lock LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 890 of 1007

AIR CONDITIONING

ADJUSTMENTS 82-3

ADJUST ME NTS

Drive belt - compressor - Td4

$% 82.10.01

Check

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Turn steering on RH lock.

4.Remove 3 bolts and RH splash shield.

5.Check condition of drive belt. Renew a drive

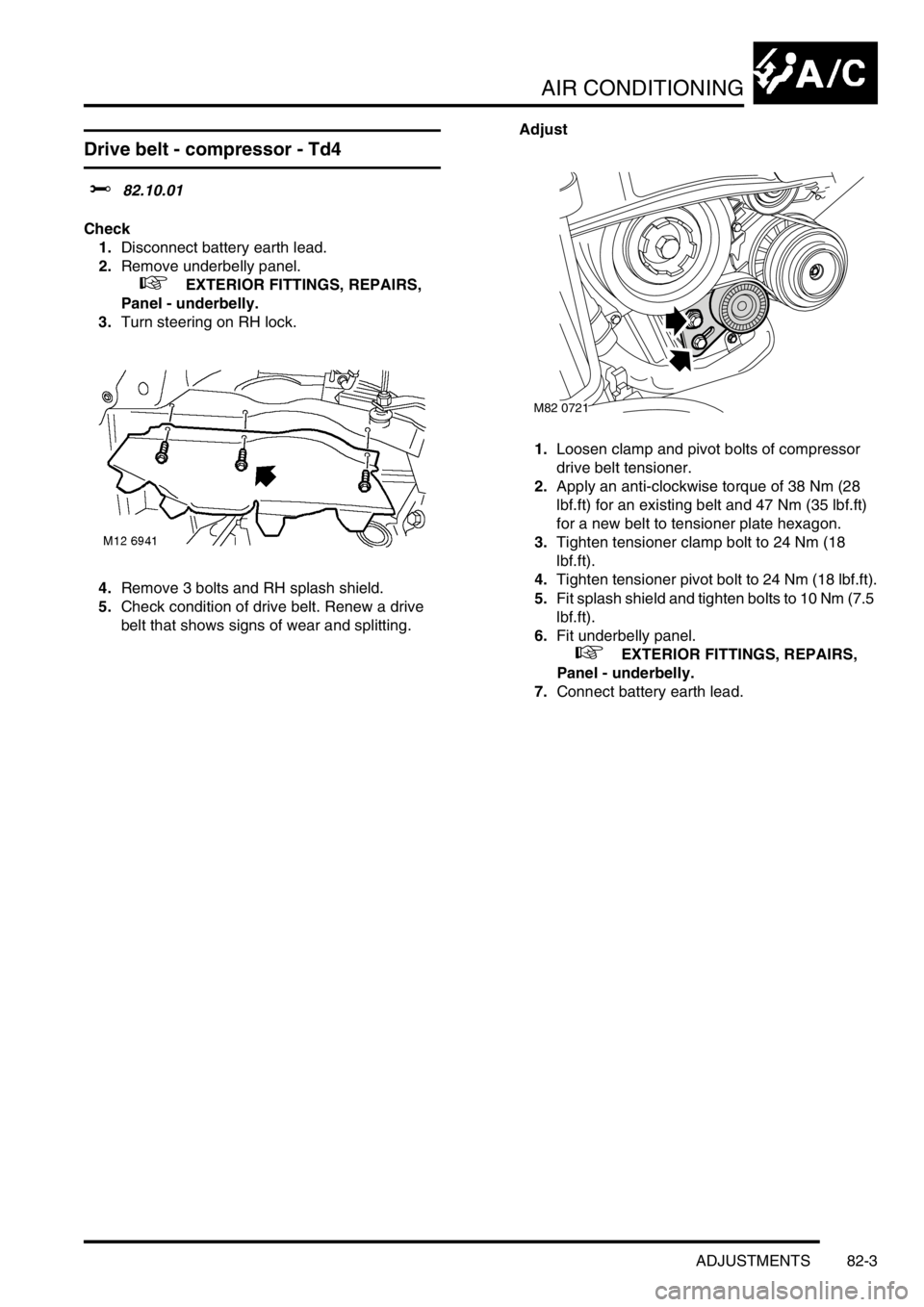

belt that shows signs of wear and splitting.Adjust

1.Loosen clamp and pivot bolts of compressor

drive belt tensioner.

2.Apply an anti-clockwise torque of 38 Nm (28

lbf.ft) for an existing belt and 47 Nm (35 lbf.ft)

for a new belt to tensioner plate hexagon.

3.Tighten tensioner clamp bolt to 24 Nm (18

lbf.ft).

4.Tighten tensioner pivot bolt to 24 Nm (18 lbf.ft).

5.Fit splash shield and tighten bolts to 10 Nm (7.5

lbf.ft).

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Connect battery earth lead.

M82 0721

Page 894 of 1007

AIR CONDITIONING

REPAIRS 82-7

Compressor - KV6

$% 82.10.20

Remove

1.Disconnect battery earth lead.

