seats LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 227 of 1007

ENGINE - K SERIES KV6

12-3-50 REPAIRS

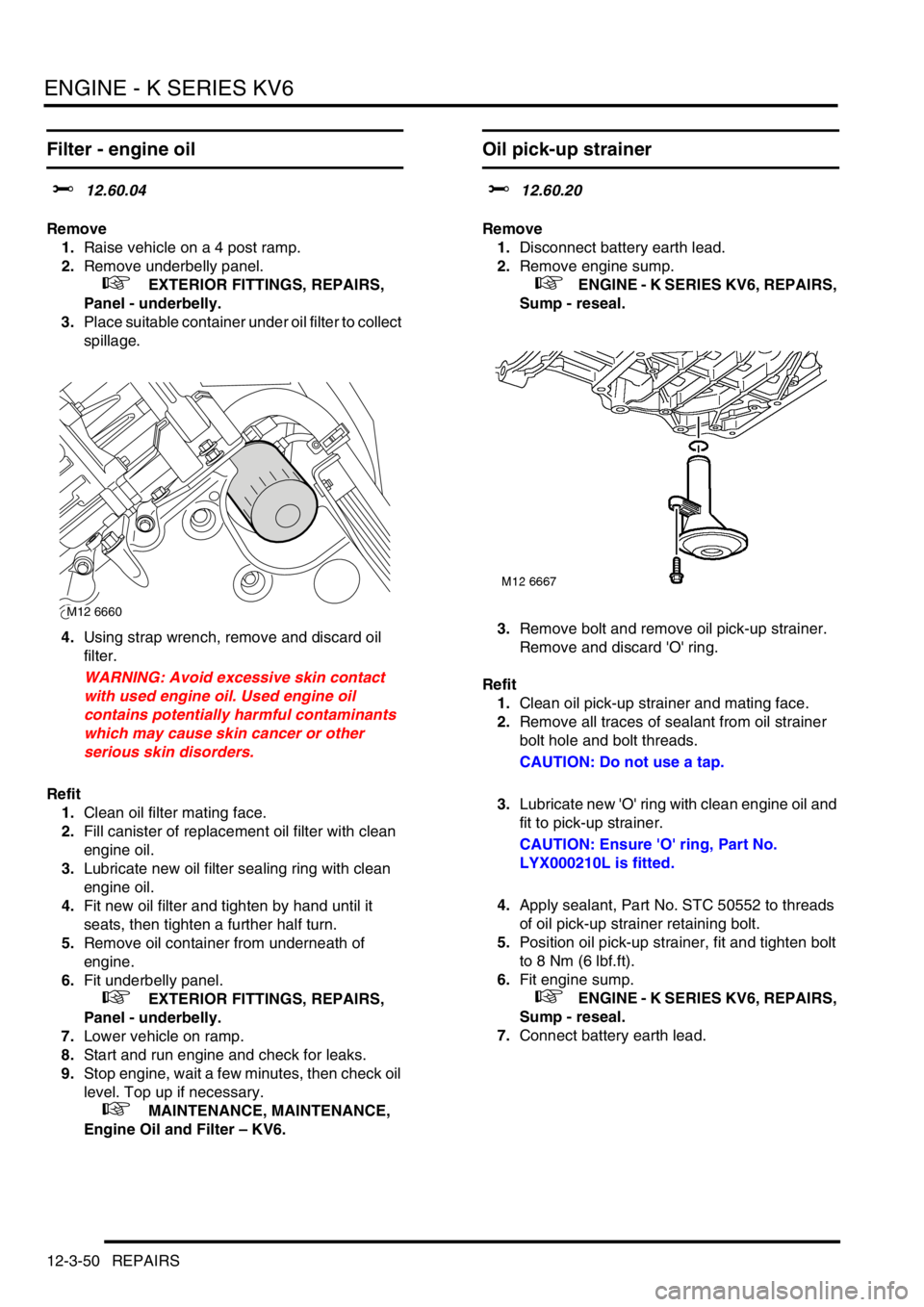

Filter - engine oil

$% 12.60.04

Remove

1.Raise vehicle on a 4 post ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place suitable container under oil filter to collect

spillage.

4.Using strap wrench, remove and discard oil

filter.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

Refit

1.Clean oil filter mating face.

2.Fill canister of replacement oil filter with clean

engine oil.

3.Lubricate new oil filter sealing ring with clean

engine oil.

4.Fit new oil filter and tighten by hand until it

seats, then tighten a further half turn.

5.Remove oil container from underneath of

engine.

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Lower vehicle on ramp.

8.Start and run engine and check for leaks.

9.Stop engine, wait a few minutes, then check oil

level. Top up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Oil pick-up strainer

$% 12.60.20

Remove

1.Disconnect battery earth lead.

2.Remove engine sump.

+ ENGINE - K SERIES KV6, REPAIRS,

Sump - reseal.

3.Remove bolt and remove oil pick-up strainer.

Remove and discard 'O' ring.

Refit

1.Clean oil pick-up strainer and mating face.

2.Remove all traces of sealant from oil strainer

bolt hole and bolt threads.

CAUTION: Do not use a tap.

3.Lubricate new 'O' ring with clean engine oil and

fit to pick-up strainer.

CAUTION: Ensure 'O' ring, Part No.

LYX000210L is fitted.

4.Apply sealant, Part No. STC 50552 to threads

of oil pick-up strainer retaining bolt.

5.Position oil pick-up strainer, fit and tighten bolt

to 8 Nm (6 lbf.ft).

6.Fit engine sump.

+ ENGINE - K SERIES KV6, REPAIRS,

Sump - reseal.

7.Connect battery earth lead.

