belt LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 664 of 1007

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-3

Trim casing - rear quarter - upper - 3 door

$% 76.13.13

Remove

1.Remove rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

2.Remove body rear side casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - body side - rear - 3

door.

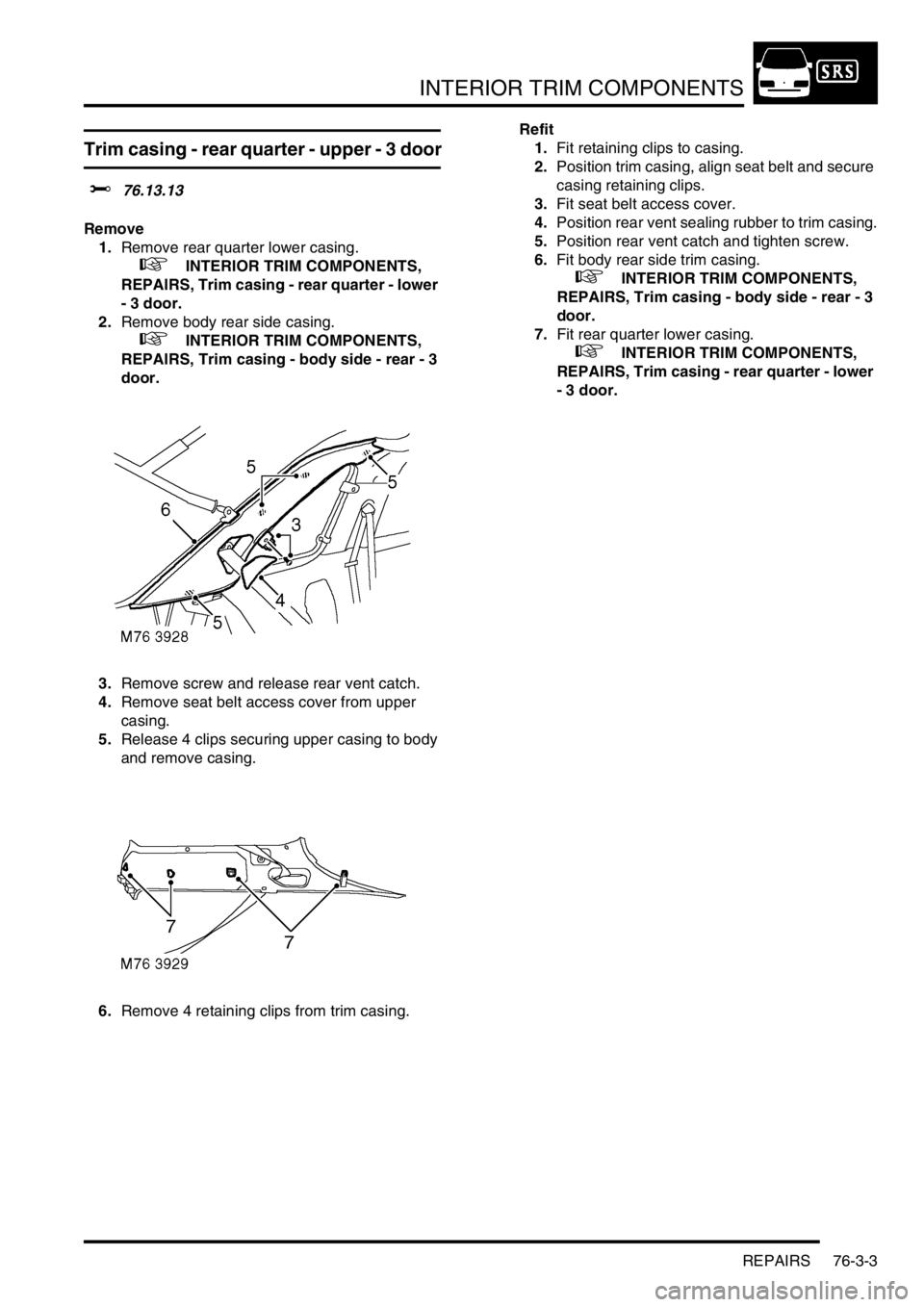

3.Remove screw and release rear vent catch.

4.Remove seat belt access cover from upper

casing.

5.Release 4 clips securing upper casing to body

and remove casing.

6.Remove 4 retaining clips from trim casing.Refit

1.Fit retaining clips to casing.

2.Position trim casing, align seat belt and secure

casing retaining clips.

3.Fit seat belt access cover.

4.Position rear vent sealing rubber to trim casing.

5.Position rear vent catch and tighten screw.

6.Fit body rear side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - body side - rear - 3

door.

7.Fit rear quarter lower casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