2.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

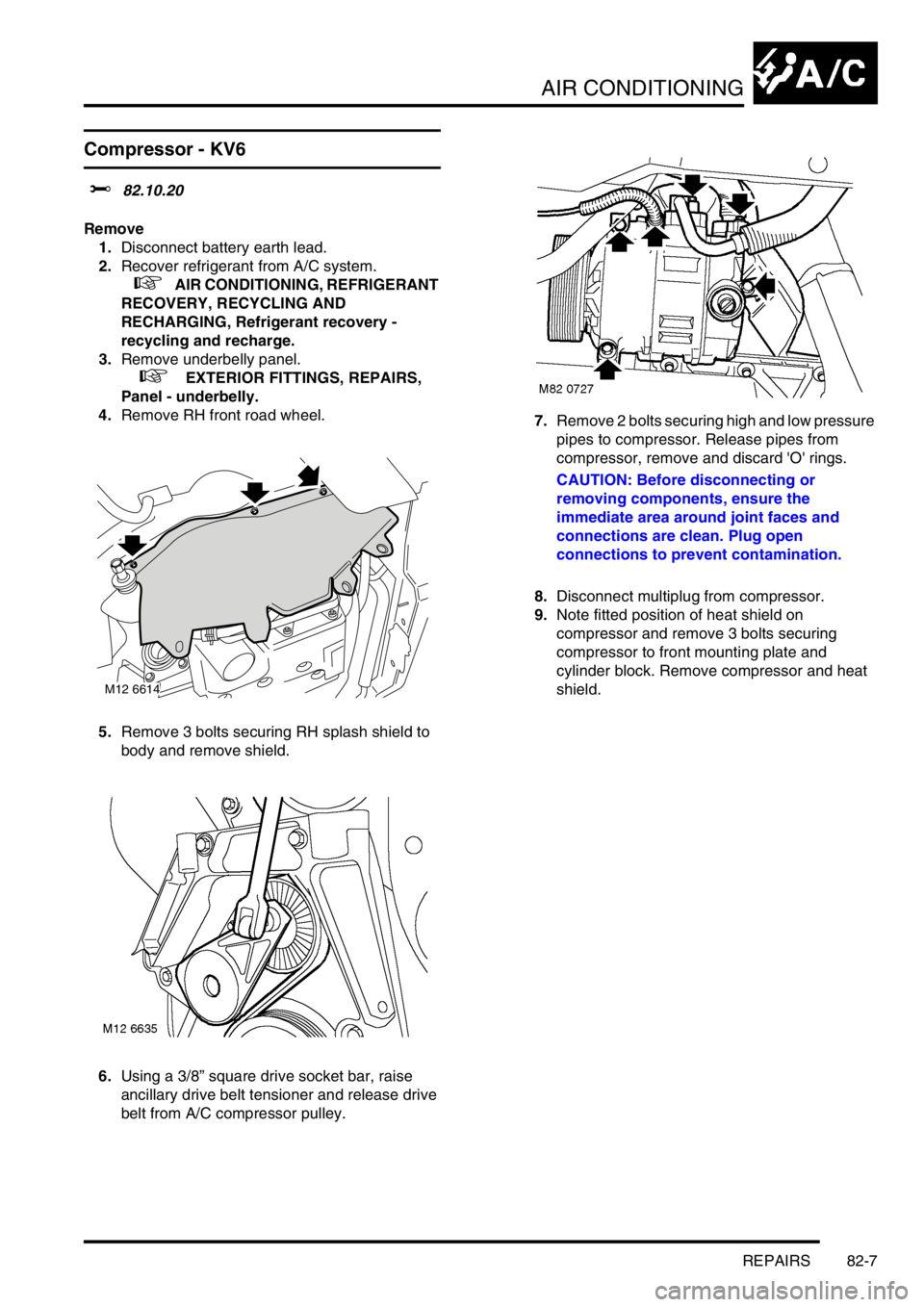

4.Remove RH front road wheel.

5.Remove 3 bolts securing RH splash shield to

body and remove shield.

6.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and release drive

belt from A/C compressor pulley.7.Remove 2 bolts securing high and low pressure

pipes to compressor. Release pipes from

compressor, remove and discard 'O' rings.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

8.Disconnect multiplug from compressor.

9.Note fitted position of heat shield on

compressor and remove 3 bolts securing

compressor to front mounting plate and

cylinder block. Remove compressor and heat

shield.

M12 6614

Page 895 of 1007

AIR CONDITIONING

82-8REPAIRS

Refit

1.If a new compressor is being installed, drain the

required amount of refrigerant oil from the new

compressor.

+ GENERAL INFORMATION, Air

conditioning compressor replacement.

2.A new compressor is sealed and pressurised

with Nitrogen gas, slowly release the sealing

cap, gas pressure should be heard to release

as the seal is broken.

3.Clean compressor and mating face on front

mounting plate and cylinder block.

4.Position compressor, fit but do not fully tighten

lower bolt.

5.Position heat shield and fit compressor upper

securing bolts. Tighten compressor upper and

lower securing bolts to 25 Nm (18 lbf.ft).

6.Remove caps from compressor and high

pressure pipe.

7.Clean compressor high pressure pipe

connection.

8.Lubricate new 'O' ring with refrigerant oil and fit

to high pressure pipe.

9.Connect high pressure pipe to compressor, fit

and tighten bolt to 25 Nm (18 lbf.ft).

10.Connect multiplug to compressor.

11.Remove caps from compressor and low

pressure pipe.

12.Clean compressor low pressure pipe

connection.

13.Lubricate new 'O' ring with refrigerant oil and fit

to low pressure pipe.

14.Connect low pressure pipe to compressor, fit

and tighten bolt to 25 Nm (18 lbf.ft).

15.Clean pulley 'V's and tensioner pulley running

surface.

16.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

17.Fit splash shield and secure with bolts.

18.Fit RH road wheel and tighten nuts to 115 Nm

85 lbf.ft).

19.Replace receiver drier.

+ AIR CONDITIONING, REPAIRS,

Receiver drier.

20.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

21.Connect battery earth lead.