M12 6660

Page 229 of 1007

ENGINE - K SERIES KV6

12-3-52 REPAIRS

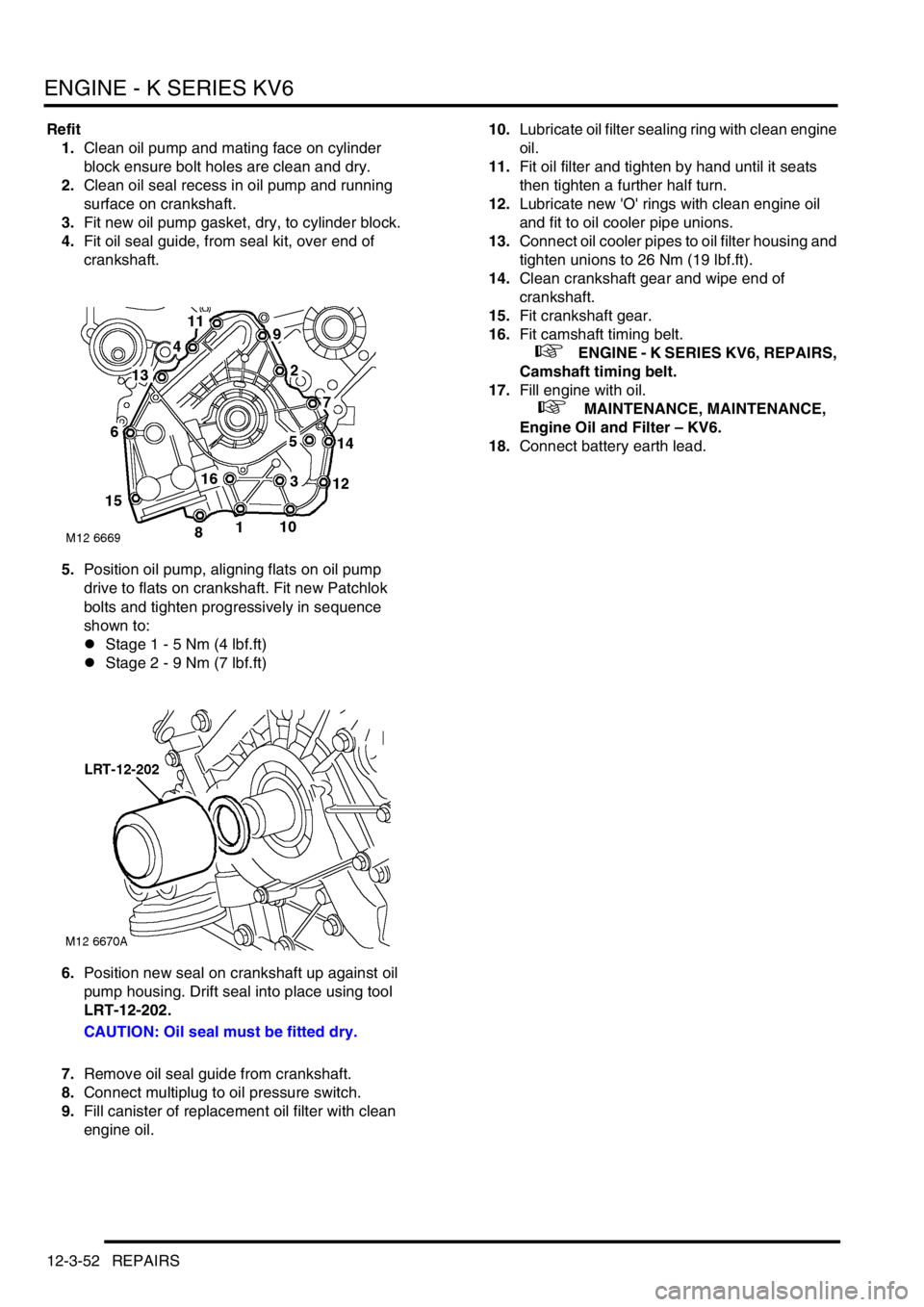

Refit

1.Clean oil pump and mating face on cylinder

block ensure bolt holes are clean and dry.

2.Clean oil seal recess in oil pump and running

surface on crankshaft.

3.Fit new oil pump gasket, dry, to cylinder block.

4.Fit oil seal guide, from seal kit, over end of

crankshaft.

5.Position oil pump, aligning flats on oil pump

drive to flats on crankshaft. Fit new Patchlok

bolts and tighten progressively in sequence

shown to:

lStage 1 - 5 Nm (4 lbf.ft)

lStage 2 - 9 Nm (7 lbf.ft)

6.Position new seal on crankshaft up against oil

pump housing. Drift seal into place using tool

LRT-12-202.

CAUTION: Oil seal must be fitted dry.

7.Remove oil seal guide from crankshaft.

8.Connect multiplug to oil pressure switch.

9.Fill canister of replacement oil filter with clean

engine oil.10.Lubricate oil filter sealing ring with clean engine

oil.

11.Fit oil filter and tighten by hand until it seats

then tighten a further half turn.

12.Lubricate new 'O' rings with clean engine oil

and fit to oil cooler pipe unions.

13.Connect oil cooler pipes to oil filter housing and

tighten unions to 26 Nm (19 lbf.ft).

14.Clean crankshaft gear and wipe end of

crankshaft.

15.Fit crankshaft gear.

16.Fit camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

17.Fill engine with oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

18.Connect battery earth lead.