Page 667 of 1007

INTERIOR TRIM COMPONENTS

76-3-6 REPAIRS

Trim finisher - 'B/C' post - upper - renew

$% 76.13.28

Remove

1.Remove seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

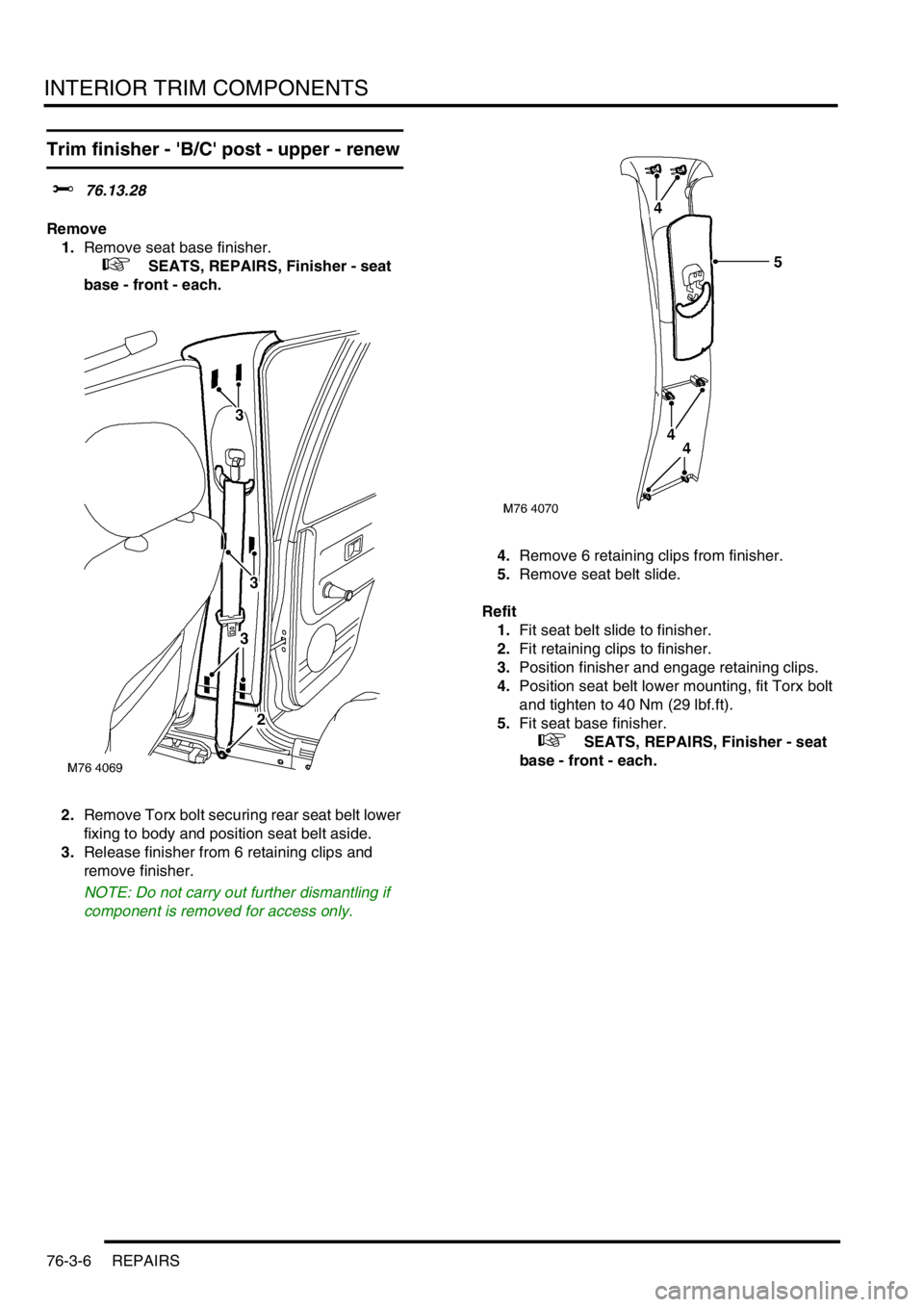

2.Remove Torx bolt securing rear seat belt lower

fixing to body and position seat belt aside.

3.Release finisher from 6 retaining clips and

remove finisher.

NOTE: Do not carry out further dismantling if

component is removed for access only.4.Remove 6 retaining clips from finisher.

5.Remove seat belt slide.

Refit

1.Fit seat belt slide to finisher.

2.Fit retaining clips to finisher.

3.Position finisher and engage retaining clips.

4.Position seat belt lower mounting, fit Torx bolt

and tighten to 40 Nm (29 lbf.ft).

5.Fit seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

Page 669 of 1007

INTERIOR TRIM COMPONENTS

76-3-8 REPAIRS

Trim casing - body side - rear - 3 door

$% 76.13.57

Remove

1.Remove rear seat.

+ SEATS, REPAIRS, Rear seat - LH.

+ SEATS, REPAIRS, Rear seat - RH.