22.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Compressor - K1.8

$% 82.10.20

Remove

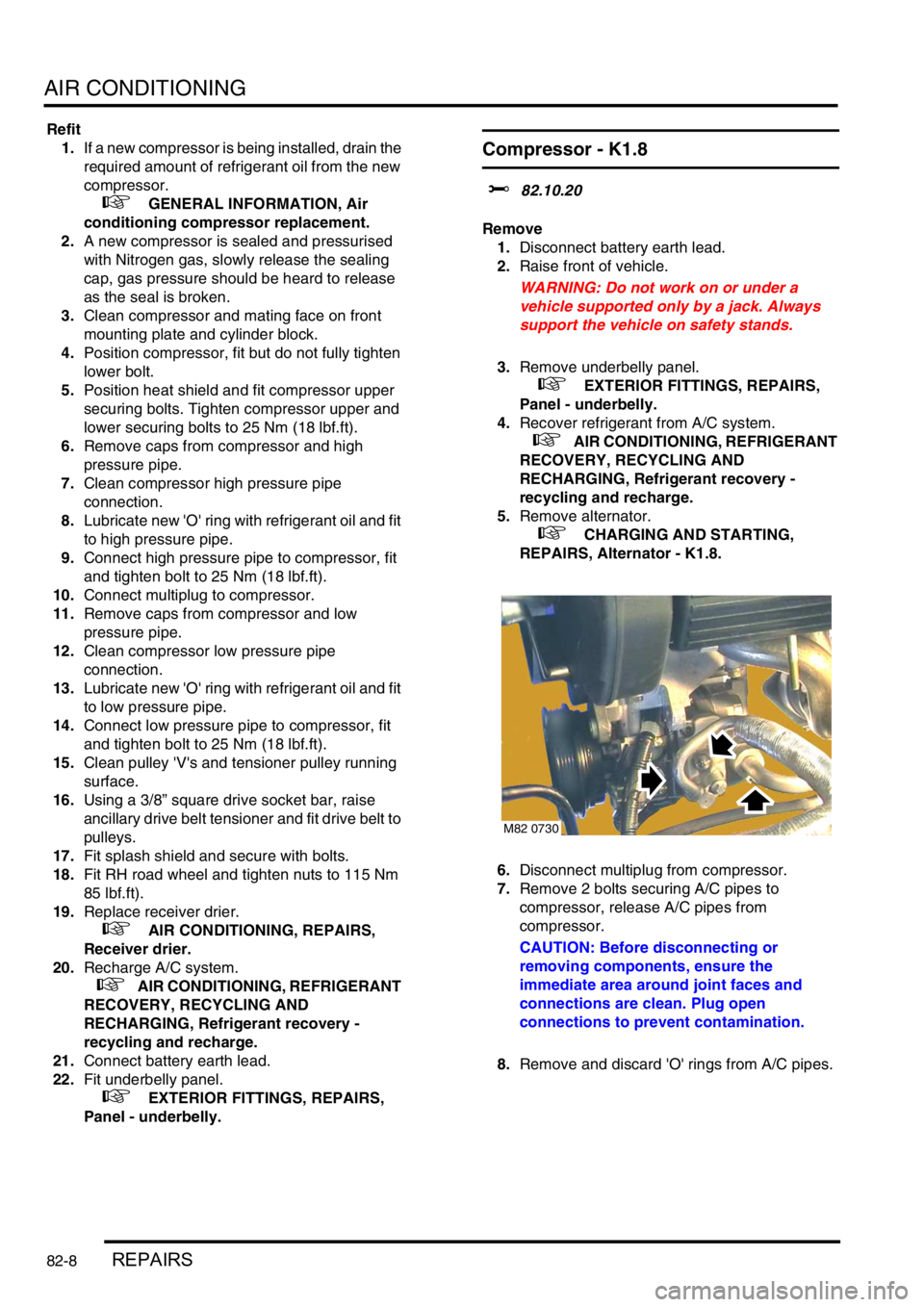

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

5.Remove alternator.

+ CHARGING AND STARTING,

REPAIRS, Alternator - K1.8.

6.Disconnect multiplug from compressor.

7.Remove 2 bolts securing A/C pipes to

compressor, release A/C pipes from

compressor.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

8.Remove and discard 'O' rings from A/C pipes.

M82 0730

Page 902 of 1007

AIR CONDITIONING

REPAIRS 82-15

Valve - thermostatic expansion (TXV)

$% 82.25.01

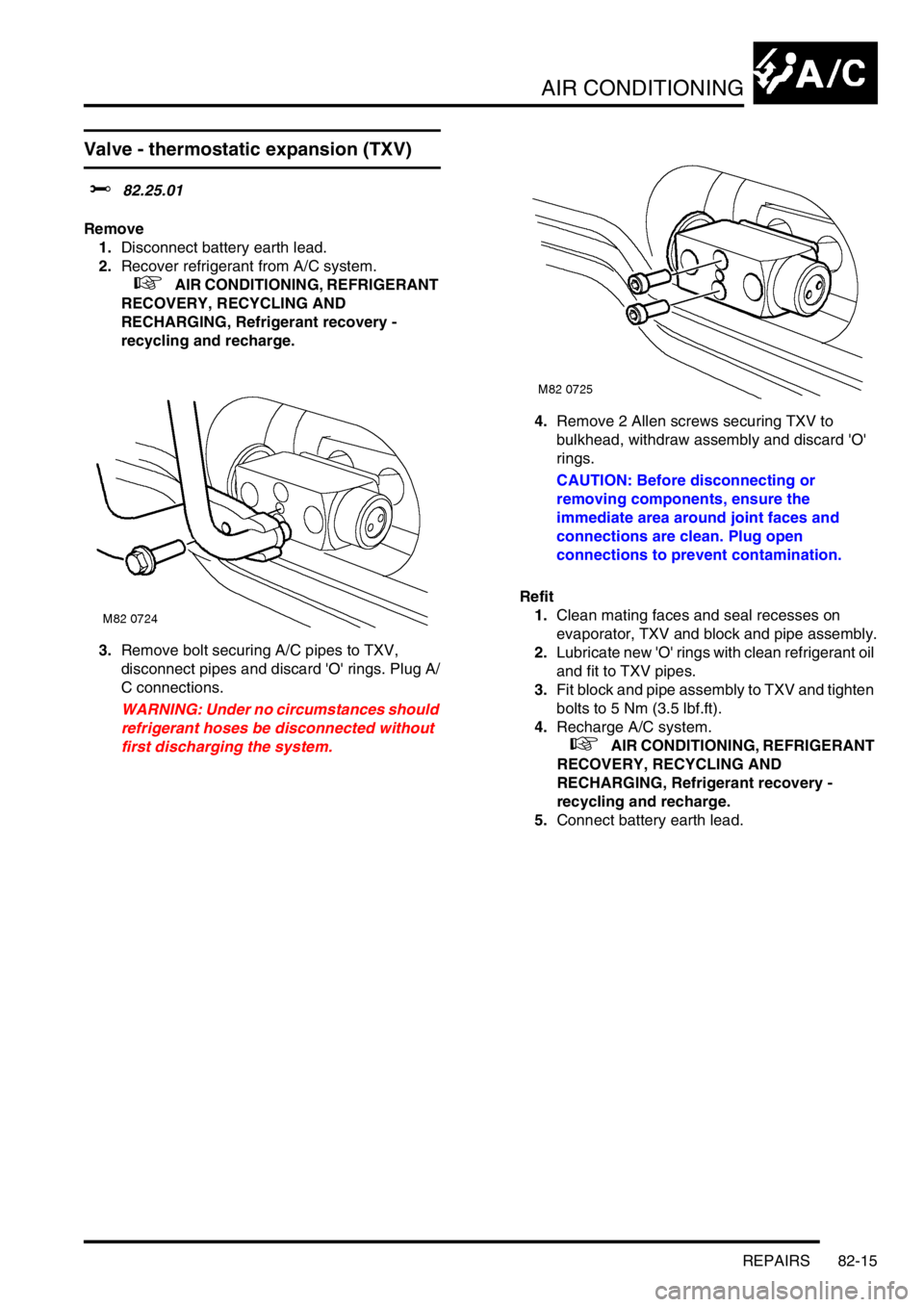

Remove

1.Disconnect battery earth lead.