Page 256 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-79

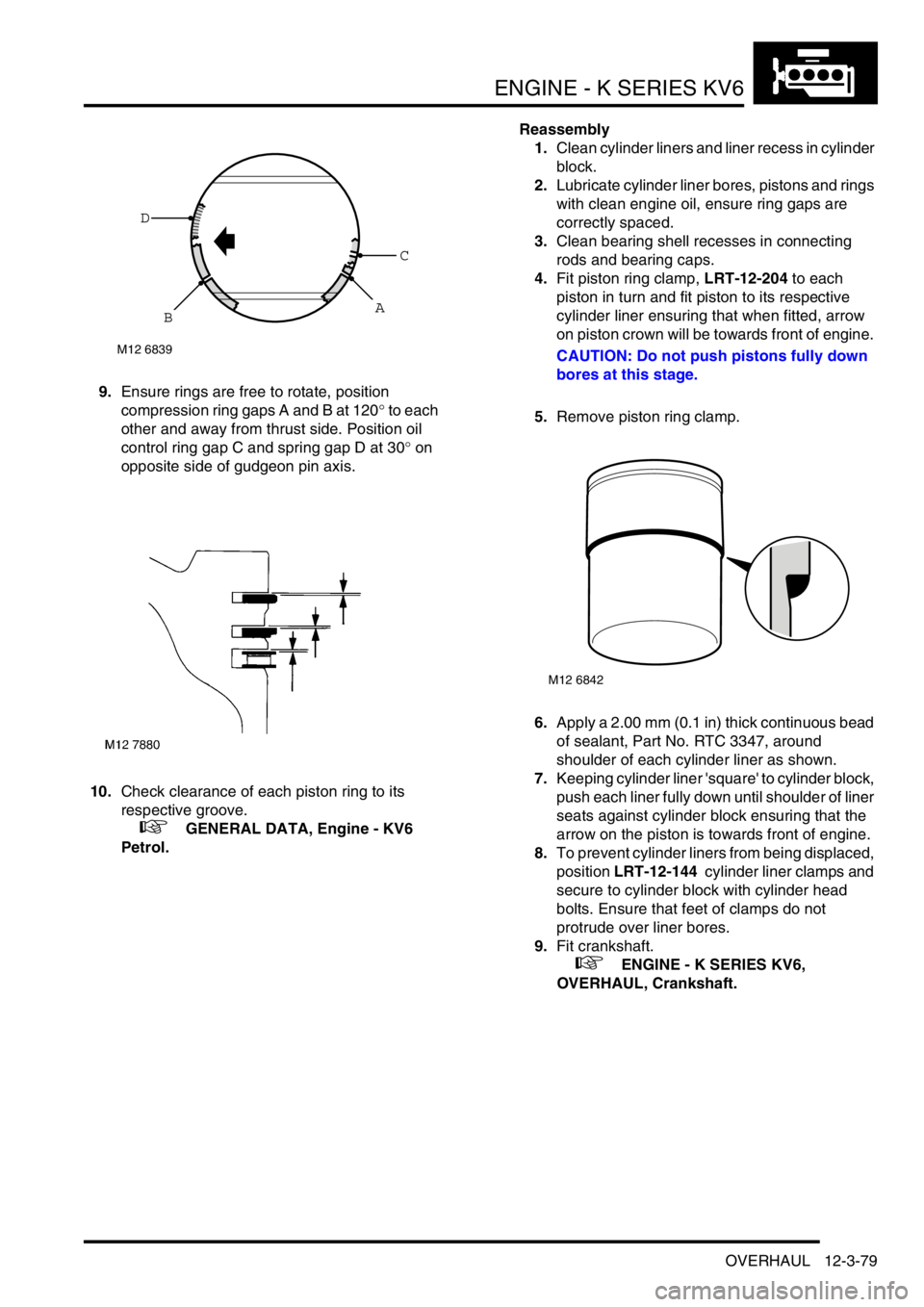

9.Ensure rings are free to rotate, position

compression ring gaps A and B at 120° to each

other and away from thrust side. Position oil

control ring gap C and spring gap D at 30° on

opposite side of gudgeon pin axis.

10.Check clearance of each piston ring to its

respective groove.

+ GENERAL DATA, Engine - KV6

Petrol.Reassembly

1.Clean cylinder liners and liner recess in cylinder

block.

2.Lubricate cylinder liner bores, pistons and rings

with clean engine oil, ensure ring gaps are

correctly spaced.

3.Clean bearing shell recesses in connecting

rods and bearing caps.

4.Fit piston ring clamp, LRT-12-204 to each

piston in turn and fit piston to its respective

cylinder liner ensuring that when fitted, arrow

on piston crown will be towards front of engine.

CAUTION: Do not push pistons fully down

bores at this stage.

5.Remove piston ring clamp.

6.Apply a 2.00 mm (0.1 in) thick continuous bead

of sealant, Part No. RTC 3347, around

shoulder of each cylinder liner as shown.

7.Keeping cylinder liner 'square' to cylinder block,

push each liner fully down until shoulder of liner

seats against cylinder block ensuring that the

arrow on the piston is towards front of engine.

8.To prevent cylinder liners from being displaced,

position LRT-12-144 cylinder liner clamps and

secure to cylinder block with cylinder head

bolts. Ensure that feet of clamps do not

protrude over liner bores.

9.Fit crankshaft.

+ ENGINE - K SERIES KV6,

OVERHAUL, Crankshaft.