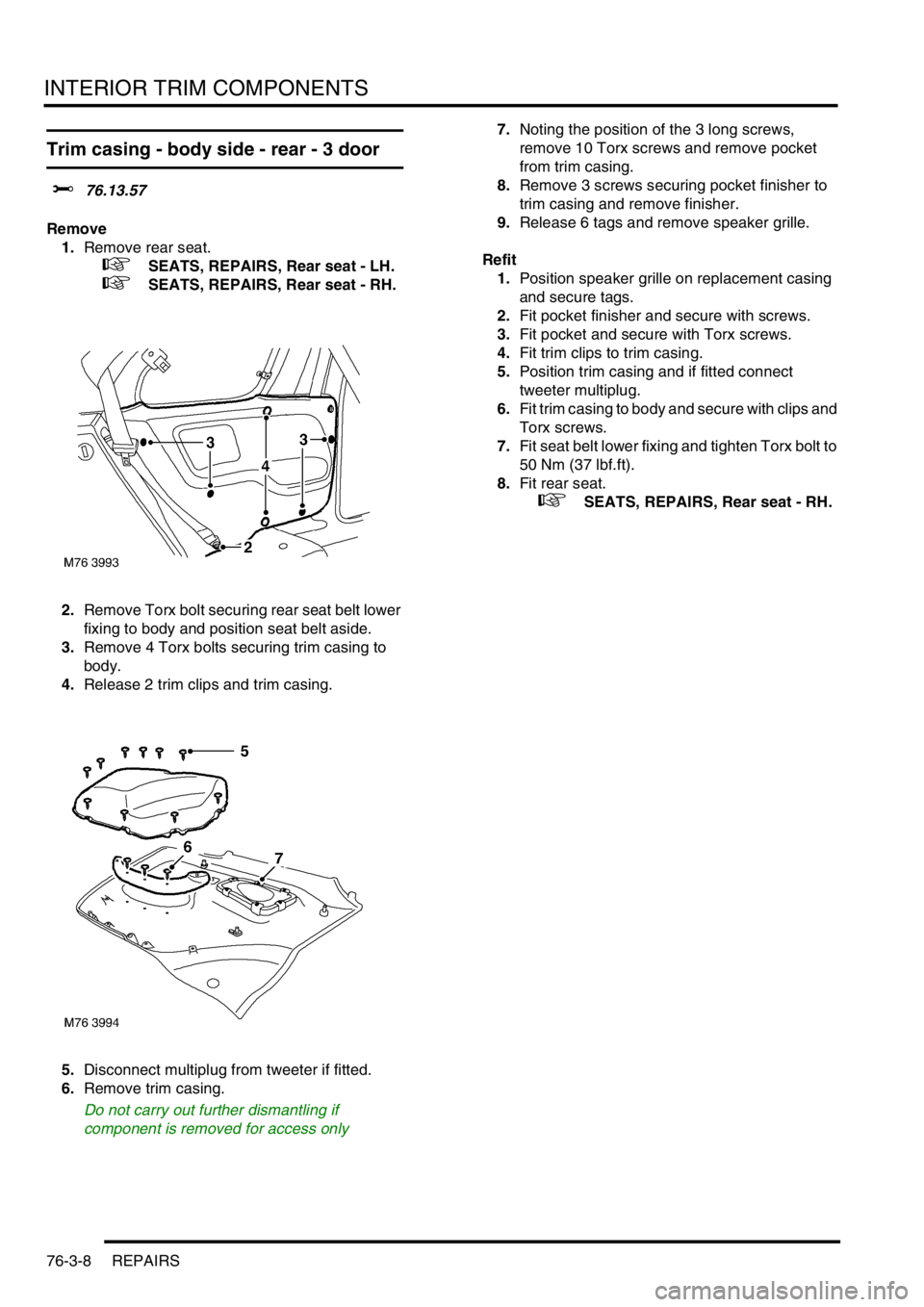

2.Remove Torx bolt securing rear seat belt lower

fixing to body and position seat belt aside.

3.Remove 4 Torx bolts securing trim casing to

body.

4.Release 2 trim clips and trim casing.

5.Disconnect multiplug from tweeter if fitted.

6.Remove trim casing.

Do not carry out further dismantling if

component is removed for access only7.Noting the position of the 3 long screws,

remove 10 Torx screws and remove pocket

from trim casing.

8.Remove 3 screws securing pocket finisher to

trim casing and remove finisher.

9.Release 6 tags and remove speaker grille.

Refit

1.Position speaker grille on replacement casing

and secure tags.

2.Fit pocket finisher and secure with screws.

3.Fit pocket and secure with Torx screws.

4.Fit trim clips to trim casing.

5.Position trim casing and if fitted connect

tweeter multiplug.

6.Fit trim casing to body and secure with clips and

Torx screws.

7.Fit seat belt lower fixing and tighten Torx bolt to

50 Nm (37 lbf.ft).

8.Fit rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

Page 699 of 1007

SEATS

76-5-4 REPAIRS

12.Remove 12 hog rings securing cover to

cushion.

13.Remove cushion cover from cushion.

Refit

1.Position cushion cover to cushion pad and

secure to frame with hog rings in position noted

during removal.

2.Position and secure cushion cover and pad to

frame.

3.Fit squab frame to cushion frame and tighten

Torx bolts to 45 Nm (33 lbf.ft).

4.Connect multiplugs.

5.Position multiplug to frame and secure clips.

6.Fit recline control knob.

7.Fit side covers and secure retaining studs.

8.Fit front seat.

+ SEATS, REPAIRS, Front seat.