2.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

3.Remove bolt securing A/C pipes to TXV,

disconnect pipes and discard 'O' rings. Plug A/

C connections.

WARNING: Under no circumstances should

refrigerant hoses be disconnected without

first discharging the system.4.Remove 2 Allen screws securing TXV to

bulkhead, withdraw assembly and discard 'O'

rings.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

Refit

1.Clean mating faces and seal recesses on

evaporator, TXV and block and pipe assembly.

2.Lubricate new 'O' rings with clean refrigerant oil

and fit to TXV pipes.

3.Fit block and pipe assembly to TXV and tighten

bolts to 5 Nm (3.5 lbf.ft).

4.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

5.Connect battery earth lead.

Page 914 of 1007

CHARGING AND STARTING

ADJUSTMENTS 86-1-1

CHARGING AND STARTING ADJUST ME NTS

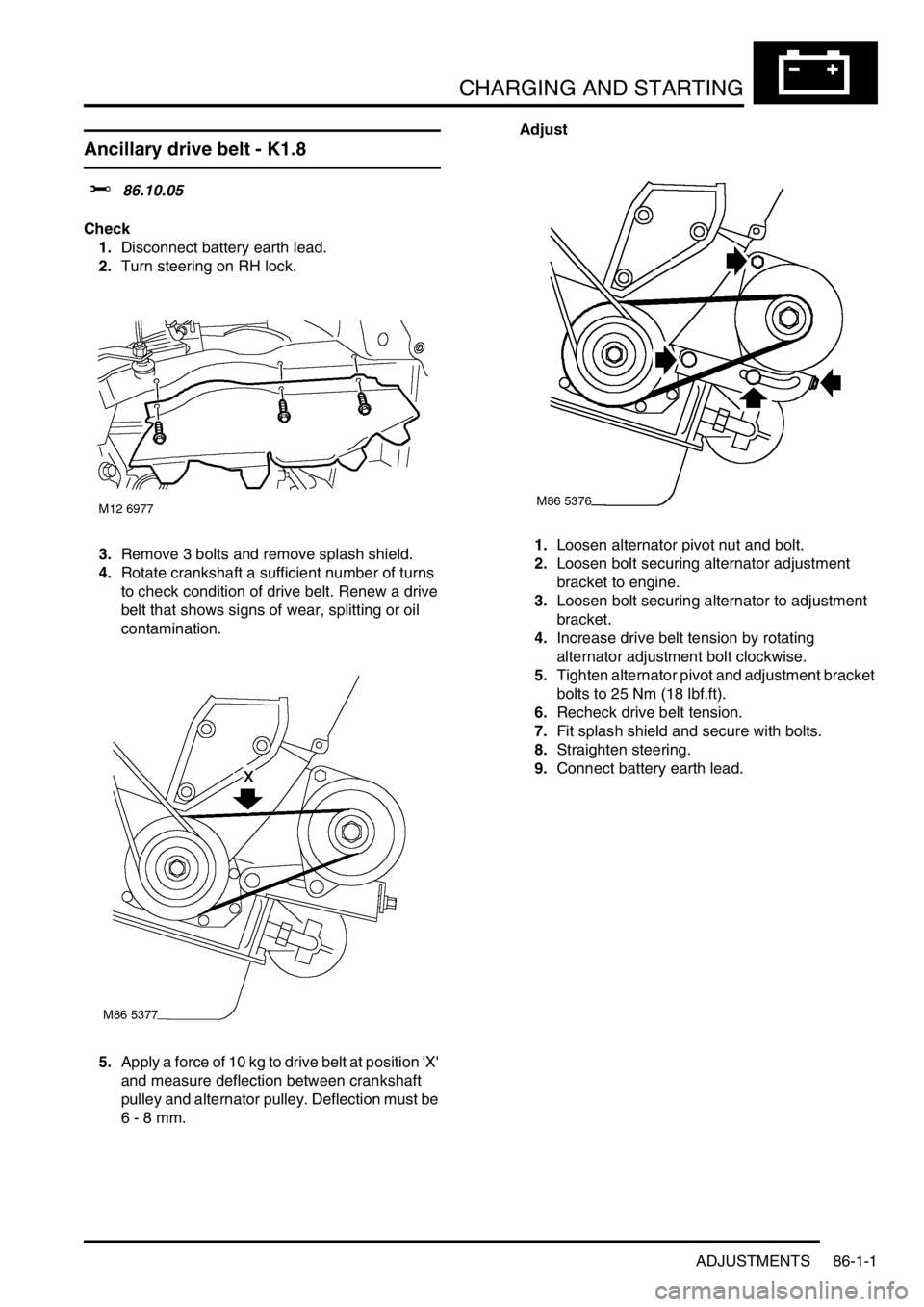

Ancillary drive belt - K1.8

$% 86.10.05

Check

1.Disconnect battery earth lead.

2.Turn steering on RH lock.

3.Remove 3 bolts and remove splash shield.

4.Rotate crankshaft a sufficient number of turns

to check condition of drive belt. Renew a drive

belt that shows signs of wear, splitting or oil

contamination.

5.Apply a force of 10 kg to drive belt at position 'X'

and measure deflection between crankshaft

pulley and alternator pulley. Deflection must be

6 - 8 mm.Adjust

1.Loosen alternator pivot nut and bolt.

2.Loosen bolt securing alternator adjustment

bracket to engine.

