose and tighten clip.

5.Fit bolt securing turbocharger pipe to coolant

rail and tighten to 25 Nm (18 lbf.ft).

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Fit bolt securing turbocharger outlet pipe to

support bracket and tighten to 10 Nm (7.5

lbf.ft).

8.Fit bolt securing fuel rails to support bracket

and tighten to 10 Nm (7.5 lbf.ft).

9.Align EGR pipe to cooler fit clamp, but do not

fully tighten until camshaft cover is refitted.

10.Fit EGR pipe clamp and tighten screw.

11.Fit camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

12.Connect battery earth lead.

13.Top up cooling system.

+ MAINTENANCE, MAINTENANCE,

Cooling System and Intercooler.

Page 302 of 1007

EMISSION CONTROL

REPAIRS 17-1-11

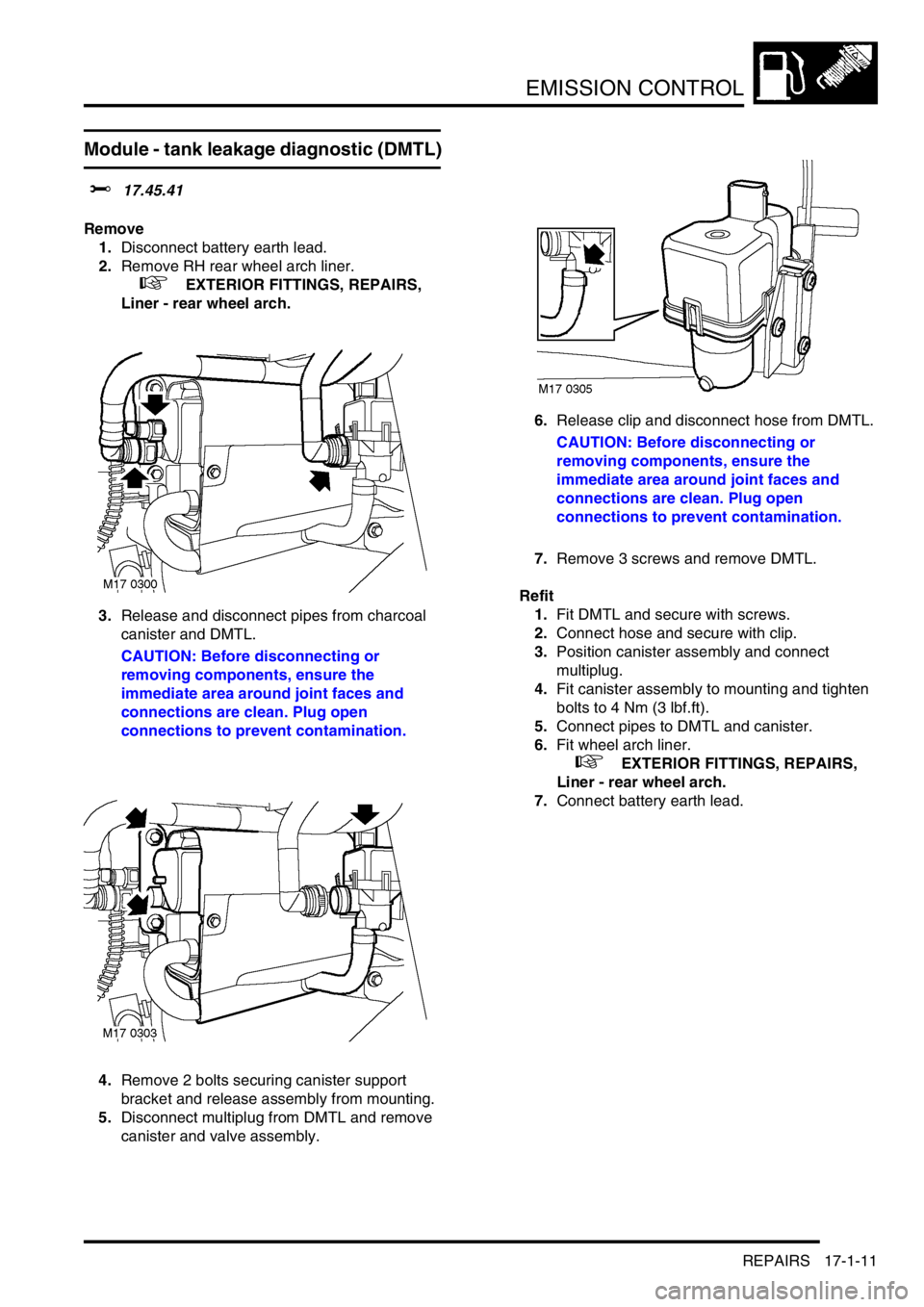

Module - tank leakage diagnostic (DMTL)

$% 17.45.41

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Release and disconnect pipes from charcoal

canister and DMTL.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

4.Remove 2 bolts securing canister support

bracket and release assembly from mounting.

5.Disconnect multiplug from DMTL and remove

canister and valve assembly.6.Release clip and disconnect hose from DMTL.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

7.Remove 3 screws and remove DMTL.