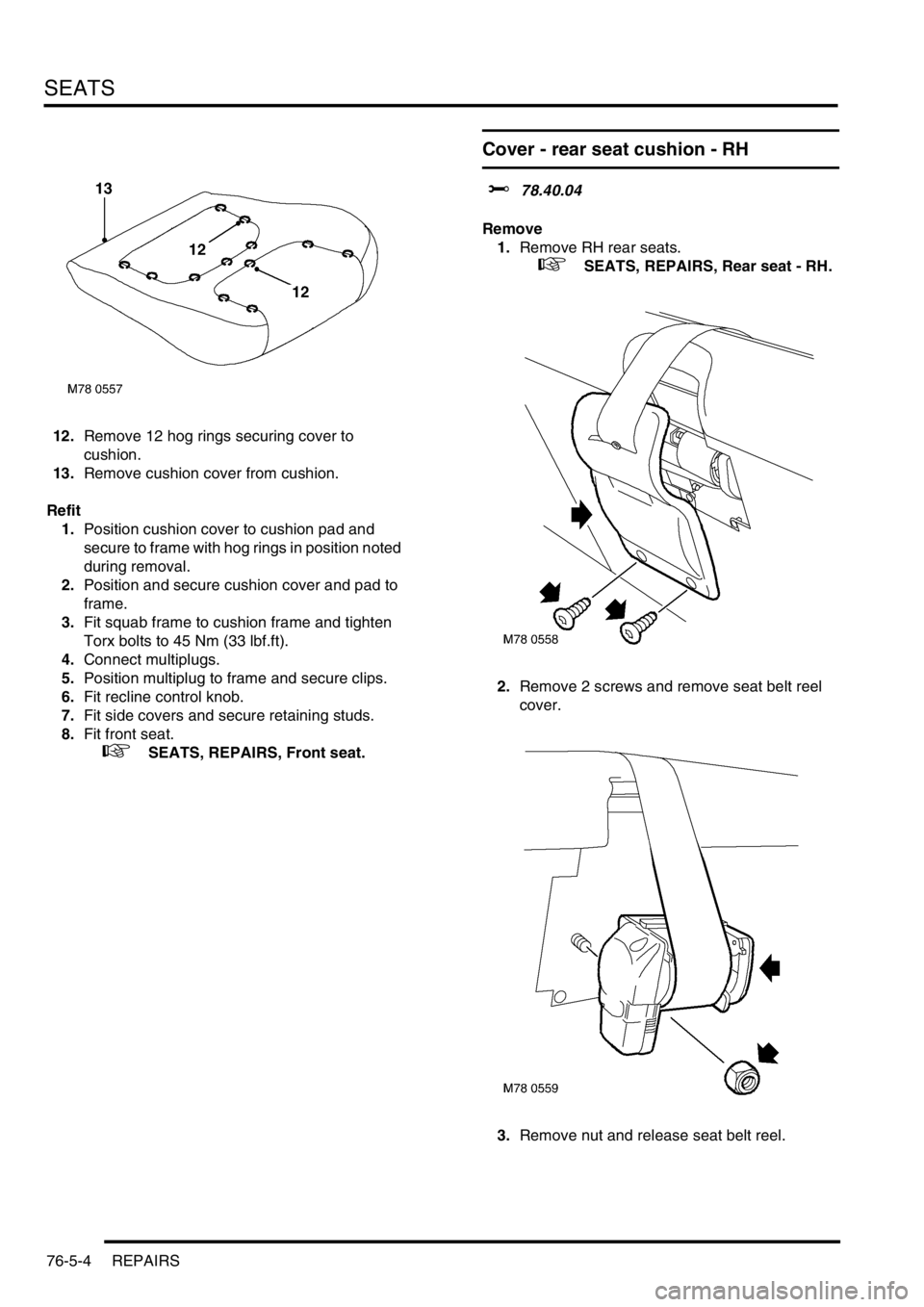

Cover - rear seat cushion - RH

$% 78.40.04

Remove

1.Remove RH rear seats.

+ SEATS, REPAIRS, Rear seat - RH.

2.Remove 2 screws and remove seat belt reel

cover.

3.Remove nut and release seat belt reel.

Page 700 of 1007

SEATS

REPAIRS 76-5-5

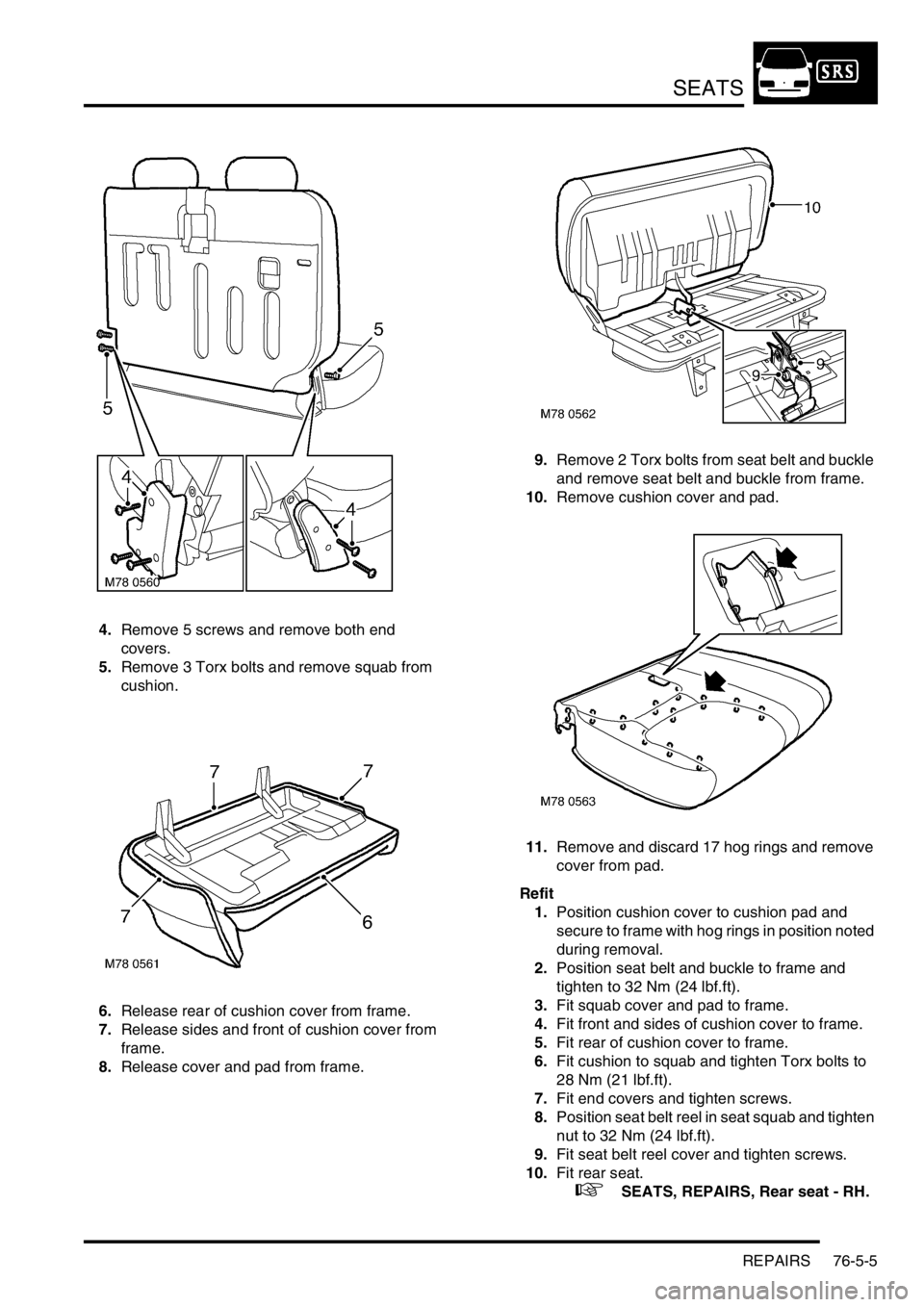

4.Remove 5 screws and remove both end

covers.