3.Loosen bolt securing alternator to adjustment

bracket.

4.Increase drive belt tension by rotating

alternator adjustment bolt clockwise.

5.Tighten alternator pivot and adjustment bracket

bolts to 25 Nm (18 lbf.ft).

6.Recheck drive belt tension.

7.Fit splash shield and secure with bolts.

8.Straighten steering.

9.Connect battery earth lead.

Page 915 of 1007

CHARGING AND STARTING

86-1-2 ADJUSTMENTS

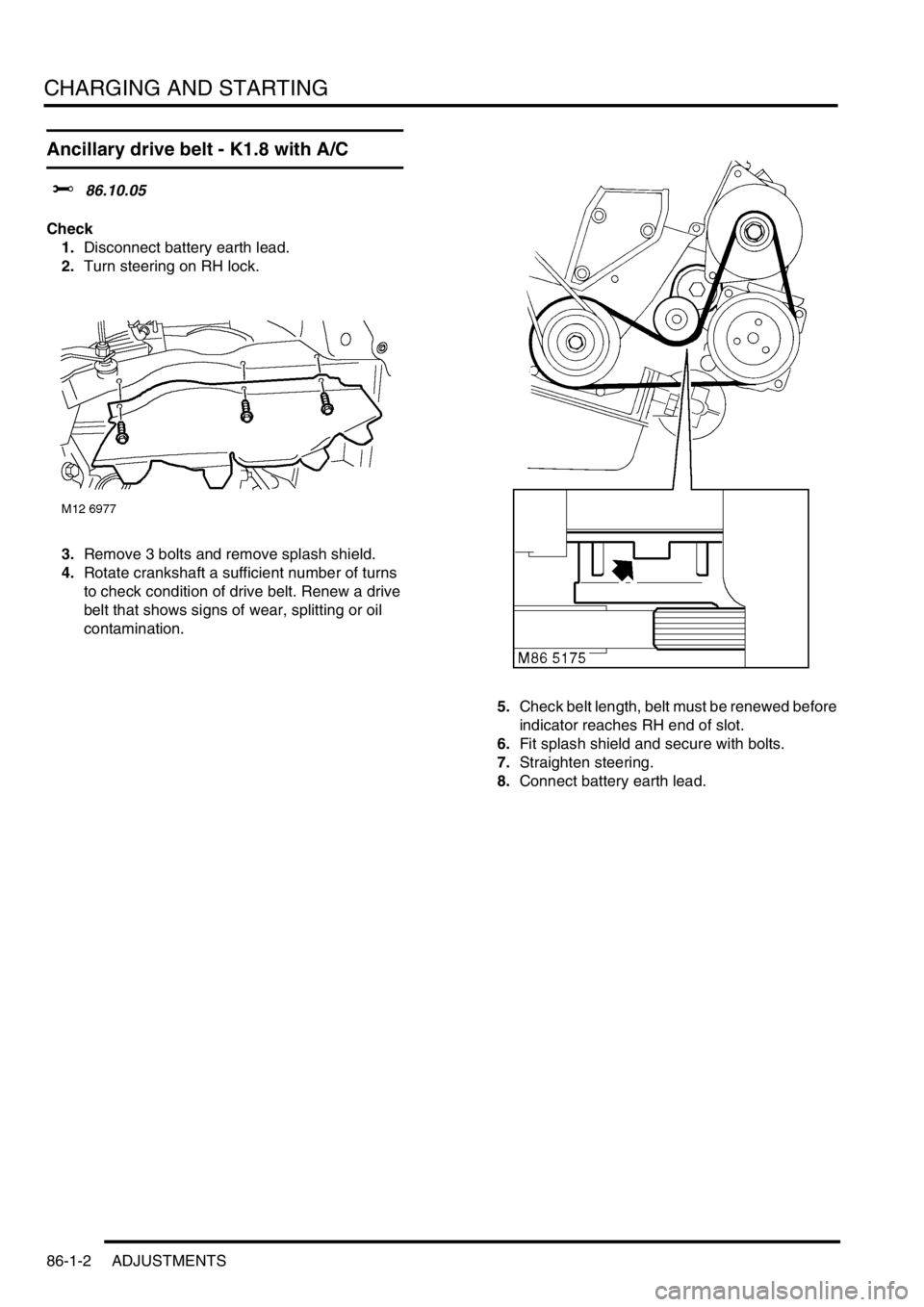

Ancillary drive belt - K1.8 with A/C

$% 86.10.05

Check

1.Disconnect battery earth lead.

2.Turn steering on RH lock.

3.Remove 3 bolts and remove splash shield.

4.Rotate crankshaft a sufficient number of turns

to check condition of drive belt. Renew a drive

belt that shows signs of wear, splitting or oil

contamination.

5.Check belt length, belt must be renewed before

indicator reaches RH end of slot.

6.Fit splash shield and secure with bolts.

7.Straighten steering.

8.Connect battery earth lead.