M12 6839

D

BA

C

M12 6842

Page 277 of 1007

ENGINE - K SERIES KV6

12-3-100 OVERHAUL

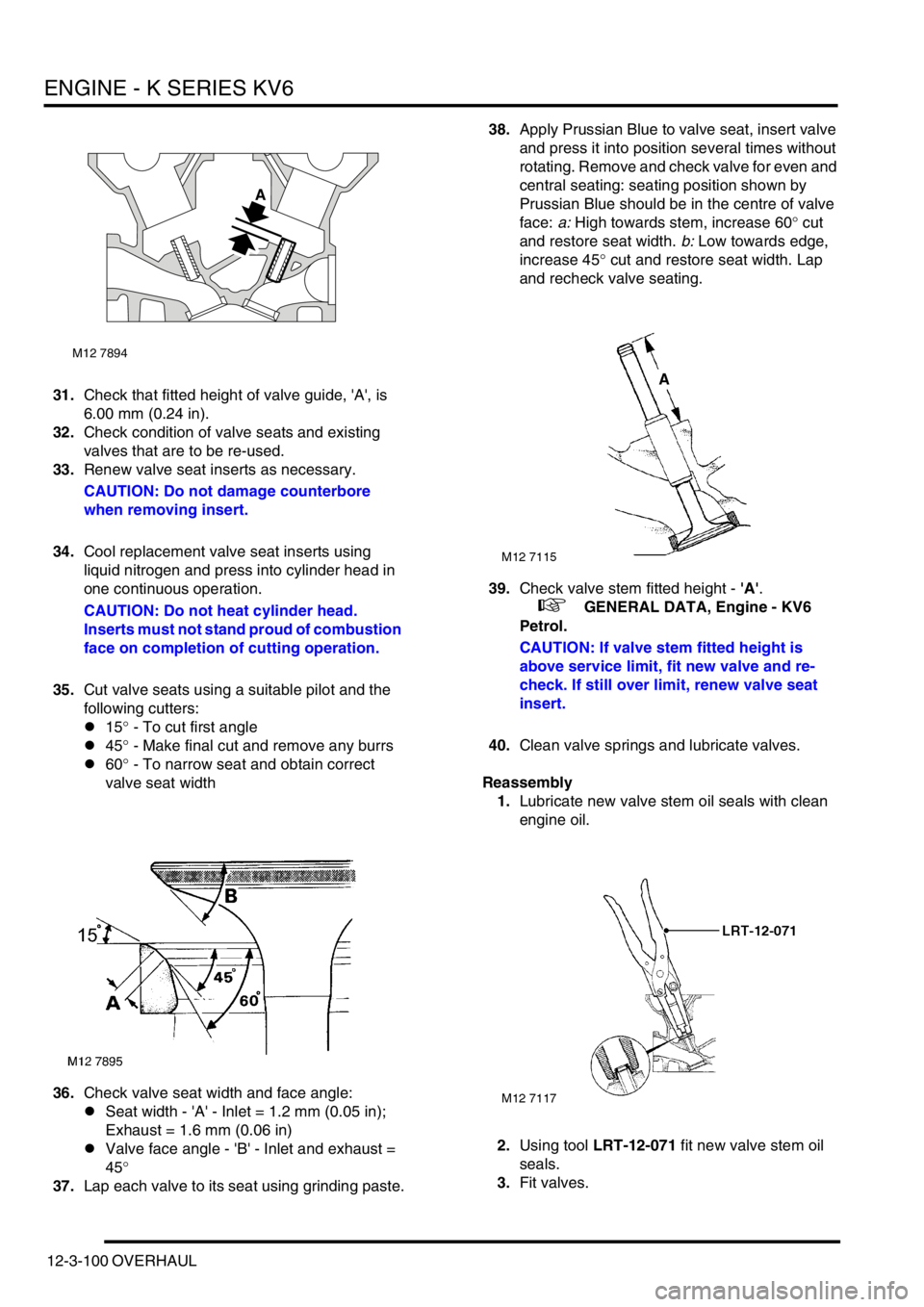

31.Check that fitted height of valve guide, 'A', is

6.00 mm (0.24 in).

32.Check condition of valve seats and existing

valves that are to be re-used.

33.Renew valve seat inserts as necessary.

CAUTION: Do not damage counterbore

when removing insert.

34.Cool replacement valve seat inserts using

liquid nitrogen and press into cylinder head in

one continuous operation.

CAUTION: Do not heat cylinder head.

Inserts must not stand proud of combustion

face on completion of cutting operation.

35.Cut valve seats using a suitable pilot and the

following cutters:

l15° - To cut first angle

l45° - Make final cut and remove any burrs

l60° - To narrow seat and obtain correct

valve seat width

36.Check valve seat width and face angle:

lSeat width - 'A' - Inlet = 1.2 mm (0.05 in);

Exhaust = 1.6 mm (0.06 in)

lValve face angle - 'B' - Inlet and exhaust =

45°

37.Lap each valve to its seat using grinding paste.38.Apply Prussian Blue to valve seat, insert valve

and press it into position several times without

rotating. Remove and check valve for even and

central seating: seating position shown by

Prussian Blue should be in the centre of valve

face: a: High towards stem, increase 60° cut

and restore seat width. b: Low towards edge,

increase 45° cut and restore seat width. Lap

and recheck valve seating.

39.Check valve stem fitted height - 'A'.

+ GENERAL DATA, Engine - KV6

Petrol.

CAUTION: If valve stem fitted height is

above service limit, fit new valve and re-

check. If still over limit, renew valve seat

insert.

40.Clean valve springs and lubricate valves.

Reassembly

1.Lubricate new valve stem oil seals with clean

engine oil.

2.Using tool LRT-12-071 fit new valve stem oil

seals.

3.Fit valves.