5.Remove 3 Torx bolts and remove squab from

cushion.

6.Release rear of cushion cover from frame.

7.Release sides and front of cushion cover from

frame.

8.Release cover and pad from frame.9.Remove 2 Torx bolts from seat belt and buckle

and remove seat belt and buckle from frame.

10.Remove cushion cover and pad.

11.Remove and discard 17 hog rings and remove

cover from pad.

Refit

1.Position cushion cover to cushion pad and

secure to frame with hog rings in position noted

during removal.

2.Position seat belt and buckle to frame and

tighten to 32 Nm (24 lbf.ft).

3.Fit squab cover and pad to frame.

4.Fit front and sides of cushion cover to frame.

5.Fit rear of cushion cover to frame.

6.Fit cushion to squab and tighten Torx bolts to

28 Nm (21 lbf.ft).

7.Fit end covers and tighten screws.

8.Position seat belt reel in seat squab and tighten

nut to 32 Nm (24 lbf.ft).

9.Fit seat belt reel cover and tighten screws.

10.Fit rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

Page 709 of 1007

SEATS

76-5-14 REPAIRS

Cover - squab - rear seat - RH

$% 78.90.13

Remove

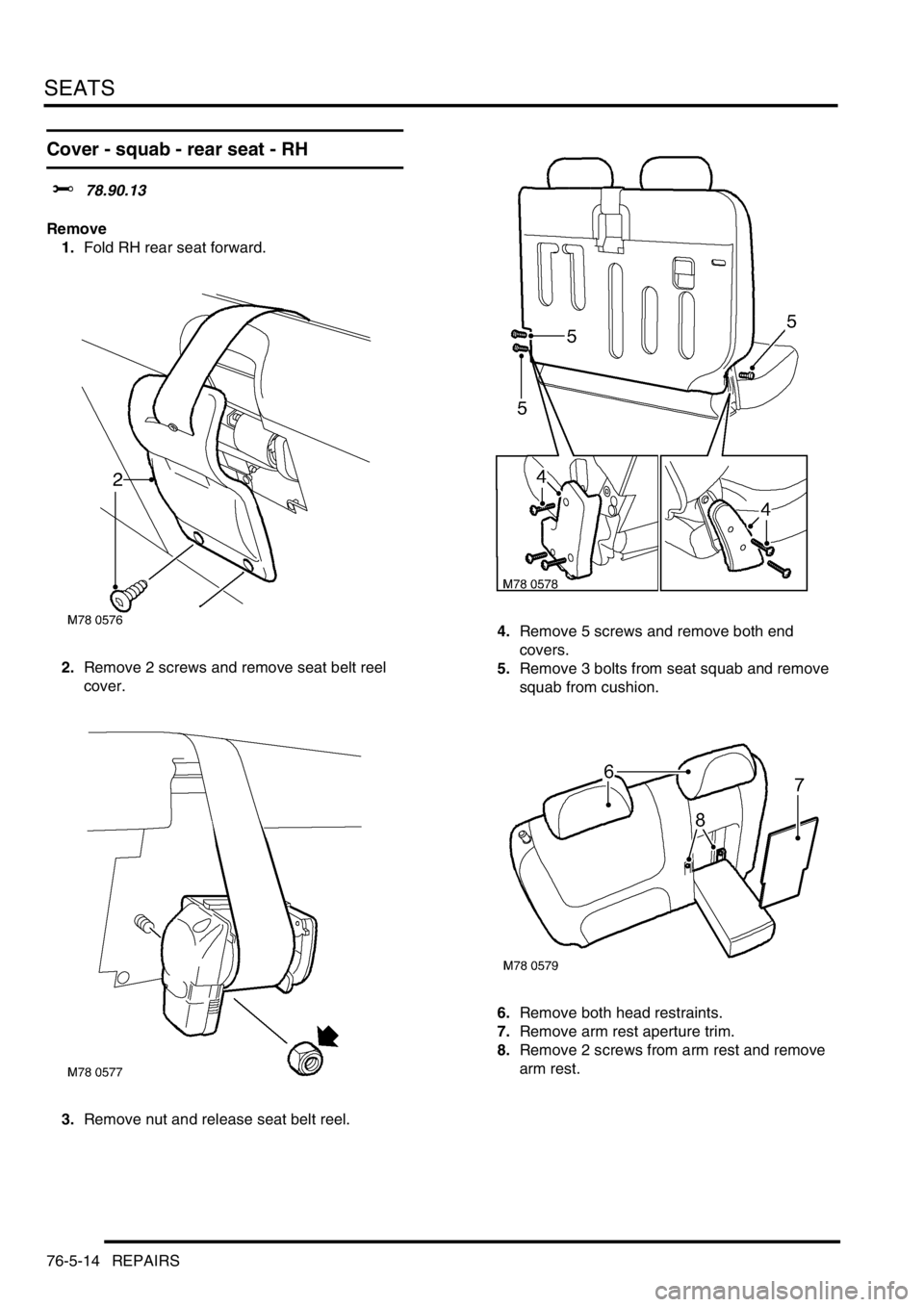

1.Fold RH rear seat forward.

2.Remove 2 screws and remove seat belt reel

cover.