Page 916 of 1007

CHARGING AND STARTING

REPAIRS 86-1-3

REPAIRS

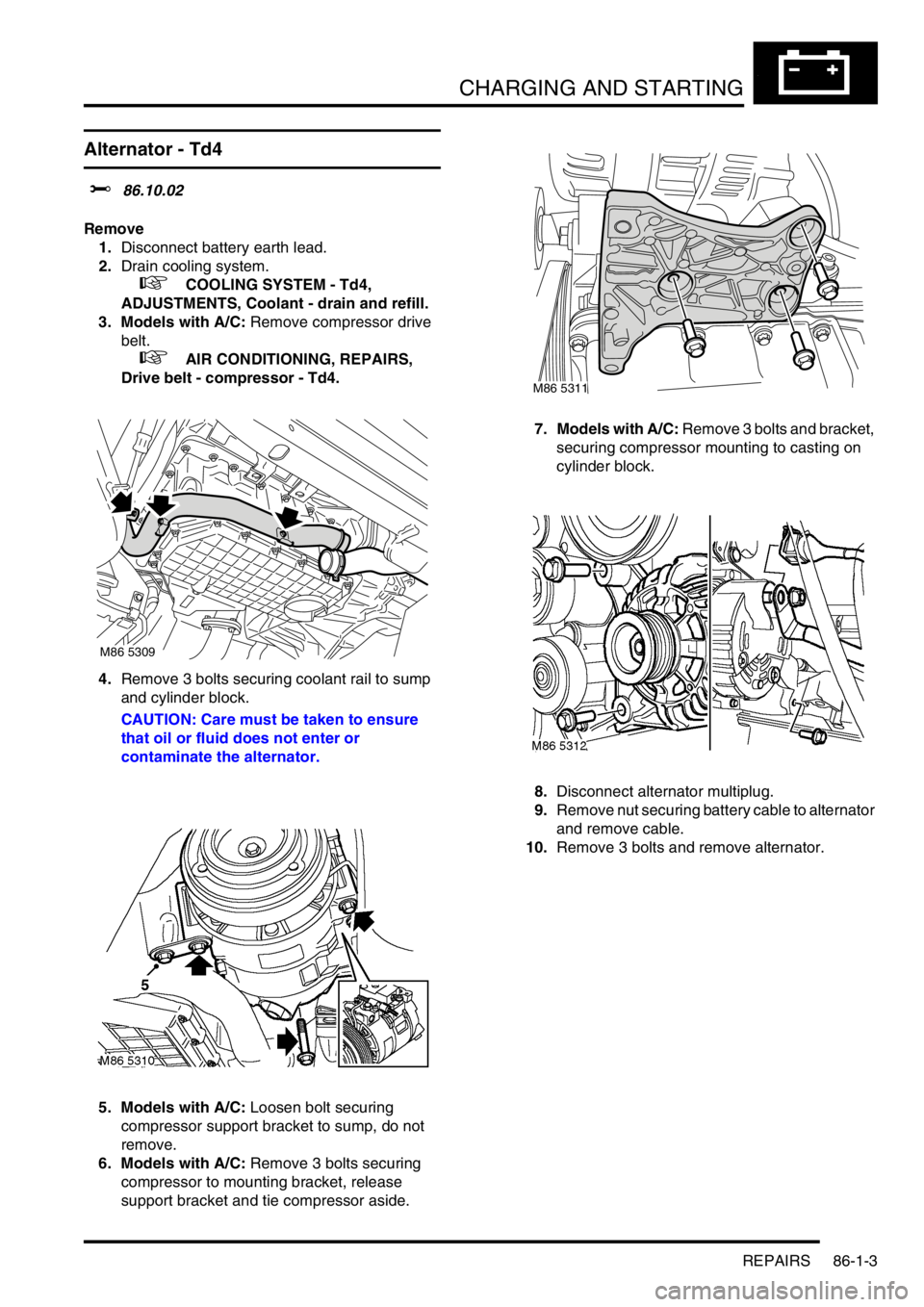

Alternator - Td4

$% 86.10.02

Remove

1.Disconnect battery earth lead.

2.Drain cooling system.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

3. Models with A/C: Remove compressor drive

belt.

+ AIR CONDITIONING, REPAIRS,

Drive belt - compressor - Td4.

4.Remove 3 bolts securing coolant rail to sump

and cylinder block.

CAUTION: Care must be taken to ensure

that oil or fluid does not enter or

contaminate the alternator.

5. Models with A/C: Loosen bolt securing

compressor support bracket to sump, do not

remove.

6. Models with A/C: Remove 3 bolts securing

compressor to mounting bracket, release

support bracket and tie compressor aside.7. Models with A/C: Remove 3 bolts and bracket,

securing compressor mounting to casting on

cylinder block.

8.Disconnect alternator multiplug.

9.Remove nut securing battery cable to alternator

and remove cable.

10.Remove 3 bolts and remove alternator.