M12 7894

A

Page 582 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-1

RESTRAINT SYSTEMS REPAIRS

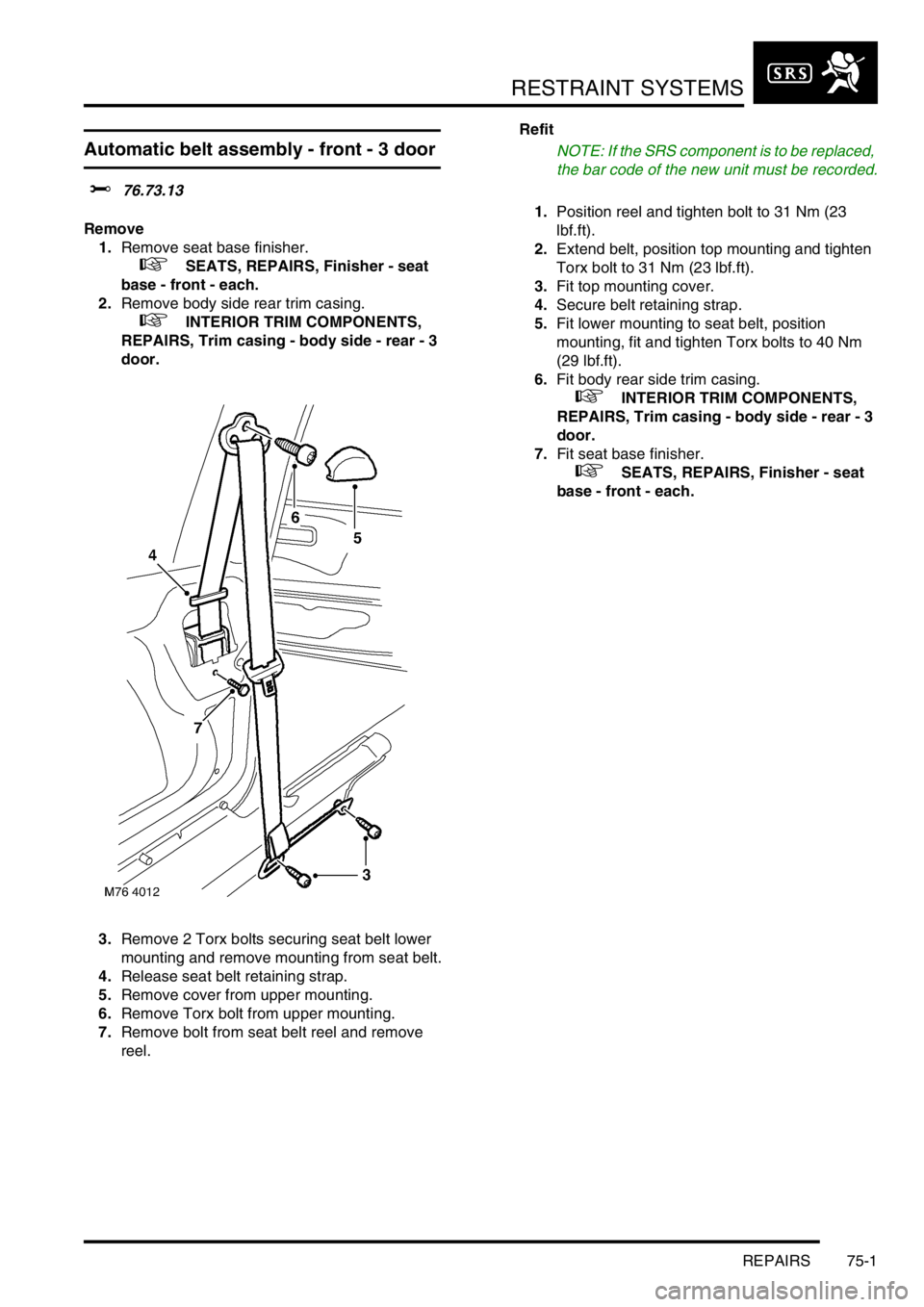

Automatic belt assembly - front - 3 door

$% 76.73.13

Remove

1.Remove seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

2.Remove body side rear trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - body side - rear - 3

door.

3.Remove 2 Torx bolts securing seat belt lower

mounting and remove mounting from seat belt.

4.Release seat belt retaining strap.

5.Remove cover from upper mounting.

6.Remove Torx bolt from upper mounting.

7.Remove bolt from seat belt reel and remove

reel.Refit

NOTE: If the SRS component is to be replaced,

the bar code of the new unit must be recorded.

1.Position reel and tighten bolt to 31 Nm (23

lbf.ft).

2.Extend belt, position top mounting and tighten

Torx bolt to 31 Nm (23 lbf.ft).

3.Fit top mounting cover.

4.Secure belt retaining strap.

5.Fit lower mounting to seat belt, position

mounting, fit and tighten Torx bolts to 40 Nm

(29 lbf.ft).

6.Fit body rear side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - body side - rear - 3

door.

7.Fit seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

Page 583 of 1007

RESTRAINT SYSTEMS

75-2 REPAIRS

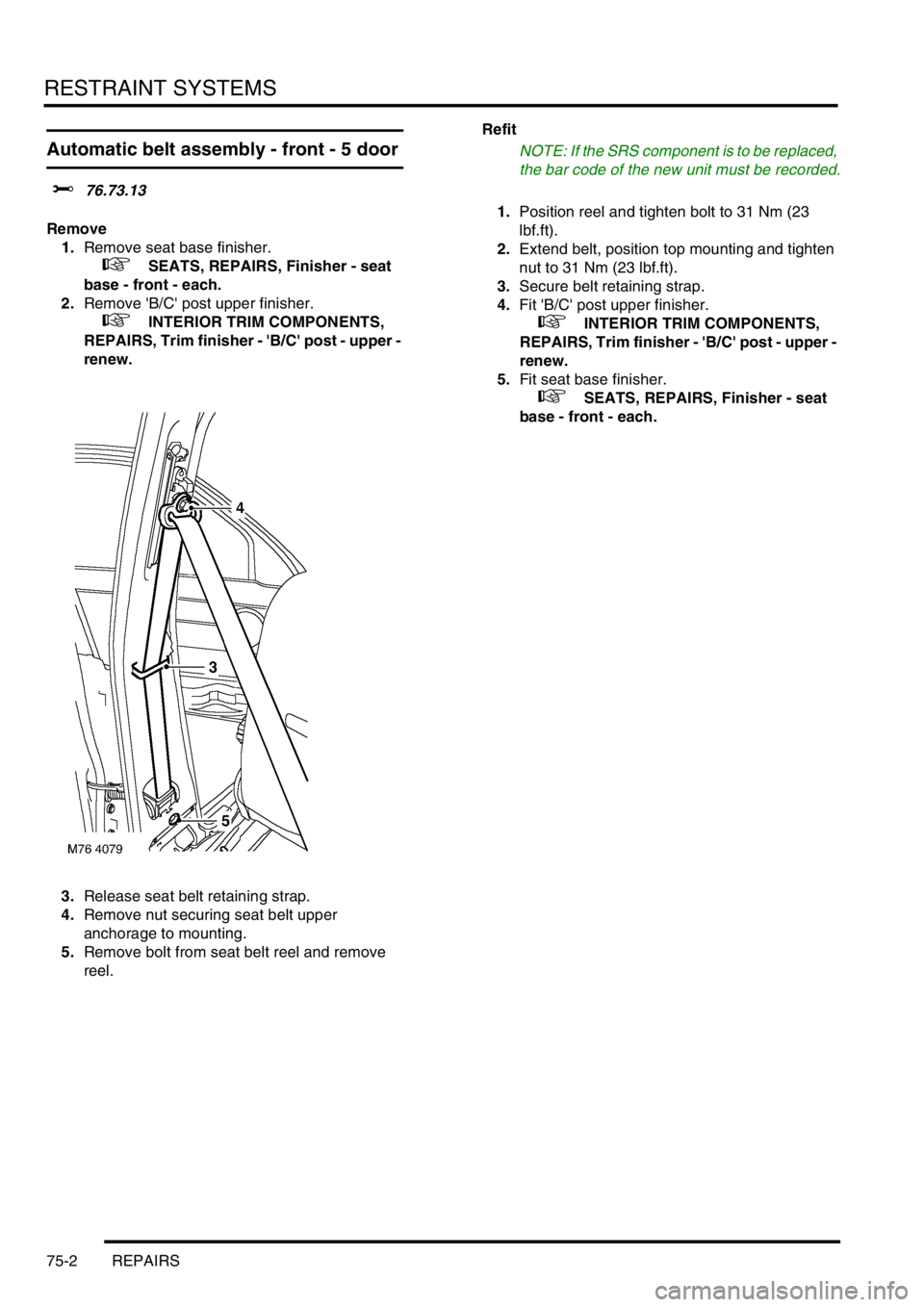

Automatic belt assembly - front - 5 door

$% 76.73.13

Remove

1.Remove seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

2.Remove 'B/C' post upper finisher.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'B/C' post - upper -

renew.

3.Release seat belt retaining strap.

4.Remove nut securing seat belt upper

anchorage to mounting.

5.Remove bolt from seat belt reel and remove

reel.Refit

NOTE: If the SRS component is to be replaced,

the bar code of the new unit must be recorded.

1.Position reel and tighten bolt to 31 Nm (23

lbf.ft).

2.Extend belt, position top mounting and tighten

nut to 31 Nm (23 lbf.ft).