3.Remove nut and release seat belt reel.4.Remove 5 screws and remove both end

covers.

5.Remove 3 bolts from seat squab and remove

squab from cushion.

6.Remove both head restraints.

7.Remove arm rest aperture trim.

8.Remove 2 screws from arm rest and remove

arm rest.

Page 710 of 1007

SEATS

REPAIRS 76-5-15

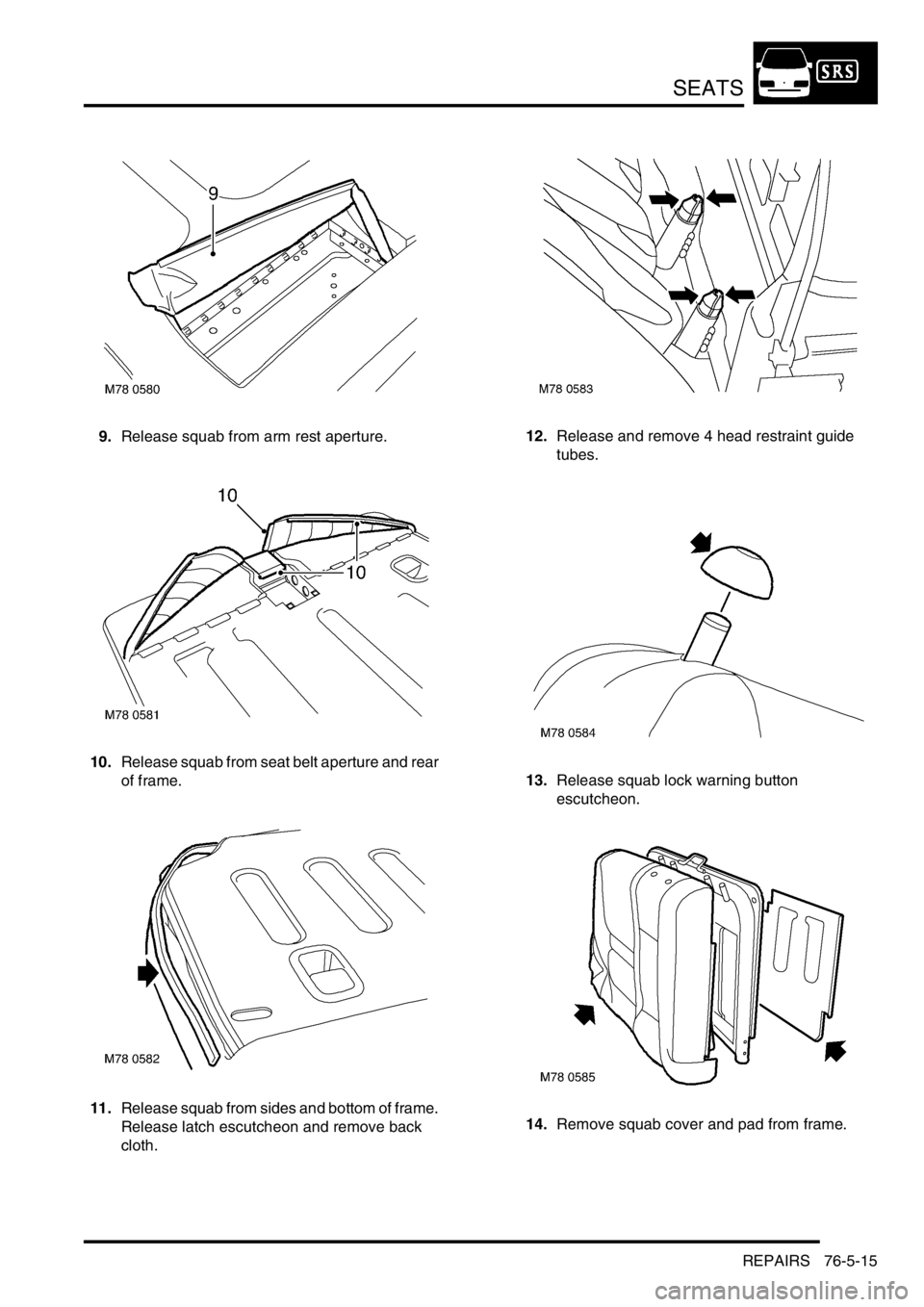

9.Release squab from arm rest aperture.

10.Release squab from seat belt aperture and rear

of frame.

11.Release squab from sides and bottom of frame.

Release latch escutcheon and remove back

cloth.12.Release and remove 4 head restraint guide

tubes.

13.Release squab lock warning button

escutcheon.

14.Remove squab cover and pad from frame.