M86 5309

M86 5311

Page 920 of 1007

CHARGING AND STARTING

REPAIRS 86-1-7

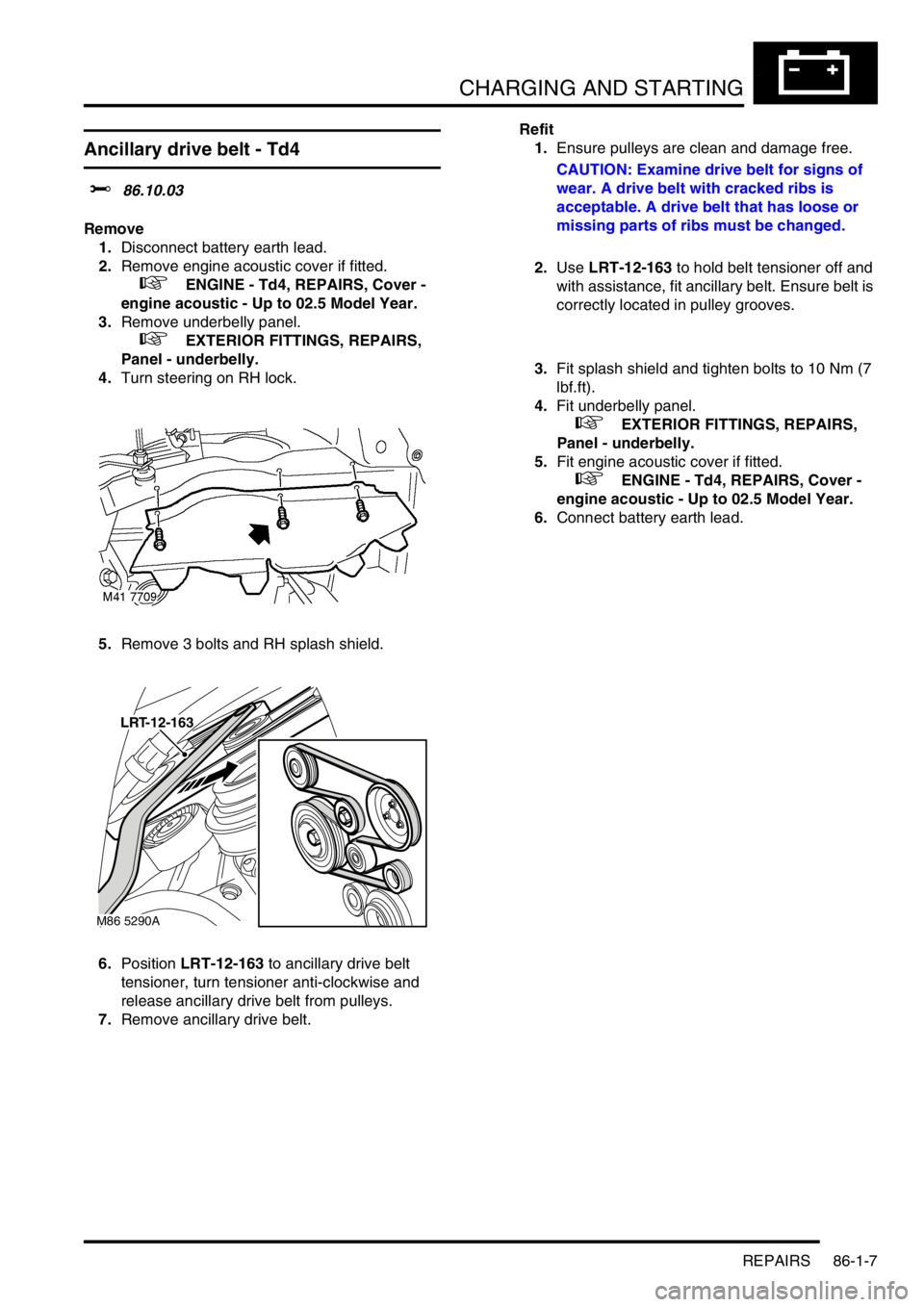

Ancillary drive belt - Td4

$% 86.10.03

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Turn steering on RH lock.

5.Remove 3 bolts and RH splash shield.

6.Position LRT-12-163 to ancillary drive belt

tensioner, turn tensioner anti-clockwise and

release ancillary drive belt from pulleys.

7.Remove ancillary drive belt.Refit

1.Ensure pulleys are clean and damage free.

CAUTION: Examine drive belt for signs of

wear. A drive belt with cracked ribs is

acceptable. A drive belt that has loose or

missing parts of ribs must be changed.

2.Use LRT-12-163 to hold belt tensioner off and

with assistance, fit ancillary belt. Ensure belt is

correctly located in pulley grooves.

3.Fit splash shield and tighten bolts to 10 Nm (7

lbf.ft).

4.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

5.Fit engine acoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

6.Connect battery earth lead.

M86 5290A

LRT-12-163

Page 921 of 1007

CHARGING AND STARTING

86-1-8 REPAIRS

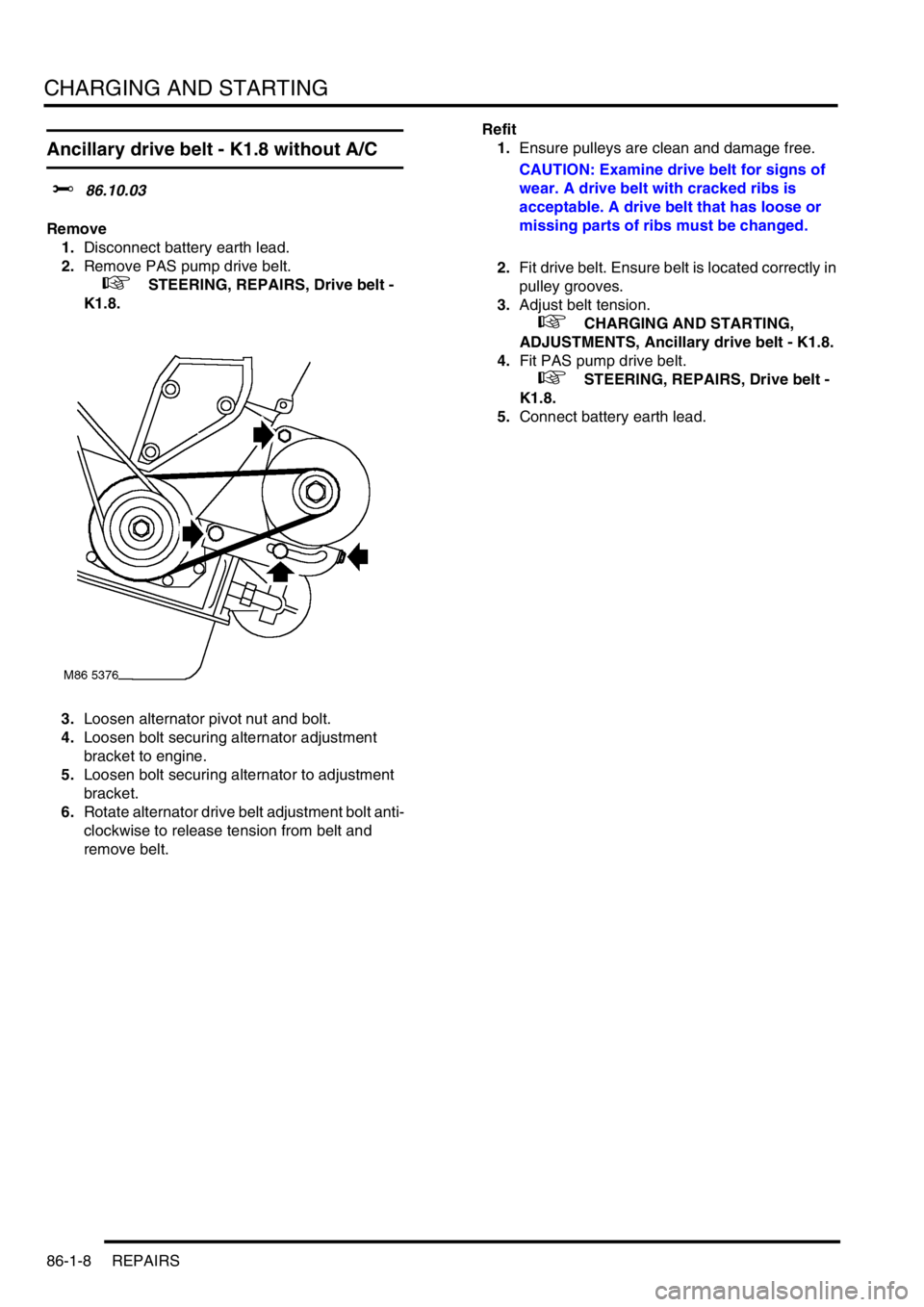

Ancillary drive belt - K1.8 without A/C

$% 86.10.03

Remove

1.Disconnect battery earth lead.