3.Secure belt retaining strap.

4.Fit 'B/C' post upper finisher.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'B/C' post - upper -

renew.

5.Fit seat base finisher.

+ SEATS, REPAIRS, Finisher - seat

base - front - each.

Page 584 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-3

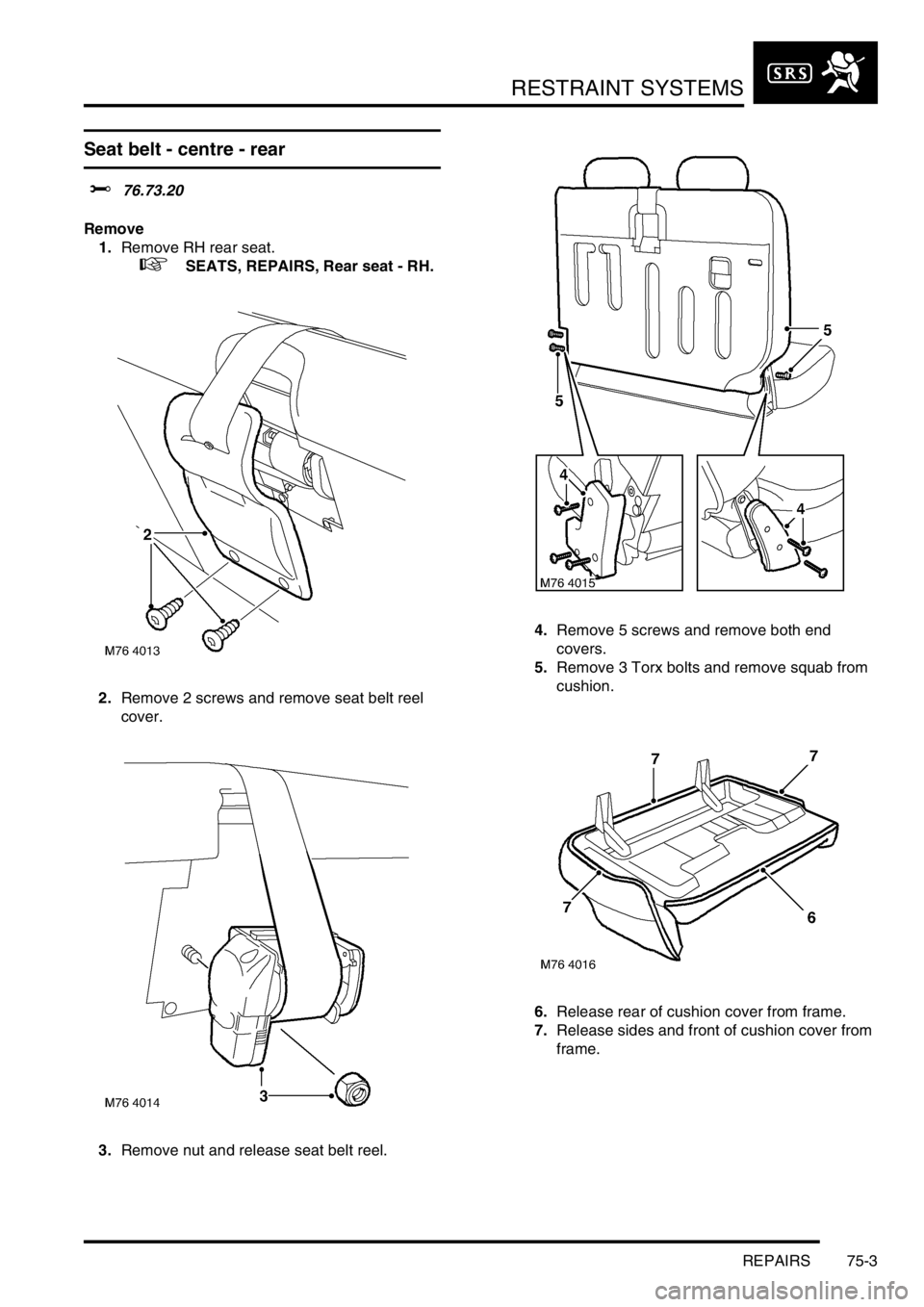

Seat belt - centre - rear

$% 76.73.20

Remove

1.Remove RH rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

2.Remove 2 screws and remove seat belt reel

cover.

3.Remove nut and release seat belt reel.4.Remove 5 screws and remove both end

covers.

5.Remove 3 Torx bolts and remove squab from

cushion.

6.Release rear of cushion cover from frame.

7.Release sides and front of cushion cover from

frame.

Page 585 of 1007

RESTRAINT SYSTEMS

75-4 REPAIRS

8.Release cover and pad from frame.

9.Remove Torx bolt from centre seat belt anchor

and right seat belt buckle.

10.Remove seat belt and right seat belt buckle.

Refit

1.Position centre seat belt anchor and right seat

belt buckle to seat and tighten Torx bolt to 32

Nm (24 lbf.ft).

2.Fit cover and pad to frame.

3.Fit front and sides of cushion cover to frame.

4.Fit rear of cushion cover to frame.

5.Fit cushion to squab and tighten Torx bolts.

6.Fit end covers and tighten screws.

7.Position seat belt reel in seat squab and tighten

nut to 32 Nm (24 lbf.ft).

8.Fit seat belt reel cover and tighten screws.