Page 711 of 1007

SEATS

76-5-16 REPAIRS

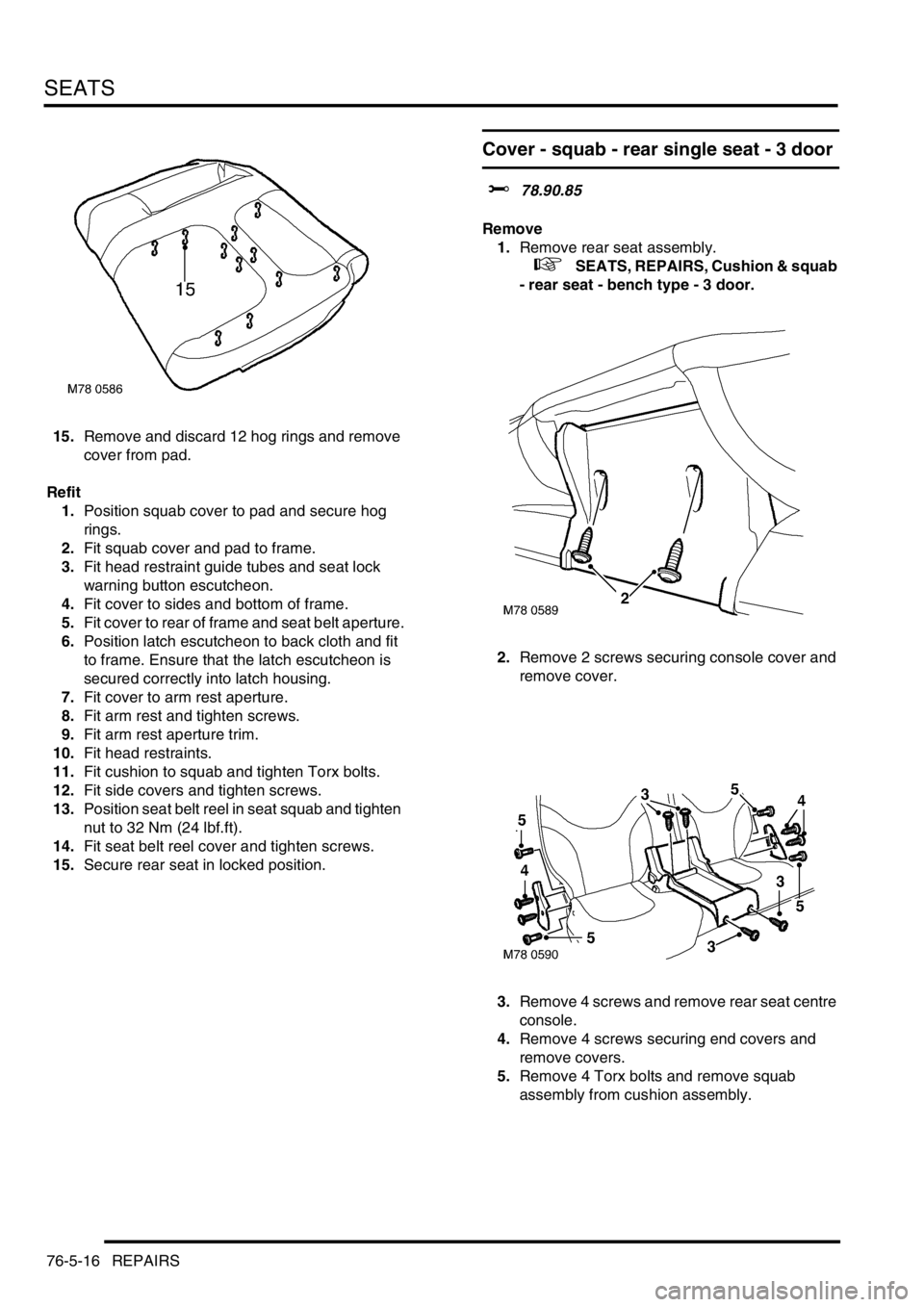

15.Remove and discard 12 hog rings and remove

cover from pad.

Refit

1.Position squab cover to pad and secure hog

rings.

2.Fit squab cover and pad to frame.

3.Fit head restraint guide tubes and seat lock

warning button escutcheon.

4.Fit cover to sides and bottom of frame.

5.Fit cover to rear of frame and seat belt aperture.

6.Position latch escutcheon to back cloth and fit

to frame. Ensure that the latch escutcheon is

secured correctly into latch housing.

7.Fit cover to arm rest aperture.

8.Fit arm rest and tighten screws.

9.Fit arm rest aperture trim.

10.Fit head restraints.

11.Fit cushion to squab and tighten Torx bolts.

12.Fit side covers and tighten screws.

13.Position seat belt reel in seat squab and tighten

nut to 32 Nm (24 lbf.ft).

14.Fit seat belt reel cover and tighten screws.

15.Secure rear seat in locked position.

Cover - squab - rear single seat - 3 door

$% 78.90.85

Remove

1.Remove rear seat assembly.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

2.Remove 2 screws securing console cover and

remove cover.

3.Remove 4 screws and remove rear seat centre

console.

4.Remove 4 screws securing end covers and

remove covers.

5.Remove 4 Torx bolts and remove squab

assembly from cushion assembly.

Page 772 of 1007

PANEL REPAIRS

WELDING PROCEDURES 77-2-17

Seat belt anchorages

Seat belt anchorages are safety critical. When making repairs in these areas, it is essential to follow design

specifications. Note that High Strength Low Alloy (HSLA) steel may be used for seat belt anchorages.

Where possible, the original production assembly should be used, complete with its seat belt anchorages, or the cut

line should be so arranged that the original seat belt anchorage is not disturbed.

All welds within 250mm (9.842) of seat belt anchorages must be carefully checked for weld quality, including spacing

of spot welds.

warn : Body parts incorporating seat belt anchorages MUST be renewed completely if damaged beyond repair, as the

welds in these areas are safety critical and cannot be disturbed.

High Strength Steels

Body panels are being increasingly manufactured in high strength steels to meet design requirements for safety and

weight saving. As panels in high strength steels cannot be visually identified by the repairer, and as they can be more

sensitive to excess heat than would be the case with low carbon steels, it is advisable that the following procedure be

observed at all times.

While individual repairs will differ in detail, the following Panel Replacement Procedure has been devised placing

emphasis on ease of repair and the elimination of unnecessary work. Where replacement of a particular panel

involves departure from the Panel Replacement Procedure, a note to that effect is included in the relevant panel

replacement operation.