2.Remove PAS pump drive belt.

+ STEERING, REPAIRS, Drive belt -

K1.8.

3.Loosen alternator pivot nut and bolt.

4.Loosen bolt securing alternator adjustment

bracket to engine.

5.Loosen bolt securing alternator to adjustment

bracket.

6.Rotate alternator drive belt adjustment bolt anti-

clockwise to release tension from belt and

remove belt.Refit

1.Ensure pulleys are clean and damage free.

CAUTION: Examine drive belt for signs of

wear. A drive belt with cracked ribs is

acceptable. A drive belt that has loose or

missing parts of ribs must be changed.

2.Fit drive belt. Ensure belt is located correctly in

pulley grooves.

3.Adjust belt tension.

+ CHARGING AND STARTING,

ADJUSTMENTS, Ancillary drive belt - K1.8.

4.Fit PAS pump drive belt.

+ STEERING, REPAIRS, Drive belt -

K1.8.

5.Connect battery earth lead.

Page 922 of 1007

CHARGING AND STARTING

REPAIRS 86-1-9

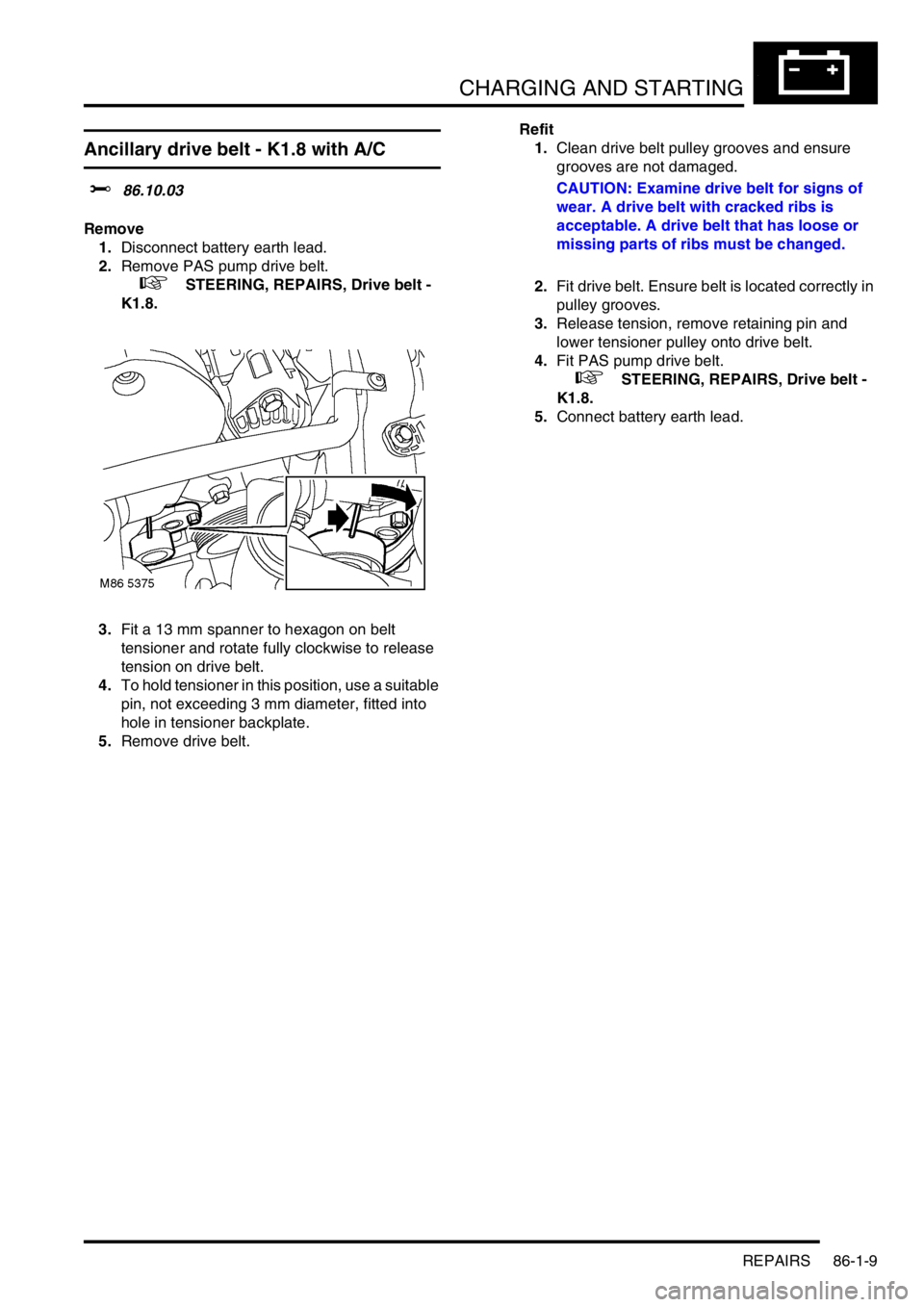

Ancillary drive belt - K1.8 with A/C

$% 86.10.03

Remove

1.Disconnect battery earth lead.

2.Remove PAS pump drive belt.

+ STEERING, REPAIRS, Drive belt -

K1.8.

3.Fit a 13 mm spanner to hexagon on belt

tensioner and rotate fully clockwise to release

tension on drive belt.

4.To hold tensioner in this position, use a suitable

pin, not exceeding 3 mm diameter, fitted into

hole in tensioner backplate.

5.Remove drive belt.Refit

1.Clean drive belt pulley grooves and ensure

grooves are not damaged.

CAUTION: Examine drive belt for signs of

wear. A drive belt with cracked ribs is

acceptable. A drive belt that has loose or

missing parts of ribs must be changed.

2.Fit drive belt. Ensure belt is located correctly in

pulley grooves.

3.Release tension, remove retaining pin and

lower tensioner pulley onto drive belt.

4.Fit PAS pump drive belt.

+ STEERING, REPAIRS, Drive belt -

K1.8.

5.Connect battery earth lead.