9.Fit rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

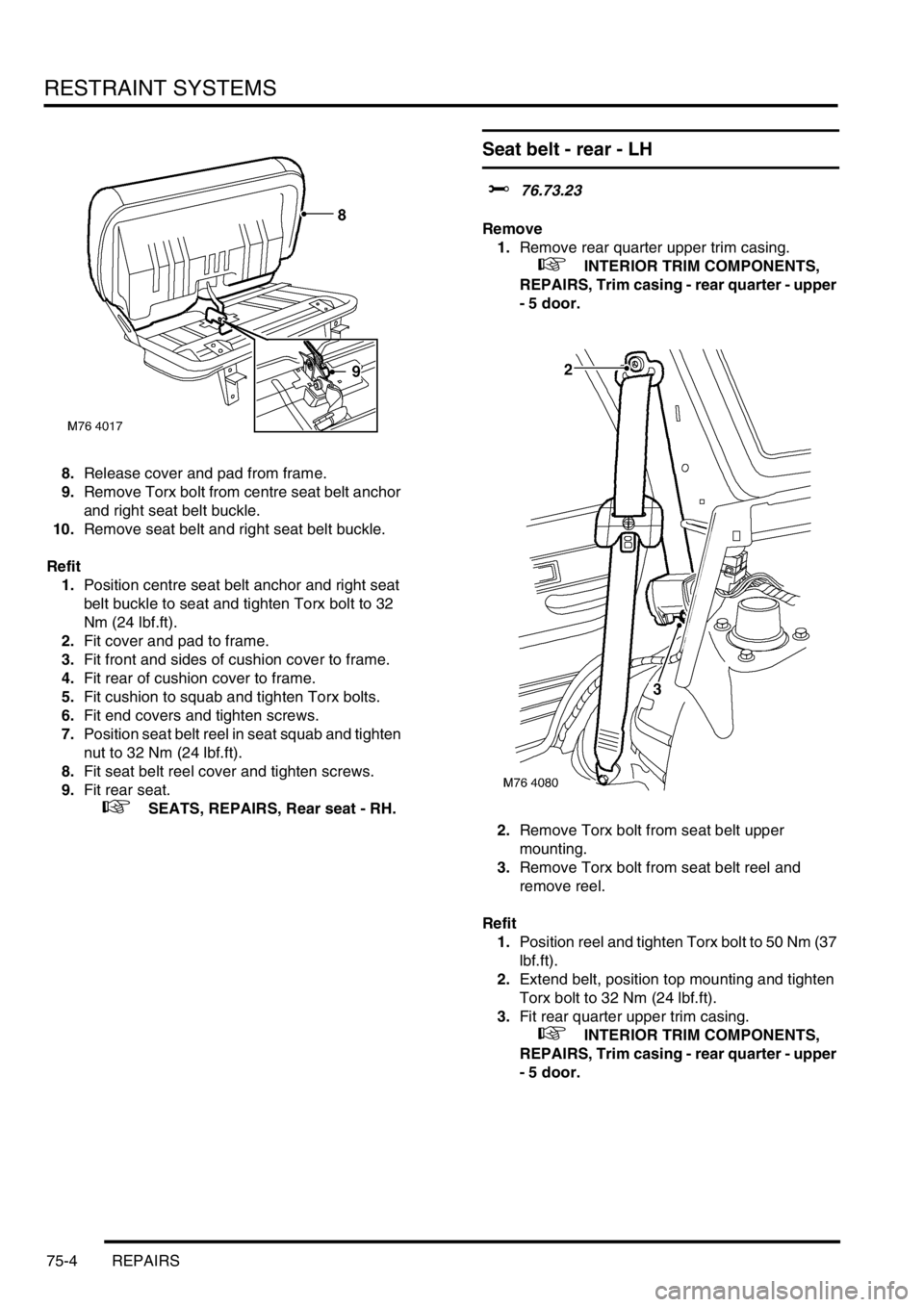

Seat belt - rear - LH

$% 76.73.23

Remove

1.Remove rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

2.Remove Torx bolt from seat belt upper

mounting.

3.Remove Torx bolt from seat belt reel and

remove reel.

Refit

1.Position reel and tighten Torx bolt to 50 Nm (37

lbf.ft).

2.Extend belt, position top mounting and tighten

Torx bolt to 32 Nm (24 lbf.ft).