Straightening

Whenever possible, structural members should be cold straightened under tension. Do not attempt to straighten with

a single pull but rework the damaged area using a series of pulls, releasing tension between each stage and using

the opportunity to check alignment

Body jig

Unless damage is limited to cosmetic panels, all repair work to body members must be carried out on a body jig, to

ensure that impact damage has not spread into more remote parts of the structure. Mounting on a jig will also ensure

that the straightening and panel replacement procedures do not cause further distortion. If original dimensions cannot

be satisfactorily restored by these methods, damaged structural members should be replaced. Damaged areas

should be cut away using a high speed saw, NOT an oxy-acetylene torch. As a rule, body dimensions are

symmetrical about the centre line. A good initial check for distortion is therefore to measure diagonally and to

investigate apparent differences in dimensions.

Inspection

Every accident produces individual variations in damage. Each repair is influenced by the extent of the damage and

the facilities and equipment available for its rectification. Most accident damage can be visually inspected and the

approximate extent of damage assessed. Sometimes deformation will extend beyond the directly damaged area, and

the severity of this must be accurately established so that steps can be taken to restore critical body components to

their original dimensions. An initial check can be carried out by means of drop checks or, preferably, trammels.

Gauges are available which will accurately check for body twist. Where repairs necessitate renewal of a critical body

component it is recommended that a body jig is used.

Page 775 of 1007

PANEL REPAIRS

77-2-20 PROCEDURES

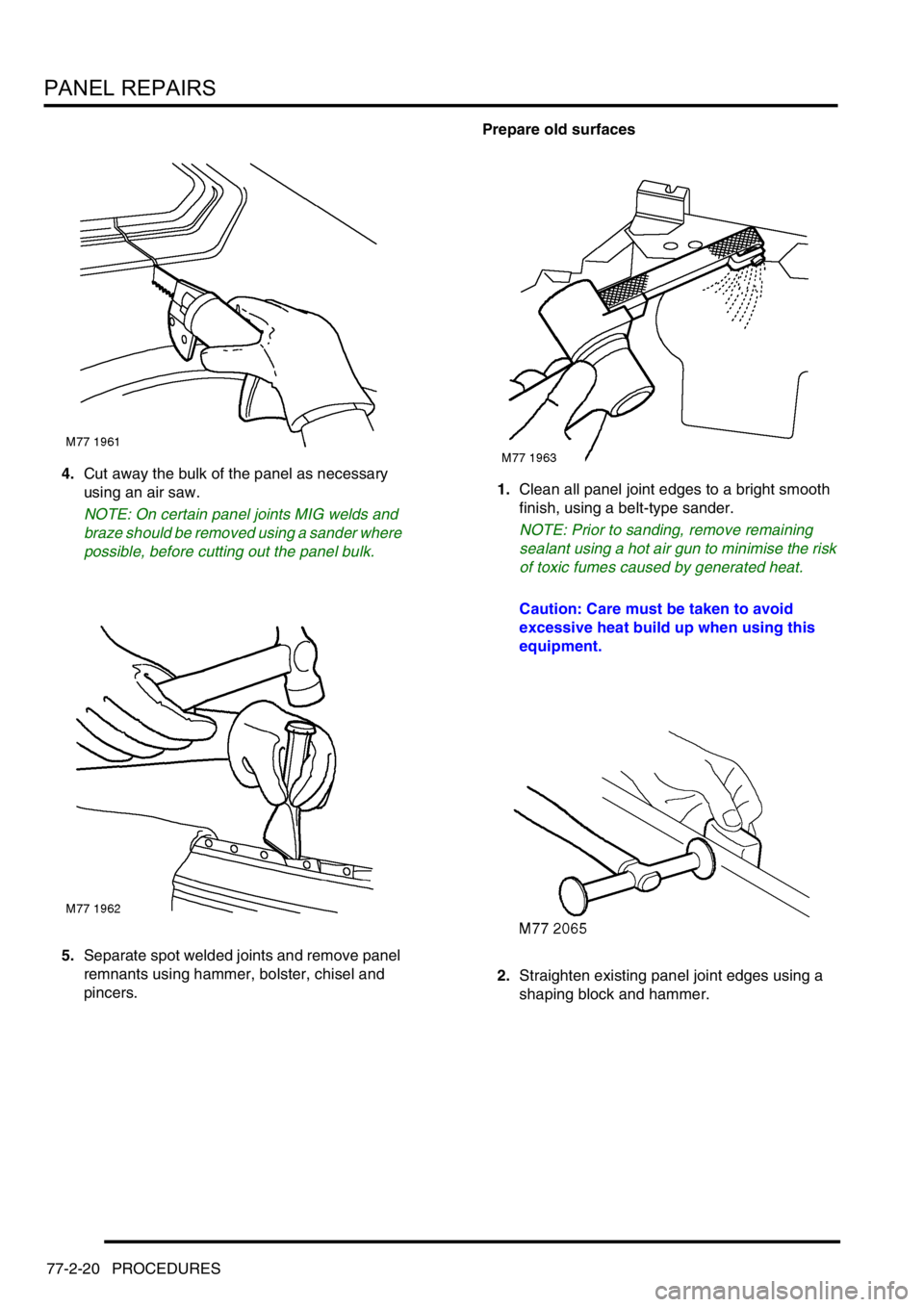

4.Cut away the bulk of the panel as necessary

using an air saw.

NOTE: On certain panel joints MIG welds and

braze should be removed using a sander where

possible, before cutting out the panel bulk.

5.Separate spot welded joints and remove panel

remnants using hammer, bolster, chisel and

pincers.Prepare old surfaces

1.Clean all panel joint edges to a bright smooth

finish, using a belt-type sander.

NOTE: Prior to sanding, remove remaining

sealant using a hot air gun to minimise the risk

of toxic fumes caused by generated heat.

Caution: Care must be taken to avoid

excessive heat build up when using this

equipment.

2.Straighten existing panel joint edges using a

shaping block and hammer.