Refit

1.Fit DMTL and secure with screws.

2.Connect hose and secure with clip.

3.Position canister assembly and connect

multiplug.

4.Fit canister assembly to mounting and tighten

bolts to 4 Nm (3 lbf.ft).

5.Connect pipes to DMTL and canister.

6.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Connect battery earth lead.

Page 303 of 1007

EMISSION CONTROL

17-1-12 REPAIRS

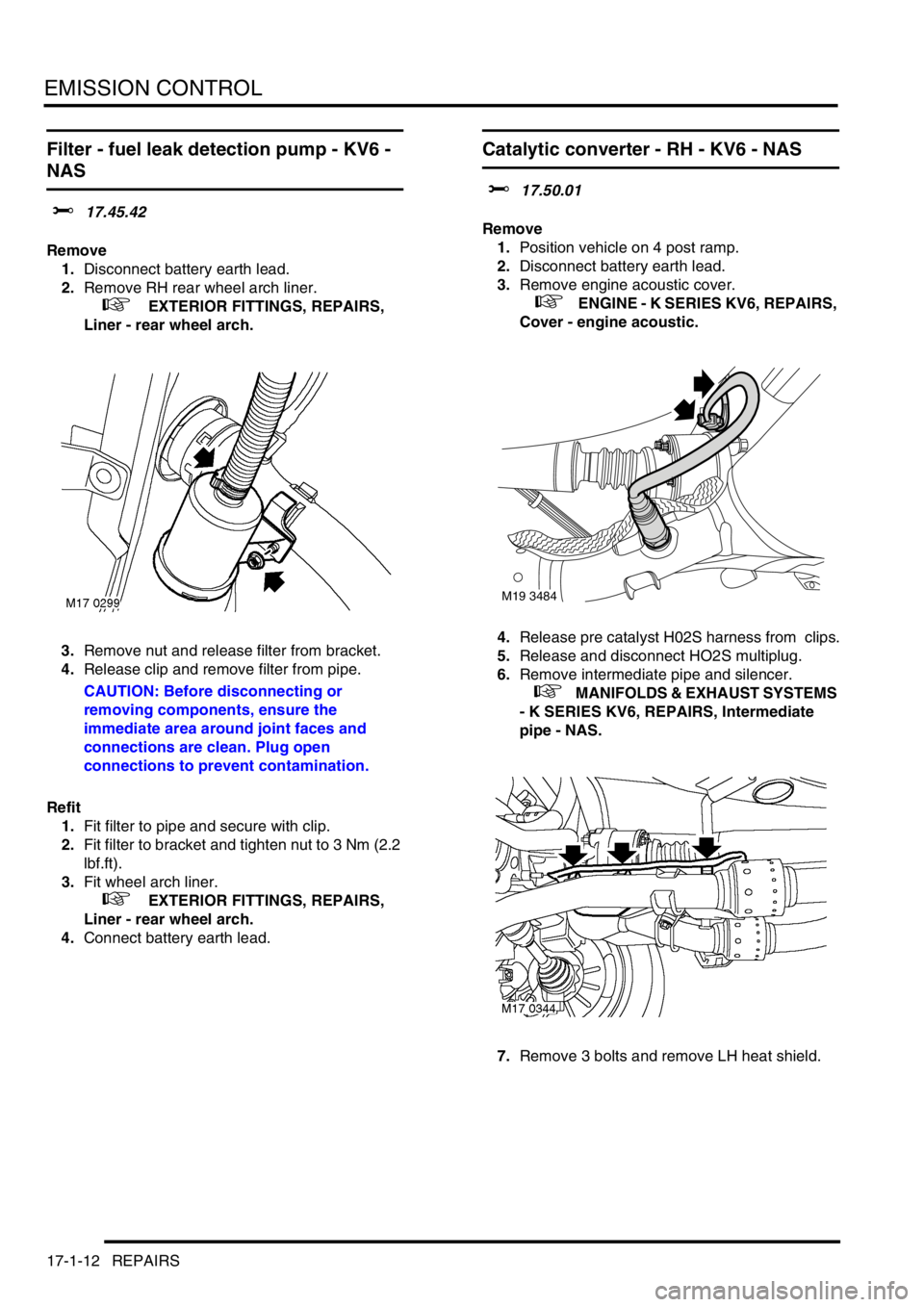

Filter - fuel leak detection pump - KV6 -

NAS

$% 17.45.42

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Remove nut and release filter from bracket.

4.Release clip and remove filter from pipe.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

Refit

1.Fit filter to pipe and secure with clip.

2.Fit filter to bracket and tighten nut to 3 Nm (2.2

lbf.ft).

3.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Connect battery earth lead.

Catalytic converter - RH - KV6 - NAS

$% 17.50.01

Remove

1.Position vehicle on 4 post ramp.

2.Disconnect battery earth lead.

3.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

4.Release pre catalyst H02S harness from clips.

5.Release and disconnect HO2S multiplug.

6.Remove intermediate pipe and silencer.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

7.Remove 3 bolts and remove LH heat shield.

M19 3484