3.Fit rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

Page 587 of 1007

RESTRAINT SYSTEMS

75-6 REPAIRS

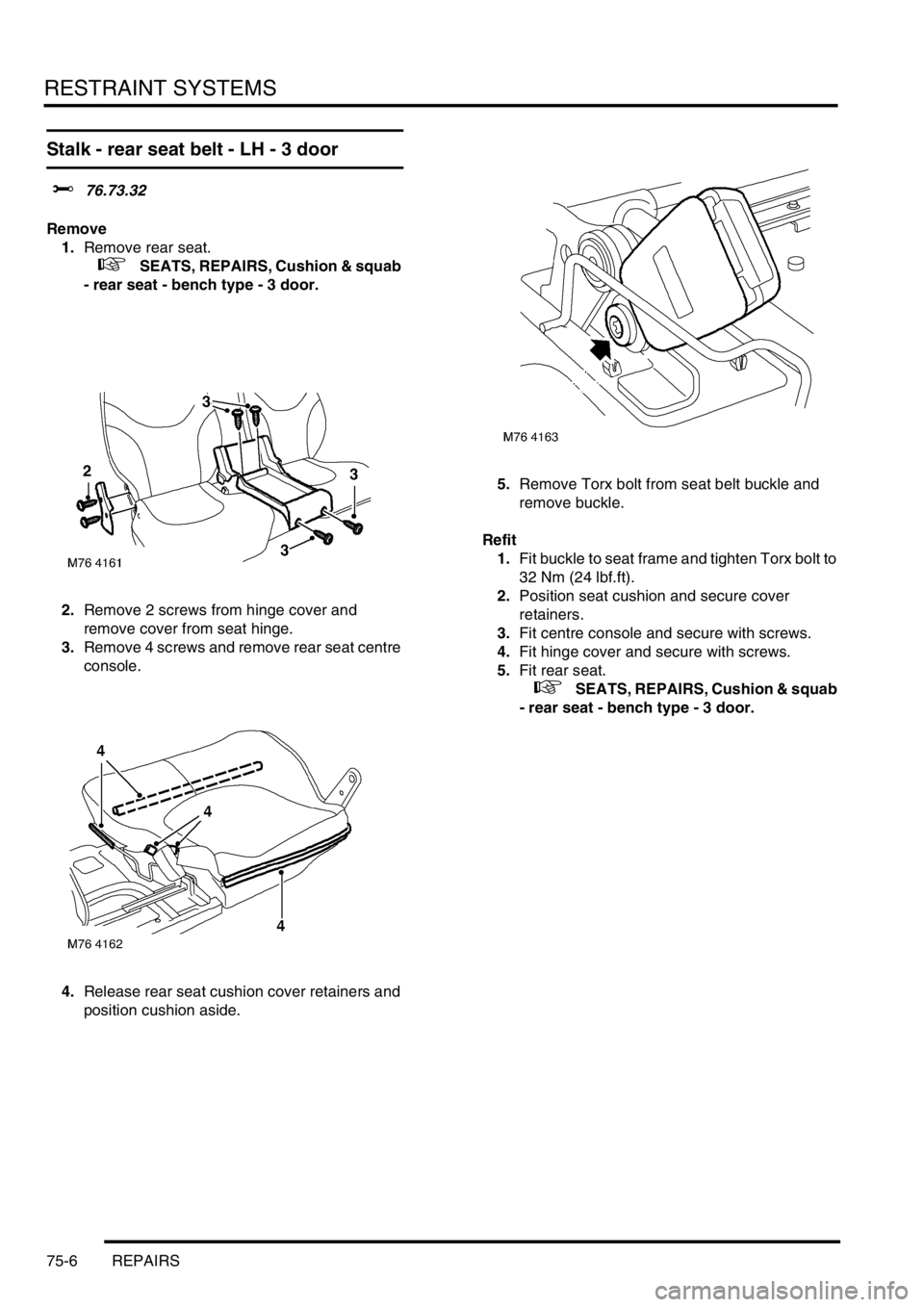

Stalk - rear seat belt - LH - 3 door

$% 76.73.32

Remove

1.Remove rear seat.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

2.Remove 2 screws from hinge cover and

remove cover from seat hinge.

3.Remove 4 screws and remove rear seat centre

console.

4.Release rear seat cushion cover retainers and

position cushion aside.5.Remove Torx bolt from seat belt buckle and

remove buckle.

Refit

1.Fit buckle to seat frame and tighten Torx bolt to

32 Nm (24 lbf.ft).

2.Position seat cushion and secure cover

retainers.

3.Fit centre console and secure with screws.

4.Fit hinge cover and secure with screws.

5.Fit rear seat.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

Page 588 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-7

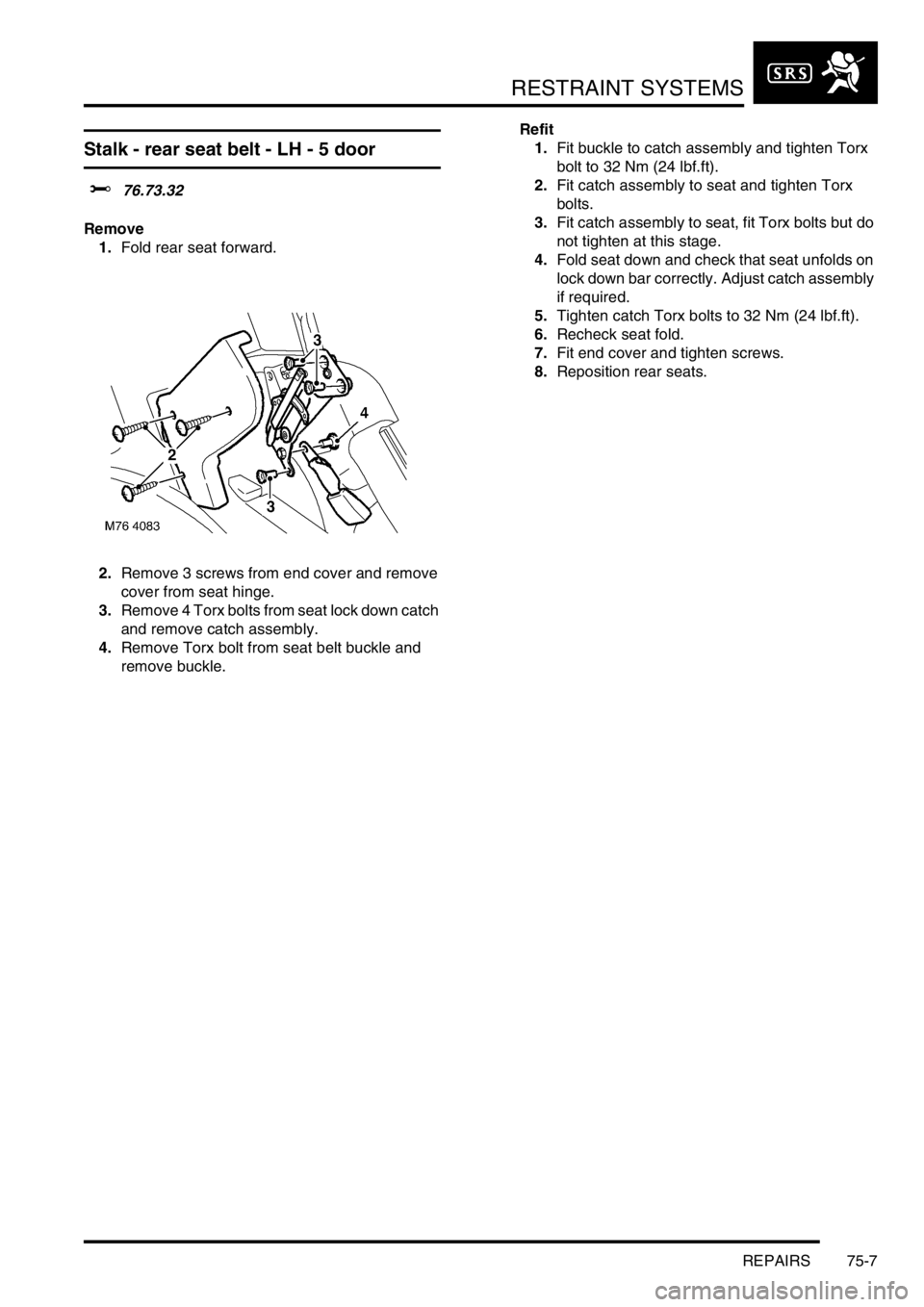

Stalk - rear seat belt - LH - 5 door

$% 76.73.32

Remove

1.Fold rear seat forward.

2.Remove 3 screws from end cover and remove

cover from seat hinge.

3.Remove 4 Torx bolts from seat lock down catch

and remove catch assembly.

4.Remove Torx bolt from seat belt buckle and

remove buckle.Refit

1.Fit buckle to catch assembly and tighten Torx

bolt to 32 Nm (24 lbf.ft).

2.Fit catch assembly to seat and tighten Torx

bolts.

3.Fit catch assembly to seat, fit Torx bolts but do

not tighten at this stage.

4.Fold seat down and check that seat unfolds on

lock down bar correctly. Adjust catch assembly

if required.

5.Tighten catch Torx bolts to 32 Nm (24 lbf.ft).

6.Recheck seat fold.

7.Fit end cover and tighten screws.

8.Reposition rear seats.